Patents

Literature

40results about How to "Improve shot blasting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

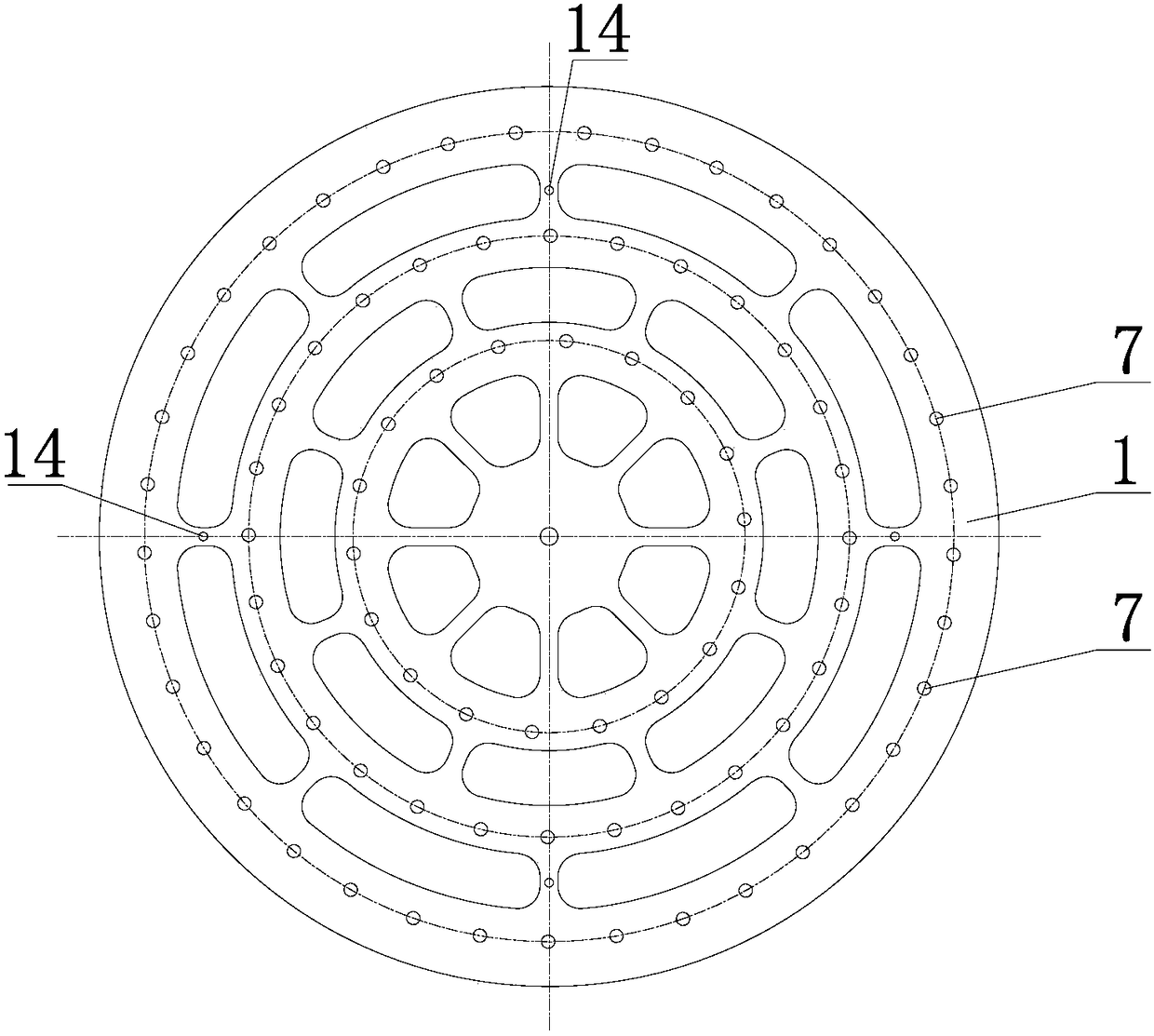

Efficient impeller head

ActiveCN105643476AIncrease profitExtended service lifeImpeller wheelsRotor bladesImpellerEngineering

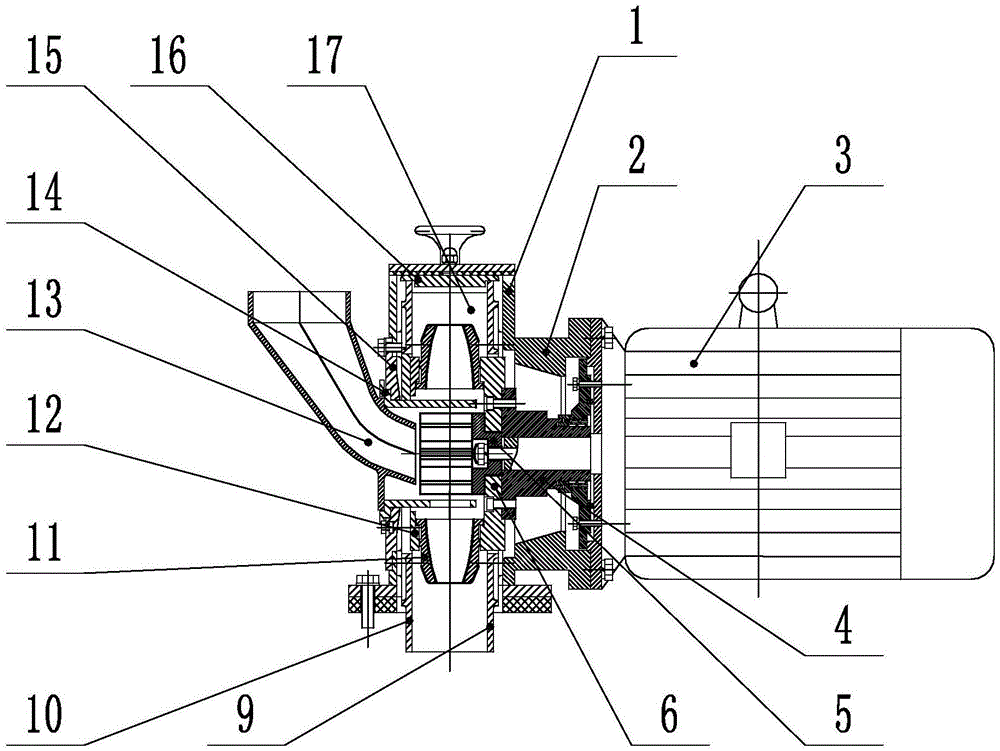

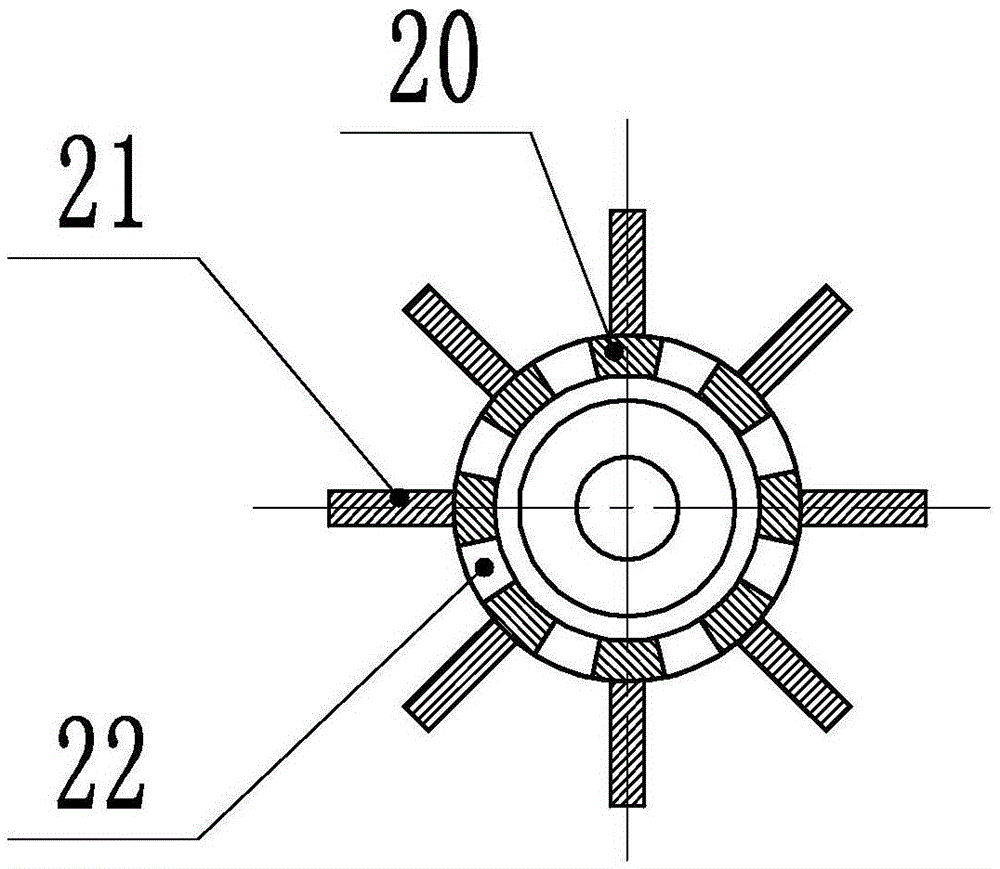

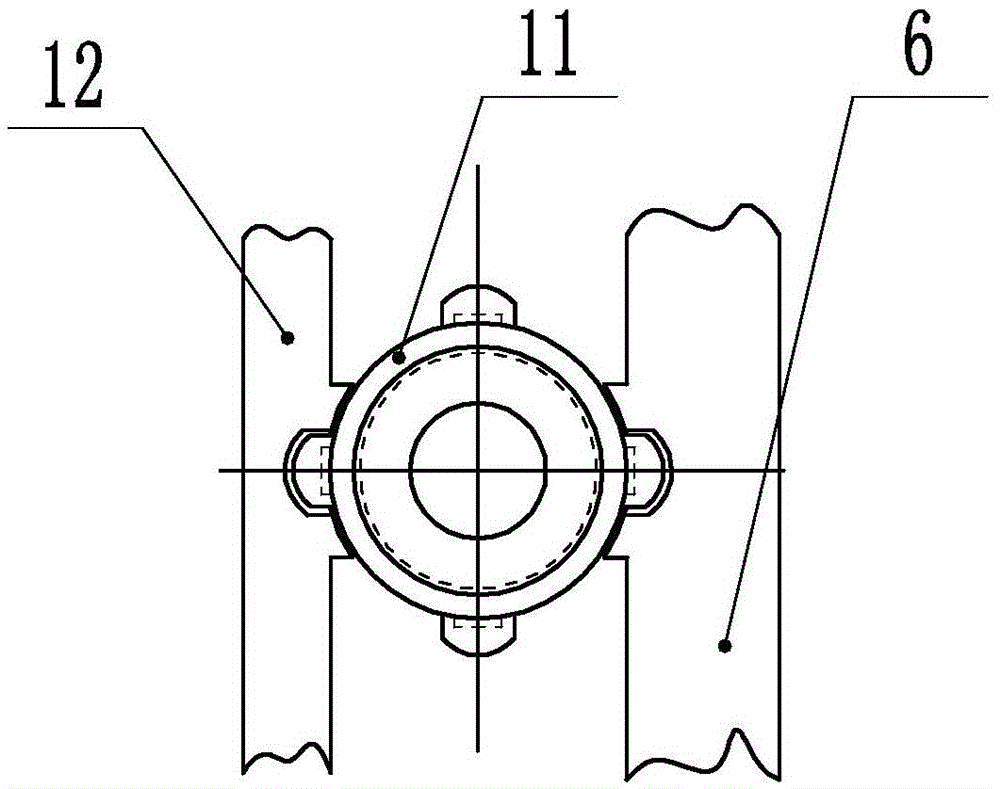

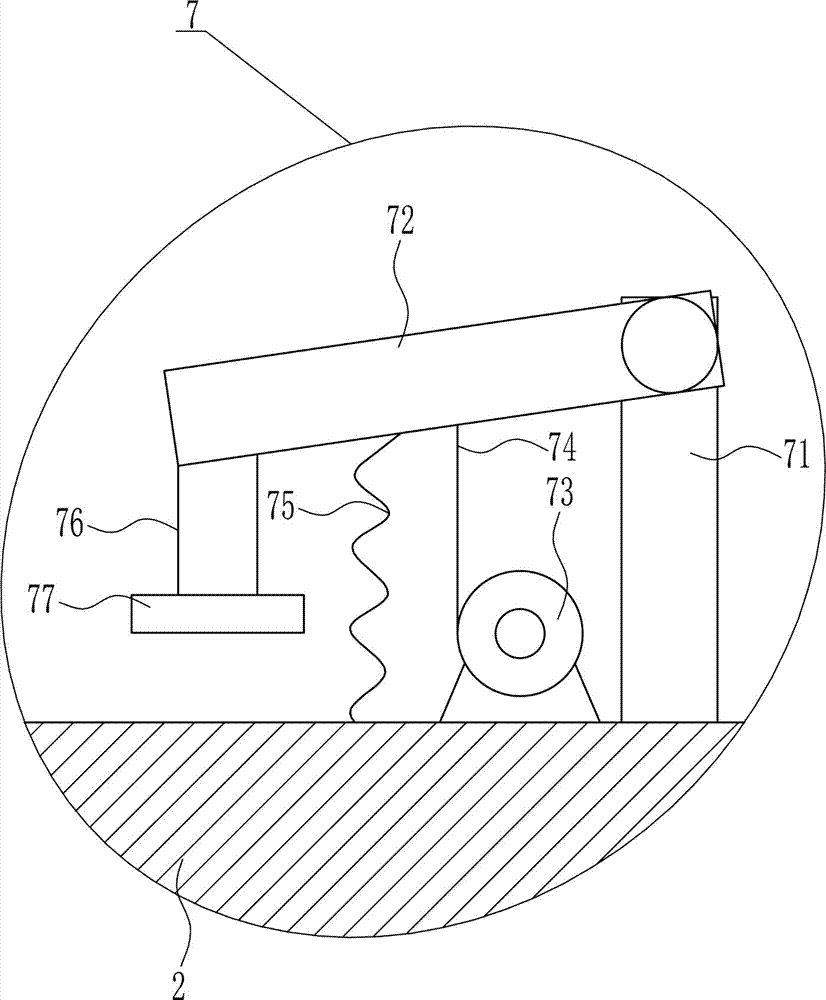

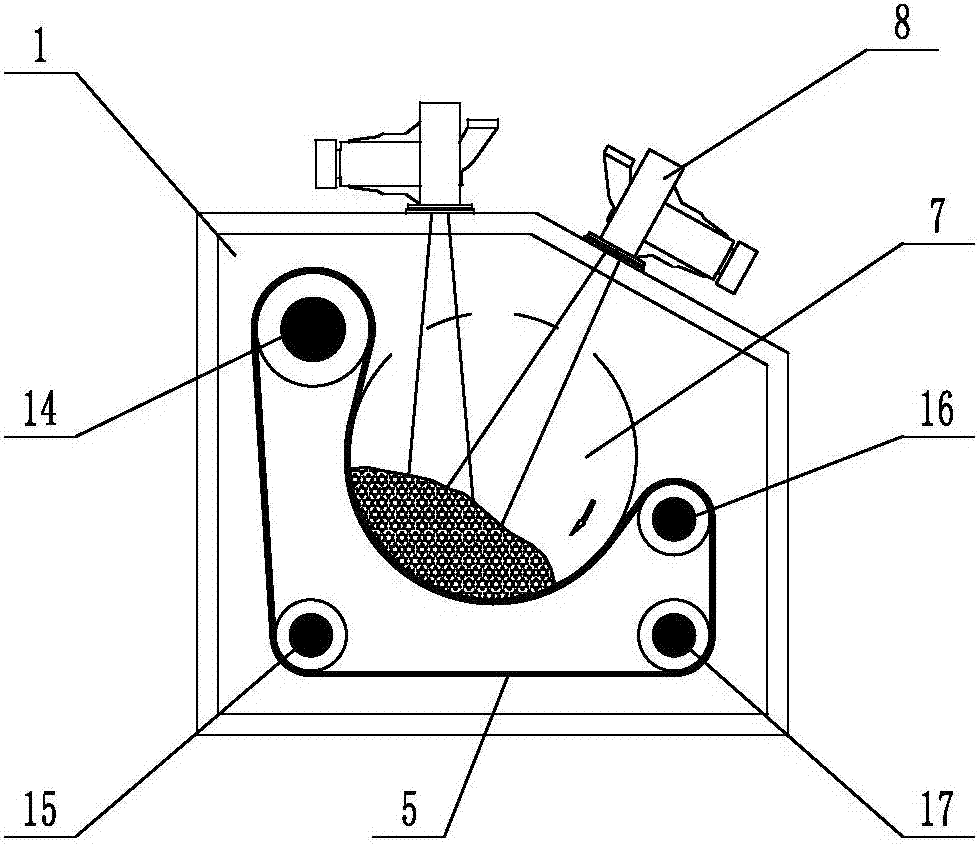

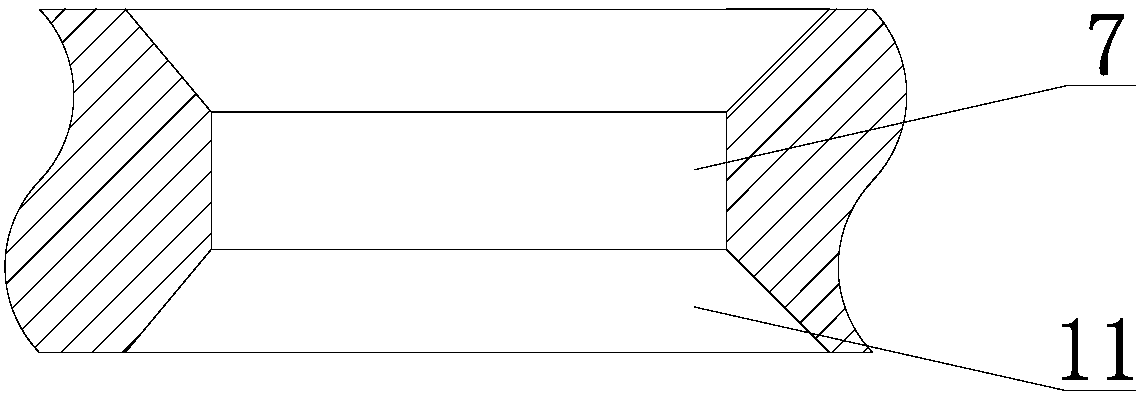

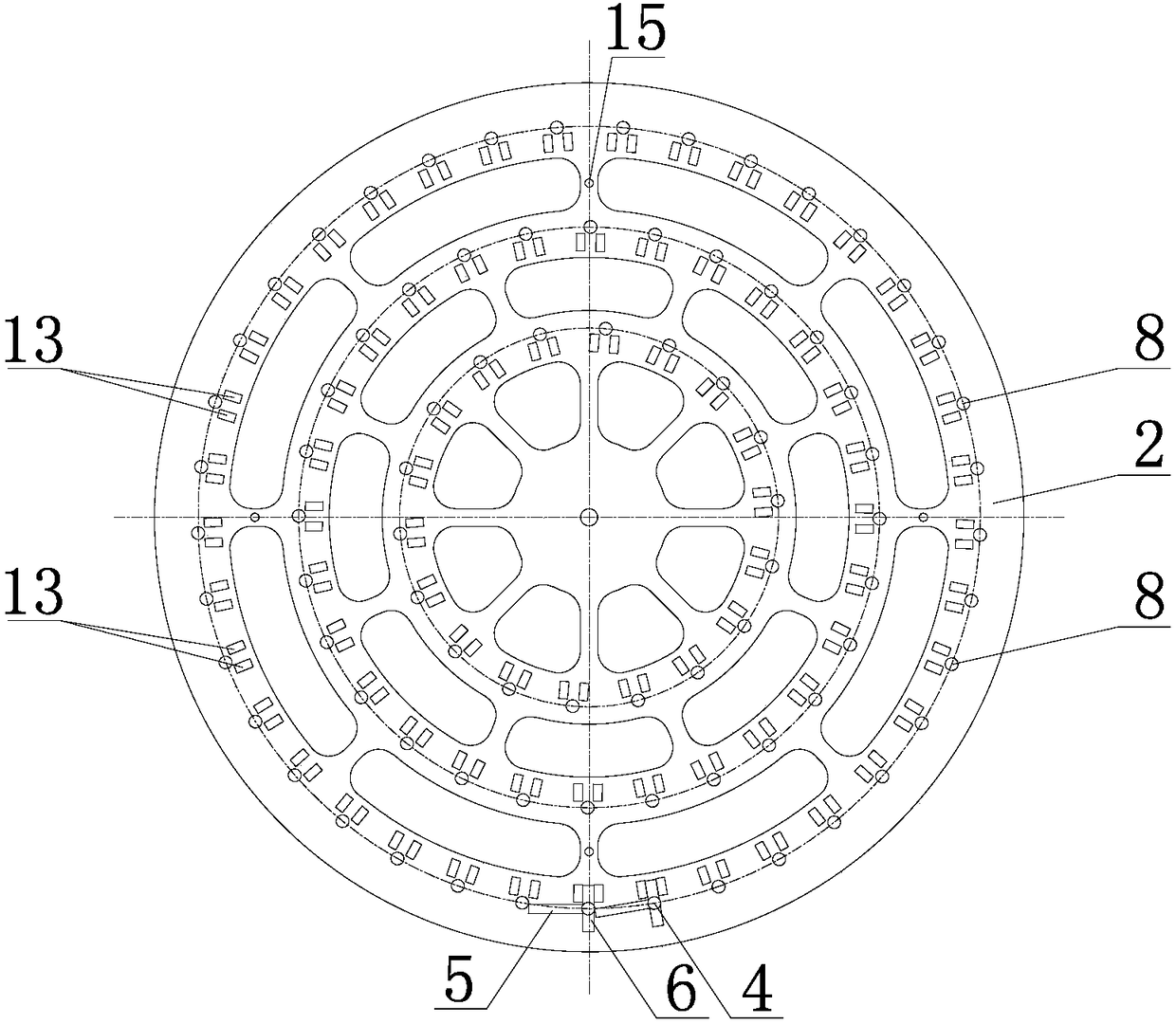

The invention discloses an efficient impeller head. The efficient impeller head comprises a shell and impeller discs. An impeller and a directional sleeve are further mounted in the centers of the two impeller discs. The directional sleeve is fixedly mounted through the shell. A motor is arranged on one side of the shell. One end of the impeller, the motor and the impeller discs are fixedly mounted, and the other end of the impeller exactly faces a shot inlet pipe. Shot blasting blades are arranged on the periphery of the directional sleeve. The impeller comprises an impeller body, the impeller body is provided with shot distributing windows and further provided with impeller blades, and the shot distributing windows are spaced by the impeller blades. A sector space is formed among the impeller blades and the directional sleeve. After the structure is adopted, shot blasting is quite smooth, the whole shot blasting process is strong in blasting force, the phenomenon of shot blocking is avoided, and the shot blasting effect is improved; and the utilization rate of the shot blasting blades is greatly increased, the service life of the shot blasting blades is greatly prolonged, the overall structural design is reasonable, dismounting and mounting are fast and convenient, the labor intensity of workers is greatly reduced, and the work efficiency is improved.

