Process additional method for vehicle exterior panel

A technique of supplementary technology and outer plate parts, applied in the field of die stamping, can solve the problems of prolonging the design and manufacturing cycle of the die, reducing production efficiency, and heavy workload, so as to shorten the design and manufacturing cycle, improve surface quality, and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in detail in conjunction with the accompanying drawings.

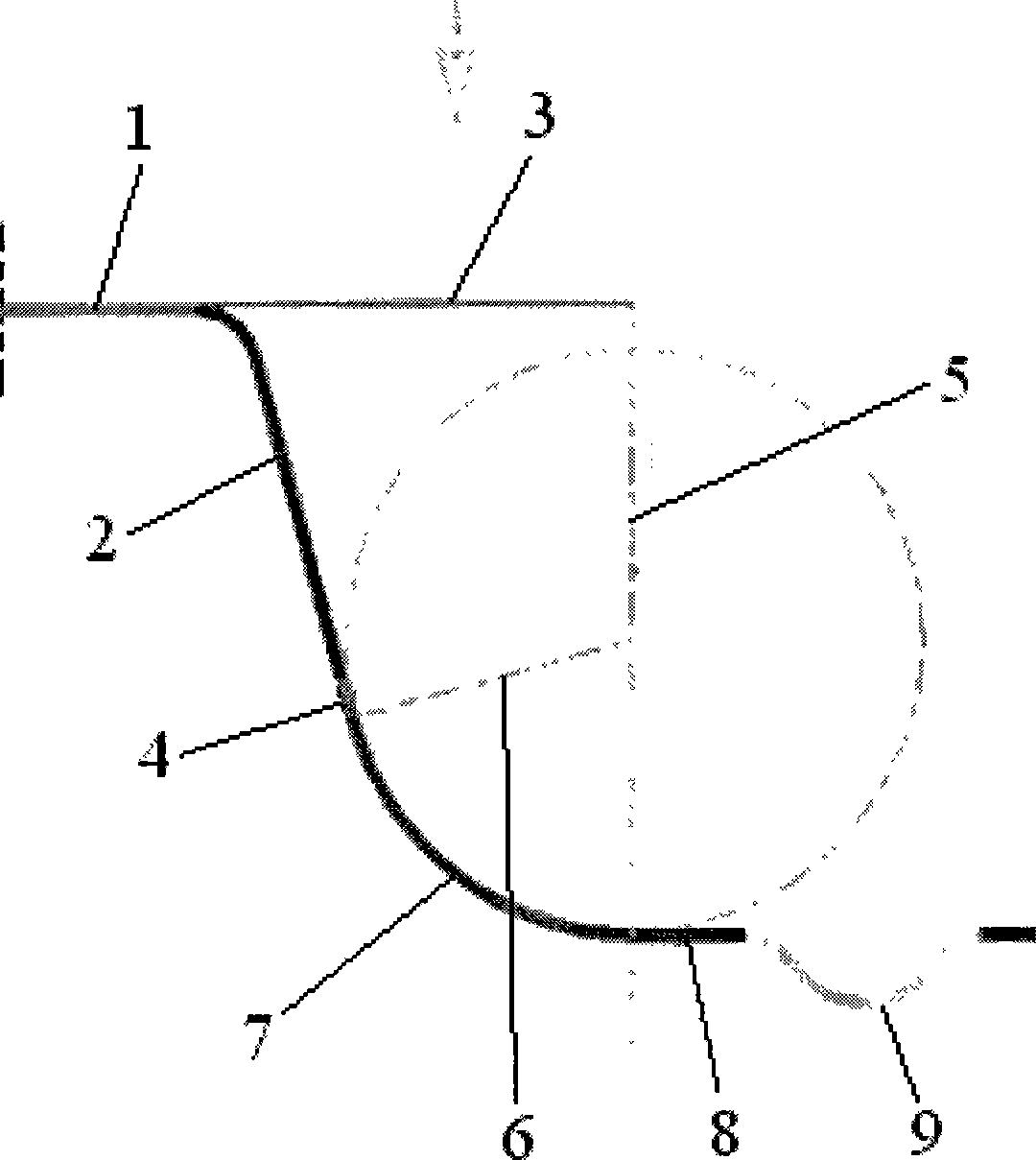

