Continuous passing type conveying caterpillar band shot blasting machine

A technology for conveying crawlers and shot blasting machines, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc. It can solve the problems of small conveying crawler space, inability to blast workpieces, and poor shot blasting effects, etc., to achieve Avoid mutual bite damage, realize the effect of automation and large open space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

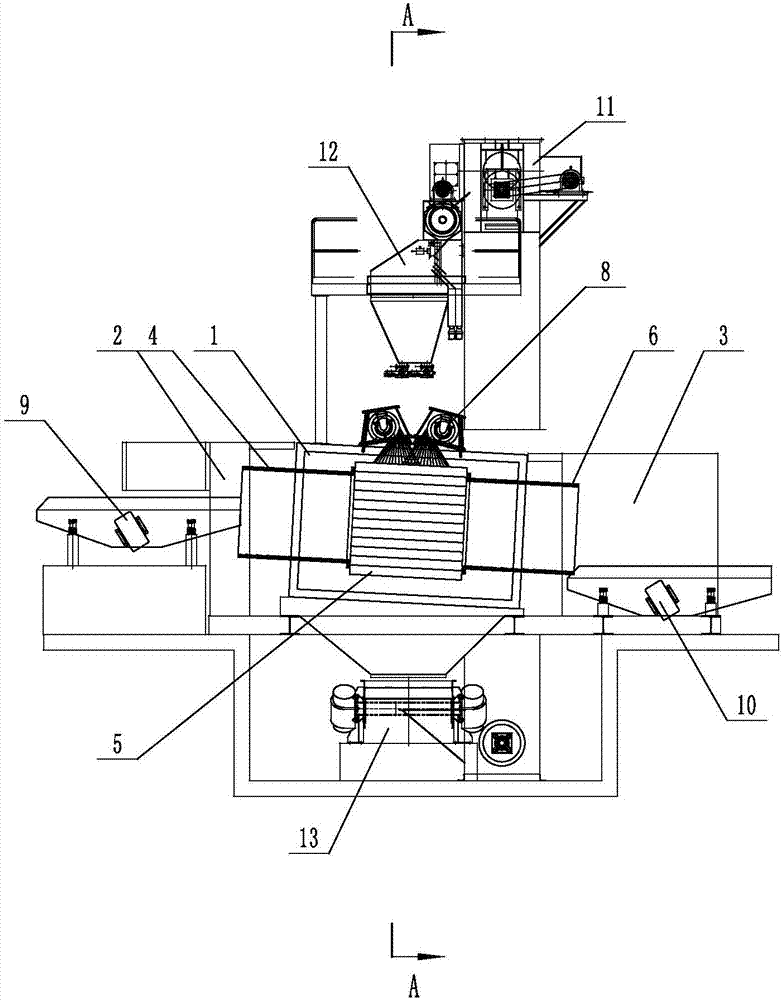

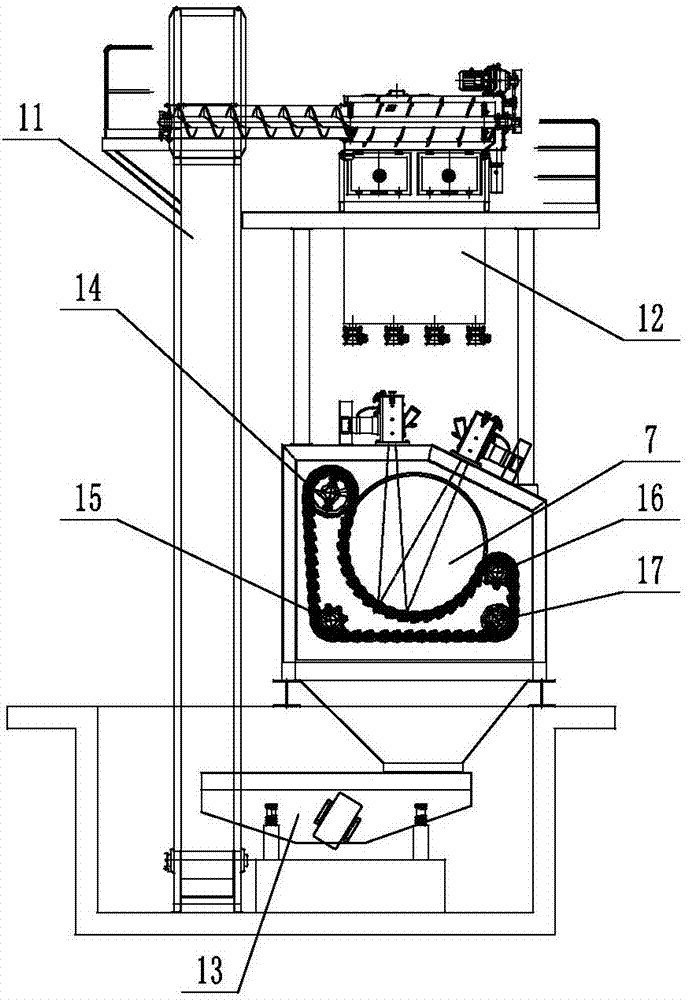

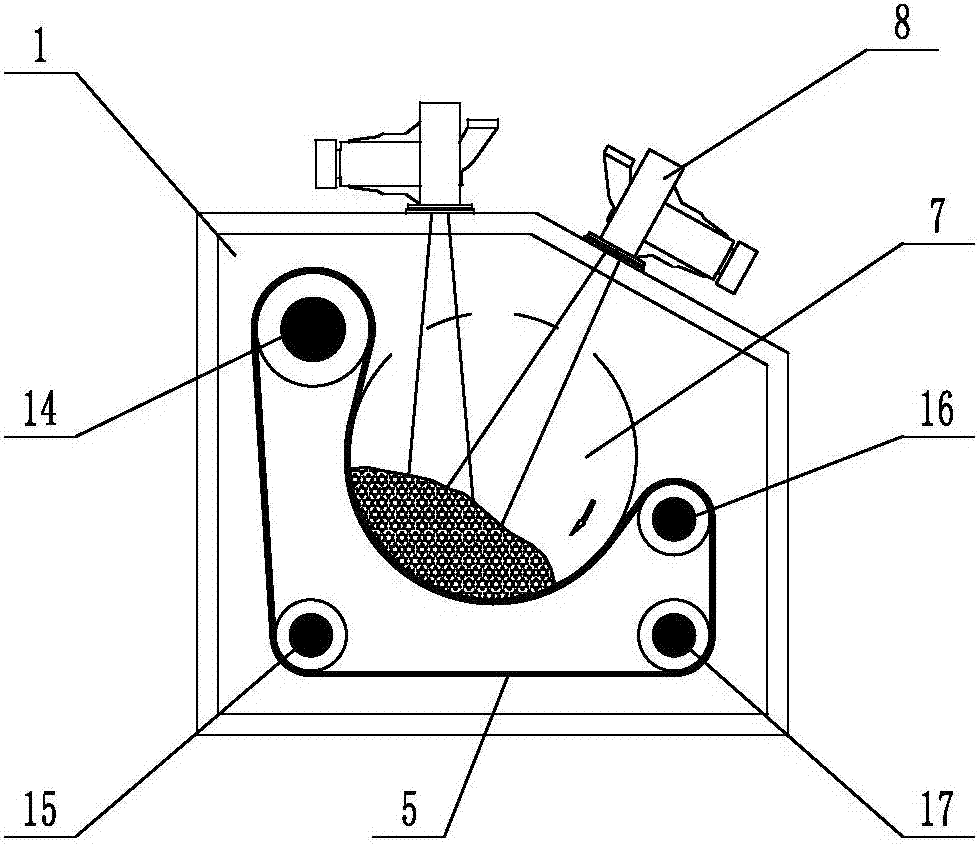

[0015] like Figure 1-3 As shown, the present invention includes a shot blasting chamber 1, a left sealed chamber 2 arranged at the left end of the shot blasting chamber 1, a right sealed chamber 3 arranged at the right end of the shot blasted chamber 1, a workpiece conveying system, a projectile circulation system, and an electric control system , an air control system, and a dust removal system, the workpiece conveying system includes a left drum 4 located inside the left sealed chamber 2, a conveyor belt 5 located inside the shot blasting chamber 1, and a right drum 6 located inside the right sealed chamber 3, The outer walls of the left drum 4 and the right drum 6 cooperate with the two ends of the conveyor belt 5 , and press the upper end of the conveyor belt 5 into an open arc-shaped cavity 7 . The upper end of the shot blasting chamber 1 is provided with a plurality of shot blasters 8 matched with the arc-shaped cavity 7, and the two ends of the workpiece conveying syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com