Owner:江苏江大金属表面处理技术研究院有限公司

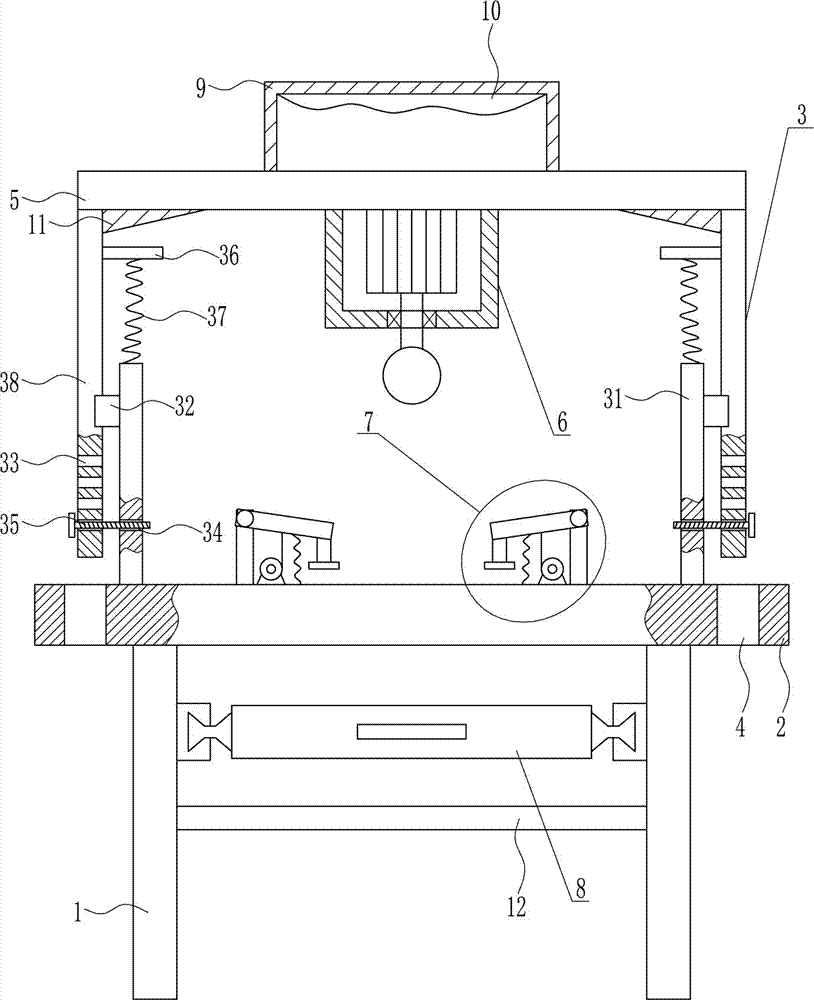

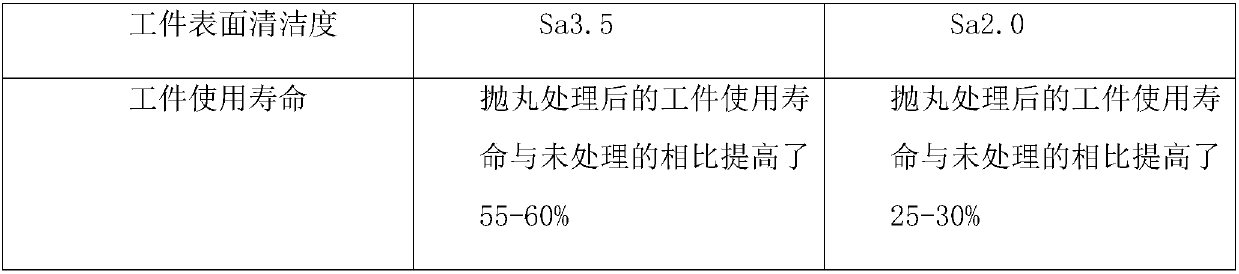

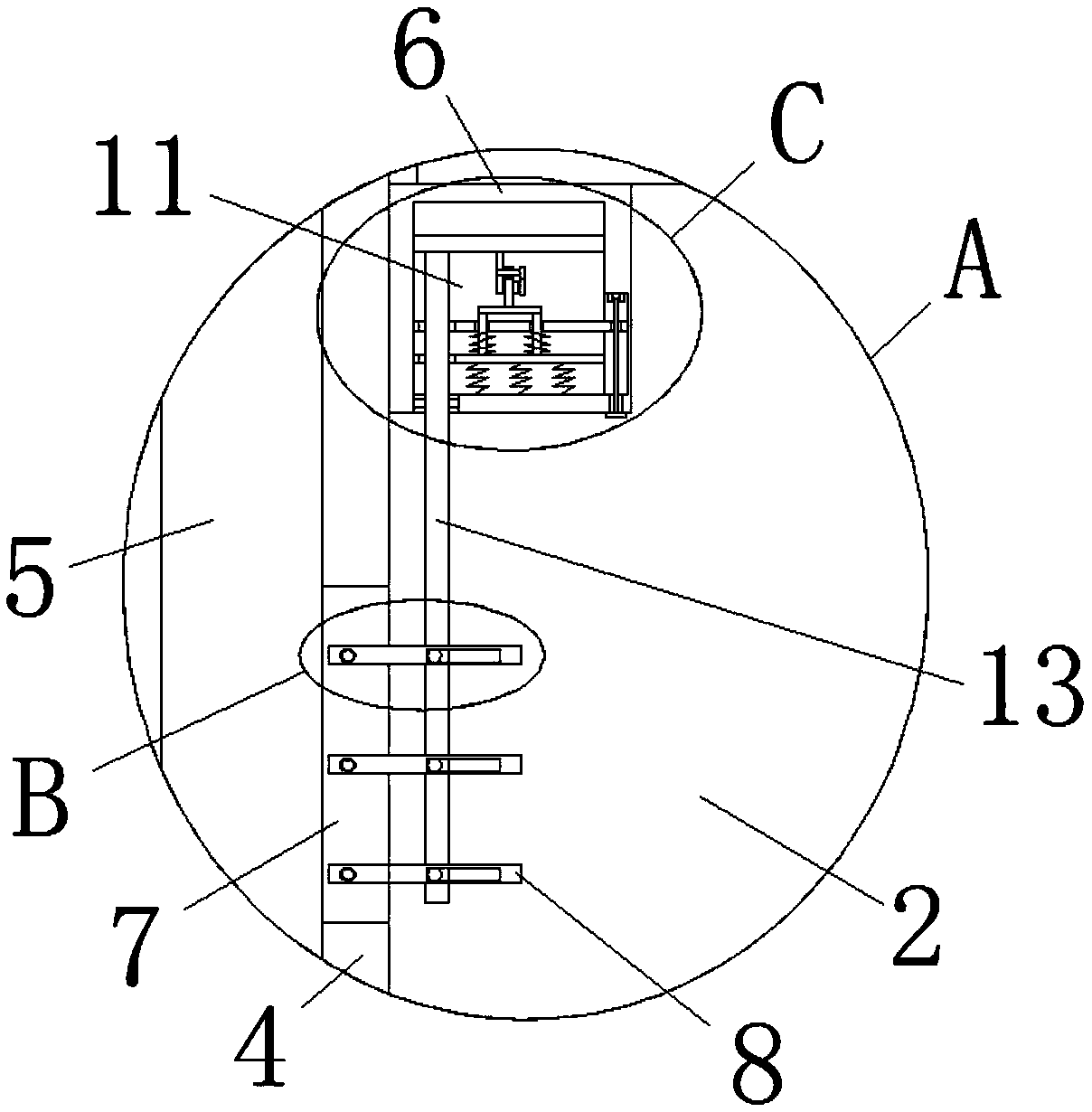

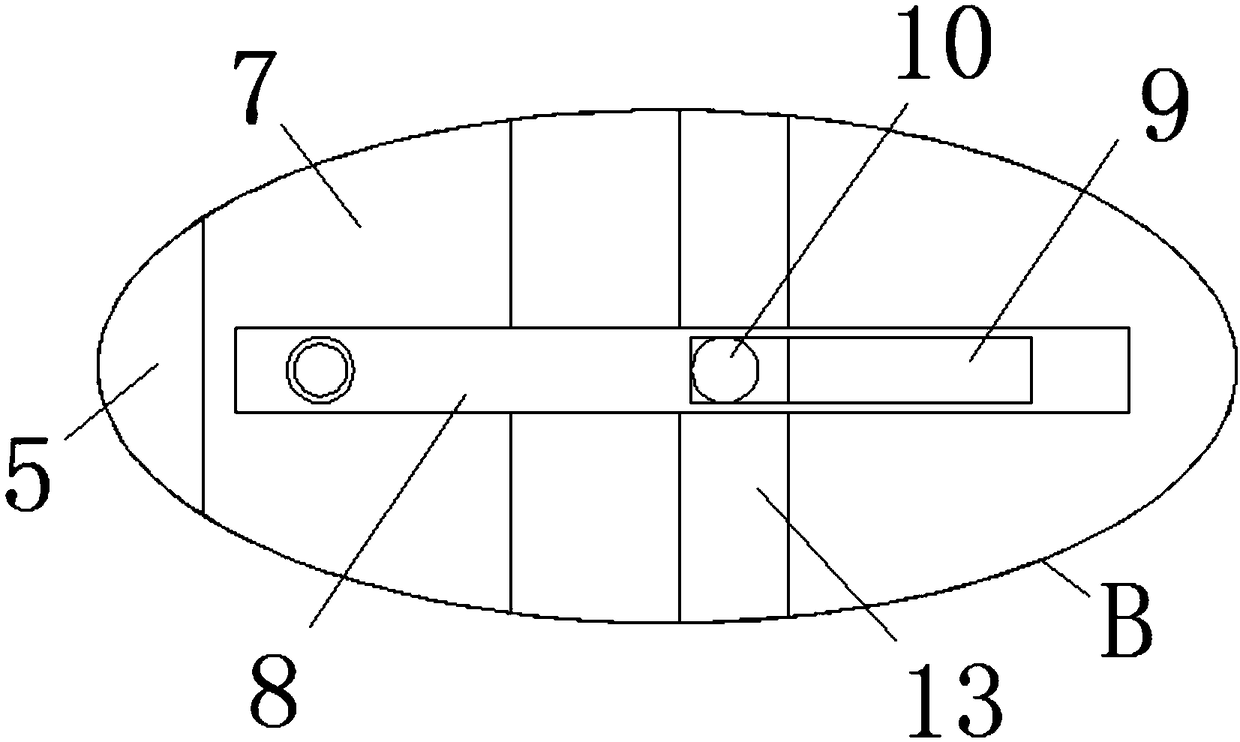

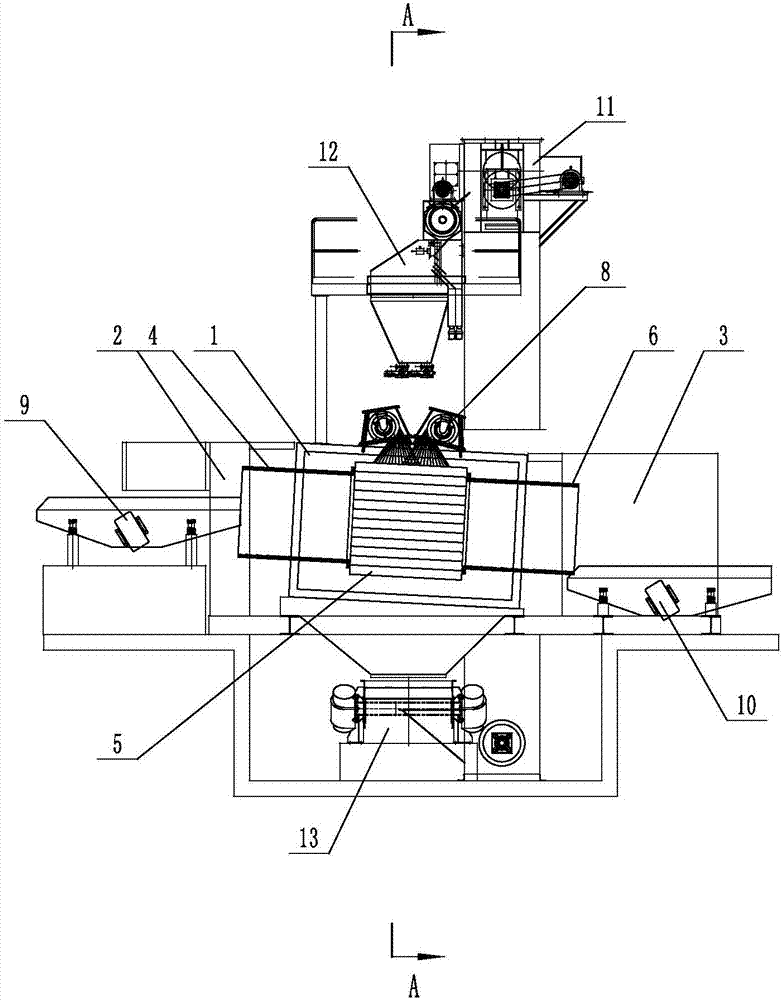

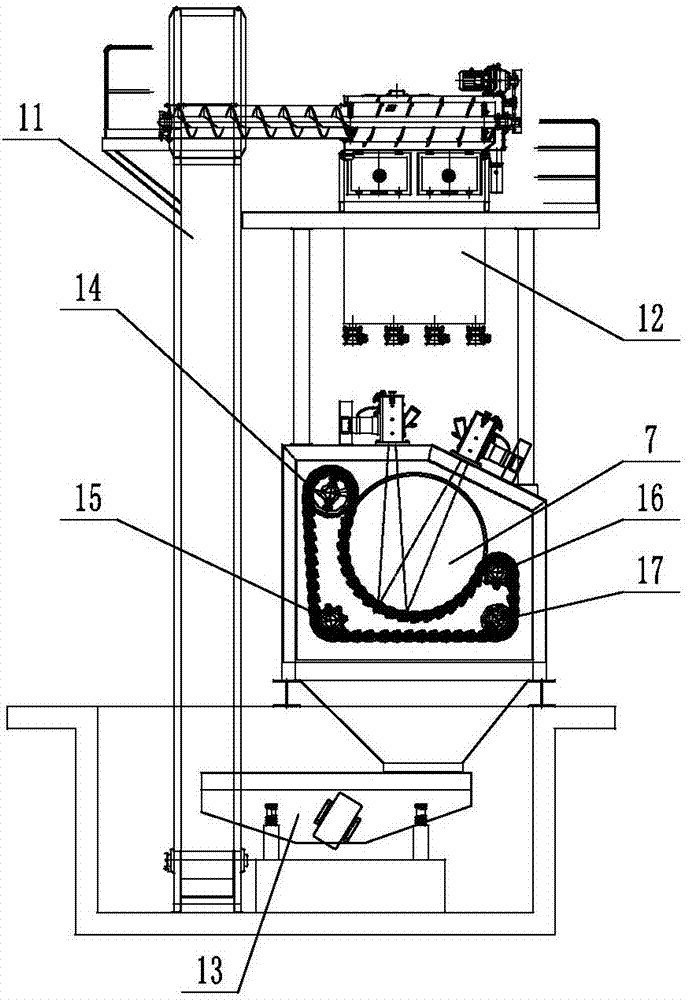

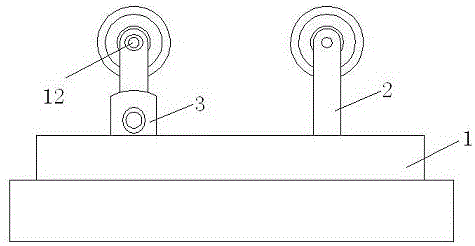

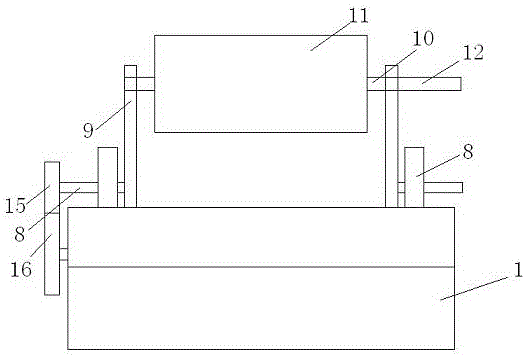

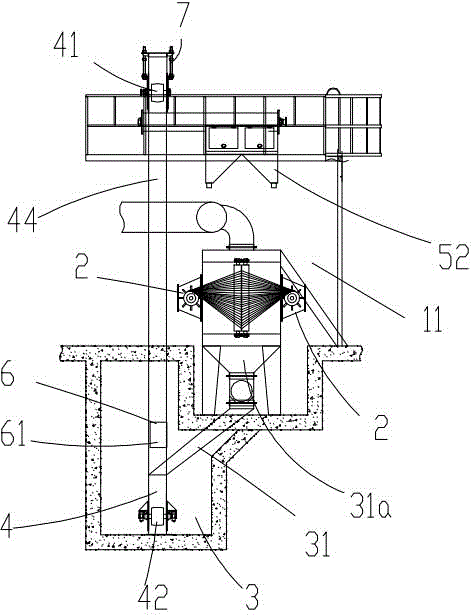

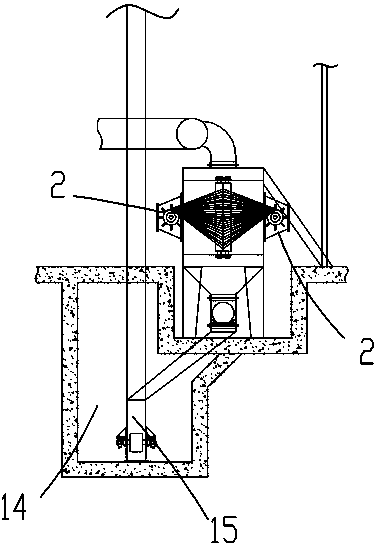

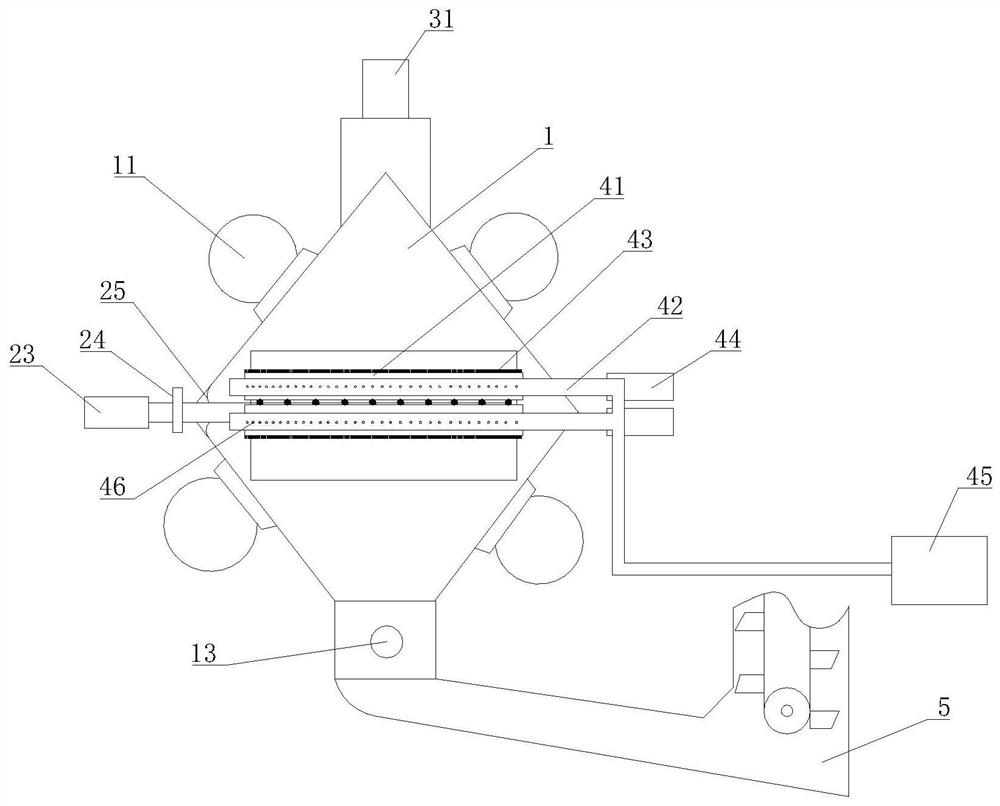

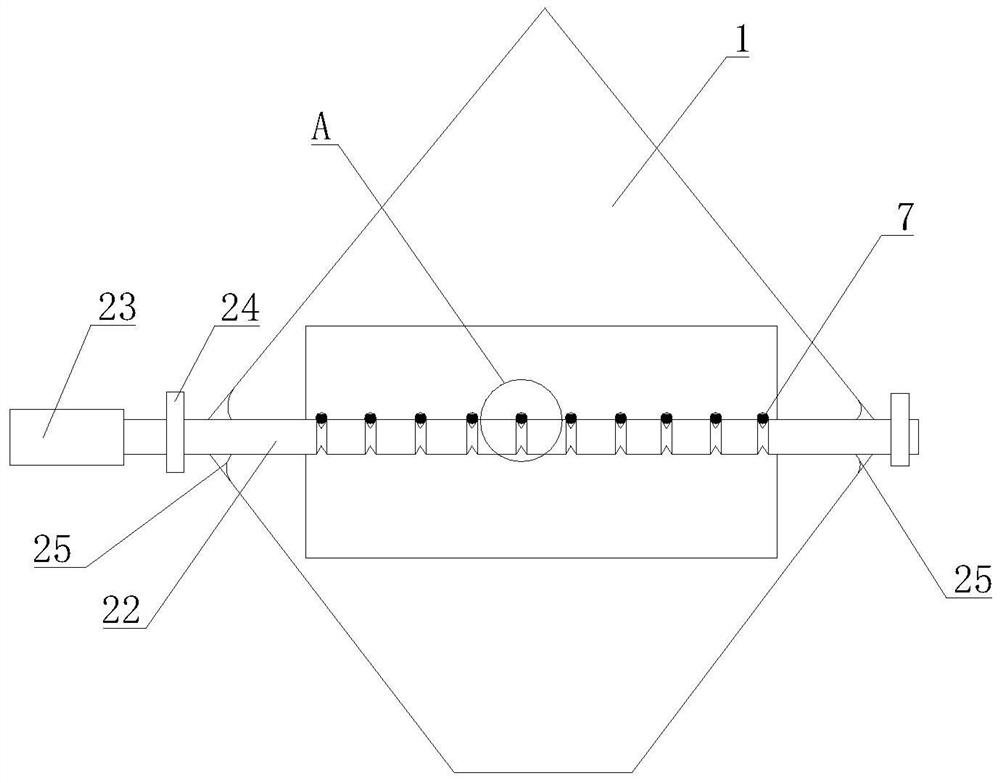

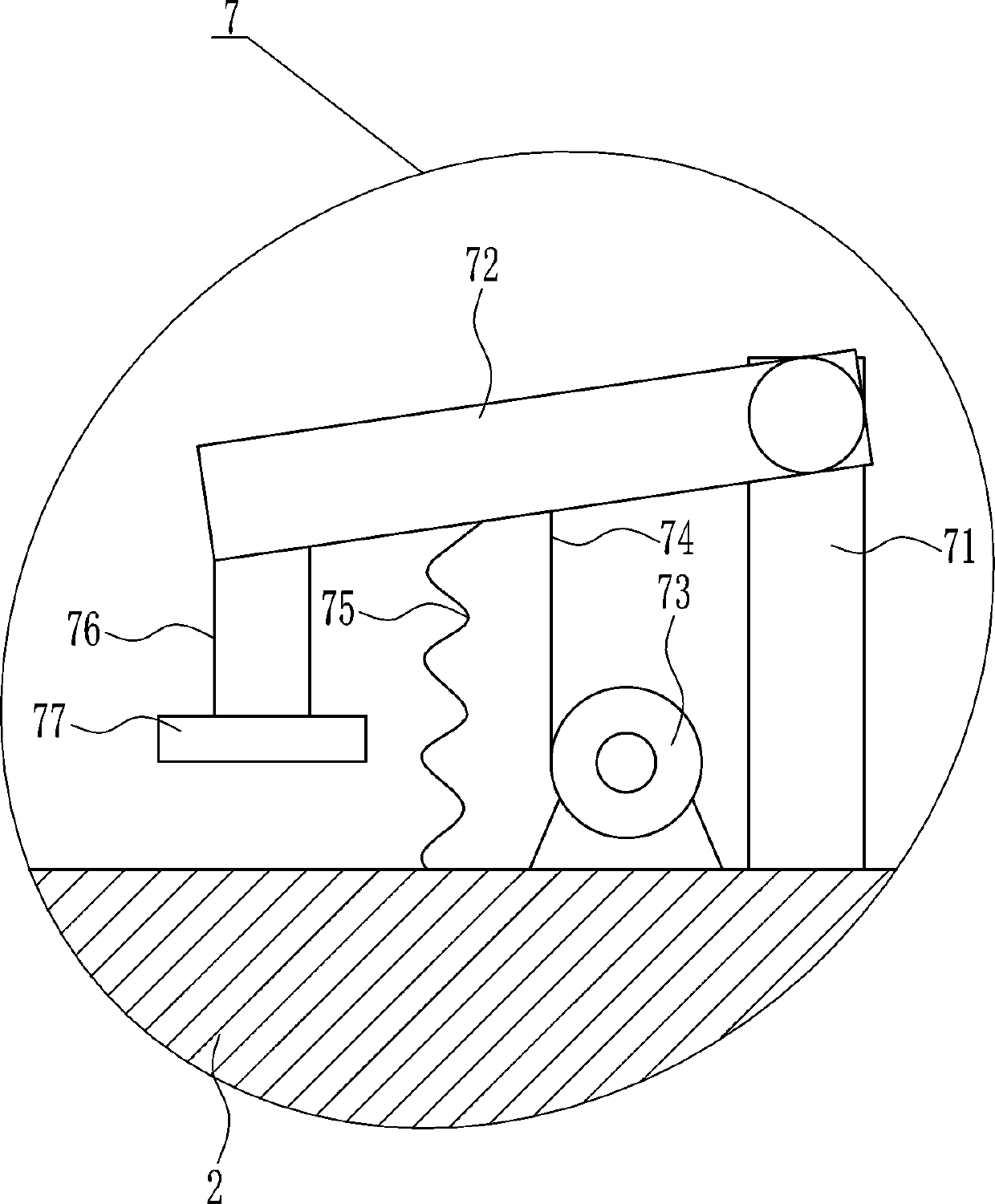

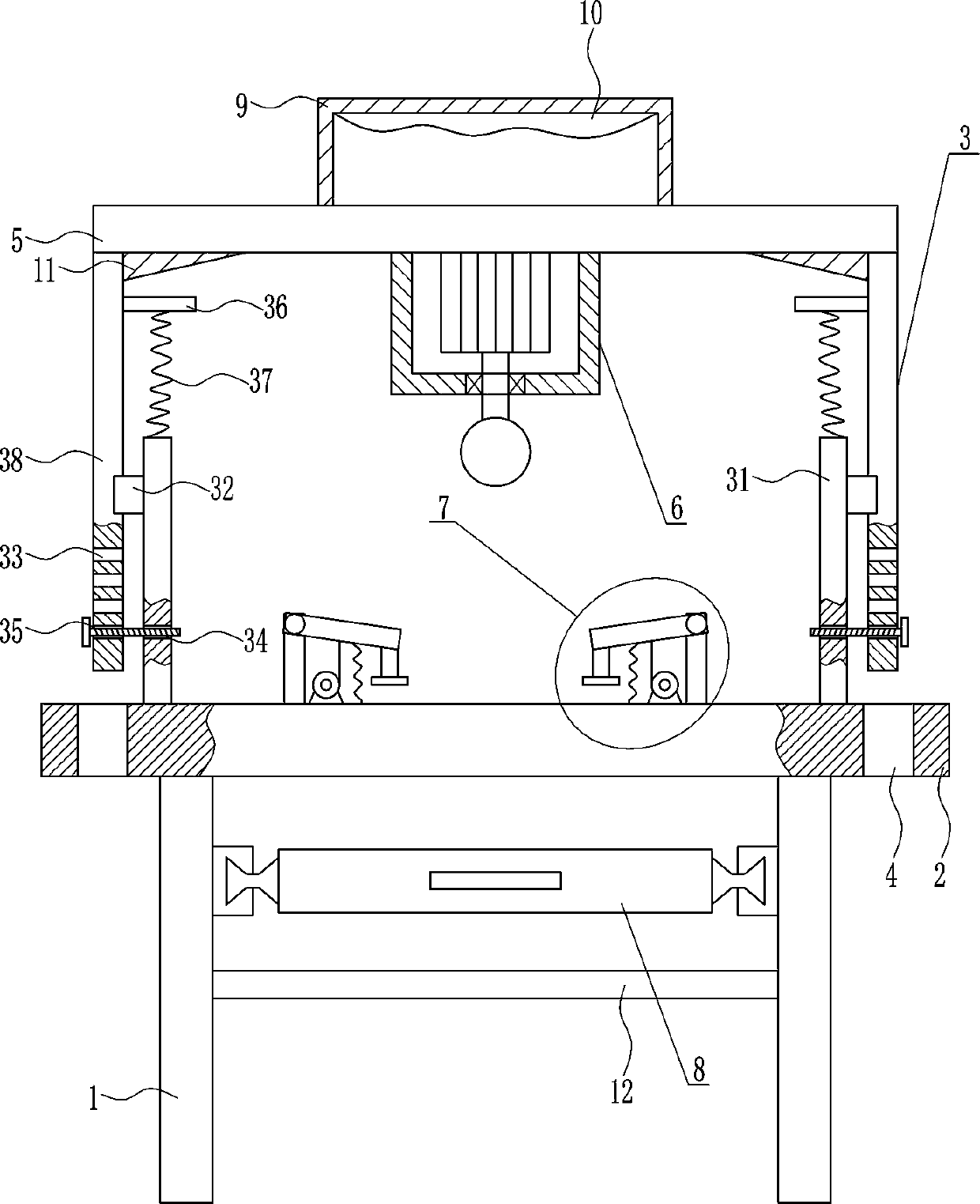

Steel backing shot blasting equipment for production of brake pads

ActiveCN107486791AReduce manufacturing costImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesArchitectural engineeringBrake pad

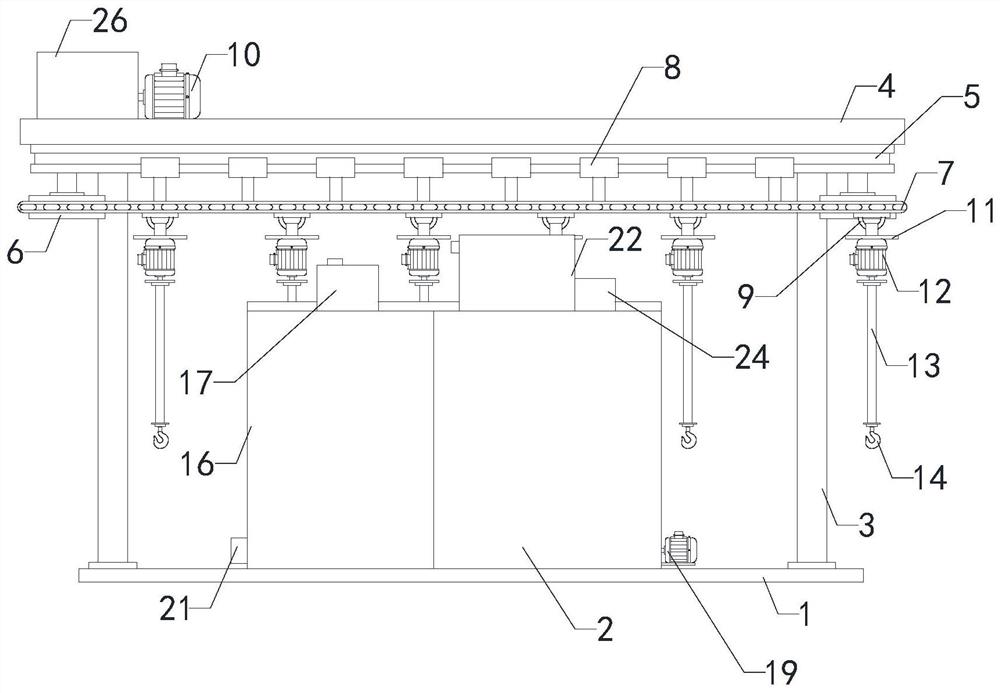

The invention belongs to the technical field of brake pad production, and particularly relates to a steel backing shot blasting device for production of brake pads. The steel backing shot blasting device for production of the brake pads has the advantages that the manufacturing cost is low, the shot blasting effect is good, operation is simple, and the working efficiency is high. The steel backing shot blasting device for production of the brake pads comprises supporting legs and the like; a transverse plate is arranged on the tops of the supporting legs through bolts; lifting devices are symmetrically arranged on the left side and the right side of the top of the transverse plate; through holes are formed in the left end and the right end of the transverse plate separately; a top plate is connected to lifting parts of the lifting devices and is horizontally arranged; a shot blasting device is arranged in the middle of the bottom of the top plate; and a cross rod is connected to the lower portion between the two supporting legs through bolts. According to the steel backing shot blasting device for production of the brake pads, the effects of low manufacturing cost, good shot blasting effect, simple operation and high working efficiency can be achieved.