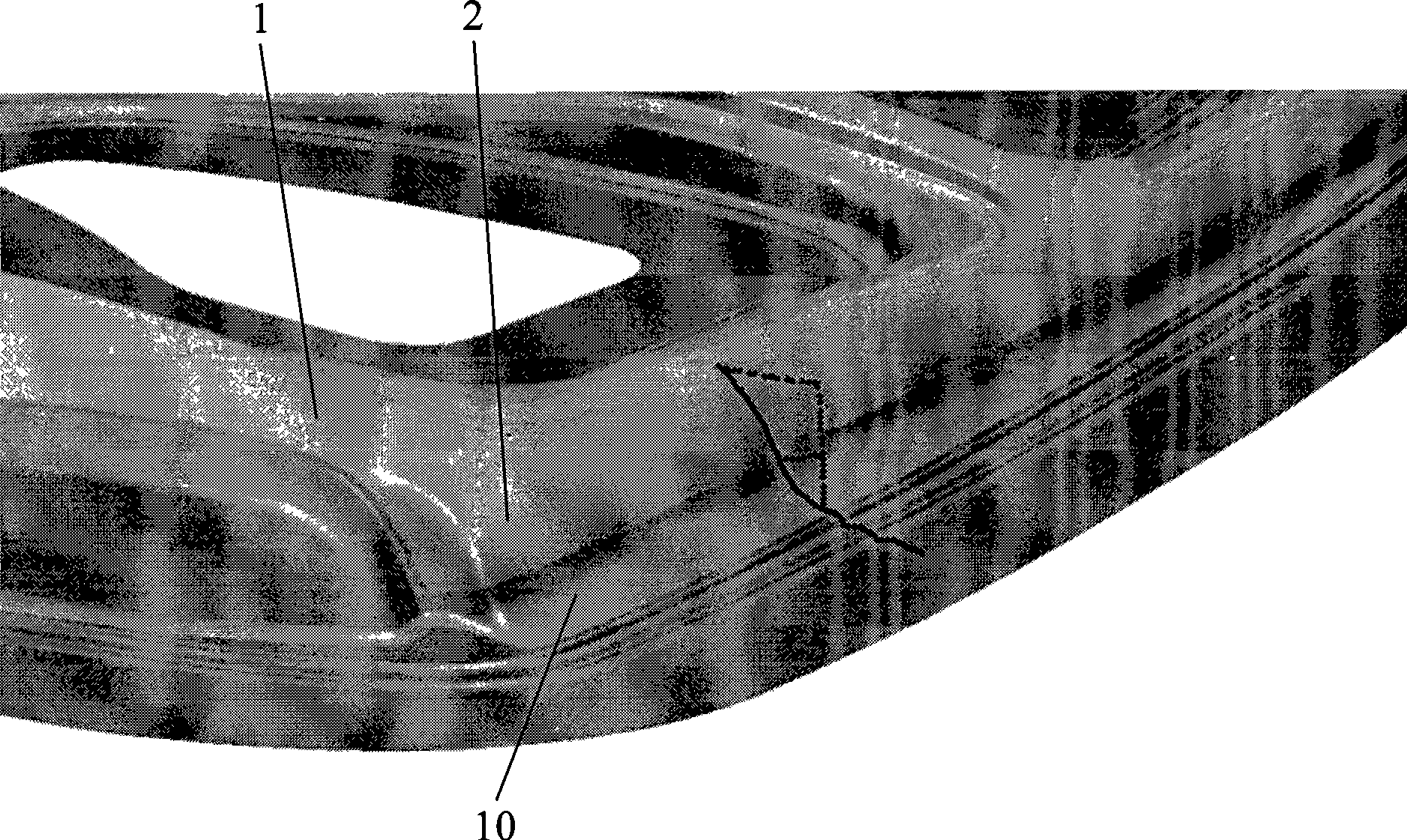

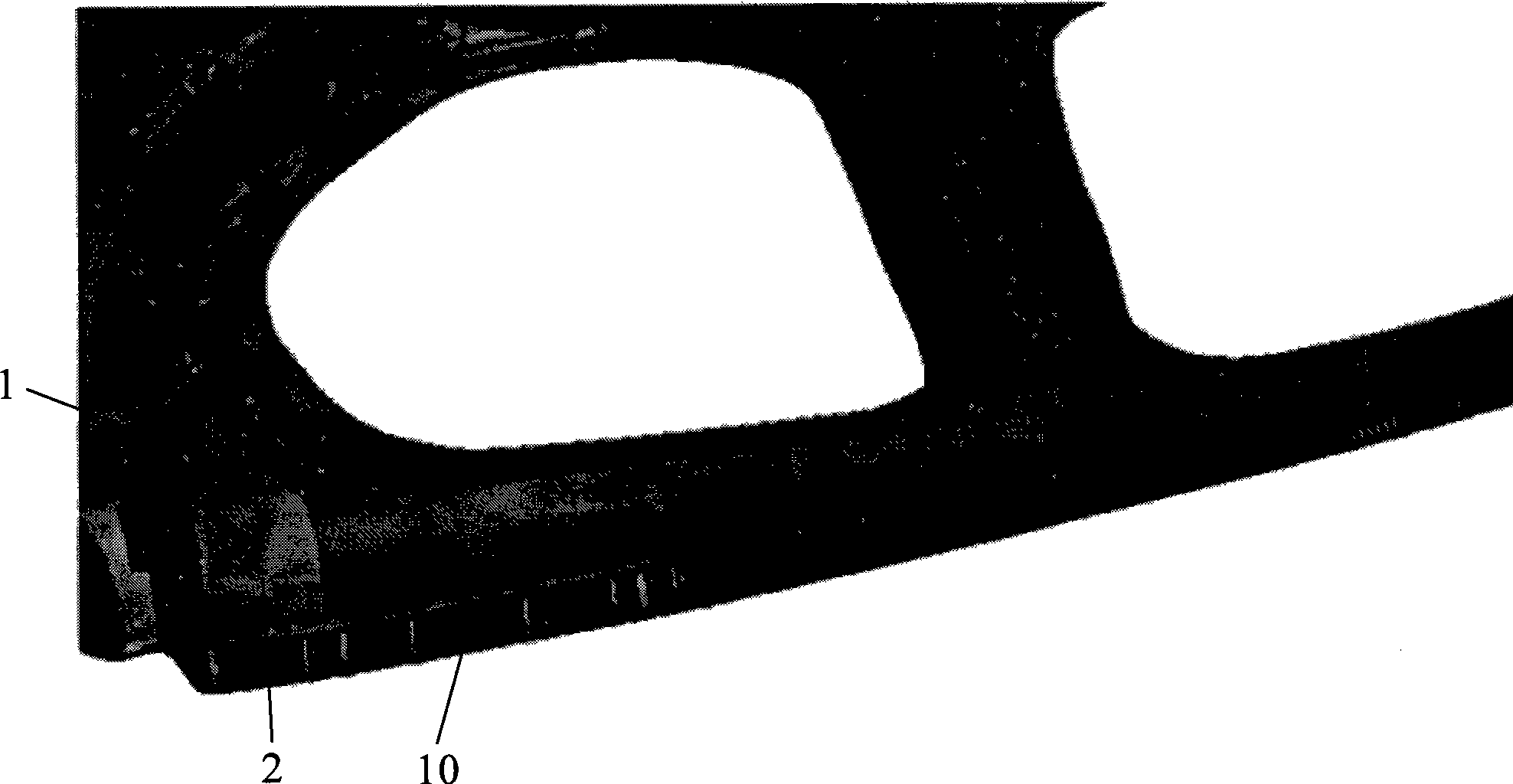

[0012] The outer panel targeted by the present invention includes an upper surface 1 and a side wall 2 connected to the upper surface 1 through a rounded surface, from figure 1 The cross-sectional shape of the outer panel can be seen in .

[0013] The method for supplementing the process of the outer panel of the vehicle provided by the present invention includes cutting at least one cross section on the outer panel, performing supplementary process on the cross section of the outer panel to obtain the supplementary process section of the cross section of the outer panel, and then converting the process The supplementary sections are extended and / or connected to form the technical supplementary surface 10 of the outer panel. When the shape of the outer panel is consistent, only one section can be cut for process supplementation, and after obtaining the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com