Tensioning device and method for transmission belt of crusher

A technology of tensioning device and crusher, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large maintenance workload, time-consuming disassembly and assembly, affecting work efficiency and output, etc. The effect of disassembly and assembly mechanization level, improving production efficiency, reducing maintenance time and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further explained in detail below in conjunction with the accompanying drawings.

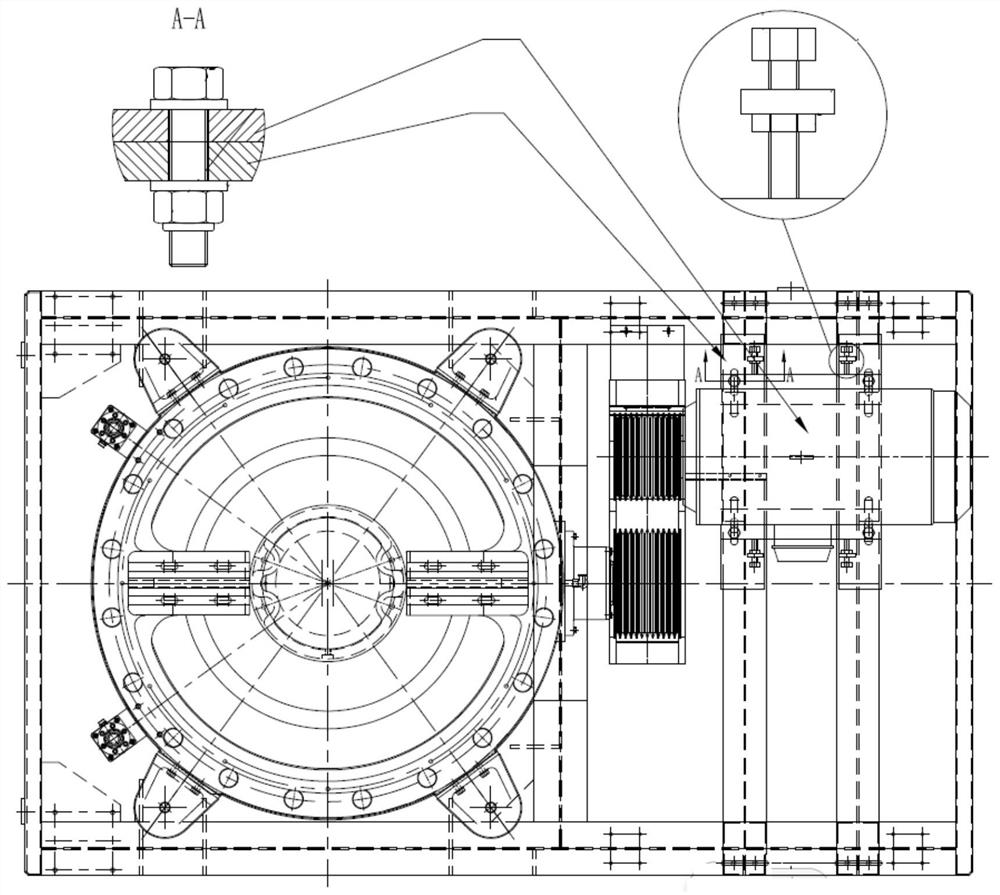

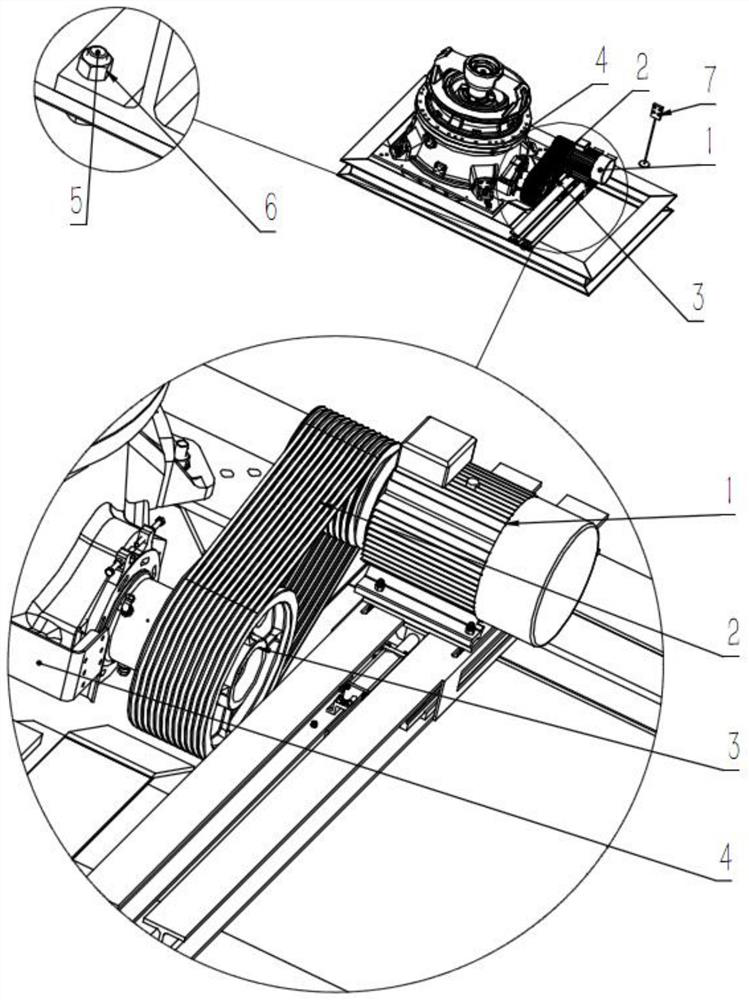

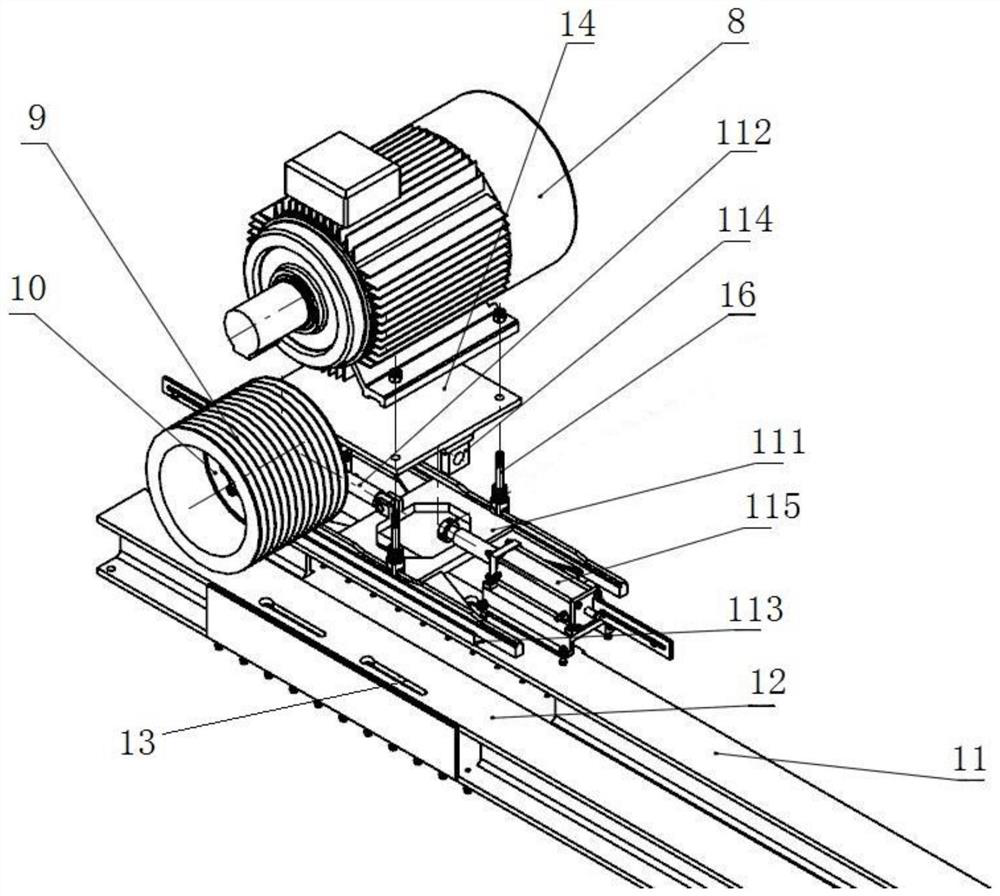

[0045] Such as Figure 2-10 As shown, the tensioning device of the main drive belt of the crusher includes belt intelligent tensioning drive mechanism 1, motor 8, motor support I11, motor support II12, motor slide seat 14, motor support I11 and motor support II12 through several sets of fixing bolts 5 and the fixed nut 6 are fixed on the supporting frame on the side of the crusher host 4, and the driven wheel 3 is installed on the crusher host 4, and the driven wheel 3 is connected with the driving wheel 9 of the motor 8 through the belt 2, and the main drive taper sleeve 10 and The driving wheel 9 is fixed on the motor 8 through a plurality of screws, and the motor support I11 and the motor support II12 are respectively provided with two motor installation chute 13, and the motor installation chute 13 is used to install the motor 8 and the motor sliding seat 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com