Anti-adhesion mesh belt for shaving board production

An anti-adhesion, particle board technology, applied in applications, household appliances, household components, etc., can solve problems such as adhesion of wood particles and mesh belts, and achieve the effect of compact structure, full utilization, and reduction of cleaning steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

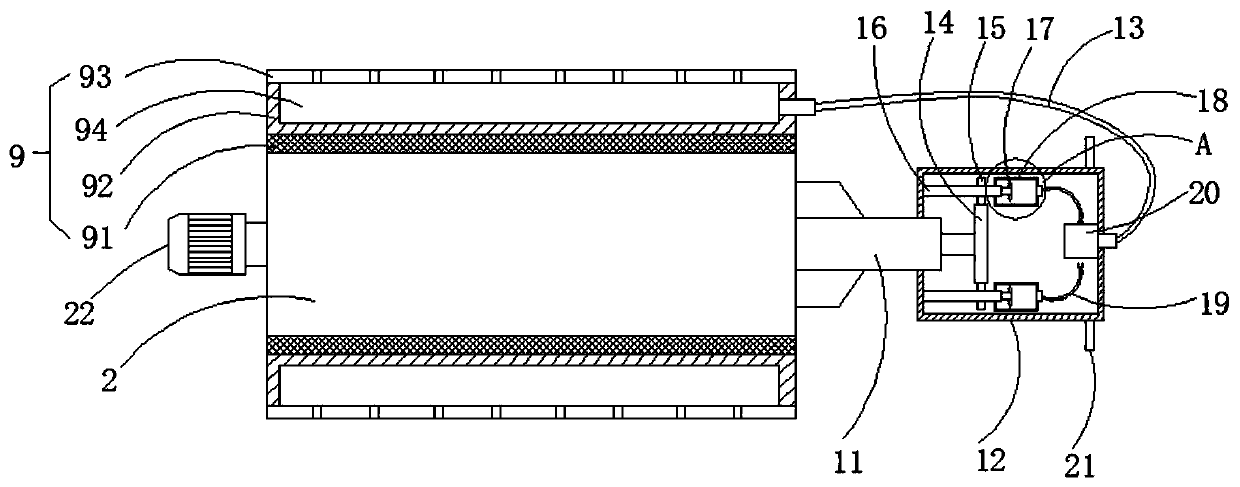

[0037] refer to image 3 The difference in Embodiment 1 is that the outer wall of the adsorption drive box 12 in the present embodiment is also provided with a baffle plate 21, and the said baffle plate 21 is arranged around the edge of the adsorption drive box 12 near the concentration box 20, and the four corners of the baffle plate 21 are Rounded corners, the baffle plate 21 can guide the negative pressure tube 13 to follow the transmission of the mesh belt 9 and rotate around the adsorption drive box 12, preventing the negative pressure tube 13 from being stuck.

