Efficient impeller head

A shot blasting machine and high-efficiency technology, which is used in explosion generating devices, abrasives, metal processing equipment, etc., can solve the problems of troublesome disassembly and installation process, reducing the high efficiency of the shot blasting machine, and blocking shots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The high-efficiency shot blasting device of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

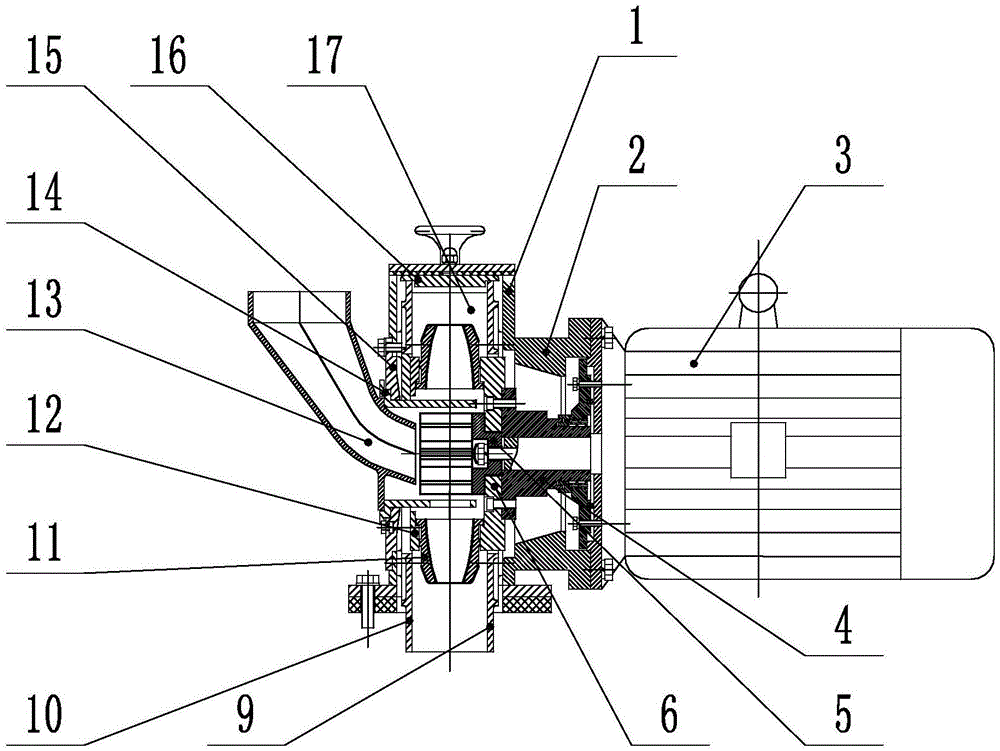

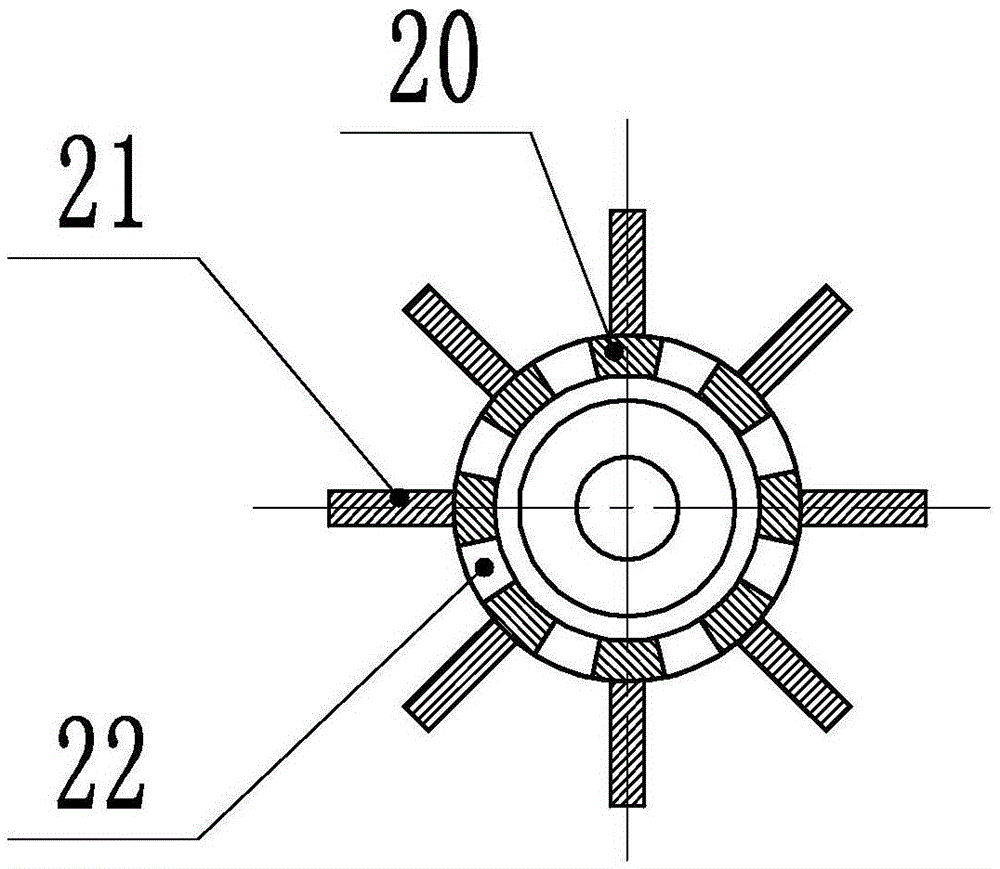

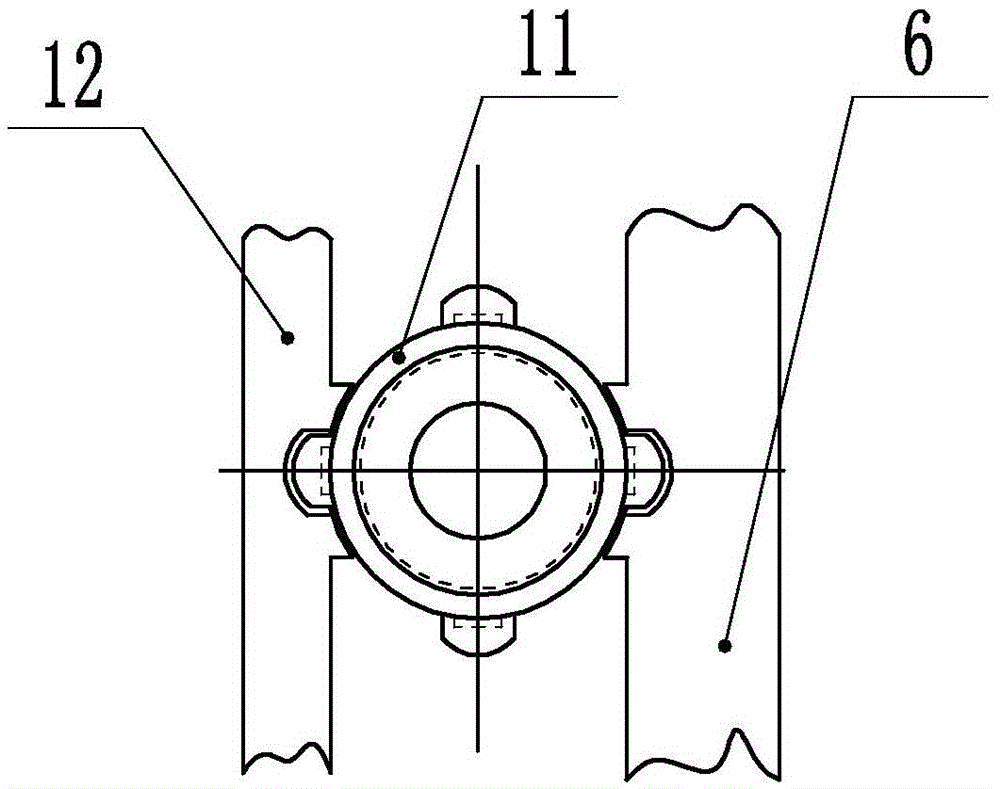

[0014] As shown in the figure, the high-efficiency shot blasting device of the present invention is mainly composed of shot blasting tube 13, shot separation wheel 5, orientation sleeve 14, impeller disc and shot blasting blade 11, and its specific structure includes a shell. The housing includes a shield 1 and a gland 15 matched with the shield 1. The top, left and right sides, and front and rear sides of the shield are respectively equipped with a top guard 16, a left end guard 10, a right end guard 9, and side guards. The plates 17 are fixed to each other by compression screws, and a pair of impeller discs for installing shot blasting blades are arranged in the housing, and the center of the two impeller discs is also equipped with a shot wheel 5 and an orientation sleeve installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com