Coating workshop steel sand shot blasting machine

A technology of shot blasting machine and steel grit, which is applied in the direction of abrasive jetting machine tools, metal processing equipment, used abrasive processing devices, etc. It can solve the problems of easy blockage of shot blasting chamber, low safety factor, low work efficiency, etc. To achieve the effect of preventing pollution of the external environment, improving the effect of cleaning and dust removal, and improving the efficiency of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0027] Example.

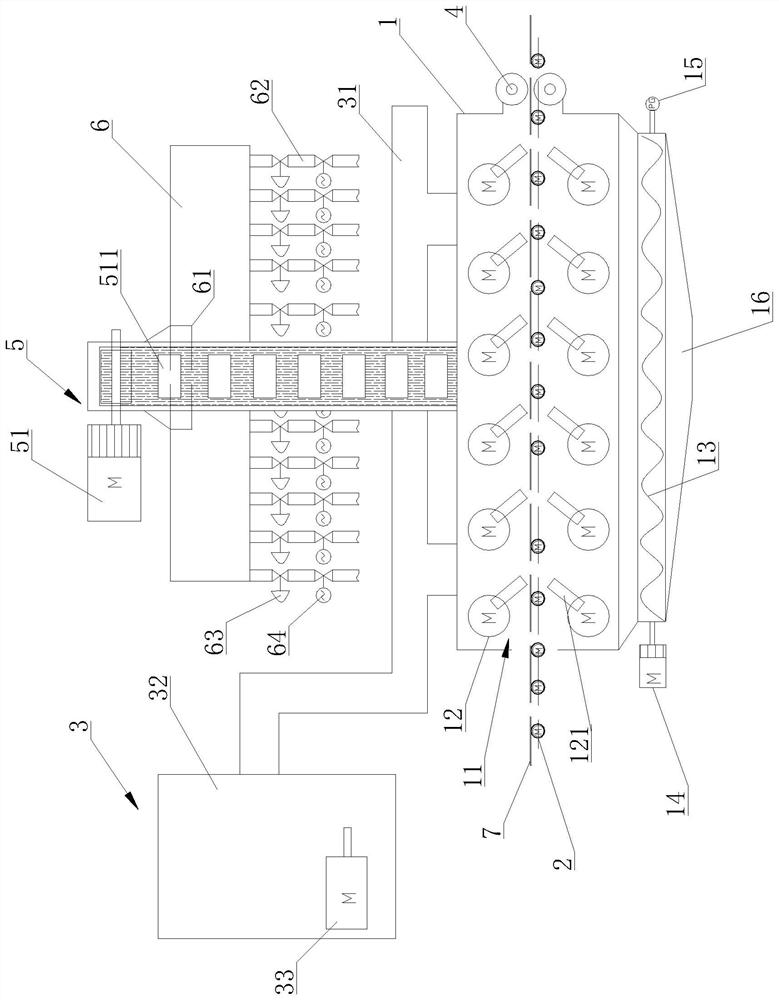

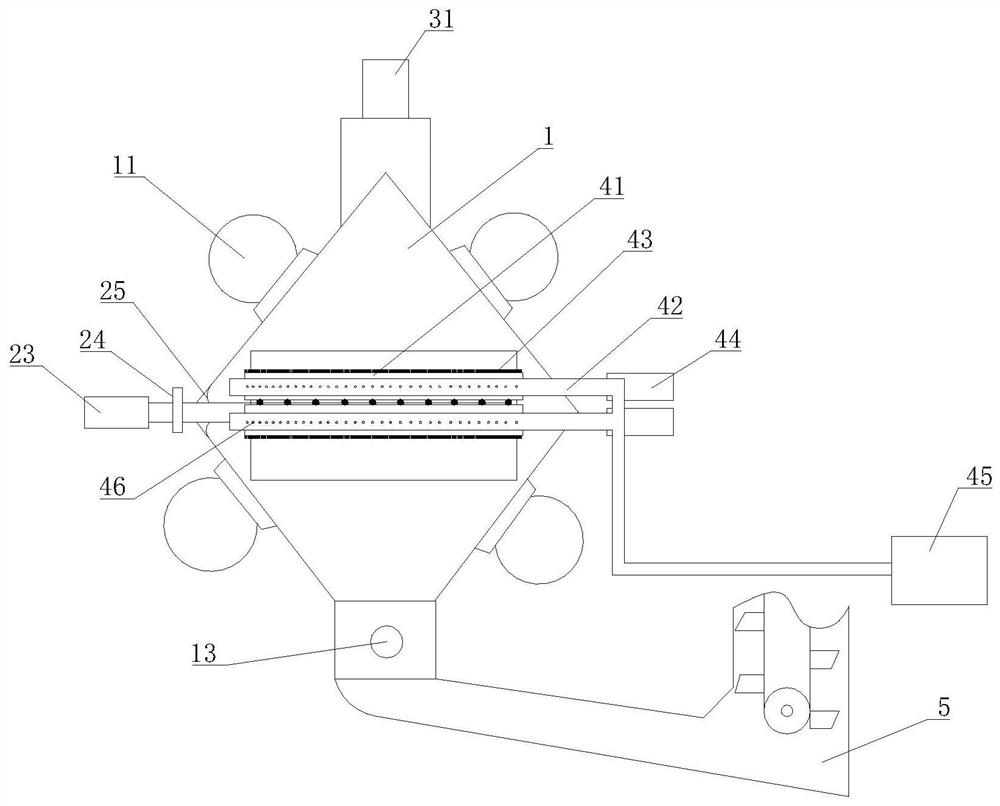

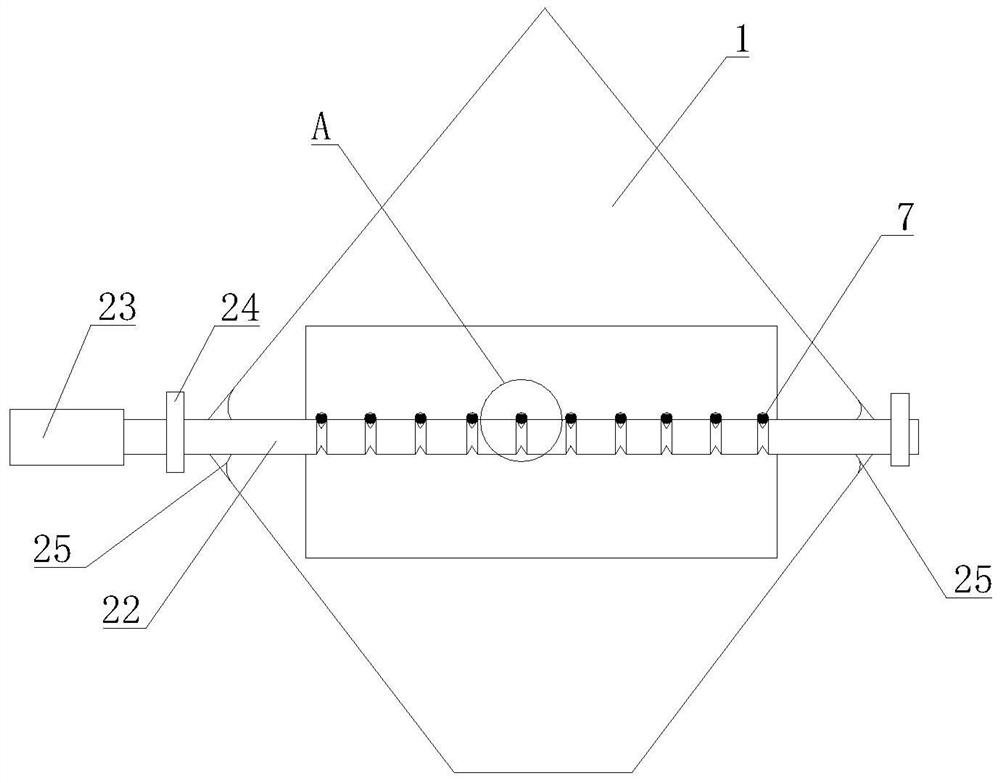

[0028] Such as Figure 1-7 As shown, the steel sand shot blasting machine in the coating workshop includes a shot blasting chamber 1, and a conveying roller table 2 is installed in the shot blasting chamber 1, and the workpiece 7 is placed on the conveying roller table 2, and the workpiece is placed on the conveying roller table 2 at a set speed or on-line Pass through the shot blasting device 11 at a constant speed, clean the workpiece 7, and then transport it out. The inner wall of the shot blasting chamber 1 is provided with a guard plate, which can withstand the long-term beating of the steel grit. The surface of the conveying roller table 2 is provided with an installation groove 21, and the conveying roller table 2 is connected with a conveying motor 23 through a rotating shaft 22. The rotating shaft 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com