Owner:浙江翘楚汽车零部件有限公司

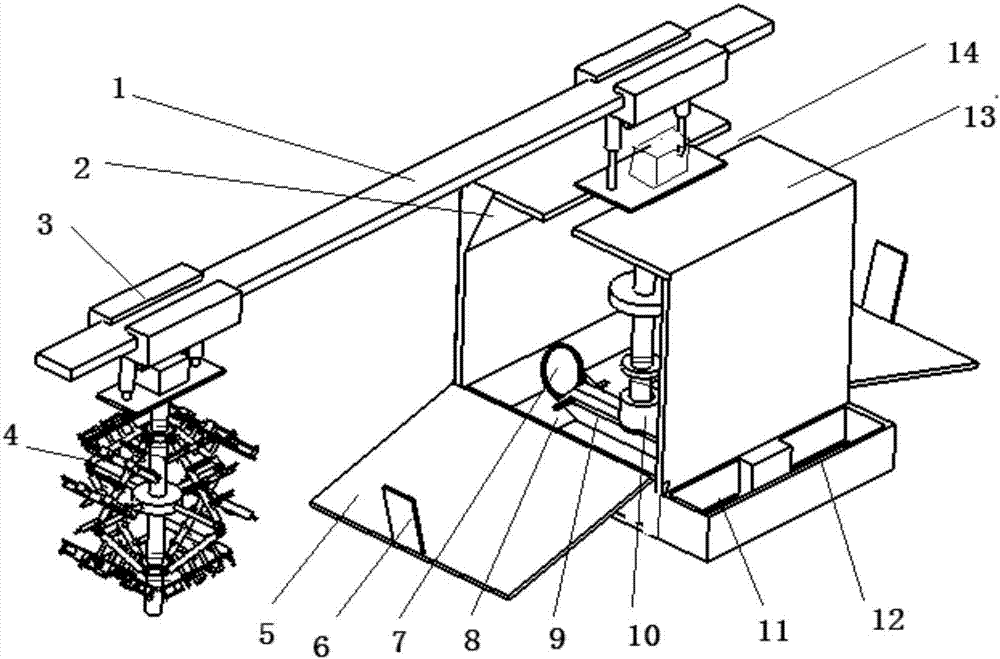

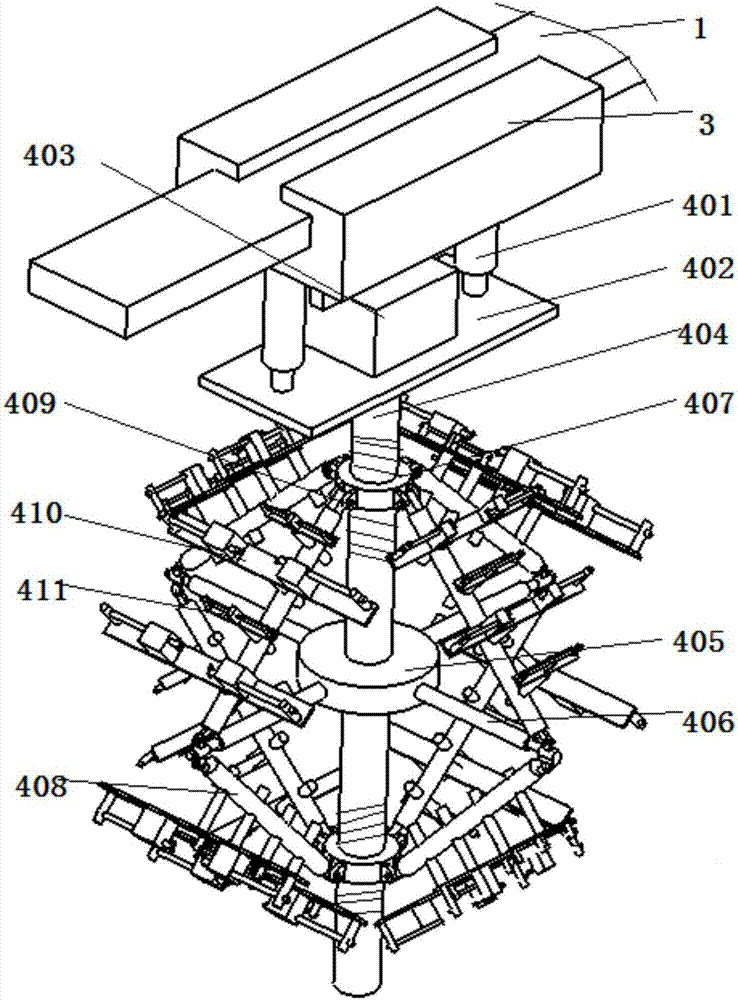

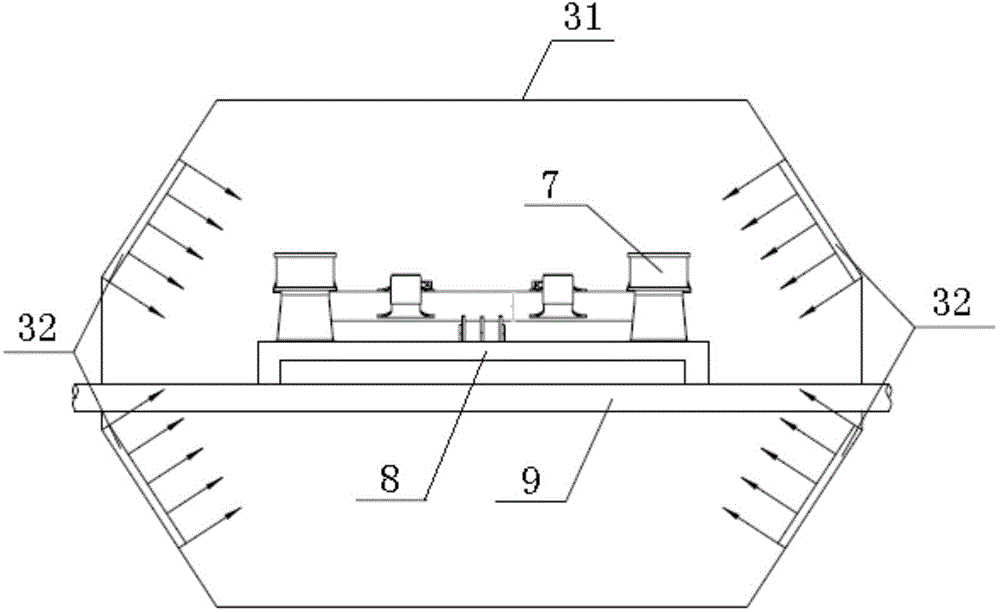

Multidirectional shot blasting device stable in structure

PendingCN107186628AShot blastingShot blasting is fast and efficientAbrasive machine appurtenancesAbrasive blasting machinesHydraulic cylinderFixed frame

The invention provides a multidirectional shot blasting device stable in structure. The multidirectional shot blasting device comprises a sliding block and a hydraulic cylinder arranged below the sliding block. A fixed plate is arranged at the top of the hydraulic cylinder. An electromotor is arranged on the fixed plate. A center shaft penetrates the fixed plate to be connected with the output end of the electromotor. A center disc is arranged on the center shaft. The side face of the center disc stretches outwards to form multiple circumferentially-distributed telescopic rods. Symmetric sliding rings are rotationally connected to the positions, arranged on the two sides of the center disc, on the center shaft. Struts are hinged to the telescopic rods through pin shafts. Multiple fixed frames are arranged on the struts. The multidirectional shot blasting device stable in structure is simple in structure and is designed for complex and irregular automobile castings; more workpieces can be clamped on the basis that the workpieces do not influence on another during shot blasting; it can be guaranteed that faces of more angles can be subjected to shot blasting; product quality can be improved; shot blasting efficiency is higher; and production cost is reduced.

Owner:中联精工(天津)有限公司

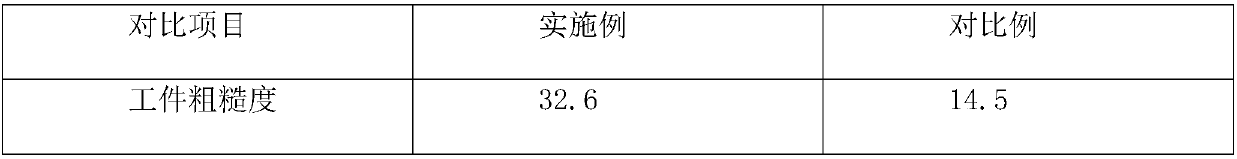

Steel shot preparing method and shot blasting technology applying steel shots

InactiveCN107914020AHigh hardnessHigh strengthFurnace typesAbrasive machine appurtenancesMetallurgyMechanical engineering

The invention discloses a steel shot preparing method, and relates to the technical field. A steel shot comprises chemical components including, by mass percent, 0.65%-0.78% of C, 0.22%-0.25% of Si, 0.14%-0.16% of W, 0.55%-0.75% of Mn, 0.49%-0.58% of Ti, 0.11%-0.18% of Al, 0.02%-0.07% of Nb, and the balance Fe. The invention further discloses a shot blasting technology. The shot blasting technology comprises the following steps that S1, degreasing, washing and drying are conducted on a workpiece which is about to be subjected to shot blasting; S2, after shot blasting line equipment is debugged, steel shots are added in the shot blasting line equipment, the workpiece is arranged in a shot blasting chamber, the position of the workpiece is adjusted, a nozzle of an impeller head faces the workpiece, and then shot blasting treatment is conducted; S3, after shot blasting treatment is finished, shot particles on the surface of the workpiece are removed; and S4, the workpiece obtained after shot blasting treatment is checked. According to the steel shot preparing method and the shot blasting technology, the steel shot hardness and deformation resisting capability are effectively improved,dust is small, the service life is longer, the shot blasting technology efficiency is effectively improved, and meanwhile the cost of the shot blasting technology is reduced.

Owner:江苏飞腾铸造机械有限公司

Shot blasting treatment process

InactiveCN107891374AAvoid severe deformationImprove shot blasting qualityBlast effectsMaterials science

The invention discloses a shot blasting treatment process, and relates to the field of shot blasting. The shot blasting treatment process comprises the following steps: (S1) the thickness of each partof a workpiece is measured; (S2) the workpiece is degreased, is put in clear water for water washing, and is taken out; water on the surface of the workpiece is blown away by adopting compressed air;and the workpiece is put in a drying chamber for drying; (S3) the dried workpiece is placed in a shot blasting chamber; according to the thickness of the part, towards a shot blasting machine, of theworkpiece, the rotating speed of the shot blasting machine is adjusted, and the shot blasting treatment is performed; after the shot blasting of the part is finished, the workpiece is overturned; theother part of the workpiece is towards a nozzle of the shot blasting machine; according to the thickness of the part, the rotating speed of the shot blasting machine is adjusted;the shot blasting treatment is performed; and the workpiece is overturned until the shot blasting treatmet is performed on all parts of the workpiece; (S4) shots on the surface of the workpiece are cleaned after the shotblasting is finished; and (S5) the workpiece is inspected. The shot blasting treatment process adopts different shot initial speeds on all parts, with different thicknesses, of the workpiece, so thatthe shot blasting effects of all the parts of the workpiece are basically kept consistent, and the service life of the workpiece is prolonged.

Owner:江苏飞腾铸造机械有限公司

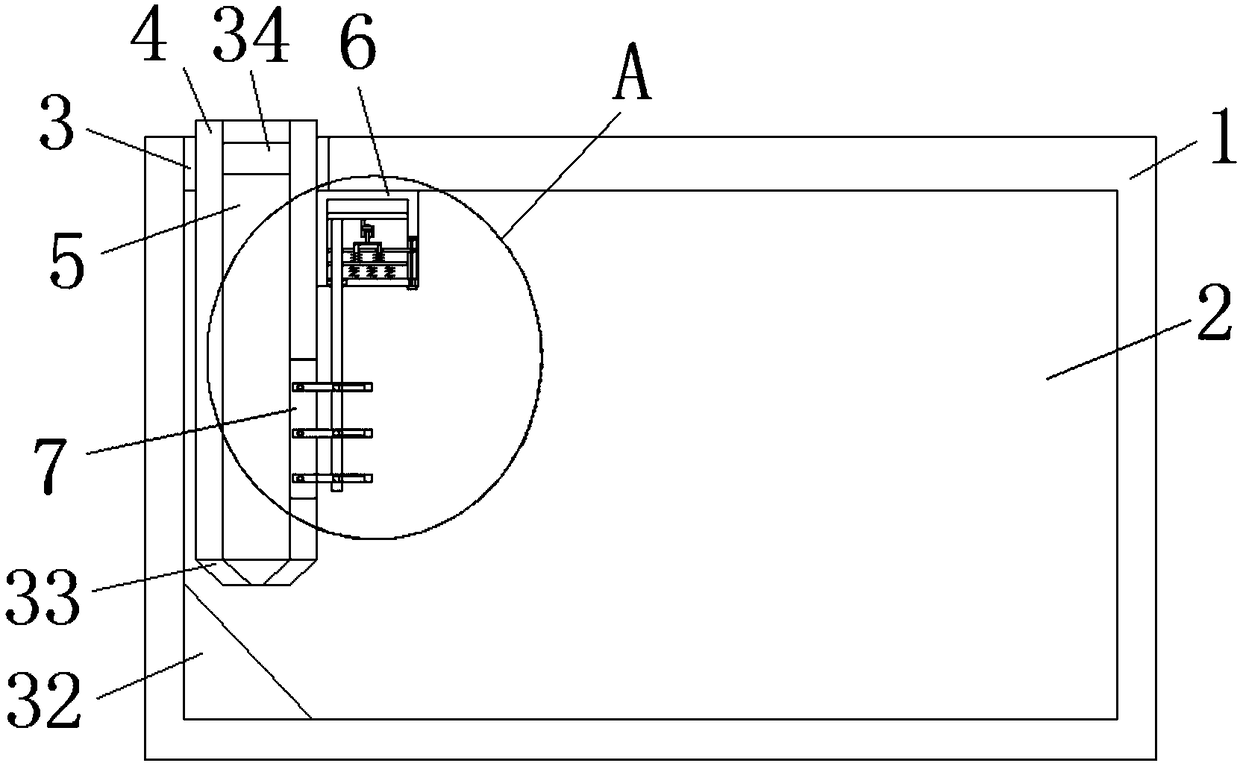

Air inlet structure at top part of shot blasting cleaning machine

ActiveCN108326760AReduce vibrationImplement buffer protectionAbrasive machine appurtenancesSlide plateEngineering

The invention discloses an air inlet structure at the top part of a shot blasting cleaning machine, wherein the air inlet structure includes a cleaning room; a cavity is arranged on the cleaning room,an installation hole is formed in the inner wall of the top part of the cavity; a rectangular air intake pipe is fixed in the installation hole, an air intake hole is formed in the rectangular air intake pipe, and an installation box is fixed at one side of the rectangular air intake pipe; the top part of the installation box is welded with the top part of the cavity; an inner wall of one side ofthe air intake hole is provided with an air outlet hole, a plurality of baffle plates are arranged in the air outlet hole in a rotating manner and are all located in the cavity; one side of each baffle plate is provided with a sliding hole; the sliding hole is internally slidingly provided with a positioning shaft; the installation box is provided with an installation cavity; the installation cavity is internally slidingly provided with a sliding plate; one side of the bottom of the sliding plate is fixedly provided with a traction rod. The air intake structure has the advantages of simple structure, high practical performance, easy adjustment of a blowing angle of the air outlet hole, can protect a stepping motor in a buffering manner, reduces dust in the cavity, improves the shot blasting effect and is beneficial for people to use.

Owner:江苏龙发铸造除锈设备有限公司

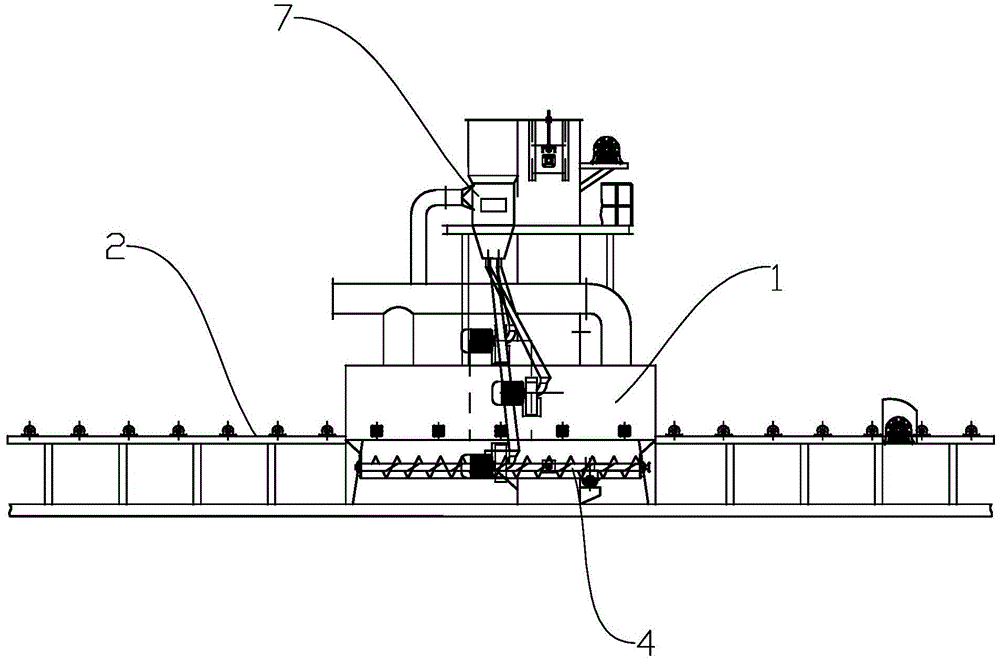

Continuous passing type conveying caterpillar band shot blasting machine

InactiveCN107020576ARealize continuous shot blastingAvoid biting each otherAbrasive machine appurtenancesAbrasive blasting machinesTransport systemMechanical engineering

The invention discloses a continuous-through transmission crawler shot blasting machine, which comprises a shot blasting chamber, a left sealed chamber arranged at the left end of the shot blasting chamber, a right sealed chamber arranged at the right end of the shot blasting chamber, a workpiece conveying system, and a shot circulation The system is characterized in that the workpiece conveying system includes a left roller arranged inside the left sealed chamber, a conveying track arranged inside the shot blasting chamber, and a right roller arranged inside the right sealed chamber, the left roller and the right roller The outer wall cooperates with the two ends of the conveyor belt, and presses the upper end of the conveyor belt into an open arc-shaped cavity. Beneficial effects of the present invention: the structure realizes continuous shot blasting of workpieces, improves work efficiency, and realizes automation; the arc-shaped conveying track provides a large open space, avoids mutual bite damage when workpieces are turned over, and improves The effect of shot blasting.

Owner:ZHUCHENG WANTONG FOUNDRY EQUIP ENG

Stroke sling chain type shot blasting cleaning machine

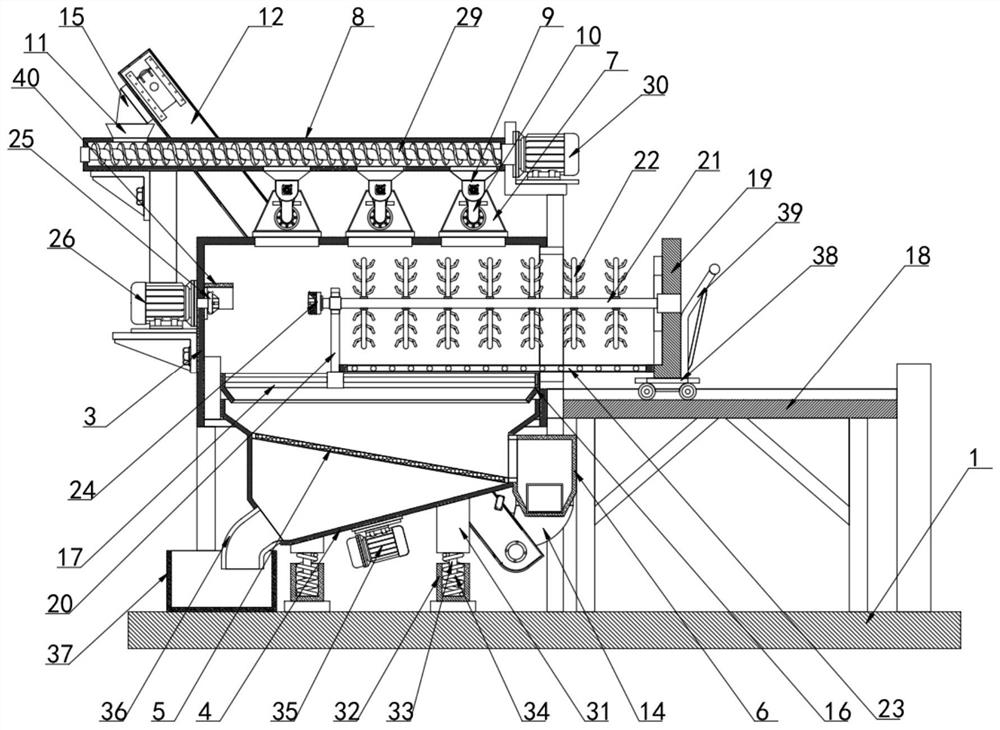

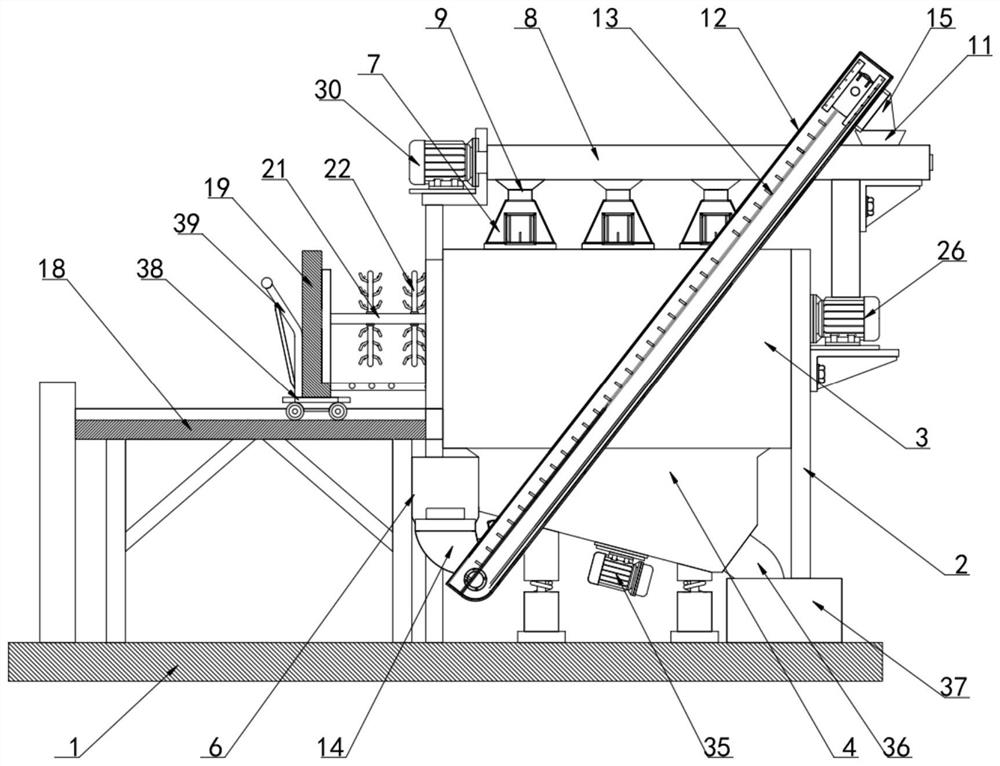

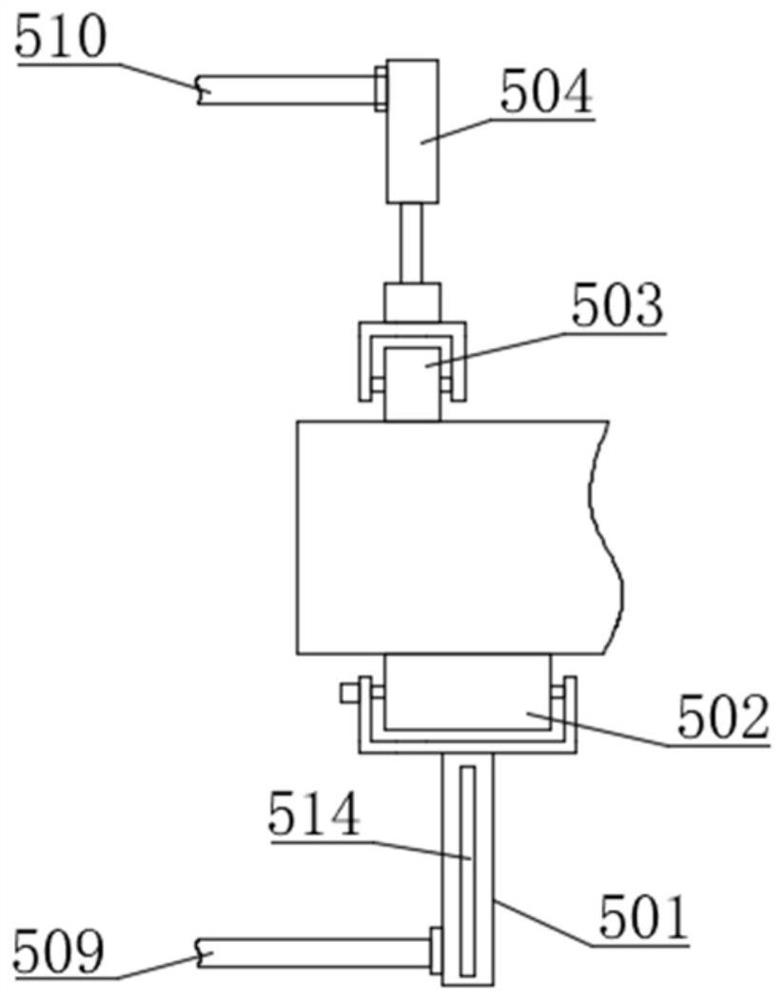

InactiveCN112536728AReduce laborImprove shot blasting speedAbrasive machine appurtenancesAbrasive blasting machinesPhysical medicine and rehabilitationDrive shaft

The invention relates to the technical field of shot blasting cleaning machines, in particular to a stroke sling chain type shot blasting cleaning machine. A plurality of groups of second motors are started, a plurality of groups of lifting hooks are made to drive a plurality of groups of materials to rotate, then a first motor is started, a chain is made to operate through transmission of a plurality of groups of transmission shafts, and the rotating materials are conveyed into a shot blasting machine through a feed port of the shot blasting machine. The materials are subjected to shot blasting through a plurality of groups of shot blasting nozzles in the shot blasting machine, and then the shot-blasted materials are discharged through a discharge port of the shot blasting machine, so that the labor amount of workers is reduced, the shot blasting speed of the equipment is increased, and the shot blasting effect of the equipment is improved. The stroke sling chain type shot blasting machine comprises a base, the shot blasting machine, a plurality of groups of supports, a top plate, a sliding rail, the plurality of groups of transmission shafts, the chain, a plurality of groups of sliding grooves, a plurality of groups of lifting rings, the first motor, the plurality of groups of second motors, a plurality of groups of connecting rods and the plurality of groups of lifting hooks. The bottom end of the shot blasting machine is connected with the top end of the base, a first reserved groove is formed in the top end of the shot blasting machine, and the feed port is formed in the right end of the shot blasting machine.

