Shot blasting machine used for machining of shell of high-voltage transformer

A high-voltage transformer and shot blasting machine technology, which is applied in metal processing equipment, additives, petroleum industry and other directions, can solve the problems of low production efficiency of high-voltage transformer shells, unsecured product quality, and low production efficiency. The effect of easy shot blasting, stable rotation and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

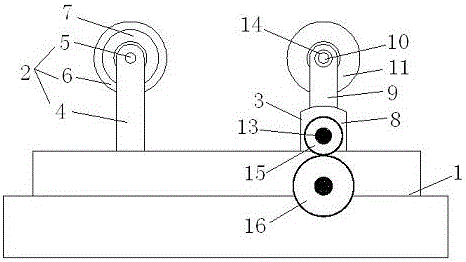

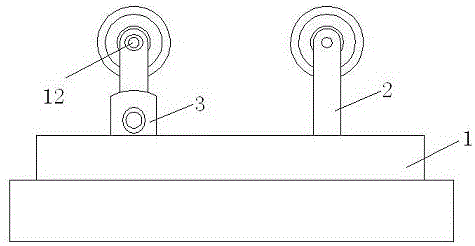

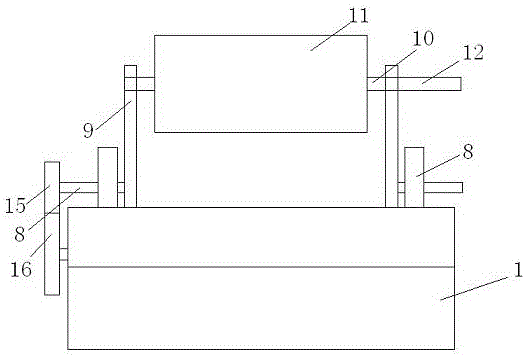

Method used

Image

Examples

Embodiment 1

[0040] The above-mentioned shot blasting machine for processing high-voltage transformer shells, wherein the preparation method of the novel lubricating grease is as follows:

[0041] 1. Take calcium hydroxide, stearic acid, boric acid, and white carbon black, put them into a blender in a weight ratio of 1:0.5:0.3:2, mix and stir until fully mixed to obtain a thickener;

[0042] 2. Take diphenylamine, dilauryl alcohol ester and dioctadecyl alcohol ester, put them into a blender in a weight ratio of 1:2:0.5, mix and stir until fully mixed to obtain an antioxidant;

[0043] 3. Take polymethyl methacrylate, polyisobutylene and dodecylbenzenesulfonic acid, put them into a mixer in a weight ratio of 1:3:0.1, mix and stir until fully mixed, and obtain a structure improving agent;

[0044] 4. Weigh the base oil and the thickener by weight, add 80% by weight of the base oil and all the thickener into the reaction kettle, heat and stir the reaction, the temperature is controlled at 135...

Embodiment 2

[0048] The above-mentioned shot blasting machine for processing high-voltage transformer shells, wherein the preparation method of the novel lubricating grease is as follows:

[0049] 1. Take calcium hydroxide, azelaic acid, stearic acid, oleic acid and white carbon black, put them into a blender in a weight ratio of 1:0.4:0.6:0.1:0.12, mix and stir until fully mixed to obtain thickener;

[0050] 2. Take didodecyl alcohol ester, ditetradecyl alcohol ester and dioctadecyl alcohol ester, put them into a blender in a weight ratio of 1:0.5:2, mix and stir until fully mixed, and obtain antioxidant agent;

[0051] 3. Take polyisobutene, n-butanol and phosphoric acid, put them into a mixer in a weight ratio of 1:1.7:0.4, mix and stir until fully mixed, and obtain a structure improving agent;

[0052] 4. Weigh the base oil and the thickener by weight, add 80% by weight of the base oil and all the thickener into the reaction kettle, heat and stir the reaction, the temperature is cont...

Embodiment 3

[0056] The above-mentioned shot blasting machine for processing high-voltage transformer shells, wherein the preparation method of the novel lubricating grease is as follows:

[0057] 1. Take sebacic acid, azelaic acid, stearic acid, oleic acid and white carbon black, put them into a blender in a weight ratio of 1:0.8:0.5:0.1:2, mix and stir until fully mixed to obtain thickener;

[0058] 2. Take diphenylamine, put it into a blender, mix and stir until it is fully mixed to obtain an antioxidant;

[0059] 3. Take polyisobutylene and phosphoric acid, put them into a mixer in a weight ratio of 1:0.8, mix and stir until fully mixed, and obtain a structure improving agent;

[0060] 4. Weigh the base oil and the thickener by weight, add 80% by weight of the base oil and all the thickener into the reaction kettle, heat and stir the reaction, the temperature is controlled at 145°C, and the stirring time is 1.9 hours to obtain Mixture A, then stand for a period of time until the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com