Strip steel shot blasting system

A technology of strip steel and shot blasting machine, which is applied in the direction of grinding/polishing equipment, used abrasive processing devices, abrasive materials, etc., which can solve problems such as low work efficiency, residual rust on strip steel, and poor treatment effect, and achieve Good shot blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

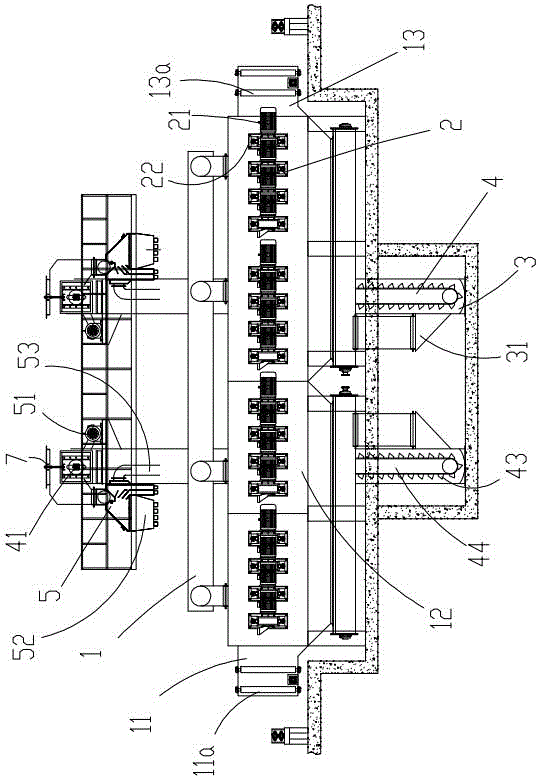

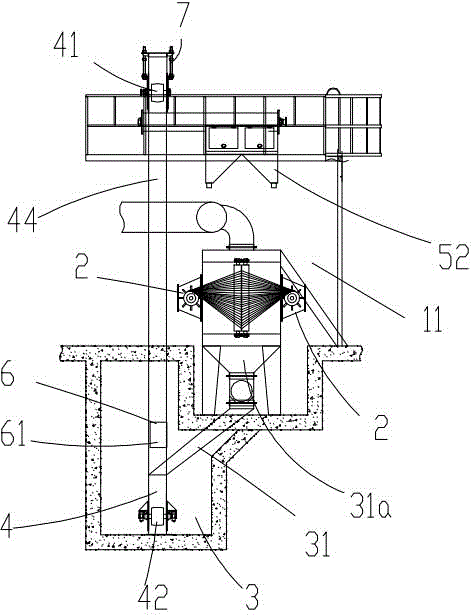

[0031] Figure 1 to Figure 2 Shown is the structural representation of the present invention.

[0032] Wherein the reference numerals are: machine base 1, strip steel entrance 11, entrance conveying roller 11a, shot blasting chamber 12, strip steel exit 13, exit conveying roller 13a, shot blasting device 2, shot blasting motor 21, centrifugal cylinder 22, Pill storage trough 3, chute 31, funnel mouth 31a, bucket elevator 4, upper drive pulley 41, lower drive pulley 42, hopper 43, belt 44, separator 5, fan 51, shot drop 52, waste Mouth 53, conveyor belt tensioning device 6, belt lock 61, fine-tuning bolt 7.

[0033] Such as Figure 1 to Figure 2 As shown, the strip steel shot blasting system of the present invention comprises a support 1, wherein: the support 1 is provided with a strip steel entrance 11, a shot blasting chamber 12 and a strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com