Owner:诸城市大宇铸造机械有限公司

Shot blasting machine for aluminum alloy castings

ActiveCN112140007ARealize circular operationAvoid affecting work efficiencySievingScreeningStructural engineeringSteel ball

The invention discloses a shot blasting machine for aluminum alloy castings, and specifically relates to the technical field of shot blasting machines. The shot blasting machine comprises a device base, a device body is fixedly arranged at one end of the top of the device base, a shot blasting chamber is fixedly arranged at the top of the device body, a screening recycling bin is fixedly arrangedat the bottom of the shot blasting chamber, a screening mesh plate is fixedly arranged in the middle of the screening recycling bin, the screening mesh plate is arranged in an inclined manner, a recycling hopper is fixedly arranged at the bottom end of the screening mesh plate, a shot blasting device is fixedly arranged at the top of the shot blasting chamber, and a spiral conveying cylinder is fixedly arranged at the top of the shot blasting device. According to the shot blasting machine, recycling and screening are conducted through the screening recycling bin, steel balls or steel shot rolls on the inclined screening mesh plate and falls into the recycling hopper, a conveying belt in a lifting material frame is lifted to the spiral conveying cylinder, the steel balls or steel shot is evenly distributed to the shot blasting device through the spiral conveying cylinder, cyclic operation of the steel balls or steel shot is achieved, the workload is reduced, and the work efficiency is affected.

Owner:江西邦展建筑模板科技有限公司

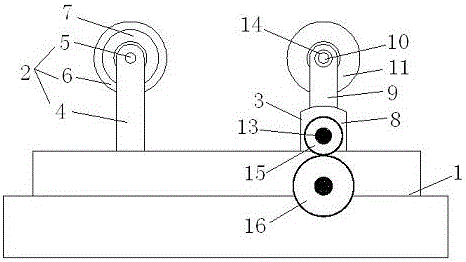

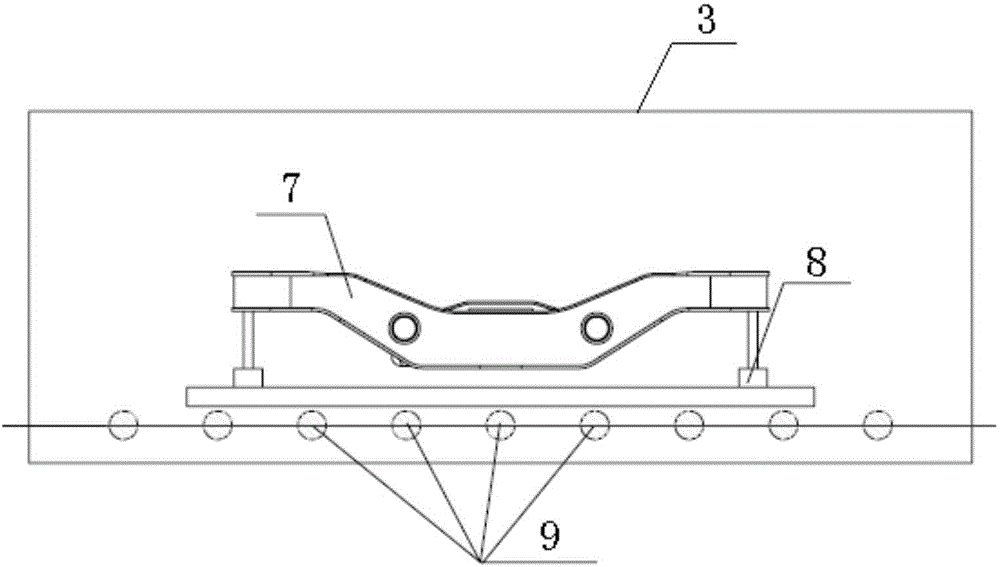

Shot blasting machine used for machining of shell of high-voltage transformer

ActiveCN105856077ASmooth rotationAvoid time-consuming situationsThickenersAdditivesEngineeringNoise reduction

The invention provides a shot blasting machine used for machining of a shell of a high-voltage transformer. A positioning and turning mechanism is arranged on the shot blasting machine. The positioning and turning mechanism comprises a base plate, a driven positioning rod and a driving positioning rod. A first roller and a second roller are arranged on the driven positioning rod and the driving positioning rod correspondingly. The shell of the high-voltage transformer is arranged between the driven positioning rod and the driving positioning rod. The driving positioning rod moves under the action of a gear so that the shell of the high-voltage transformer can be positioned and lifted. The second roller rotates along with the shot blasting operation, the first roller is driven to move, and accordingly the shell of the high-voltage transformer is rotated, so that the situation that time and labor are wasted due to the fact that a shell of a high-voltage transformer needs to be rotated is avoided. In addition, rotation is more stable, the shot blasting effect is improved while shot blasting operation of personnel is facilitated, and accordingly the product quality of the shell of the high-voltage transformer is greatly improved. Meanwhile, the invention discloses novel lubricating grease, the novel lubricating grease is good in lubricating effect, noise reduction effect and rust prevention effect, the kinetic energy loss of the shot blasting machine is reduced, and the rotation stability of the shell is guaranteed.

Owner:SUQIAN GENERAL MACHINERY

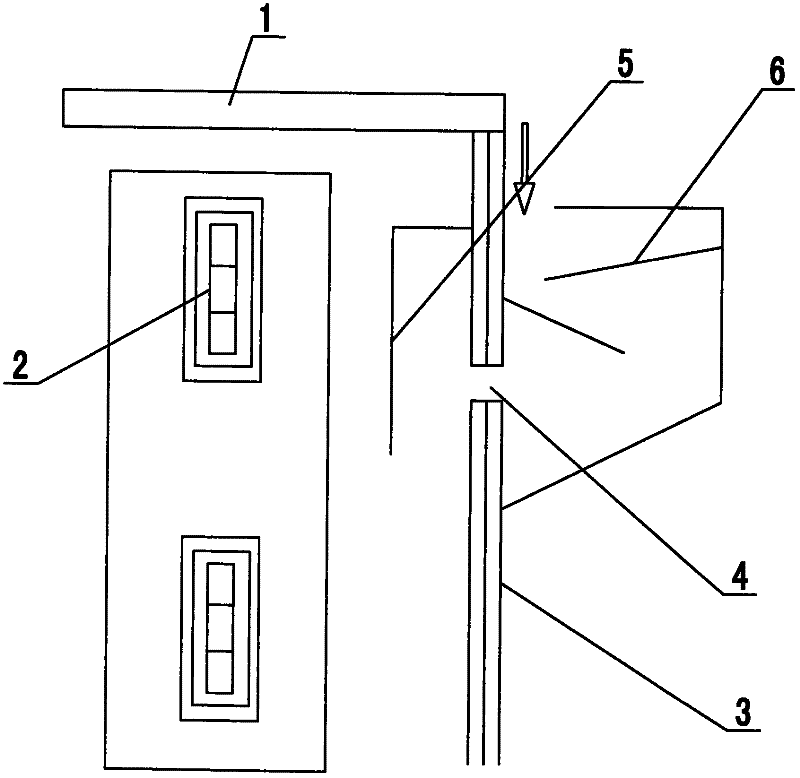

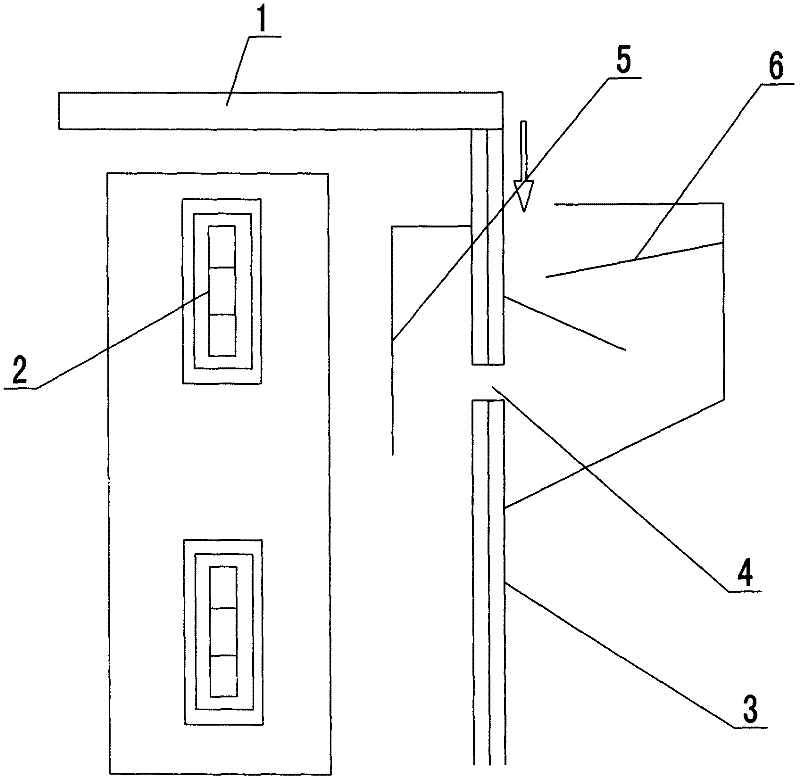

Air inlet structure of door of shot blasting machine

InactiveCN102371551AReduce dustReduce the amount of dustAbrasive machine appurtenancesWorking environmentEngineering

The invention discloses a cleaner air inlet structure of a door of a shot blasting machine, comprising a cleaning room, an impeller head which is arranged in the cleaning room, a door which is arranged on one side of the cleaning room, an air inlet which is arranged on the door, a protection cover which is matched with the air inlet in the cleaning room, and a labyrinth air inlet which is communicated with the air inlet outside the cleaning room. The invention has the advantages that: as the air inlet structure of the door of the shot blasting machine is provided with the air inlet on the door of the shot blasting machine, the amount of dust in the cleaning room is greatly reduced, the dust on workpieces is less, thus the workpieces are cleaner, a shot blasting effect is improved, and a work environment is effectively improved.

Owner:江苏省成越科技有限公司

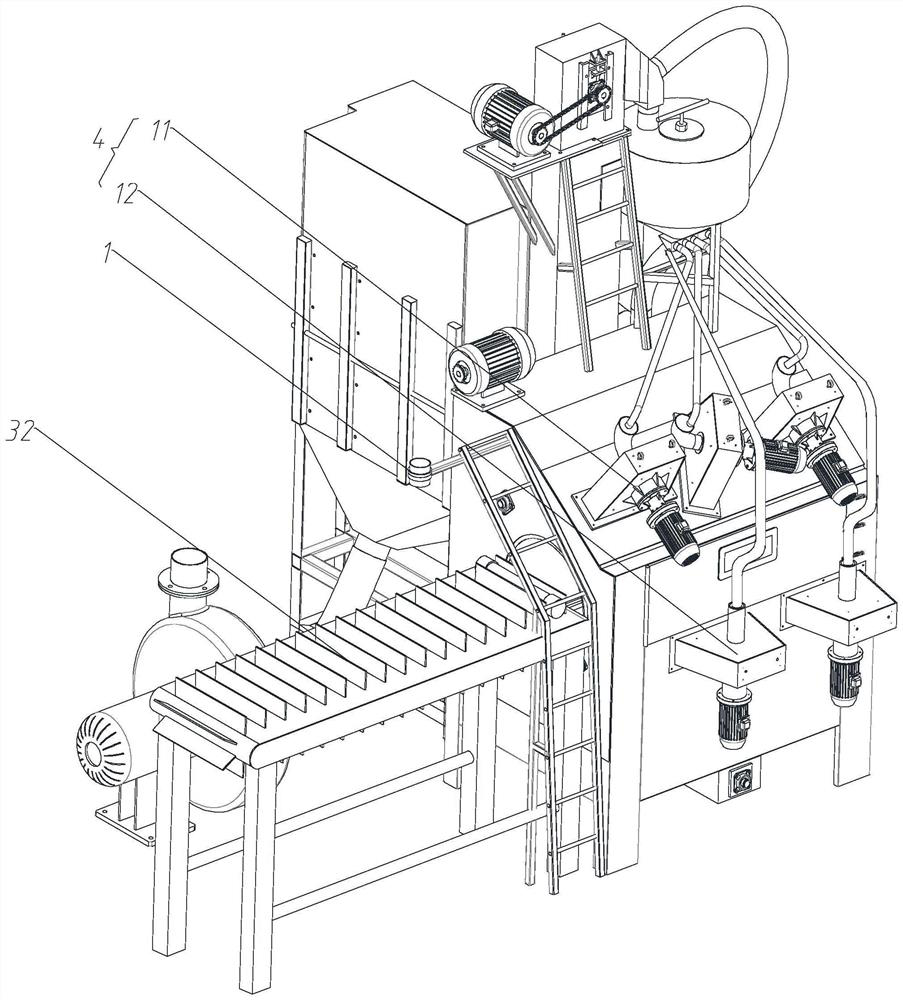

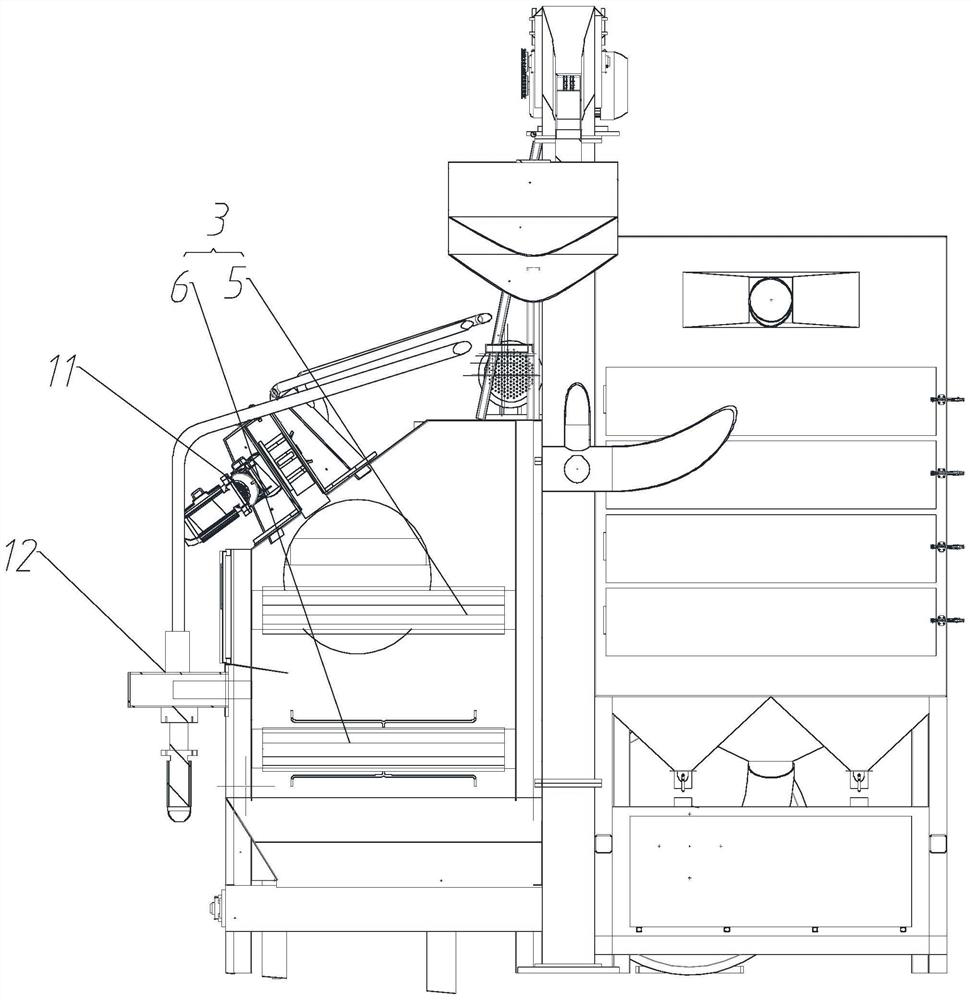

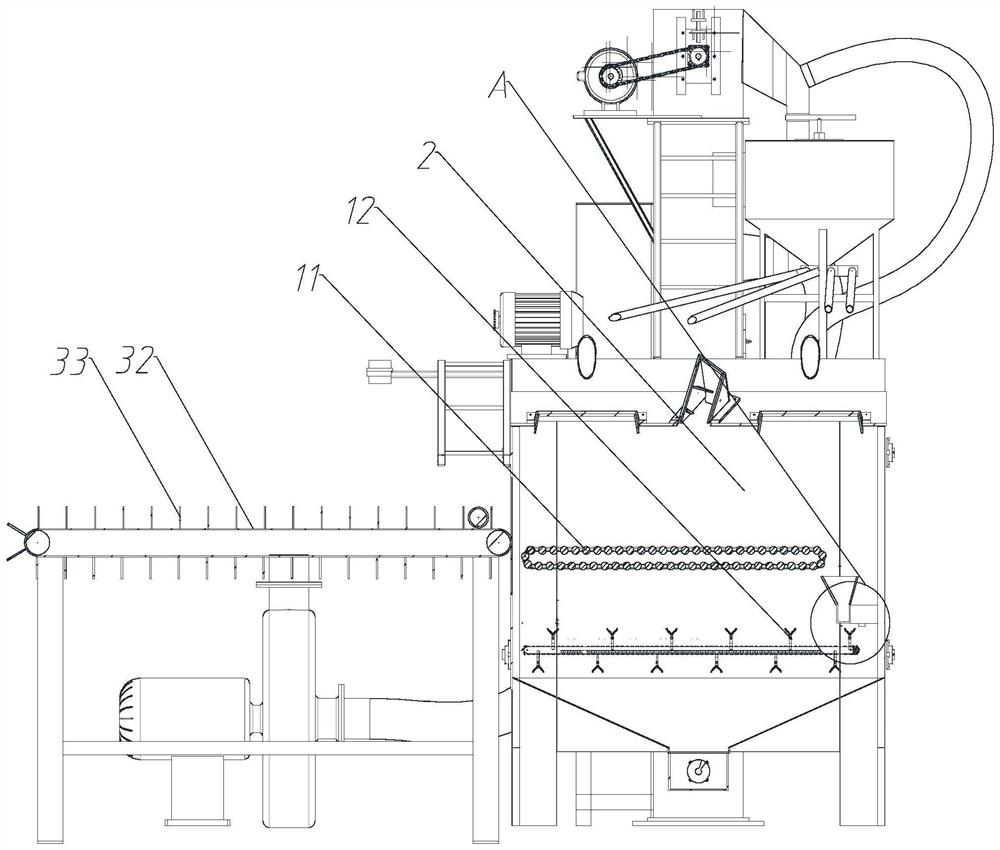

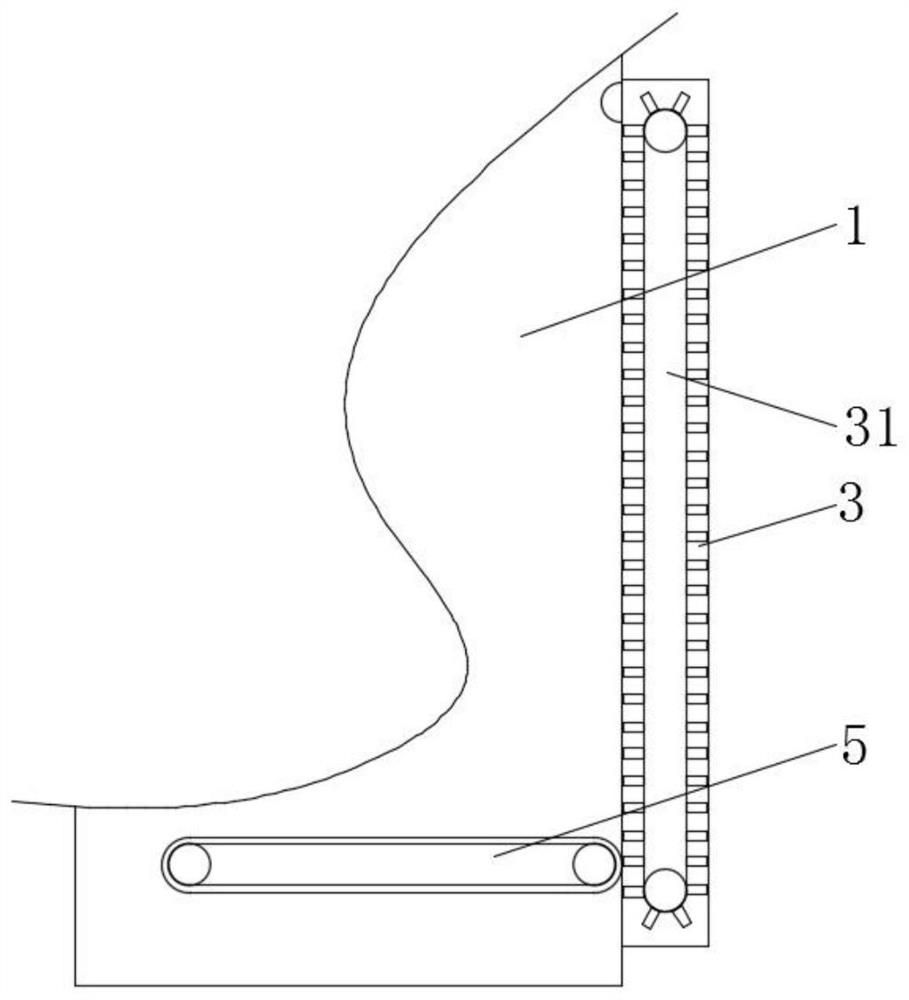

Shot blasting machine special for outer wall of cylinder steel pipe

InactiveCN105598853AReduce maintenance costsImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesSteel tubeEngineering

The invention relates to a shot blasting machine special for the outer wall of a cylinder steel pipe. The shot blasting machine comprises a shot blasting cleaning chamber, a cylinder steel pipe conveying mechanism, shot blasting devices, a steel shot recycling mechanism, a steel shot lifting device and a shot and sand separation device which is connected to the top of the steel shot lifting device; in the shot blasting process, after shots and sand located at the bottom of the shot blasting cleaning chamber pass through the steel shot lifting device and the shot and sand separation device, steel shots return to all shot blasting devices through a steel shot conveying pipeline; the cylinder steel pipe conveying mechanism is a parallel roller conveying mechanism, and a plurality of shot blasting devices are mounted on the inner wall of the shot blasting cleaning chamber in the circumferential direction. A conventional tapered roller conveying mechanism is changed into the parallel roller conveying mechanism, the problem that abrasion occurs between the roller and the cylinder steel pipe is solved, so that frequent maintenance is not required, the maintenance cost is reduced, at the same time, the plurality of shot blasting devices are mounted on the inner wall of the shot blasting cleaning chamber in the circumferential direction, so that full processing of the cylinder steel pipe is guaranteed, that is the maintenance cost of the roller conveying device is reduced while the shot blasting effect is improved.