Embodiment 3

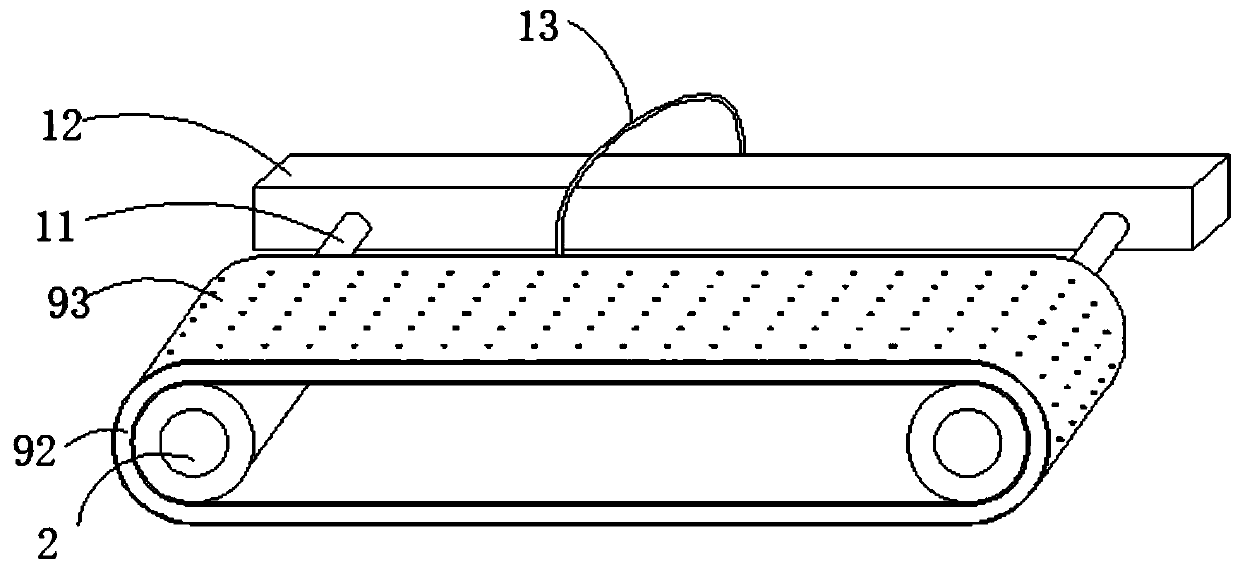

[0039] refer to figure 1 The difference in Embodiment 2 is that a sealing plate 23 is also provided under the mesh belt 9 in this embodiment, and the sealing plate 23 is adapted to the external shape of the mesh belt surface 93, and the sealing plate 23 is fixedly arranged on The bottom of the mesh belt 9 is attached to the mesh belt surface 93. When the mesh belt 9 conveys the plate, the mesh belt surface 93 can generate relative movement with the sealing plate 23. The sealing plate 23 is used to seal the mesh belt on the lower surface of the mesh belt 9. Face 93 is sealed, strengthens the negative pressure of the mesh belt face 93 of the upper surface of mesh belt 9.

Embodiment 4

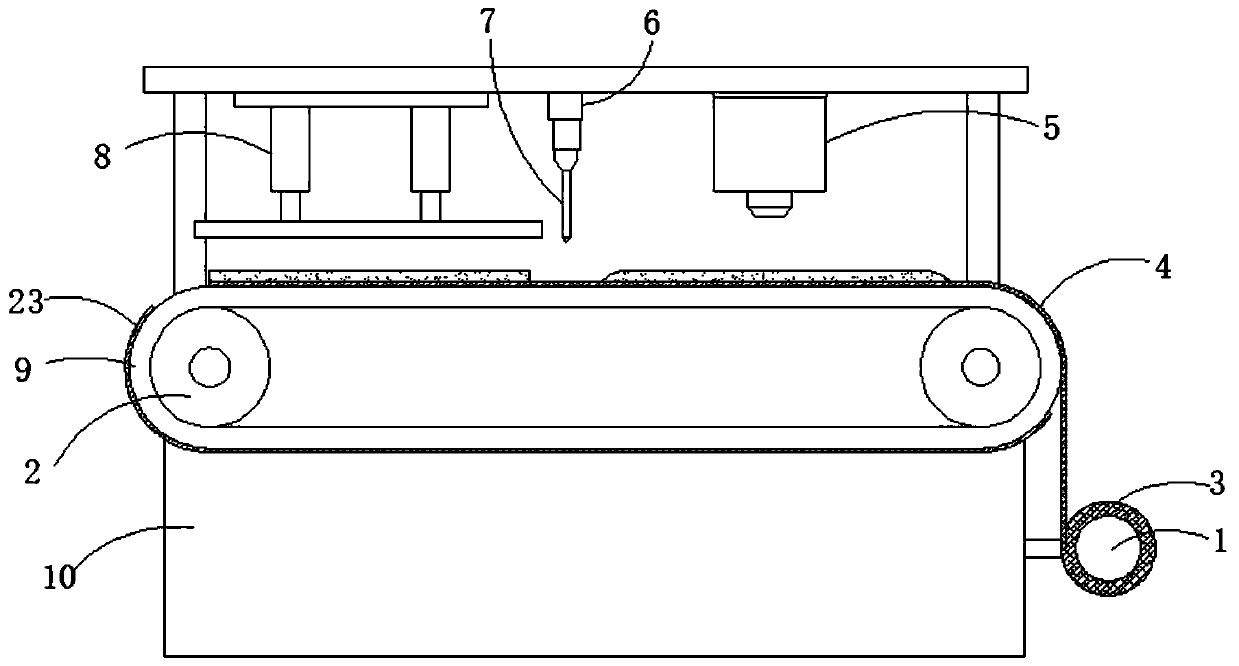

[0041] This embodiment provides a plate pressing machine, the conveying component part of which includes the anti-adhesion mesh belt for particleboard production in the above-mentioned embodiment 1, embodiment 2 or embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com