Shot blasting technology of electric heating wire

A technology of electric heating wire and process, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of high waste water treatment cost, long treatment cycle, improper discharge, etc., to improve shot blasting efficiency, save energy, and increase impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

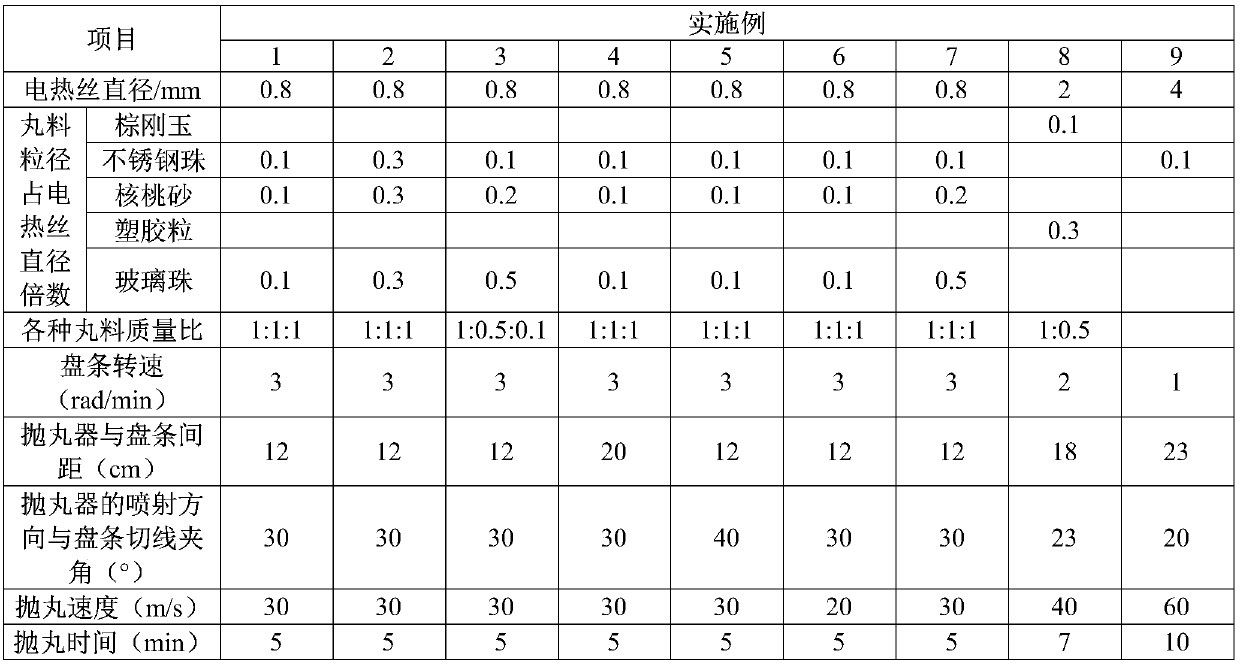

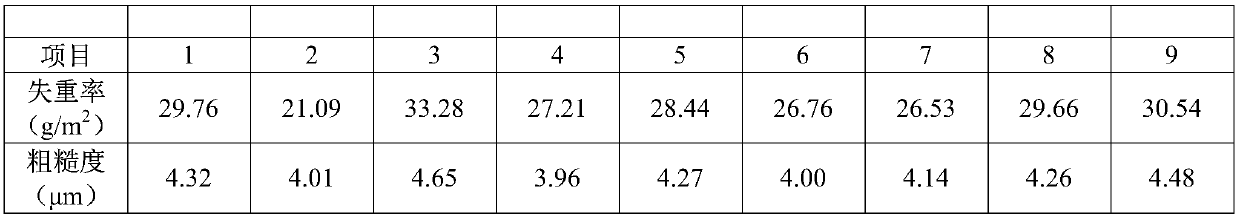

[0023] The present invention is described in further detail now in conjunction with embodiment.

[0024] The shot blasting process of the heating wire includes the following steps:

[0025] (1) Surface pretreatment of the heating wire rod can be degreased, cleaned and dried;

[0026] (2) Pre-mix the shot in the shot blaster;

[0027] (3) Fix the heating wire rod on the hanging shaft, send it into the shot blasting room, make the heating wire rod rotate at a speed of 1-3rad / min, adjust the distance between the blasting machine and the heating wire according to the diameter of the heating wire The distance, the blasting direction of the shot blaster and the shot blasting speed, the shot blasting time is 5-15min;

[0028] (4) After the shot blasting is over, send the heating wire rod into the cleaning room to clean up the pellets adhered to the heating wire rod.

[0029] Among them, the blasting device can be arranged in one row in the axial direction of the heating wire rod, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com