Hanging bracket for shot blasting and shot blasting method

A hanger and frame technology, applied in the field of shot blasting suspension hanger and shot blasting, can solve the problems of high cost and poor shot blasting effect, and achieve long service life, good shot blasting effect, cleanliness and roughness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

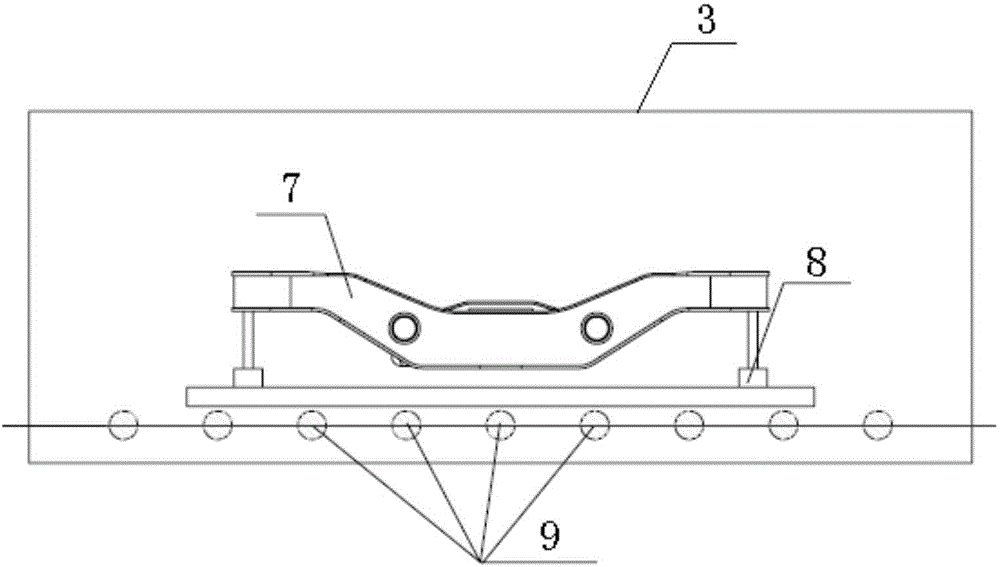

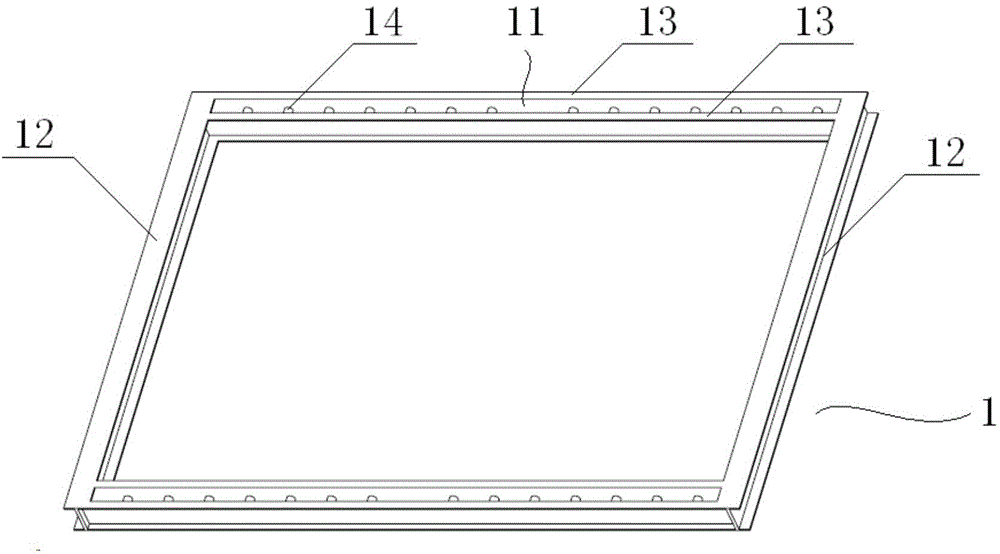

[0035] combine Figure 3 to Figure 8 As shown, the suspension hanger for shot blasting of the present invention includes a main frame 1 and a connecting part 2; the main frame is a rectangular frame composed of two oppositely arranged side beams 11 and two oppositely arranged end beams 12, each side The beam 11 has two opposite vertical plates 13, and a plurality of connecting rods 14 are arranged at intervals between the two vertical plates 13, and the two ends of each connecting rod 14 are respectively fixed on the two vertical plates 13; 2 has a crossbeam 21, two vertical beams 22 are vertically arranged at the bottom of the crossbeam 21, and a first stopper 23 is arranged at the top of the crossbeam 21, and the bottoms of the two vertical beams 22 are respectively fixed on the tops of the two end beams 12.

