Air inlet structure at top part of shot blasting cleaning machine

A shot blasting machine and air inlet technology, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve problems such as unfavorable use, inconvenience to change the blowing direction of the air inlet, and inconvenience to remove dust in the cleaning room. , to achieve the effect of reducing dust, improving shot blasting effect and high practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

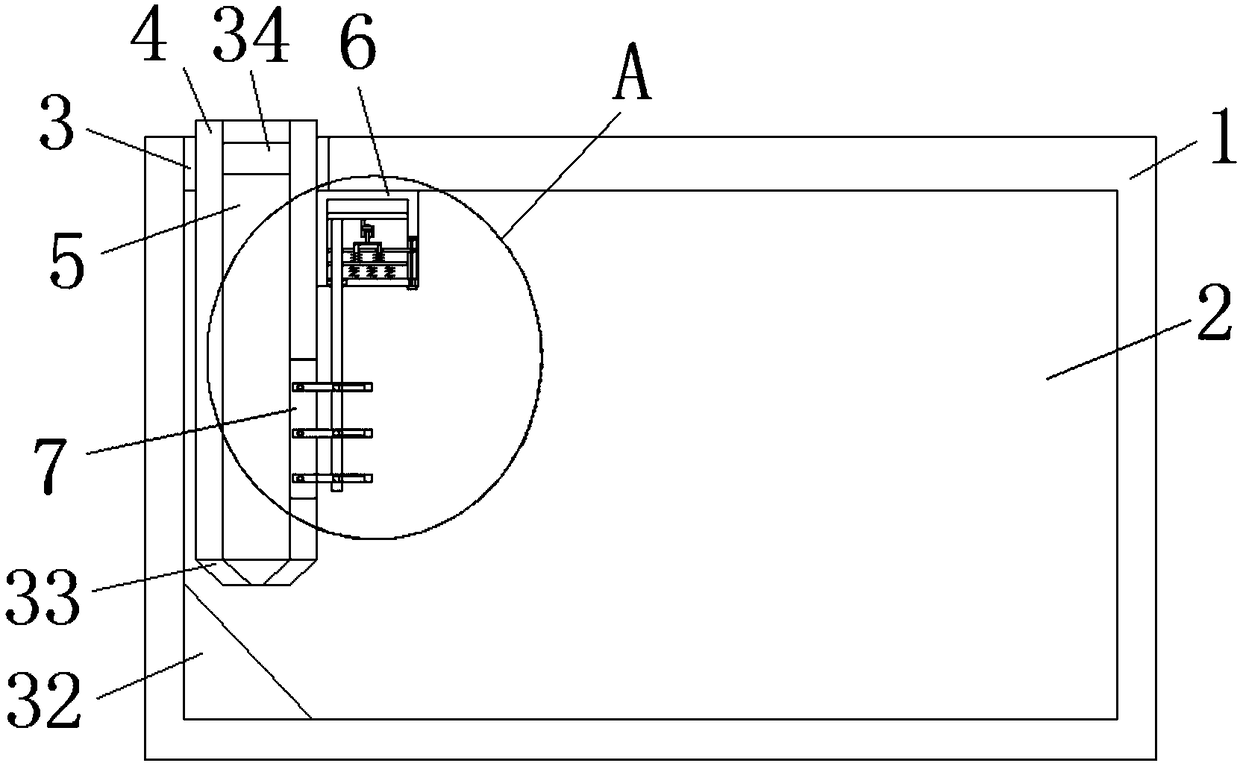

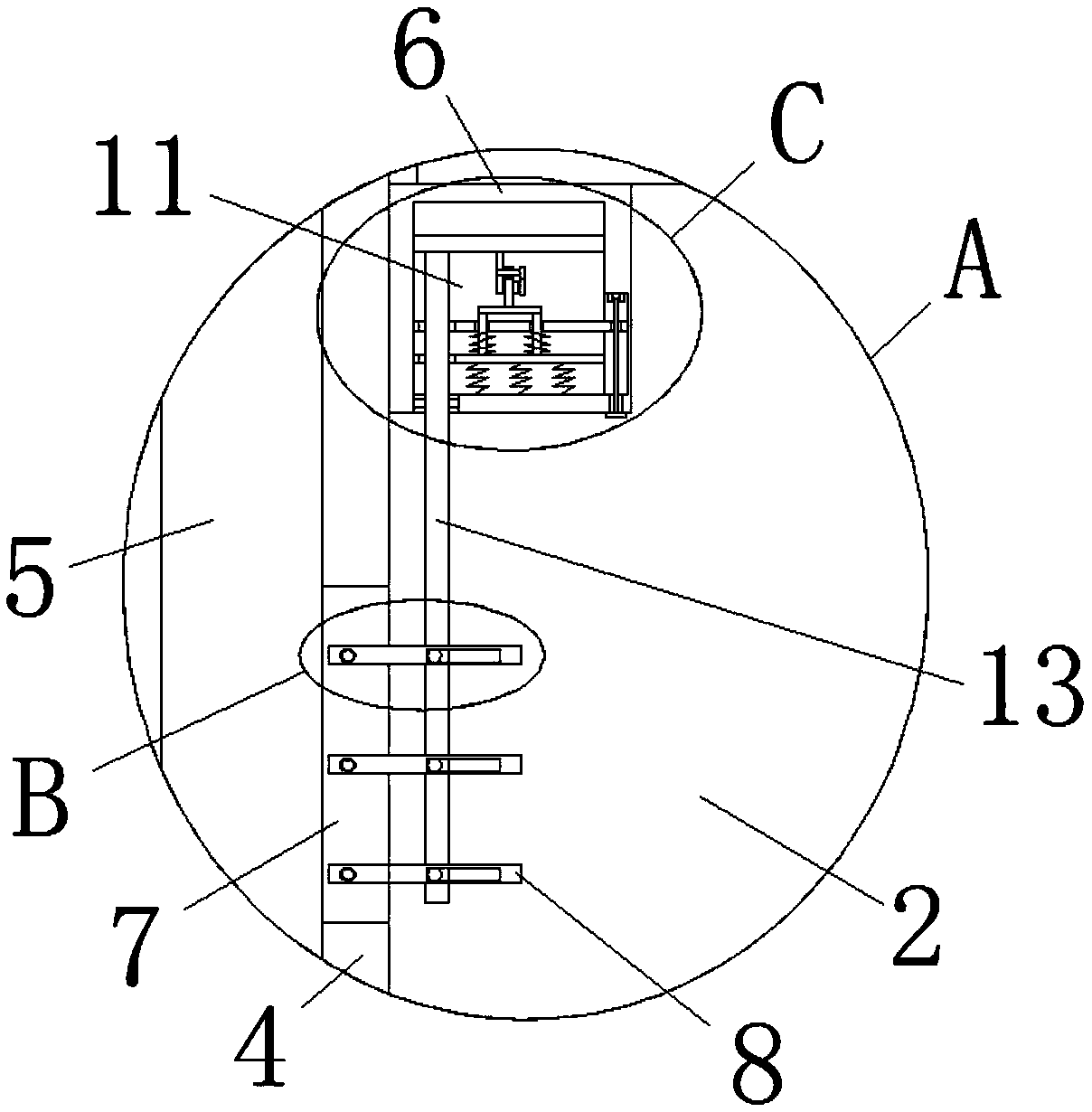

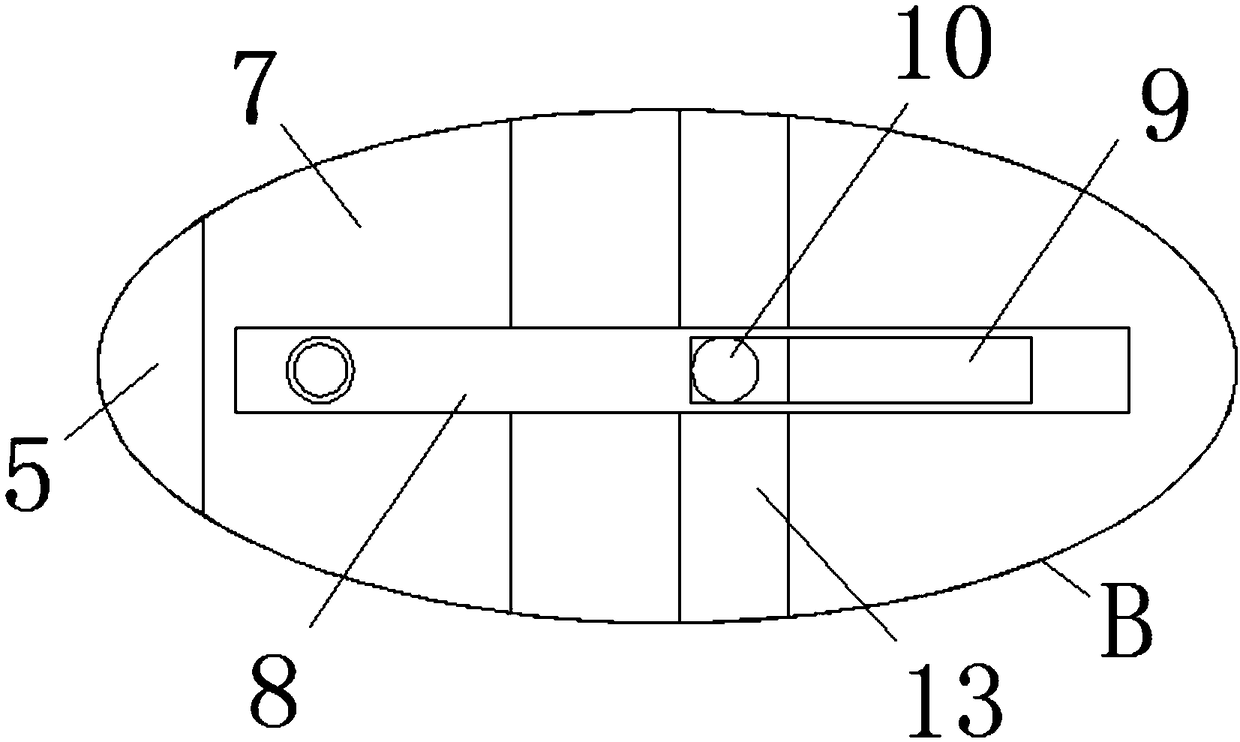

[0028] refer to Figure 1-6, the air inlet structure at the top of the shot blasting machine is proposed in this embodiment, including a cleaning chamber 1, a cavity 2 is provided on the cleaning chamber 1, and a mounting hole 3 is provided on the top inner wall of the cavity 2, and the mounting hole 3 is fixedly installed There is a rectangular air inlet pipe 4, and the rectangular air inlet pipe 4 is provided with an air inlet hole 5, and one side of the rectangular air inlet pipe 4 is fixedly installed with an installation box 6, and the top of the installation box 6 is welded to the top of the cavity 2, and the One side inner wall of the air hole 5 is provided with an air outlet hole 7, and a plurality of baffle plates 8 are rotatably installed in the air outlet hole 7, and the plurality of baffle plates 8 are all located in the cavity 2, and one side of the baffle plate 8 is provided with a sliding A positioning shaft 10 is slidably installed in the hole 9 and the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com