Owner:DAFENGYIBAIJIA IND & TRADE CO LTD

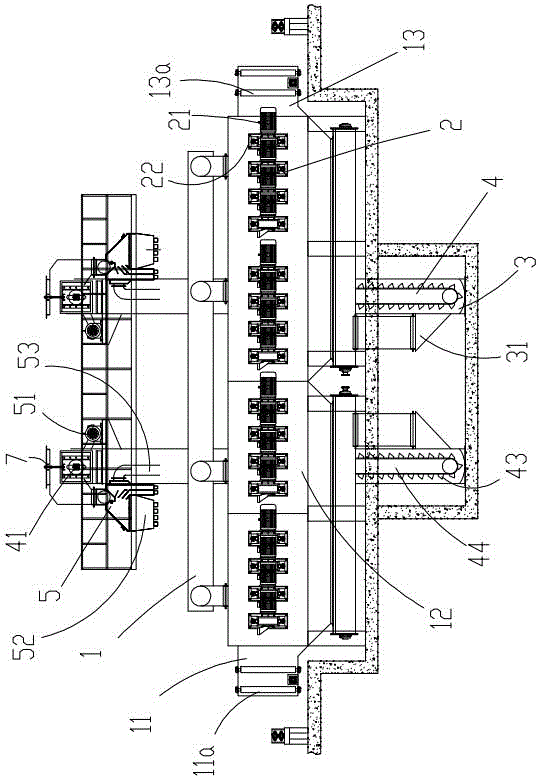

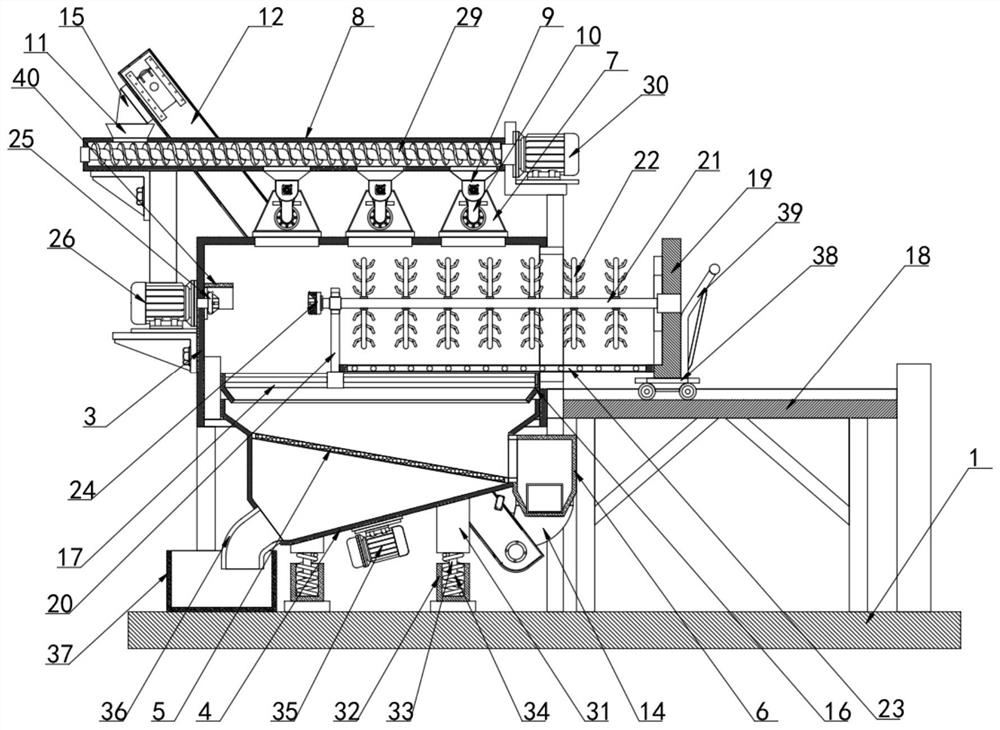

Strip steel shot blasting system

InactiveCN104369112AImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesSlagEngineering

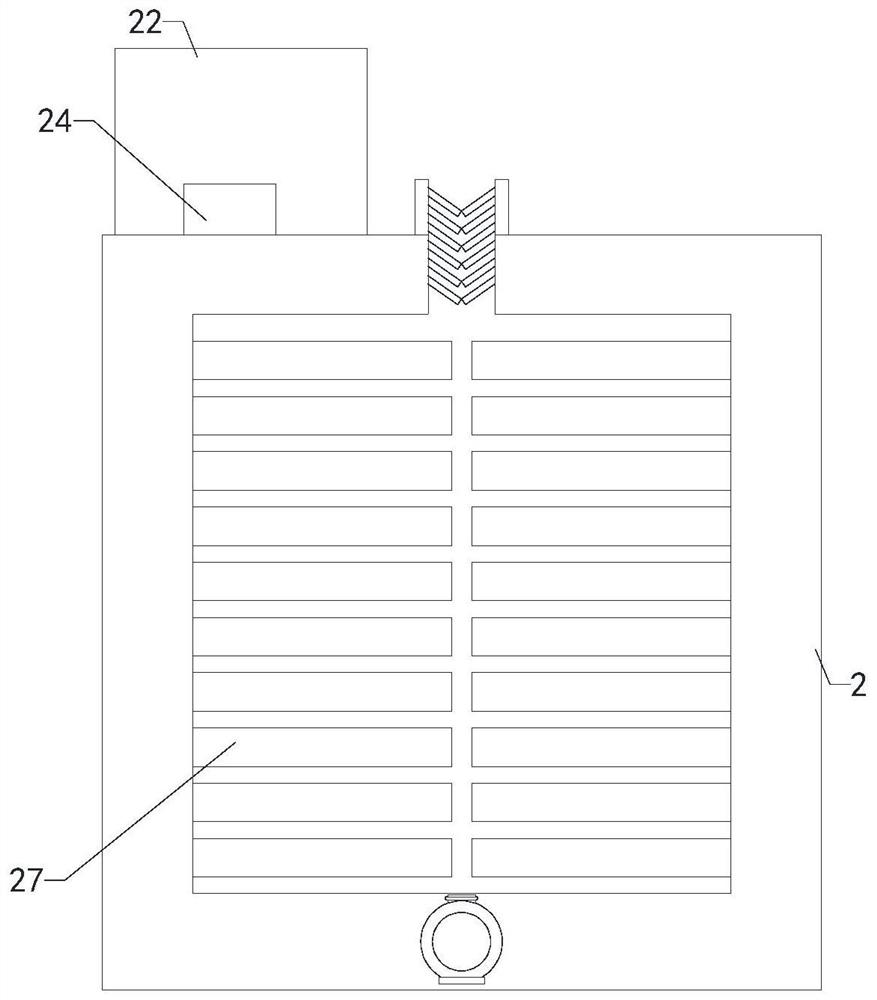

The invention discloses a strip steel shot blasting system. A shot blasting chamber is internally provided with shot blaster groups comprising shot blasters; the lower part of the shot blasting chamber is communicated with shot accommodating grooves which are internally provided with bucket type elevators; each bucket type elevator comprises an upper drive belt wheel and a lower drive belt wheel which are sleeved by a belt which is provided with a hopper; each lower drive belt wheel is arranged in the corresponding shot accommodating groove; each upper drive belt wheel is arranged above the shot blasting chamber, and is matched with a separator which is provided with a separation fan, a filtering screen, a waste material opening and a shot blanking opening; the separation fans are used for blowing a shot dust mixture conveyed from the hoppers to the filtering screens, and shots are blocked by the filtering screens and then fall off into the shot blanking openings; disintegrated shot slag and iron scraps pass through the filtering screens to fall off into the waste material openings to be discharged out; the shot blanking openings and the shot blasters are connected with each other. The strip steel shot blasting system has the advantages of capability of multiple orientations and shot blasting for multiple times, good shot blasting effect and capability of tensioning the belts.

Owner:WUXI XINJIAYUAN METALLURGY MACHINERY MFG

Shot blasting process for crankshaft

InactiveCN108486339AHigh strengthInfluence intensityProcess efficiency improvementSurface conditionsEngineering

The invention discloses a shot blasting process for a crankshaft. The process is characterized by comprising the following steps: the crankshaft is placed into a cleaning solution added with anti-rustoil for cleaning and dried; the dried crankshaft is placed on a lathe, wherein a 6140 common lathe is preferably adopted, two ends of the crankshaft are separately located into a three-jaw chuck andon a tip of a tailstock, and a motor is started and a lathe spindle rotates at the speed of 1.5-2.5 r / s; during grinding, corresponding grinding time is selected according to the surface condition ofeach part of the crankshaft to ensure sufficient grinding; the ground crankshaft is suspended on a rotating suspending device and in a central axis of a shot blasting bin, after a shot blasting bin door is closed, the suspending device rotates at the rotating speed of 5.2 rpm, a plurality of injecting holes are formed in the periphery side wall, far away from the center of the shot blasting bin for 0.8m, and steel shots with the diameter of 0.75mm are injected into the surface of the crankshaft from the injecting holes at the shot blasting amount of 300 kg / min. The process can greatly improvethe strength and reliability of the crankshaft, thus obtaining an excellent shot blasting effect.

Owner:王华银

Crawler-type shot blasting machine capable of automatically feeding and shot blasting method

PendingCN114274054APrevent splashAchieve rotationAbrasive machine appurtenancesAbrasive blasting machinesGear wheelIndustrial engineering

The invention relates to the technical field of shot blasting, and provides a crawler-type shot blasting machine capable of automatically feeding and a shot blasting method.The crawler-type shot blasting machine capable of automatically feeding comprises a rack, a crawler belt and a shot blasting device, the shot blasting device is arranged on the rack, the crawler belt comprises a first belt, the first belt comprises a supporting plate and a driving roller, the supporting plate is arranged on the rack, and the supporting plate is provided with a plurality of teeth; the driving rollers are rotationally arranged between the two supporting plates, gears and cog belts are arranged at the two ends of each driving roller, and the cog belts connect the multiple driving rollers and are engaged with the multiple driving rollers. According to the technical scheme, the problems that in the prior art, when a crawler-type shot blasting machine treats some long-strip-shaped parts, due to the transmission property of a crawler belt, a plurality of parts are stacked together, and some parts are always in a state of being surrounded by the plurality of parts when the parts are turned over, so that the parts are damaged are solved. And shots thrown by the shot blasting machine cannot touch the surrounded parts, so that the problems that some parts are poor in shot blasting effect and need to be secondarily processed occur.

Owner:唐山腾龙重型机械设备制造有限公司

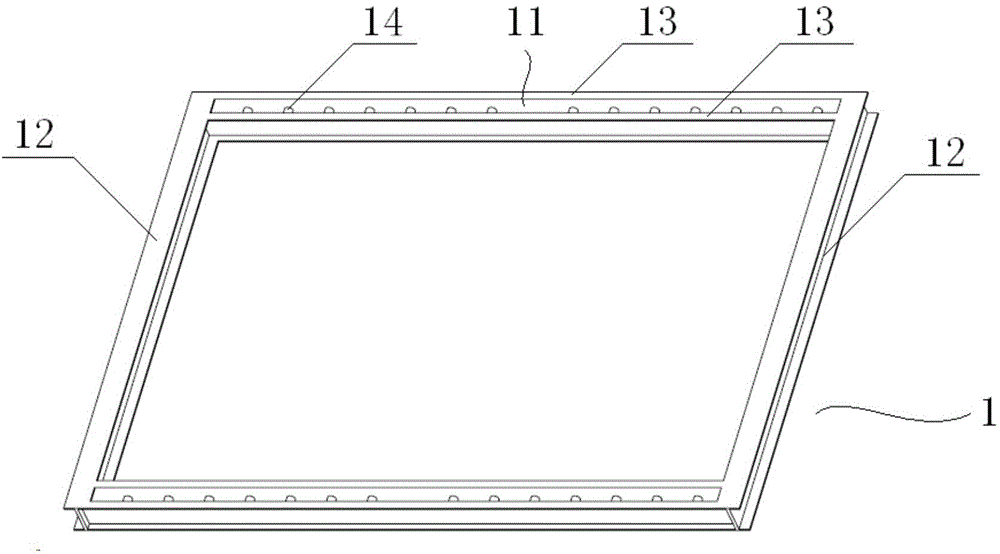

Hanging bracket for shot blasting and shot blasting method

ActiveCN104476415AGuaranteed shot blasting effectWill not consumeAbrasive machine appurtenancesAbrasive blasting machinesBogieCost savings

The invention provides a hanging bracket for shot blasting and a shot blasting method. The hanging bracket for shot blasting comprises a main frame and a connecting part, wherein the main frame is a rectangular frame formed by two opposite side beams and two opposite end beams, each side beam is provided with two opposite vertical plates, a plurality of connecting rods are arranged between every two vertical plates at intervals, and two ends of each connecting rod are fixed on every two vertical plates respectively; the connecting part is provided with a cross beam, two vertical beams are vertically arranged at the bottom of the cross beam, a first limiting part is arranged at the top of the cross beam, bottoms of the two vertical beams are fixed at tops of the two end beams respectively. When the hanging bracket for shot blasting performs shot blasting on bogie frames, problems of insufficient shot blasting, shot blasting dead corners and the like on frame surfaces can be solved, and the shot blasting effect is good; besides, the hanging bracket is long in service life, and cost saving is facilitated.

Owner:CRRC TANGSHAN CO LTD

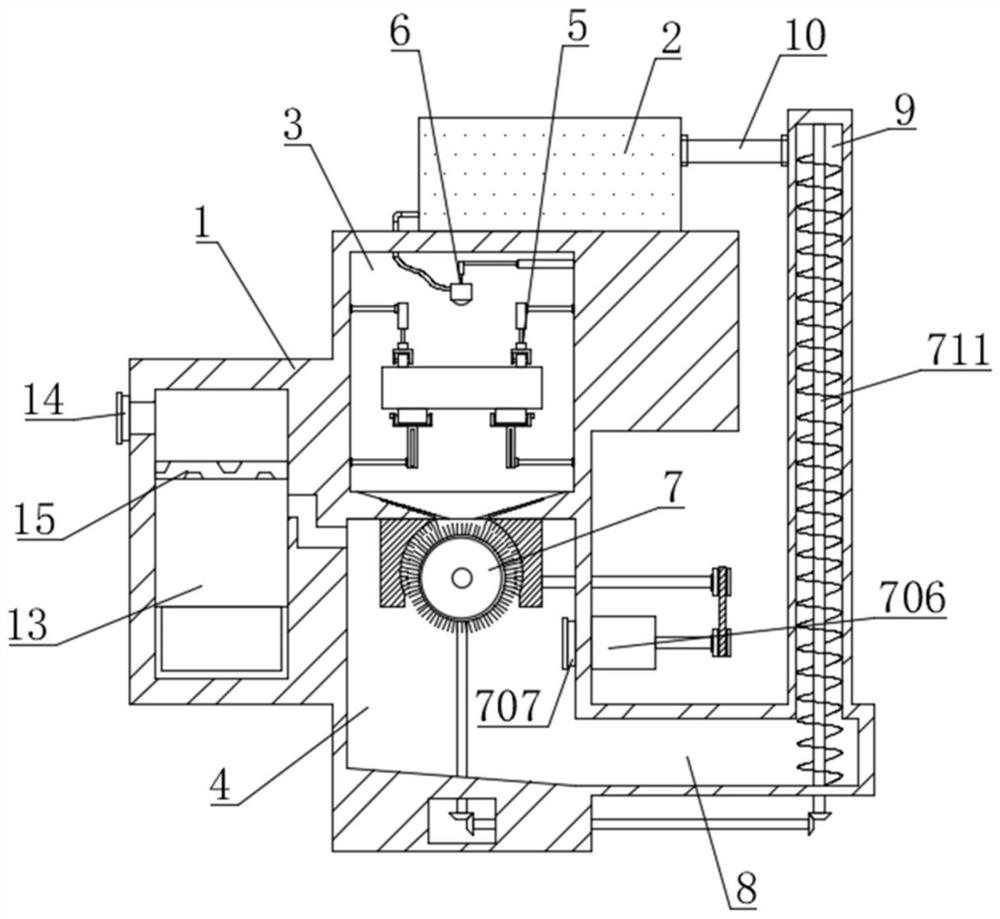

Finished product shot blasting machine for metal heat treatment

PendingCN112775849AShot blasting thoroughlyImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesSlide plateIndustrial engineering

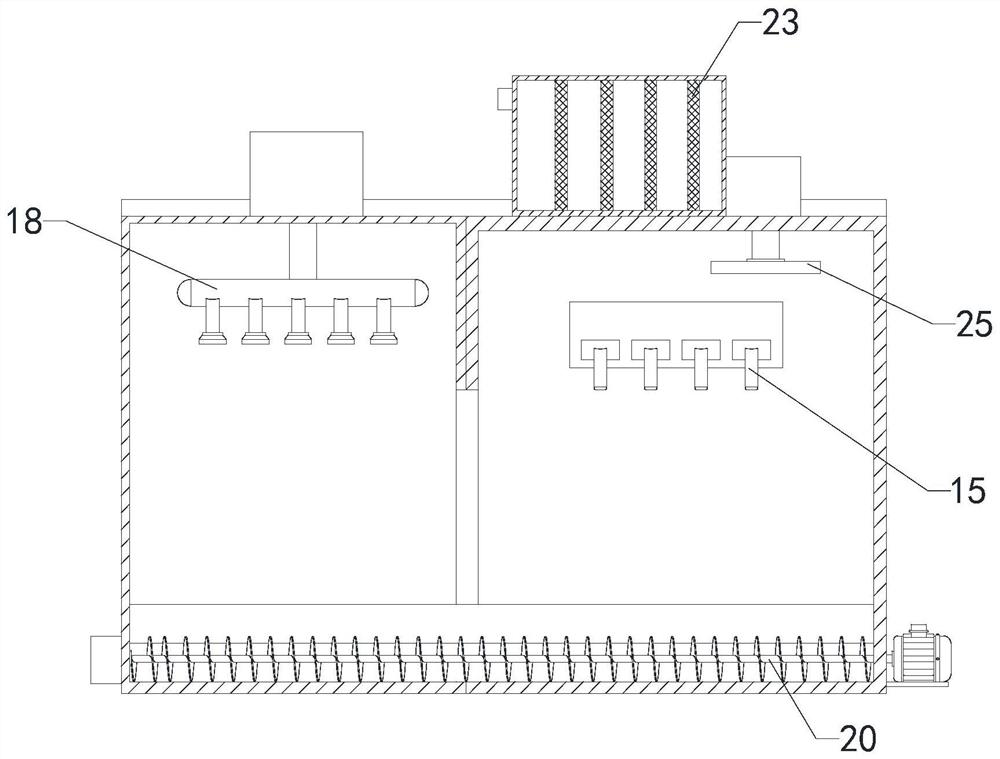

The invention relates to the technical field of shot blasting machines, in particular to a finished product shot blasting machine for metal heat treatment. The finished product shot blasting machine comprises a lower bottom seat, an upper top seat and an impeller head. The lower bottom seat and the upper top seat are integrally arranged, a side seat is welded to the side walls of the lower bottom seat and the upper top seat, and an elevator is mounted in the side seat. A feeding pipe is arranged on the lower bottom seat, partition plates are welded to the two sides of the interior of the lower bottom seat, and a conveying crawler belt is arranged between the partition plates on the two sides. A sliding plate is welded to the inner wall of one side of the lower bottom seat, sieve holes are formed in the sliding plate, and one end of the sliding plate is connected with the tail end of the conveying crawler belt end to end. A conveying belt is installed at the position, close to the bottom, in the lower bottom seat and is located below the sliding plate, and a baffle is movably arranged above the tail end of the conveying crawler belt through an electric push rod. The impeller head is installed between the lower bottom seat and the upper top seat and located above the conveying crawler belt, and a shot channel is connected between the side seat and the impeller head. According to the finished product shot blasting machine, the shot blasting effect can be improved, so that workpieces can be treated more thoroughly; and dust and debris in the machine can be conveniently removed.

Owner:厦门澄志精密科技有限公司

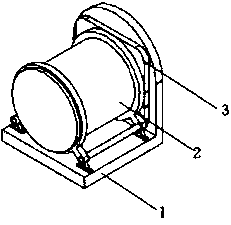

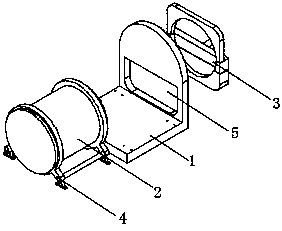

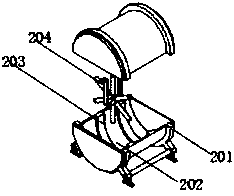

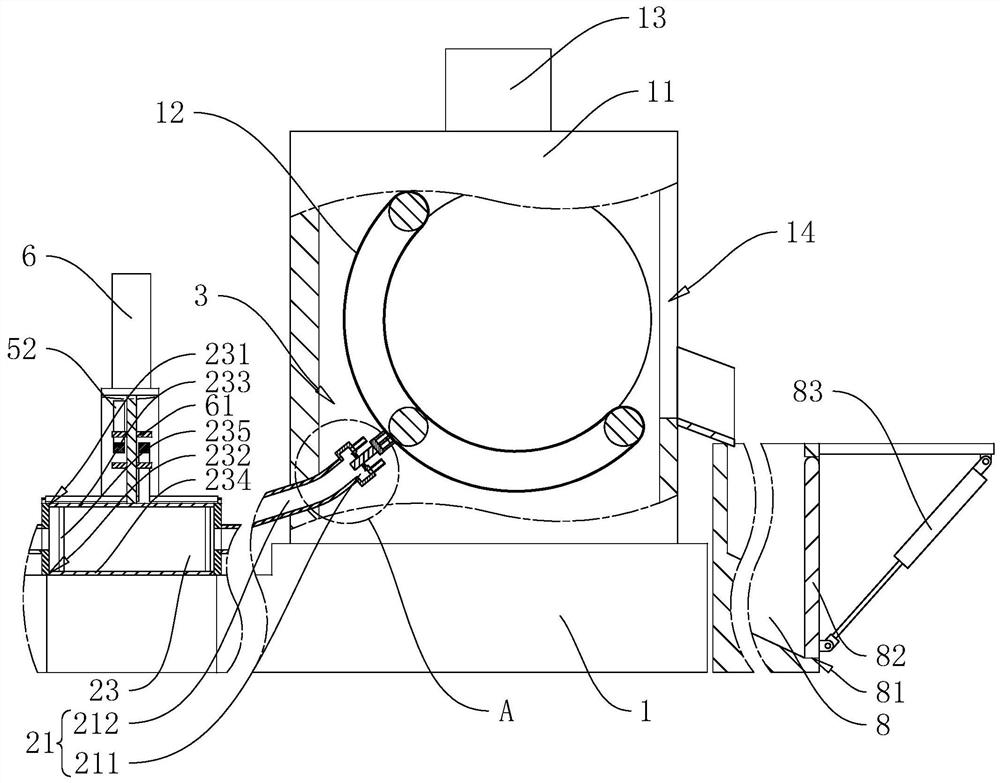

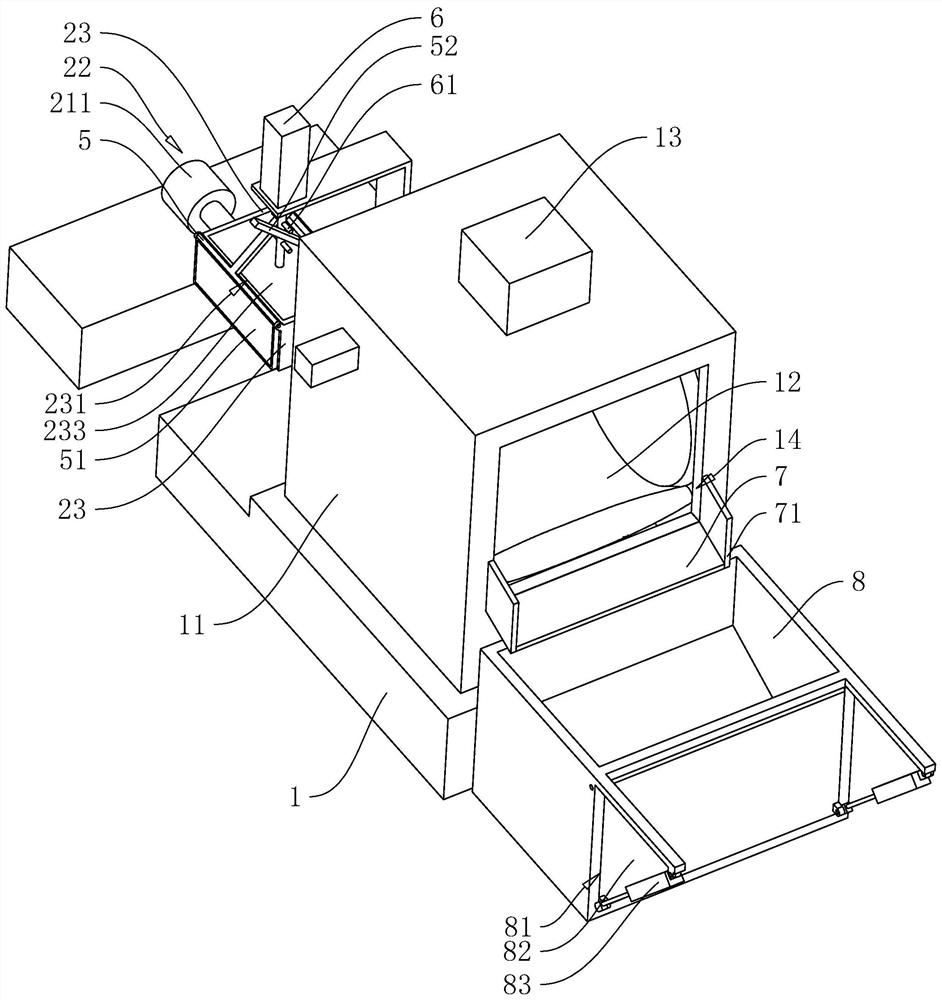

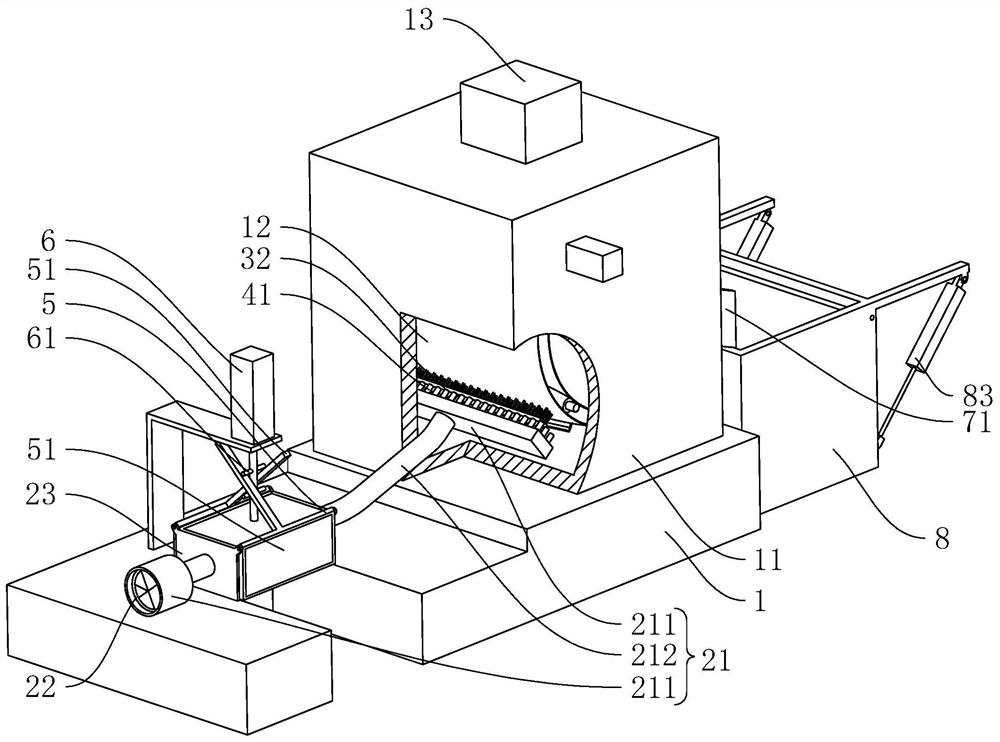

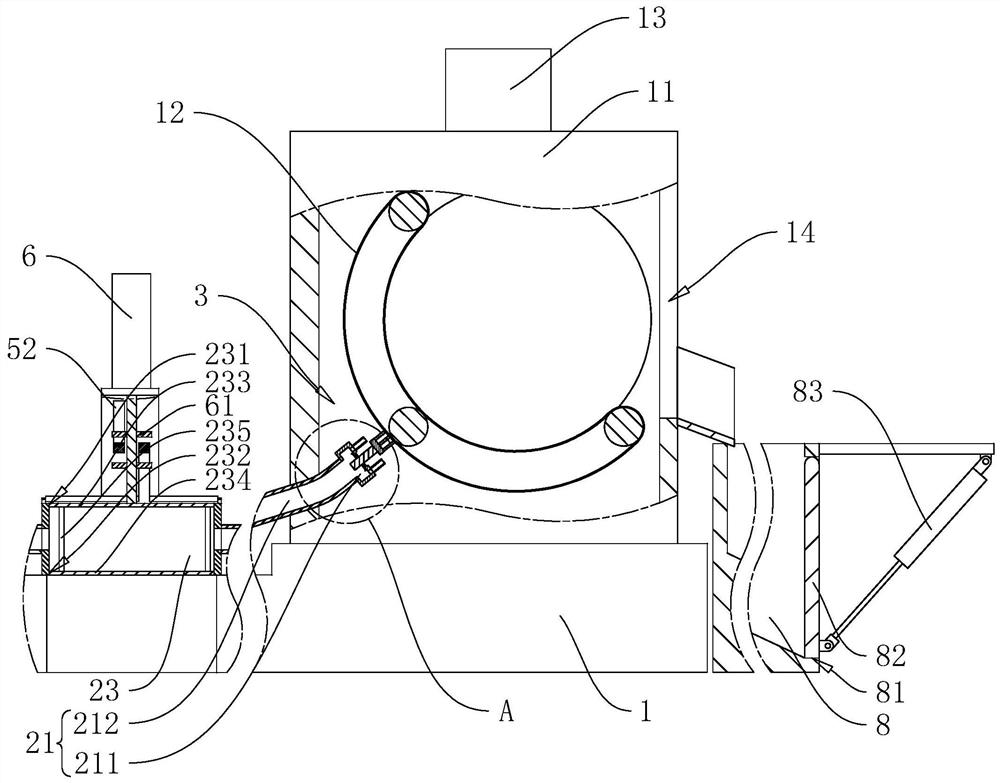

Automobile brake pad drum-type shot blasting treatment machine

PendingCN110605651AIncrease flipping frequencyGood for shot blastingEdge grinding machinesPolishing machinesBrake padDust collector

The invention discloses an automobile brake pad drum-type shot blasting treatment machine which comprises a supporting base. A through groove is formed in the lower portion of the other side of the supporting base, and a collecting dust arresting structure is arranged in the through groove. The collecting dust arresting structure is composed of a collecting box, a through hole, a dust arresting connecting pipe, a discharging pipe, a collecting bin and a filter screen, and the through hole is formed in one end of the collecting box. According to the automobile brake pad drum-type shot blastingtreatment machine, a stirring piece can rotate along with rotation of a shot blasting bin, an automobile brake pad can be turned over after impacting a stirring rod, the turn-over frequency of the automobile brake pad is increased, the contact frequency of the automobile brake pad and shot blasting materials is also increased and the shot blasting effect is better. A screw panel can further increase the turn-over frequency of the automobile brake pad, and shot blasting treatment of the automobile brake pad can be facilitated. The collecting bin communicates with the shot blasting bin, and theshot blasting materials and scraps can be collected conveniently. Due to the fact that the filter screen and the dust arresting connecting pipe are connected with a dust collector, the scraps and theshot blasting materials can be separated, and the shot blasting materials can be recycled conveniently.

