Method for protecting internal of tank from pill entrance during pill blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below with reference to the accompanying drawings.

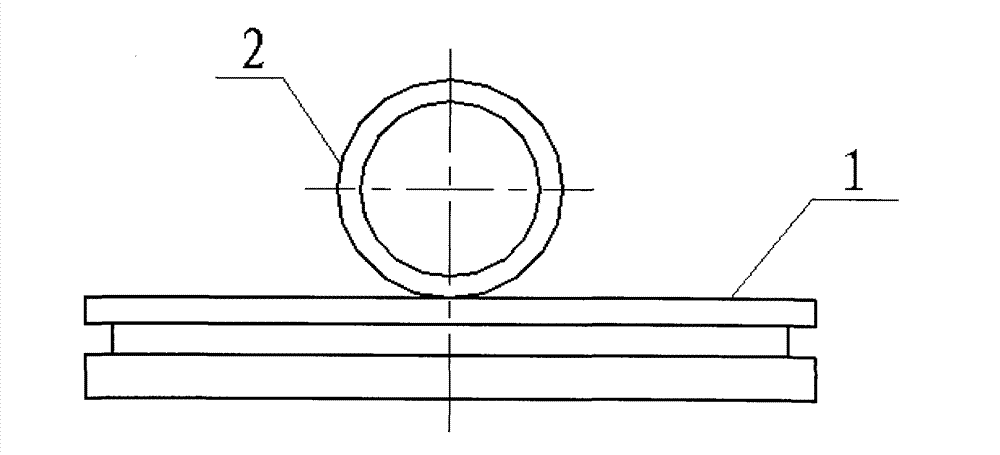

[0009] In this method, according to the inner diameter of the steel pipe at the branch pipe port, a piece of round steel is processed into the shape shown in the attached figure. The outer diameter of the round steel is 1mm smaller than the inner diameter of the steel pipe. A groove is processed in the middle of the round steel, and the groove is used to assemble the rubber O-ring. , The outer diameter of the O-ring is 1mm larger than the inner diameter of the steel pipe, and the round steel is welded with a steel pipe (2) for easy access. Make the tooling, put the tooling corresponding to the specification of the branch pipe into the inside of the branch pipe and clamp it tightly, and then paste the rubber pad on the flange. When a projectile enters the interior of the branch pipe from the flange and the rubber pad, the projectile can be sucked out with a magnet.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com