[0036] In the present invention, the main frame 1 is used to connect and fix the frame 7 to be shot blasted, wherein the outer dimensions of the rectangular frame shou...

Embodiment 2

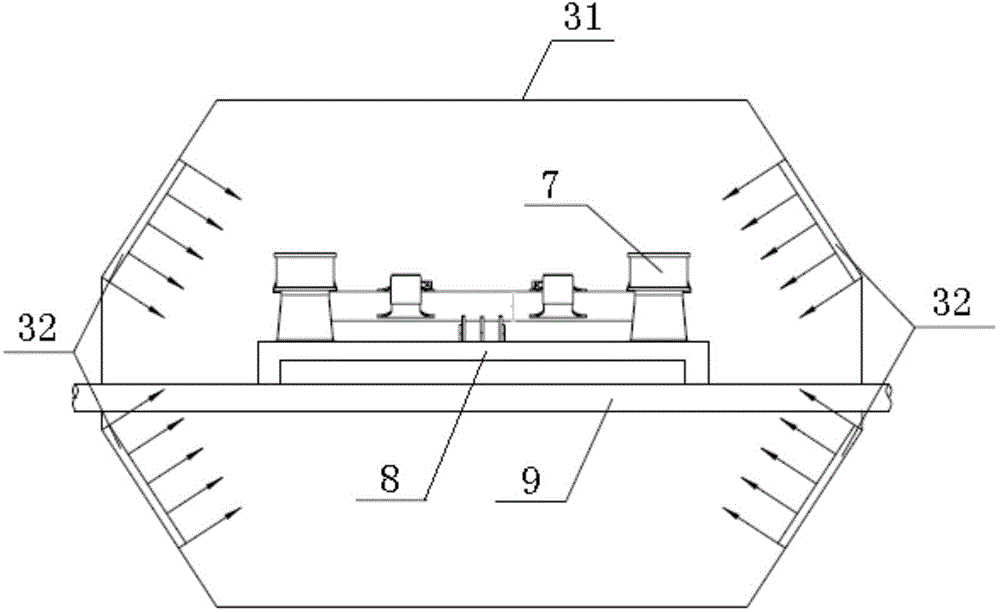

[0048] combine Figure 3 to Figure 8 As shown, the shot blasting equipment of the present invention includes a shot blasting part 3, a horizontal transmission part 4, a lifting part 5 and any suspension hanger for shot blasting in Embodiment 1. The shot blasting part 3 has a shell 31, and a shot blasting head 32 is provided on the inner wall of the shell 31; the horizontal transmission part 4 can pass through the inside of the shot blasting part 3 shell 31 in a horizontal movement mode, There is a second limiting part 41, the second limiting part 41 can cooperate with the first limiting part 23 and drive the connecting part 2 to move horizontally when the horizontal transmission part 4 moves horizontally; the lifting part 5 is fixed on the horizontal transmission part 4 and connected with the connecting part 2, the lifting part 5 can drive the connecting part 2 to move up and down.

[0049] The shot blasting part 3 is a conventional structure in the field, and it is used to p...

Embodiment 3

[0054] Shot blasting method of the present invention, adopts the shot blasting equipment of embodiment 2 to carry out, and shot blasting method comprises:

[0055] Set soft connectors on the connecting rods of the two side beams of the shot blasting equipment, and make the soft connectors cover at least two connecting rods on the same side beam, and connect the soft connectors to the frame to be shot blasted. The shot blasting frame is suspended horizontally, and the angle between the soft connector and the vertical direction is controlled to be 3°~11°;

[0056] Start the lifting part of the shot blasting equipment, so that the first limit part on the connecting part cooperates with the second limit part on the horizontal transmission part;

[0057] Use the shot blasting part of the shot blasting equipment to blast the shot blasting frame.

[0058] The shot blasting method of one embodiment of the present invention carries out shot blasting to rail vehicle bogie (i.e. frame 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com