Owner:长兴广辰汽车配件制造有限公司

Strip steel shot blaster

InactiveCN104369111AEasy to cleanImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesSheet steelWear resistant

The invention discloses a strip steel shot blaster. The strip steel shot blaster comprises a machine base, wherein the machine base is provided with a strip steel inlet, a shot blasting chamber and a strip steel outlet which are connected with one another sequentially; a front auxiliary chamber and a rear auxiliary chamber which are used for preventing steel shots from being splashed are arranged between the strip steel inlet and the shot blasting chamber; the bottom of the shot blasting chamber is provided with steel shot accommodating grooves connected with elevators; each elevator is connected with the outside; the shot blasting chamber is internally provided with a plurality of shot blaster groups which are ranked along the strip steel proceeding direction; each shot blaster group comprises two shot blasters, the shot blasters in a same pass are symmetrically arranged at two sides of strip steel, and each shot blaster is connected with a shot charge channel; steel shots blasted by the shot blasters are blasted dispersively, the upper end of a dispersive track is tangential to the upper end of the strip steel, and the lower end of the dispersive track is tangential to the lower end of the strip steel; the shot blasting chamber is of a double-layer structure, the inner layer is a chrome cast iron wear-resistant plate, and the outer layer is a steel plate. The strip steel shot blaster has the advantages of capability of multiple orientations and shot blasting for multiple times and good shot blasting effect.

Owner:WUXI XINJIAYUAN METALLURGY MACHINERY MFG

A crawler shot blasting machine

ActiveCN113664729BIncrease frictionImprove Flip EffectCleaningAbrasive machine appurtenancesBlast effectsClassical mechanics

The application relates to a crawler shot blasting machine, which includes a frame, on which a shot blasting chamber is installed, a curved conveyor belt is arranged in the shot blasting chamber, a shot blasting device is arranged on the top wall of the shot blasting chamber, and the The discharge end is connected with the inner cavity of the shot blasting chamber, and the side wall of the shot blasting chamber at one end of the conveyor belt is provided with a feed inlet, and the frame is equipped with a dust removal mechanism and a dust suction mechanism. The belt surface is cleaned, and the dust suction mechanism is used to absorb and discharge the iron filings falling from the conveyor belt. The application has the advantages of removing dust from the conveyor belt through the dust removal mechanism while the conveyor belt is working, sucking and discharging iron filings through the dust suction mechanism, reducing the content of iron filings on the belt surface of the conveyor belt, increasing the friction between the workpiece and the conveyor belt, and improving The flipping effect of the conveyor belt on the workpiece is improved, which in turn makes the shot blasting of the workpiece more comprehensive and improves the effect of the shot blasting effect on the workpiece.

Owner:浙江孚菱机械有限公司

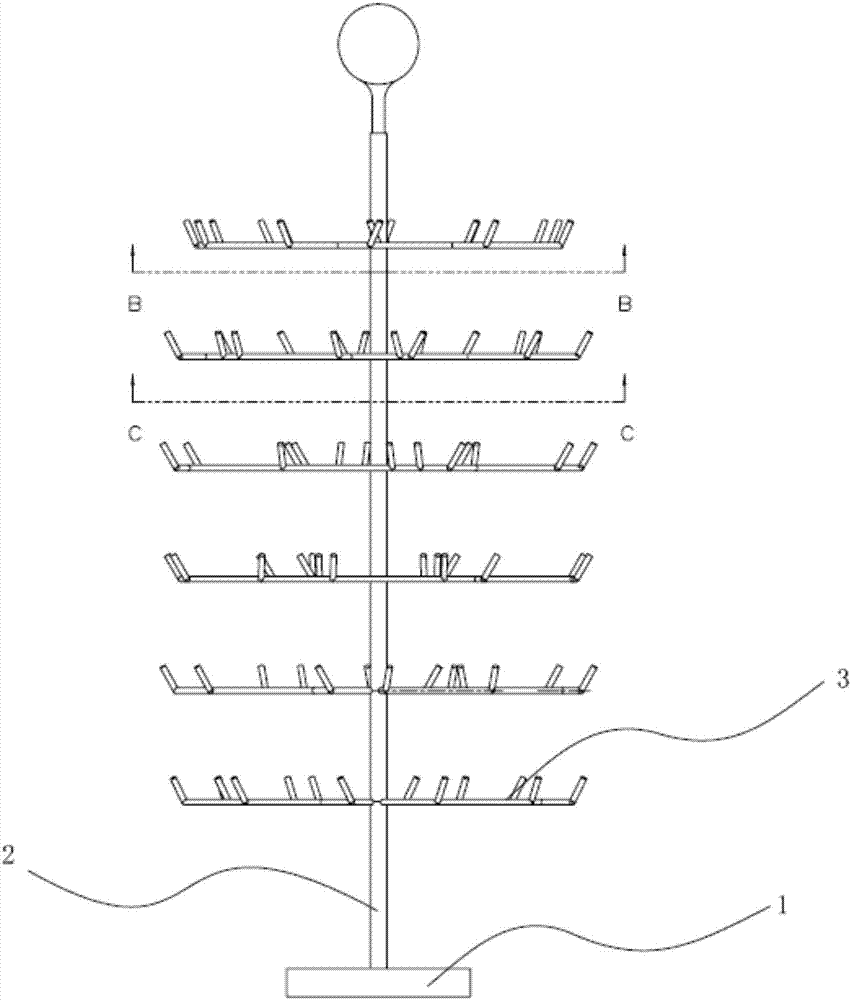

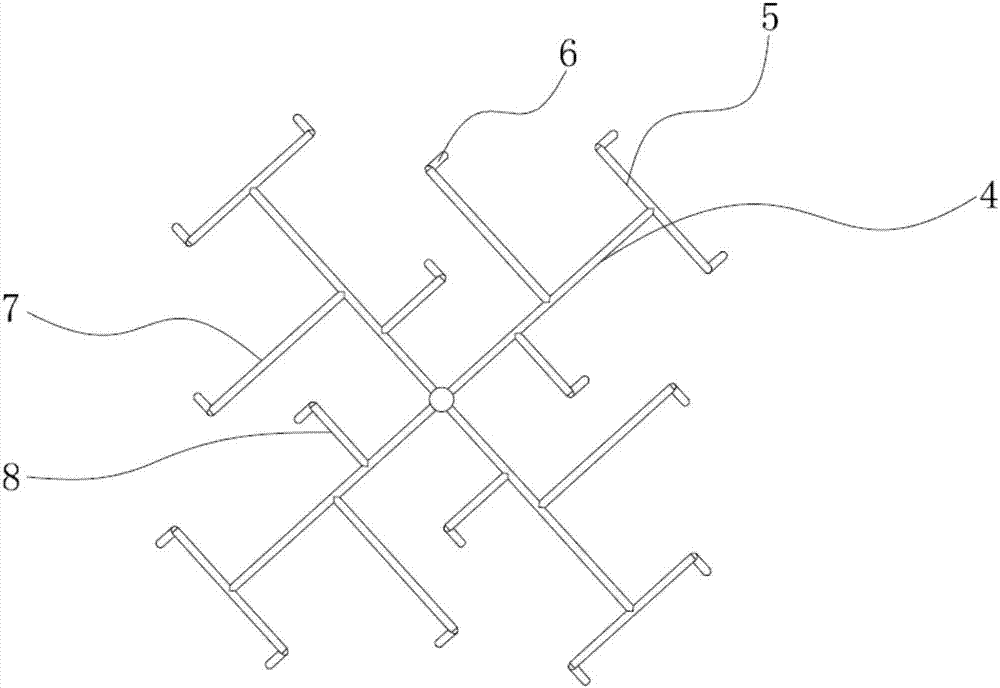

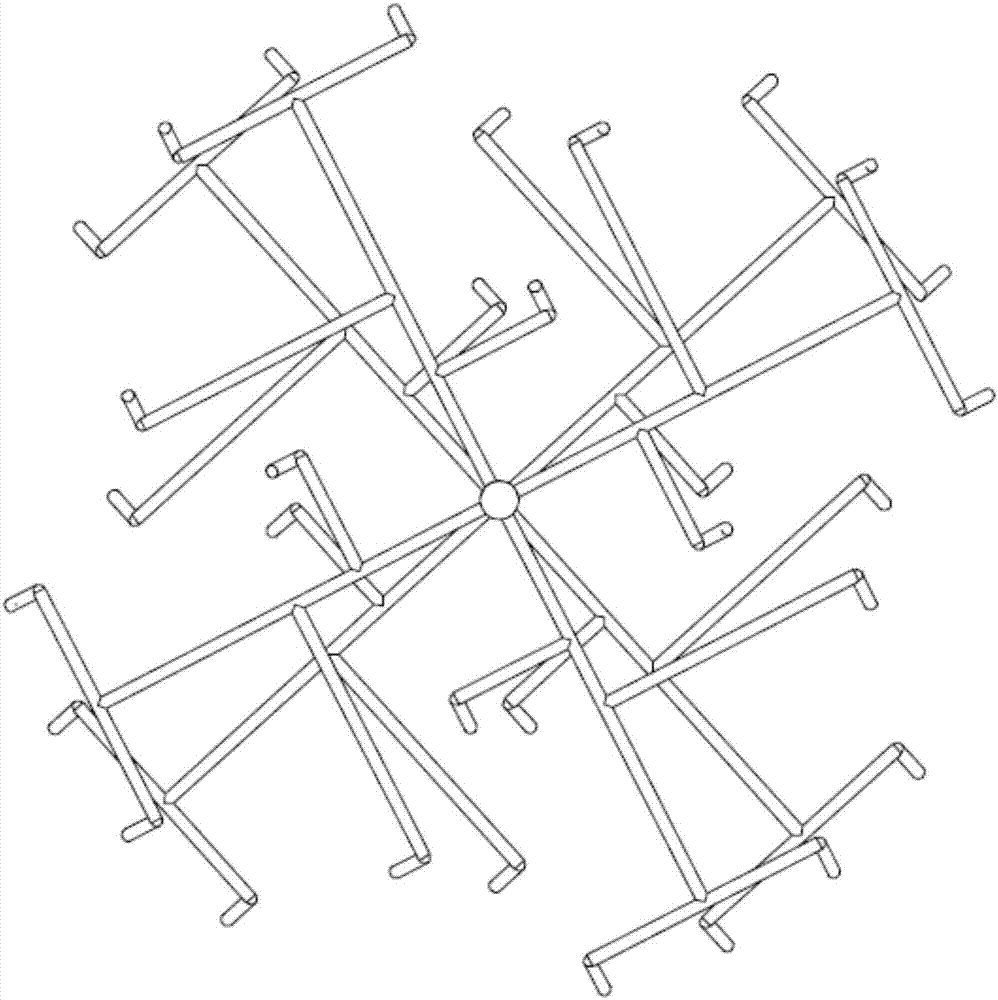

Shielding-free hanging basket used for pressure casting shot blasting technology

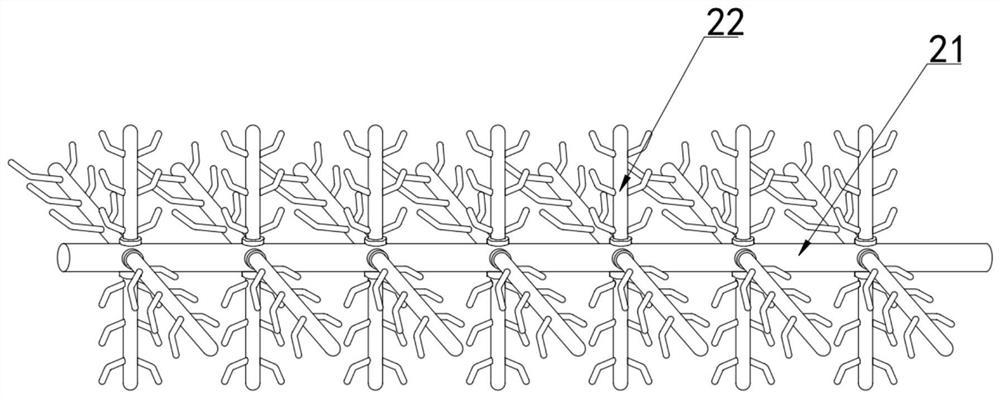

InactiveCN107363734AIngenious and reasonable structureIncrease productivityAbrasive machine appurtenancesVertical projectionPressure casting

The invention relates to a shielding-free hanging basket used for a pressure casting shot blasting technology. The shielding-free hanging basket comprises a base and a stand column. The stand column is vertically installed at the upper end of the base. Multiple layers of hanging assemblies are vertically arranged on the stand column in the axial direction. Each hanging assembly comprises multiple main supporting rods which are evenly arranged around the side wall of the stand column and stretch out in the radial direction. The end portions of the main supporting rods are connected with the middle portions of end portion supporting rods which are horizontally arranged and are perpendicular to the main supporting rods. Long supporting rods horizontally stretch out from the middle portions of one sides of the main supporting rods, and short supporting rods staggered with the long supporting rods horizontally stretch out from the other sides of the main supporting rods. Product supporting rods are perpendicular to the end portions of the long supporting rods, the end portions of the short supporting rods and the end portiosn of the end portion supporting rods. The product supporting rods incline towards the axial outer sides of the corresponding main supporting rods, and the vertical projections of the hanging assemblies are not overlapped. The shielding-free hanging basket and reasonable and ingenious in structure, the space utilization rate can be effectively increased, the product shot blasting effect is also obviously improved, the production efficiency is improved, and the cost is reduced.

Owner:NINGBO ZUNHANG AUTO PARTS

Crawler-type shot blasting machine

ActiveCN113664729AIncrease frictionImprove Flip EffectCleaningAbrasive machine appurtenancesBlast effectsDust control

The invention relates to a crawler-type shot blasting machine which comprises a rack. A shot blasting chamber is installed on the rack, a bent conveying belt is arranged in the shot blasting chamber, a shot blasting device is arranged on the top wall of the shot blasting chamber, the discharging end of the shot blasting device communicates with an inner cavity of the shot blasting chamber, and a feeding port is formed in the side wall, located at one end of the conveying belt, of the shot blasting chamber; and the rack is provided with a dust removal mechanism and a dust suction mechanism, the dust removal mechanism is used for cleaning the belt face, away from the feeding port, of the conveying belt, and the dust suction mechanism is used for sucking and discharging scrap iron falling from the conveying belt. The crawler-type shot blasting machine has the beneficial effects that the conveying belt is subjected to dust removal through the dust removal mechanism while working, the scrap iron is sucked away and discharged through the dust suction mechanism, the content of the scrap iron on the belt surface of the conveying belt is reduced, the friction force between a workpiece and the conveying belt is increased, the overturning effect of the conveying belt on the workpiece is improved, the shot blasting of the shot blasting device on the workpiece is more comprehensive, and the shot blasting effect of the workpiece is improved.

Owner:浙江孚菱机械有限公司

A shot blasting machine for aluminum alloy castings

ActiveCN112140007BRealize circular operationAvoid affecting work efficiencySievingScreeningStructural engineeringSteel ball

The invention discloses a shot blasting machine for aluminum alloy castings, specifically relates to the technical field of shot blasting machines, comprising a device base, a device body is fixedly arranged at one end of the top of the device base, and a device body is fixedly arranged on the top of the device body The shot blasting chamber, the bottom of the shot blasting chamber is fixed with a screening recovery bin, the middle part of the screening recovery bin is fixed with a screening screen, the screening screen is inclined, and the bottom of the screening screen is fixed with a The recovery hopper, the top of the shot blasting chamber is fixed with a shot blaster, and the top of the shot blaster is fixed with a screw feeding tube. In the present invention, recycling and screening are carried out through the screening recovery bin. Steel balls or steel sand roll on the inclined screening screen and fall into the recycling hopper. To the shot blasting machine, the circular operation of steel balls or steel sand is realized, which reduces the workload and affects work efficiency.

Owner:江西邦展建筑模板科技有限公司

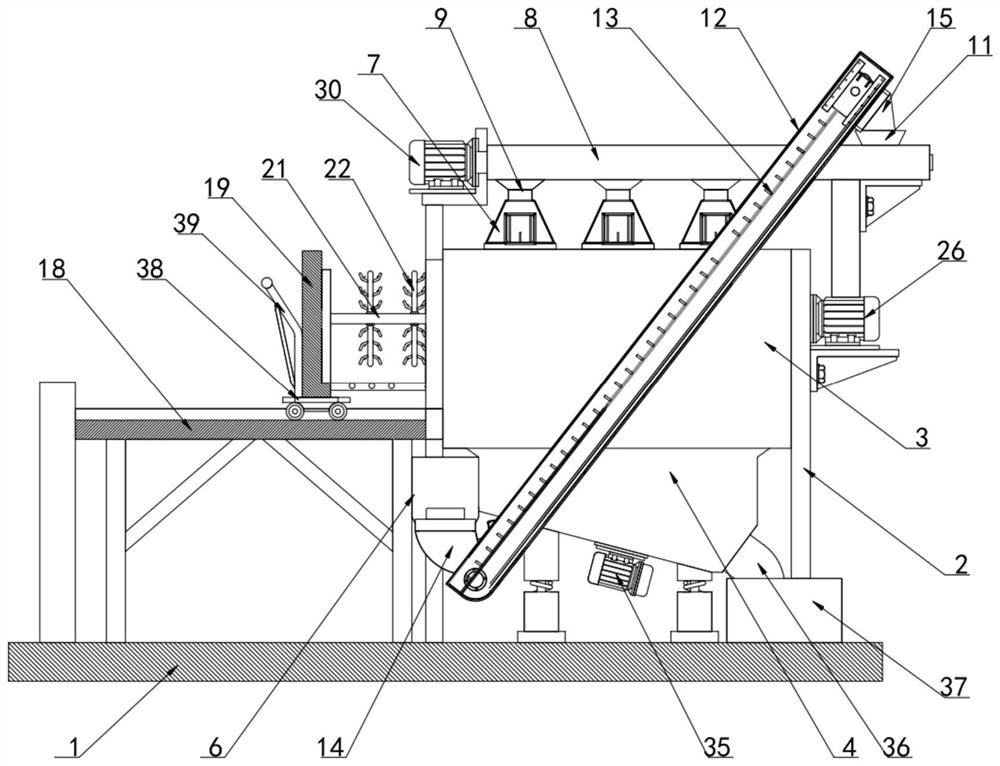

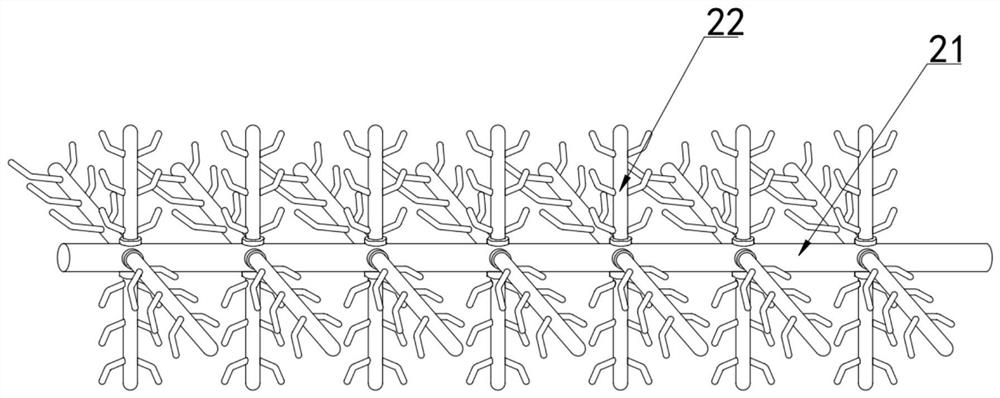

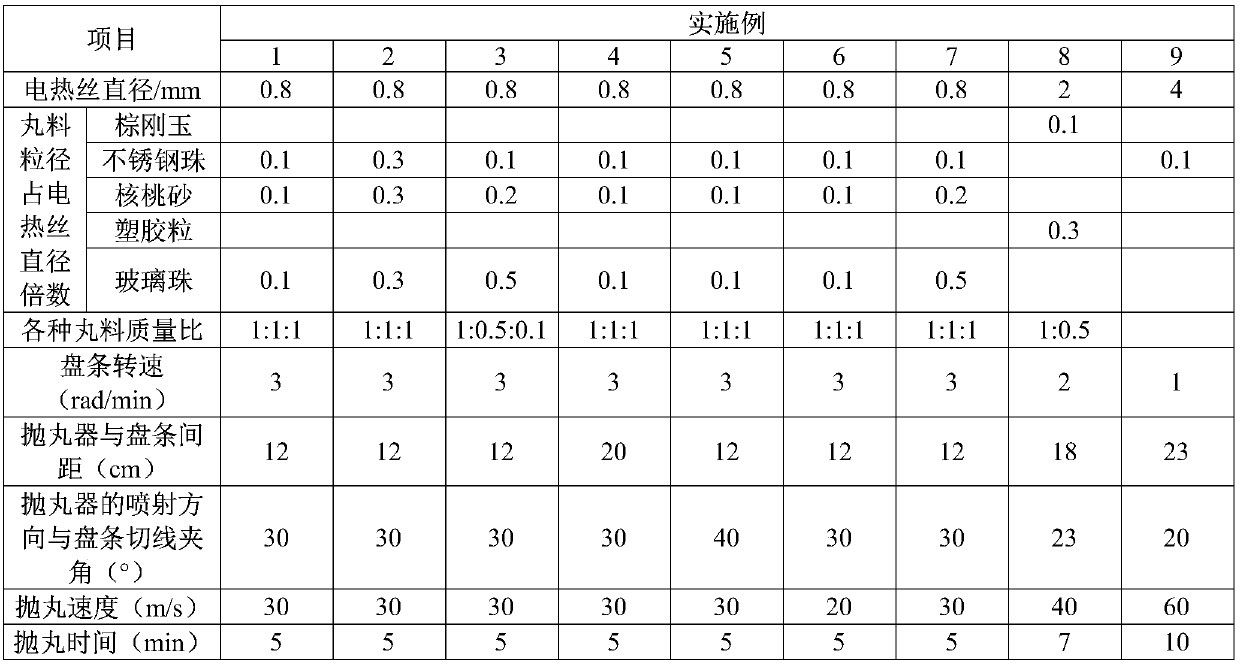

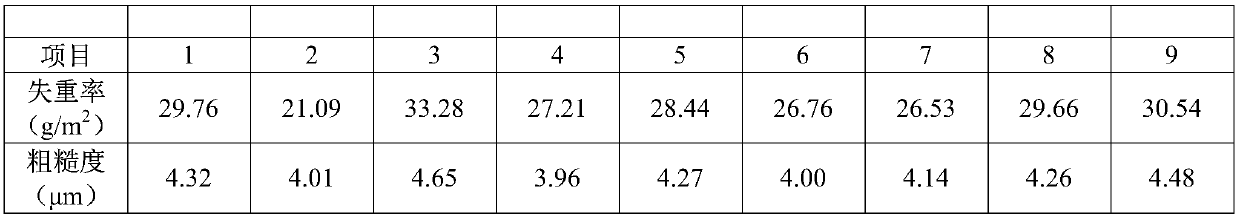

Shot blasting technology of electric heating wire

InactiveCN109571271AAvoid problems such as low processing efficiency and environmental pollutionAvoid problems such as pollutionAbrasion apparatusElectric heatingEngineering

The invention belongs to the field of processing of electric heating wires, and specifically relates to a shot blasting technology of an electric heating wire. The technology comprises the following steps of (1) preprocessing the surface of an electric heating wire coil rod; (2) premixing shots in a shot blasting machine; (3) feeding the electric heating wire coil rod into a shot blasting chamber;rotating the electric heating wire coil rod at the speed of 1-3 rad / min; adjusting the distance from the shot blasting machine to the electric heating wire, the injecting direction of the shot blasting machine and the shot blasting speed based on the diameter of the electric heating wire; and blasting the shots for 3-10 min; and (4) conveying the electric heating wire coil rod into a cleaning chamber after shot blasting; and cleaning the shots adhered to the electric heating wire coil rod. According to the technology, the surface of the electric heating wire is processed with the shot blasting technology, so that the problems such as low pickling processing efficiency, environmental pollution and the like can be avoided; the diameter of the shot is 0.1-0.5 time that of the electric heating wire; the contact area of the electric heating wire can be increased due to the small diameter of the shots, and thus the shot blasting efficiency can be improved.

