Economical steel with excellent comprehensive mechanical properties for hot-dip galvanized automobile outer plate and production method thereof

A technology of comprehensive mechanics and production methods, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of poor comprehensive mechanical properties, achieve qualified cold bending performance, improve plate shape quality and finished product performance , Good economic benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

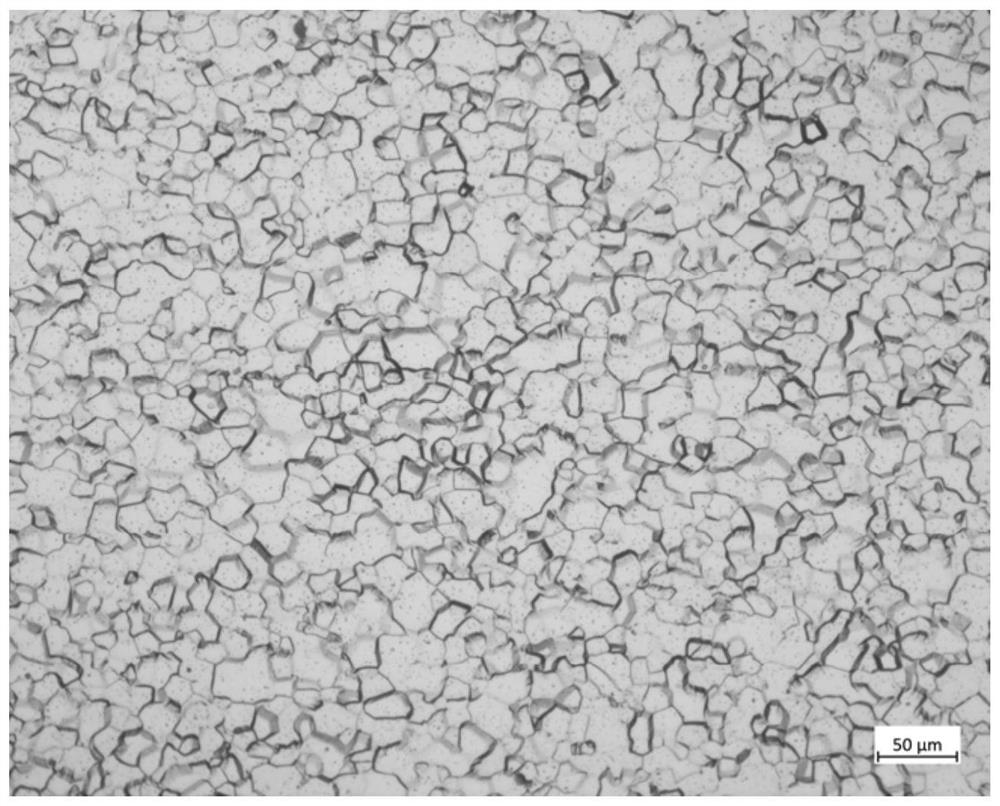

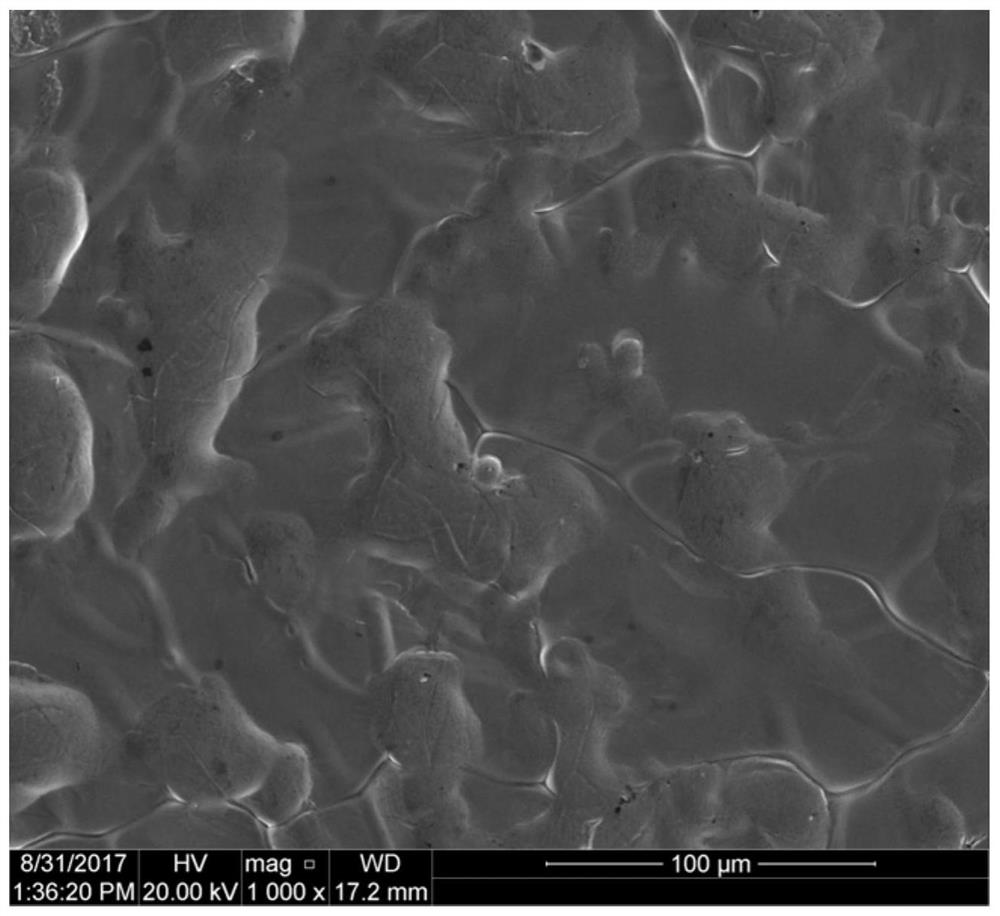

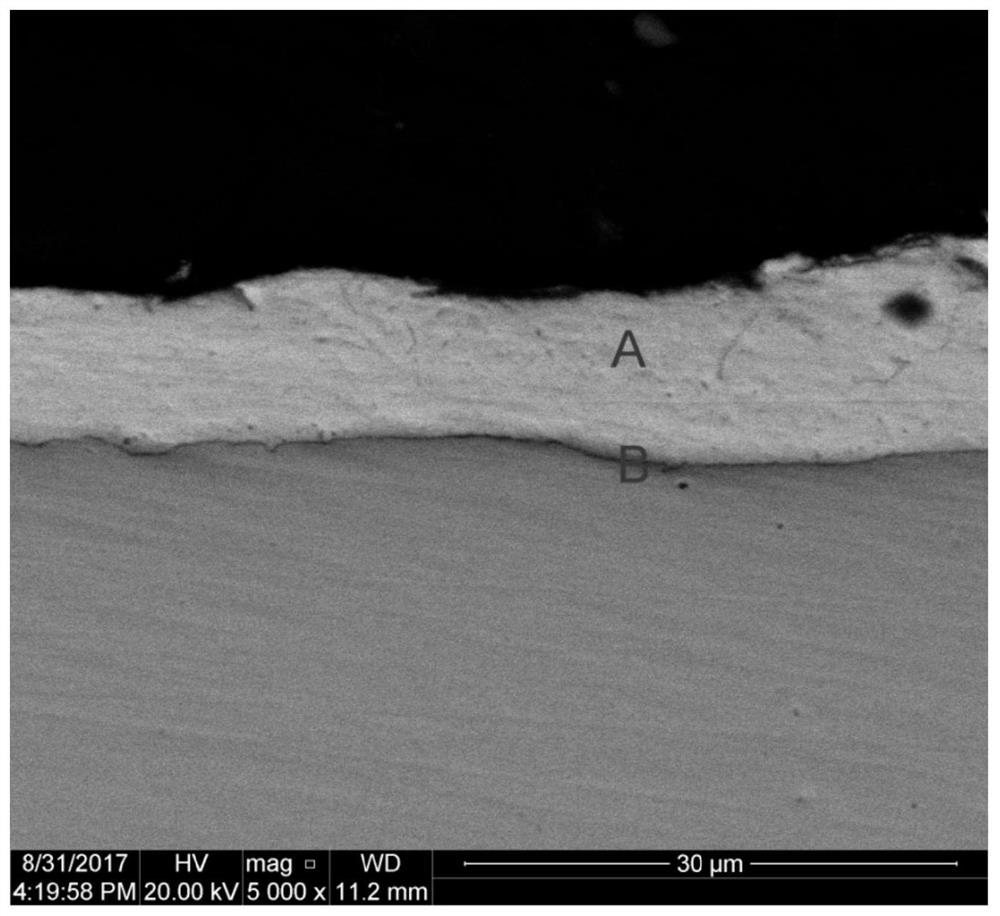

Image

Examples

Embodiment 1

[0086] An economical steel with excellent comprehensive mechanical properties for hot-dip galvanized automobile outer panels in this embodiment, the main chemical element composition and mass percentage content are shown in Example 1 of Table 1.

[0087] The production method of a kind of economical excellent comprehensive mechanical properties hot-dip galvanized steel for automobile outer plate of the present embodiment comprises the following steps on the basis of the composition of the chemical elements of the present embodiment:

[0088] S1. Hot metal pretreatment requires front slag removal and rear slag removal, front slag removal bright side ≥ 70%, rear slag removal bright side ≥ 80%, stirring time ≥ 5.0min, hot metal desulfurization target [S] ≤ 0.01%.

[0089] S2. Converter smelting, without adding pig iron and slag steel, using self-circulating scrap steel, the smelting period is 35-50 minutes, no deoxidation of molten steel, argon blowing during tapping, slag blockin...

Embodiment 2

[0105] An economical steel with excellent comprehensive mechanical properties for hot-dip galvanized automobile outer panels in this embodiment, the main chemical element composition and mass percentage content are shown in Example 2 of Table 1.

[0106] The production method of a kind of economical excellent comprehensive mechanical properties hot-dip galvanized steel for automobile outer plate of the present embodiment comprises the following steps on the basis of the composition of the chemical elements of the present embodiment:

[0107] S1. Hot metal pretreatment requires front slag removal and rear slag removal, front slag removal bright side ≥ 70%, rear slag removal bright side ≥ 80%, stirring time ≥ 5.0min, hot metal desulfurization target [S] ≤ 0.01%.

[0108] S2. Converter smelting, without adding pig iron and slag steel, using self-circulating scrap steel, the smelting period is 35-50 minutes, no deoxidation of molten steel, argon blowing during tapping, slag blockin...

Embodiment 3

[0123] An economical steel with excellent comprehensive mechanical properties for hot-dip galvanized automobile outer panels in this embodiment, the main chemical element composition and mass percentage content are shown in Example 3 of Table 1.

[0124] The production method of a kind of economical excellent comprehensive mechanical properties hot-dip galvanized steel for automobile outer plate of the present embodiment comprises the following steps on the basis of the composition of the chemical elements of the present embodiment:

[0125] S1. Hot metal pretreatment requires front slag removal and rear slag removal, front slag removal bright side ≥ 70%, rear slag removal bright side ≥ 80%, stirring time ≥ 5.0min, hot metal desulfurization target [S] ≤ 0.01%.

[0126] S2. Converter smelting, without adding pig iron and slag steel, using self-circulating scrap steel, the smelting period is 35-50 minutes, no deoxidation of molten steel, argon blowing during tapping, slag blockin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com