Automobile interior trim part slush molding bed

A technology for automotive interior parts and frames, applied in the field of slush-plastic beds, can solve problems such as hidden safety hazards and low efficiency, and achieve the effects of fast locking speed and eliminating the tendency to break away from the frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

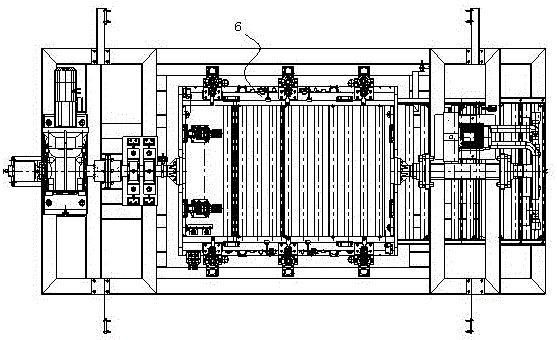

[0053] like Figure 7 , 8 As shown, the powder box automatic locking mechanism 65 includes a powder box locking pin 651, a powder box locking seat 652, a connecting plate 653, a first guide seat 654, a second guide seat 655, a locking guide post 656 and a powder box lock Tight cylinder 657;

[0054] The locking guide column 656 is supported by the first guide seat 654 and the second guide seat 655 on the mouth-shaped working surface on the installation side of the flip frame powder box, and can be guided by the first guide seat 654 and the second guide seat 655 along the locking guide The column moves axially; and in this embodiment, the locking guide column 656 and the first guide seat 654 and the second guide seat 655 adopt a linear bearing structure for cooperative guidance;

[0055] The axial direction of the powder box locking pin 651 is parallel to the axis of the locking guide column 656. The powder box locking pin 651 is supported by the powder box locking seat 652 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com