Owner:DANYANG BROTHER ALLOY

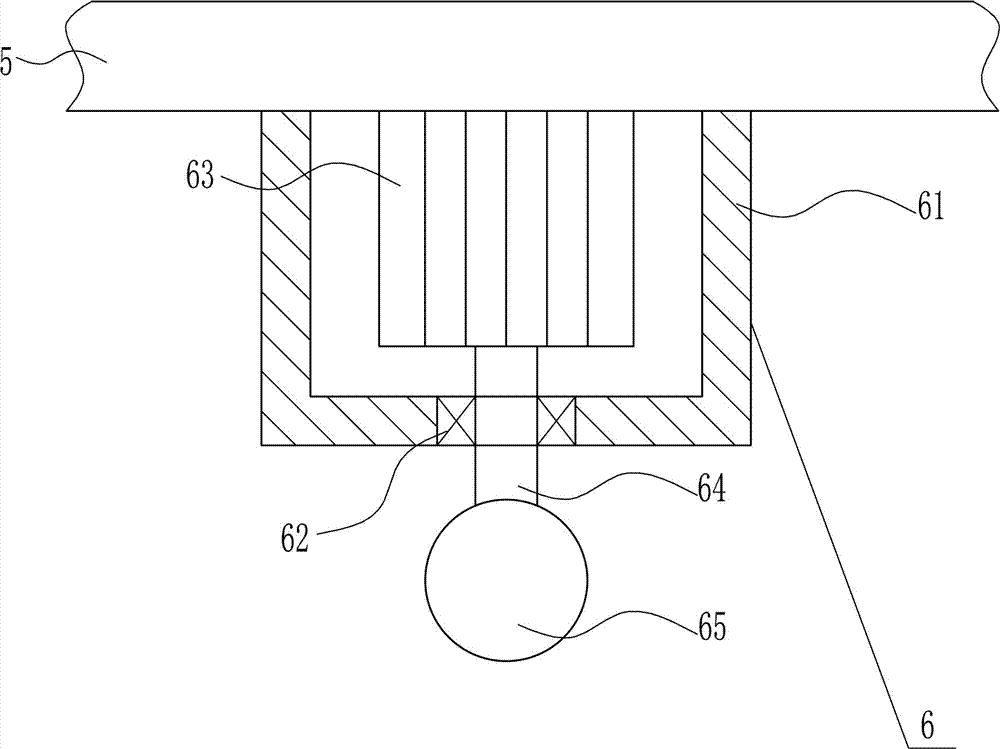

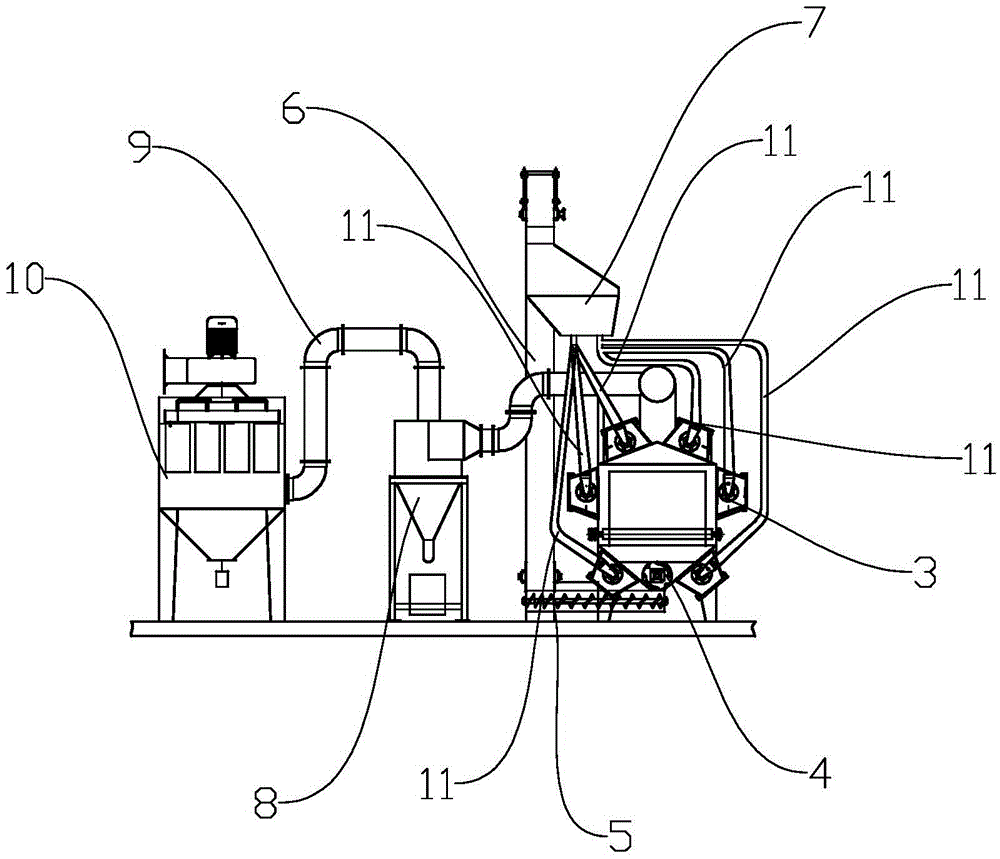

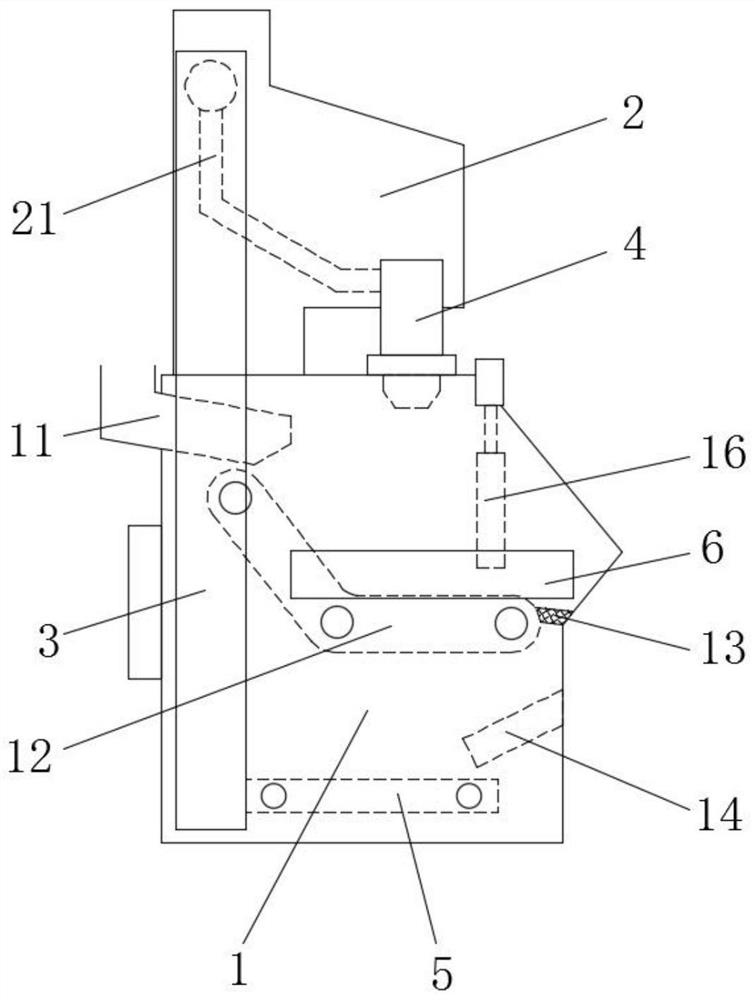

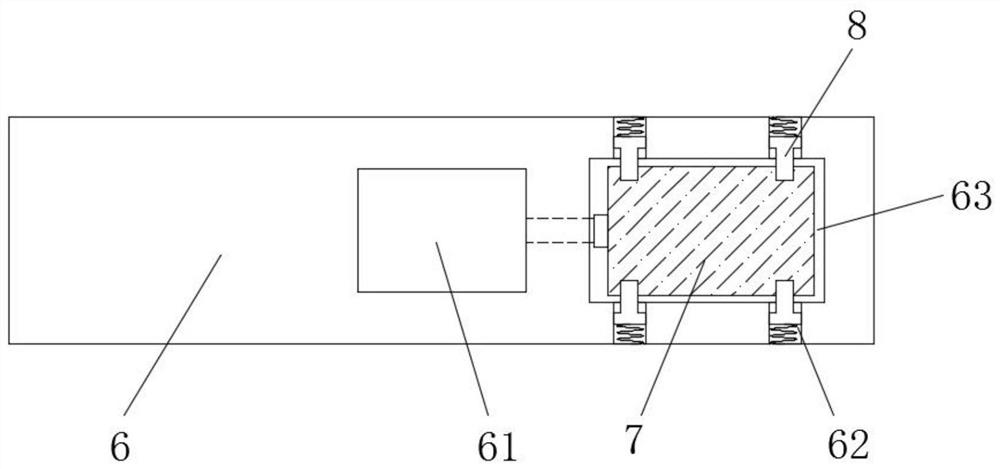

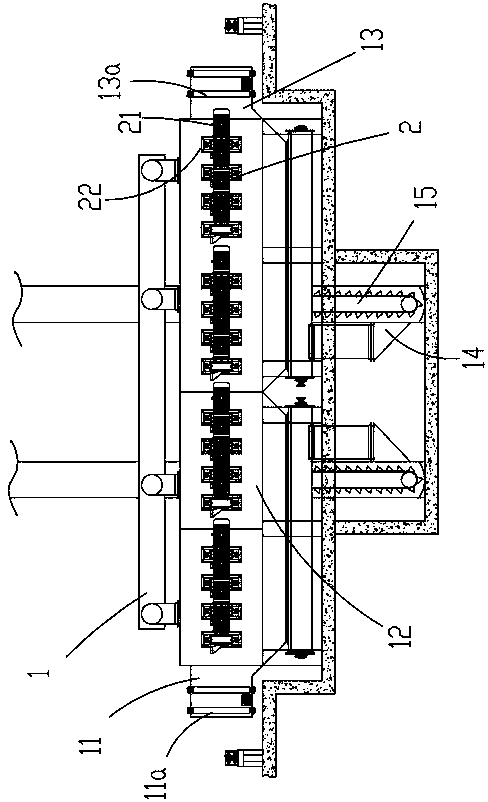

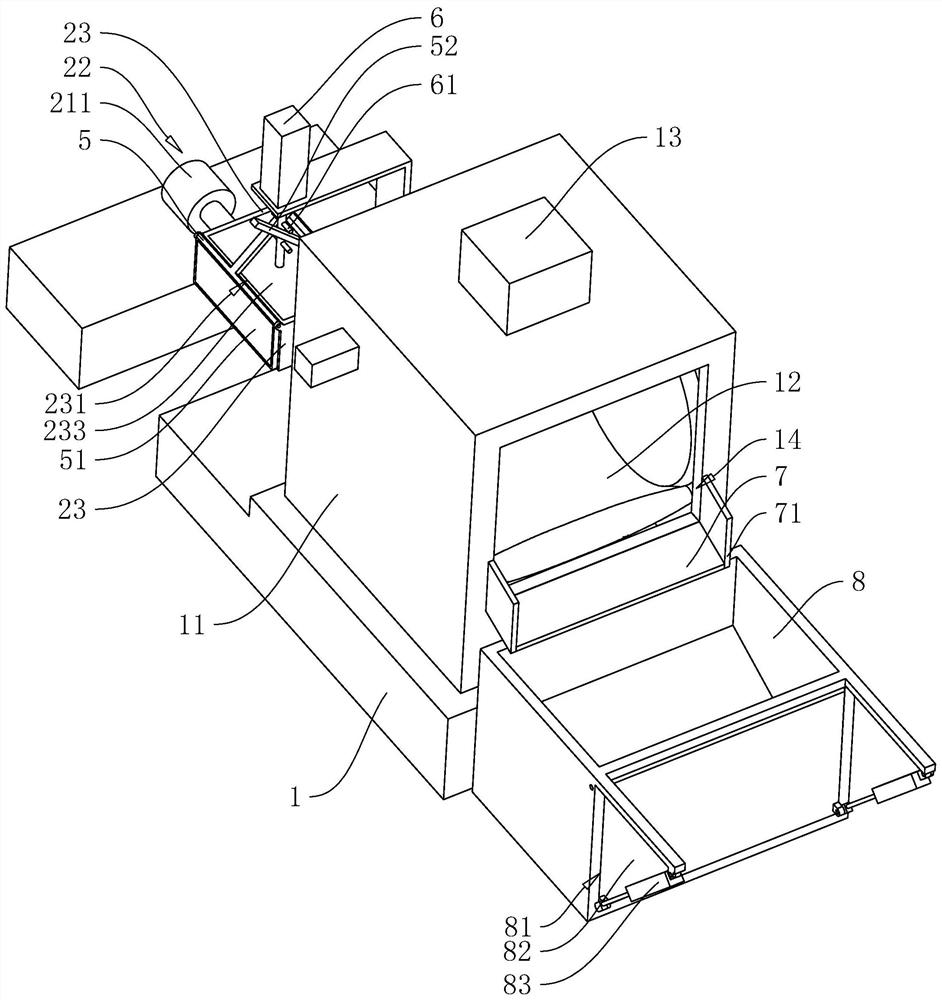

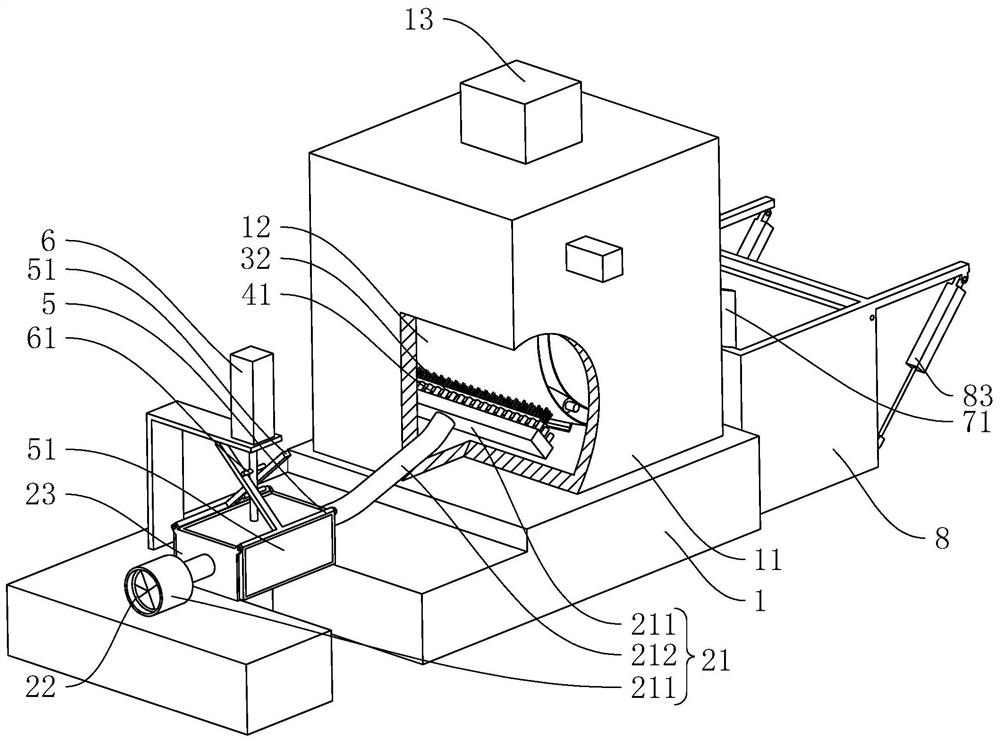

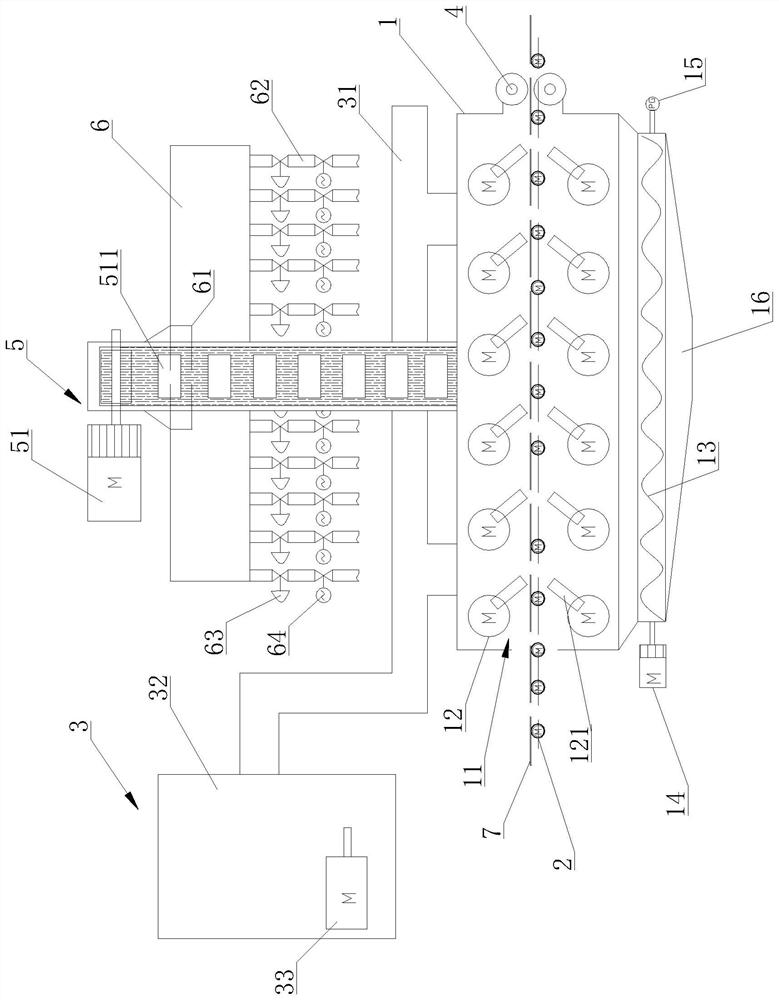

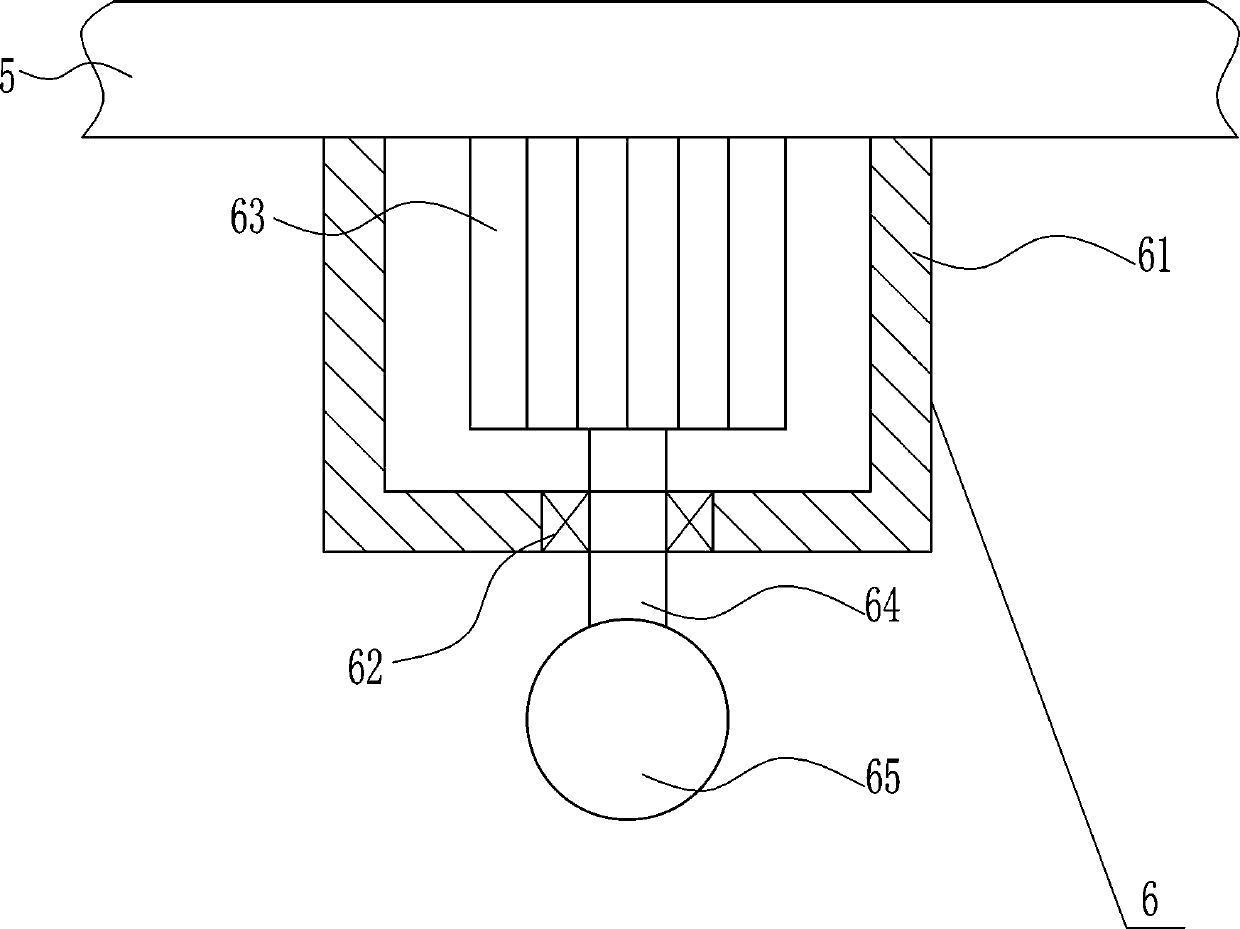

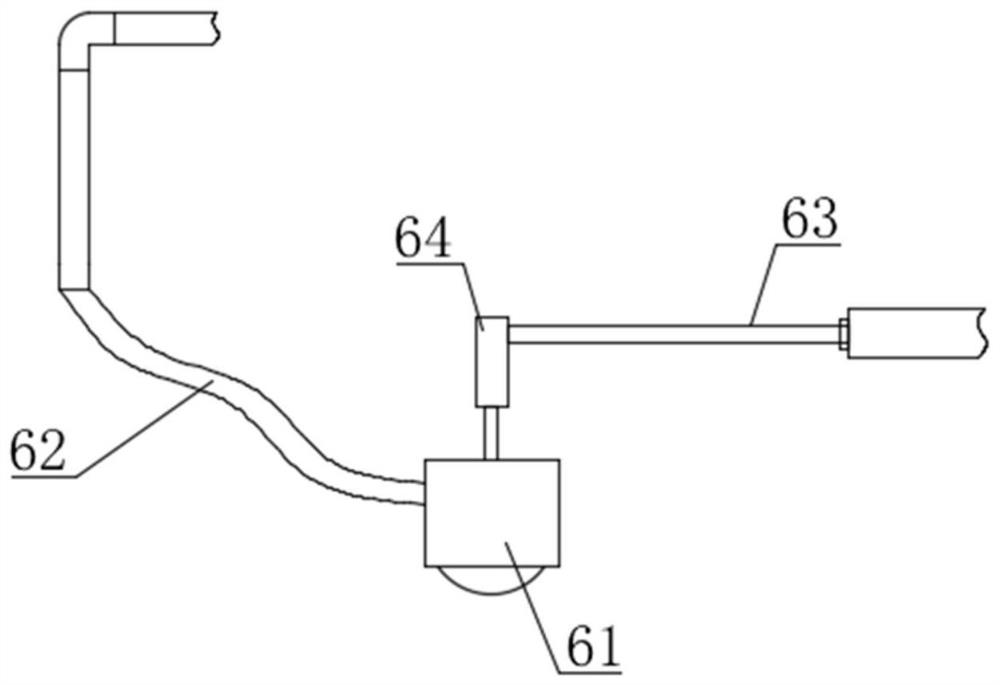

Coating workshop steel sand shot blasting machine

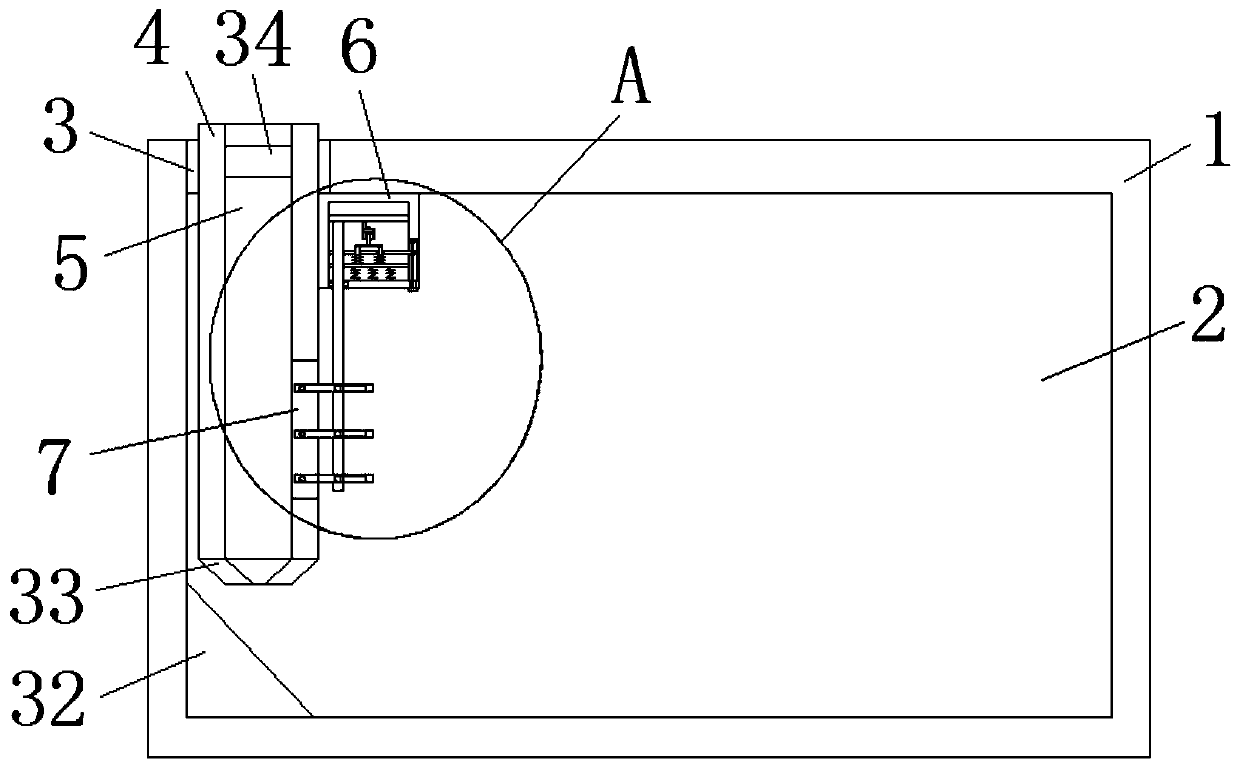

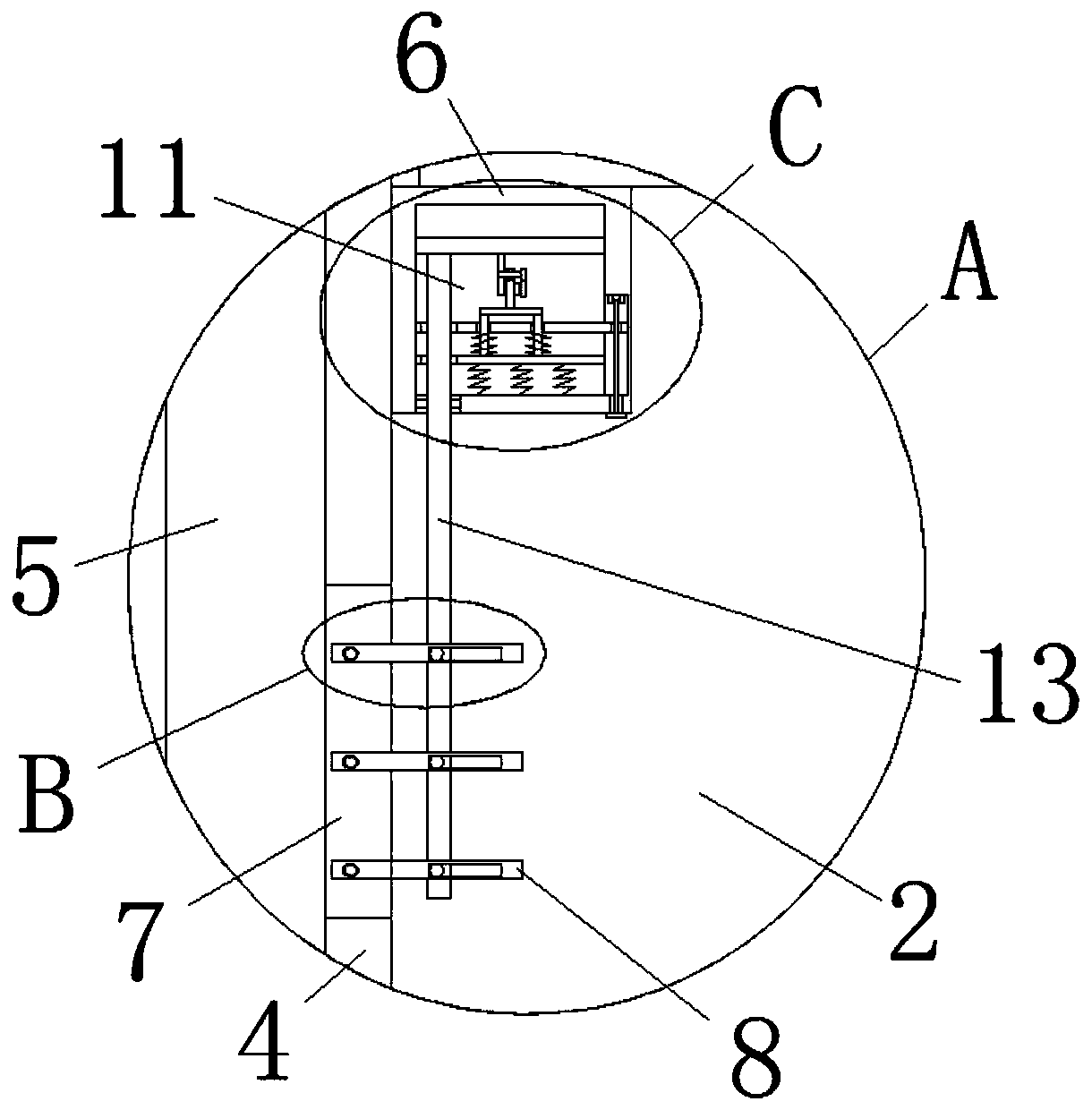

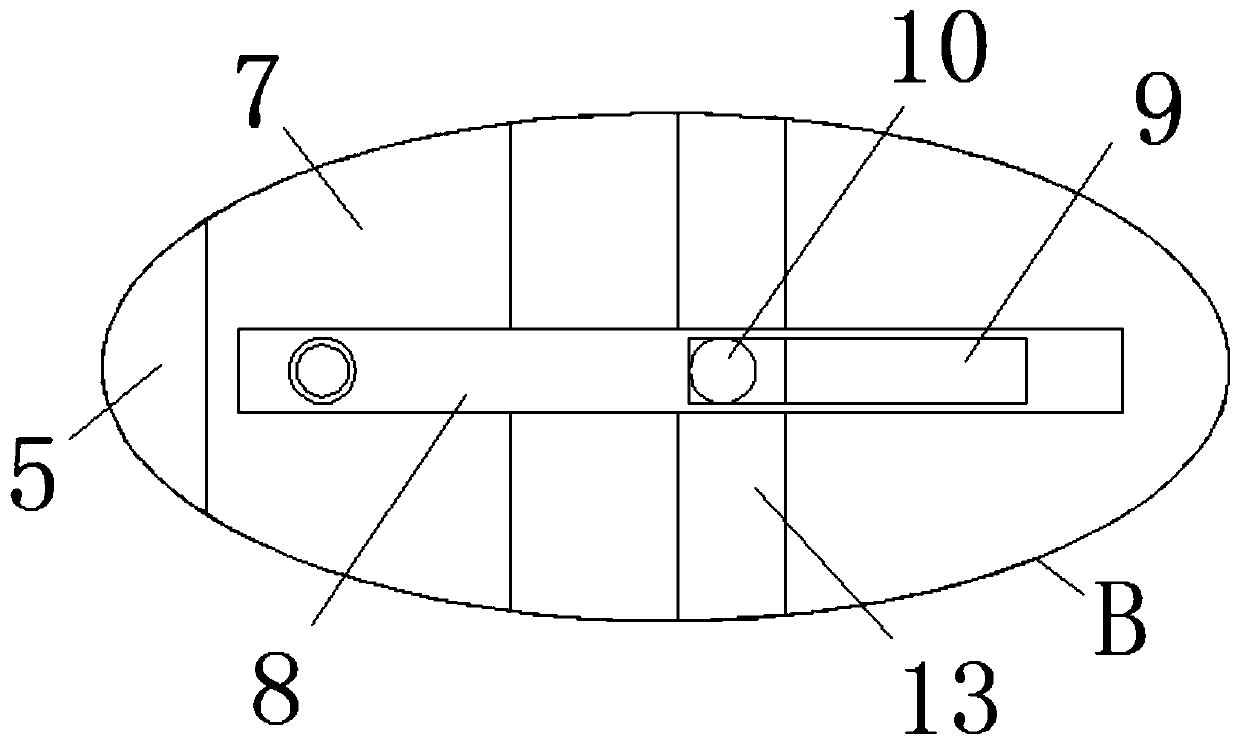

ActiveCN110315438BIncrease friction areaImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesDust controlEngineering

The invention discloses a coating workshop steel grit blasting machine. The coating workshop steel grit blasting machine comprises a shot blasting chamber (1), wherein a conveying roller way (2) is arranged in the shot blasting chamber (1) in a penetrating manner; the outlet end of the shot blasting chamber (1) is provided with a reverse dust removal device (4); the shot blasting chamber (1) is connected with a belt type elevator (5) through an auger mechanism; a steel grit collector (6) is arranged between the belt type elevator (5) and the shot blasting chamber (1), a steel grit filtering device (61) is arranged at the inlet end of the steel grit collector (6), a plurality of sand discharging pipelines (62) are arranged at the lower end of the steel grit collector (6), and the sand discharging pipelines (62) are provided with a quick-cutting valve (63) and a regulating valve (64). The coating workshop steel grit blasting machine is high in safety coefficient, high in working efficiency, good in dust removal effect and shot blasting effect and not easy to block.

Owner:FUSTEEL CO LTD

A steel back shot blasting equipment for brake pad production

ActiveCN107486791BReduce manufacturing costImprove shot blasting effectAbrasive machine appurtenancesAbrasive blasting machinesEngineeringBrake pad

The invention belongs to the technical field of brake pad production, and particularly relates to a steel backing shot blasting device for production of brake pads. The steel backing shot blasting device for production of the brake pads has the advantages that the manufacturing cost is low, the shot blasting effect is good, operation is simple, and the working efficiency is high. The steel backing shot blasting device for production of the brake pads comprises supporting legs and the like; a transverse plate is arranged on the tops of the supporting legs through bolts; lifting devices are symmetrically arranged on the left side and the right side of the top of the transverse plate; through holes are formed in the left end and the right end of the transverse plate separately; a top plate is connected to lifting parts of the lifting devices and is horizontally arranged; a shot blasting device is arranged in the middle of the bottom of the top plate; and a cross rod is connected to the lower portion between the two supporting legs through bolts. According to the steel backing shot blasting device for production of the brake pads, the effects of low manufacturing cost, good shot blasting effect, simple operation and high working efficiency can be achieved.

Owner:浙江翘楚汽车零部件有限公司

Intelligent welding seam shot blasting machine

ActiveCN114800282AEasy to handleImprove operational efficiencyAbrasive machine appurtenancesAbrasive blasting machinesMachine partsDust control

The invention belongs to the technical field of shot blasting machines, aims at solving the problems that in the prior art, the machining efficiency is low, operation is hard, recycling of shots is difficult to achieve, the shot blasting process and the shot cleaning process are difficult to comprehensively analyze to achieve automatic adjustment, and the intelligent degree is low, and particularly relates to an intelligent welding seam shot blasting machine which comprises a shot blasting machine body. A shot blasting chamber and a cleaning chamber are formed in the shot blasting machine body, and a shot blasting device and a positioning driving assembly are arranged in the shot blasting chamber; a cleaning and recycling assembly is arranged in the shot blasting machine body; according to the shot blasting machine, a cylindrical or tubular machined part is effectively supported and fixed through the positioning driving assembly, rotation of the machined part in the shot blasting process is achieved, the functions of brushing and sweeping cleaning, blowing dust removal cleaning, shot collection and shot lifting and conveying are integrated and synchronously operated through the cleaning and recycling assembly, and the using effect is remarkably improved; and material cleaning analysis and diagnostic analysis are combined, so that the intelligent degree of the equipment is remarkably improved.

Owner:江苏锐达科技有限公司

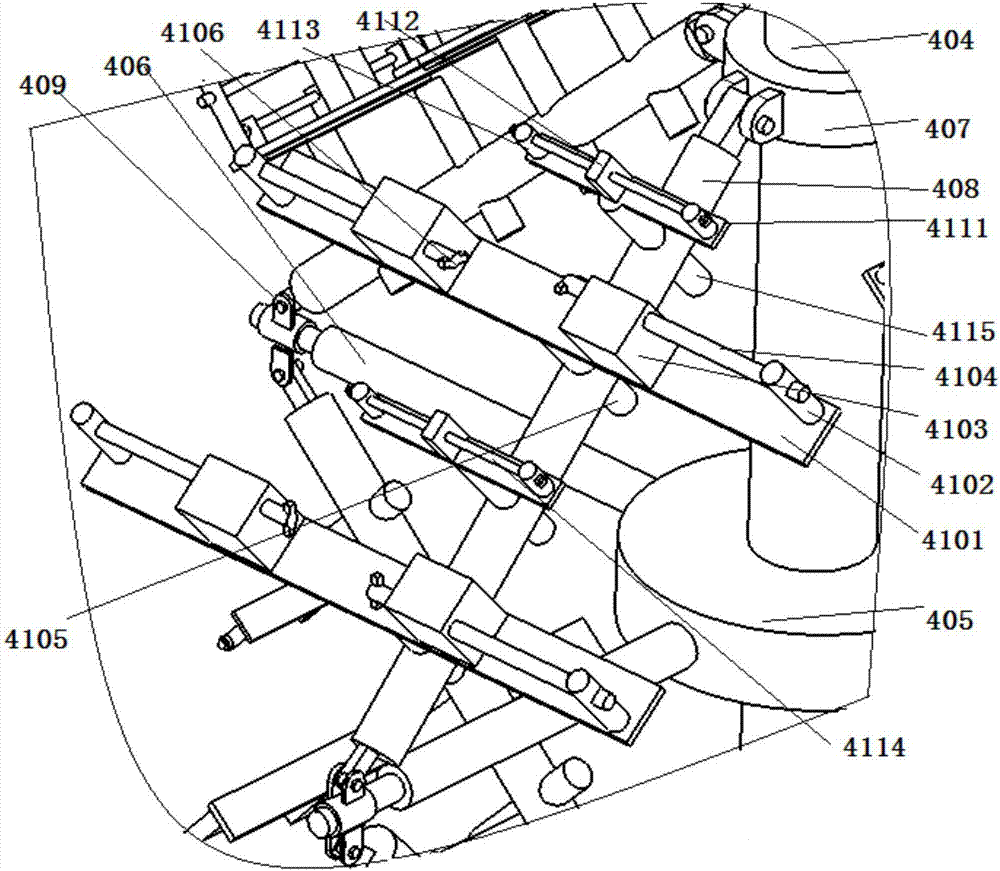

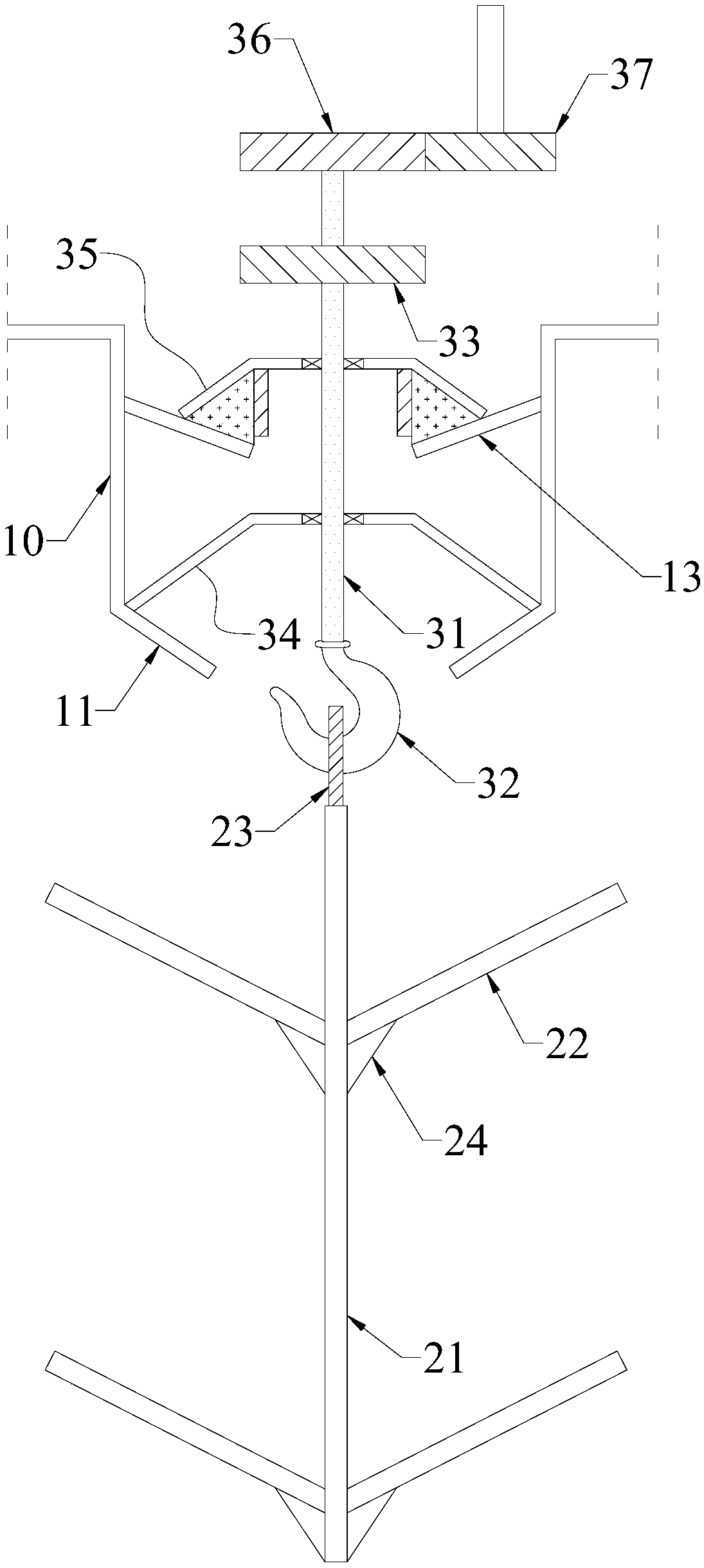

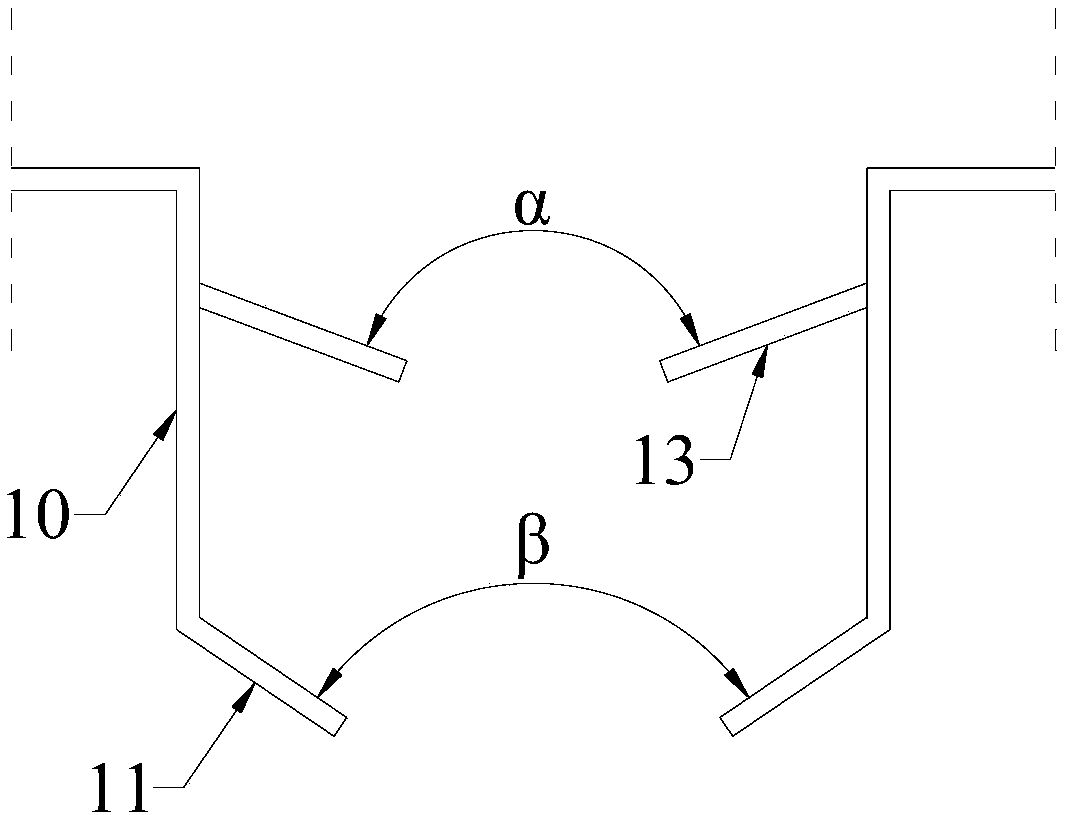

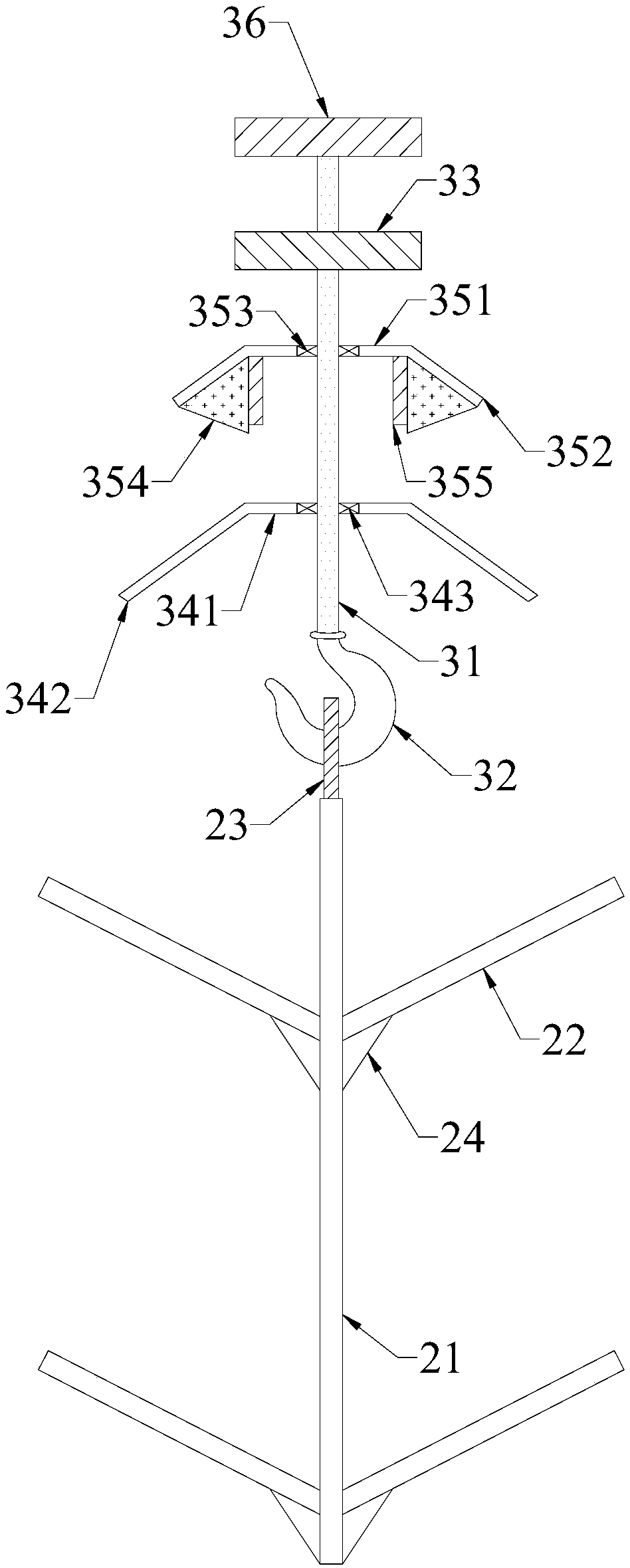

Dedicated hanging rack for shot blasting of cast cylinder block of engine

The invention relates to a dedicated hanging rack for shot blasting of a cast cylinder block of an engine. The dedicated hanging rack for shot blasting of the cast cylinder block of the engine comprises a lower hanging rod, multiple inclined rods arranged on the outer side of the lower hanging rod, a lifting lug fixedly arranged at the upper end of the lower hanging rod, a lifting hook matched with the lifting lug and an upper hanging rod. The two sides of a guide groove are provided with first inclined plates which are mutually symmetrical. The outer side of the upper hanging rod is sleeved with a first baffle. The two sides of the guide groove are further provided with second inclined plates which are mutually symmetrical. The outer side of the upper hanging rod is further sleeved with asecond baffle. Elastic rods with triangular cross sections are arranged between second inclined plate portions and the second inclined plates. The side, close to the upper hanging rod, of each elastic rod is fixedly provided with a plate-shaped electromagnet. The upper end of the upper hanging rod is fixedly provided with a driven wheel. In the shot blasting process, the cast cylinder block of the engine can rotate, a shot blasting dead angle is avoided, the shot blasting effect is good, and the shot blasting efficiency is high. The seal performance between the dedicated hanging rack and a guide groove in a shot blasting machine is good, it is avoided that shot blasting dust overflows, and the shot blasting dust is not prone to accumulating in the guide groove.

Owner:HEFEI JAC CASTING

Air inlet structure on top of shot blasting machine

ActiveCN108326760BReduce vibrationImplement buffer protectionAbrasive machine appurtenancesSoftware engineeringSlide plate

The invention discloses an air inlet structure at the top part of a shot blasting cleaning machine, wherein the air inlet structure includes a cleaning room; a cavity is arranged on the cleaning room,an installation hole is formed in the inner wall of the top part of the cavity; a rectangular air intake pipe is fixed in the installation hole, an air intake hole is formed in the rectangular air intake pipe, and an installation box is fixed at one side of the rectangular air intake pipe; the top part of the installation box is welded with the top part of the cavity; an inner wall of one side ofthe air intake hole is provided with an air outlet hole, a plurality of baffle plates are arranged in the air outlet hole in a rotating manner and are all located in the cavity; one side of each baffle plate is provided with a sliding hole; the sliding hole is internally slidingly provided with a positioning shaft; the installation box is provided with an installation cavity; the installation cavity is internally slidingly provided with a sliding plate; one side of the bottom of the sliding plate is fixedly provided with a traction rod. The air intake structure has the advantages of simple structure, high practical performance, easy adjustment of a blowing angle of the air outlet hole, can protect a stepping motor in a buffering manner, reduces dust in the cavity, improves the shot blasting effect and is beneficial for people to use.

Owner:江苏龙发铸造除锈设备有限公司

Motorcycle gear shot blasting tool

PendingCN108161770ASolve bumps up and downReduce contact areaAbrasive machine appurtenancesEngineeringAnnular array

The invention provides a motorcycle gear shot blasting tool, and belongs to the technical field of machinery. The problem that a existing gear shot blasting tool is prone to being hit by steel shots in a shot blasting process, a product shot blasting is not clean, and a surface has a collision mark are solved. The motorcycle gear shot blasting tool comprises a circular upper chassis, a circular lower chassis and supporting columns arranged between the upper chassis and the lower chassis, the upper chassis and the lower chassis are coaxially arranged, the four supporting columns are distributedin an annular array along the central axis of the lower chassis, at least one combined hook ring composed of a plurality of combined hooks is arranged between the upper chassis and the lower chassis,and the centers of the combined hook rings are concentric with the center of the lower chassis, and a fixing structure used for fixing the combined hooks is arranged on the lower chassis. The motorcycle gear shot blasting tool has the advantages that the shot blasting effect is good, a workpiece cannot be shot by shot blasting.

Owner:ZHEJIANG ZOMAX TRANSMISSION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com