Shot blasting machine special for outer wall of cylinder steel pipe

A shot blasting machine and a technology for shot blasting, which are used in used abrasive treatment devices, abrasive jet machine tools, abrasives, etc., can solve problems such as low work efficiency, large damage to dust removal devices, and increased maintenance costs. The effect of good dust removal, improving shot blasting effect and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

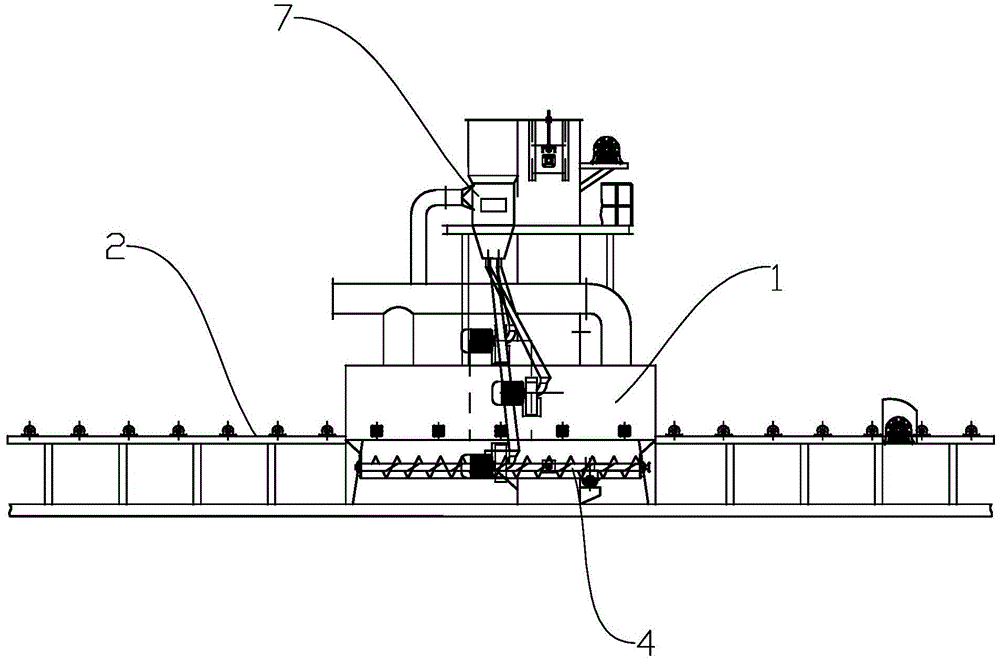

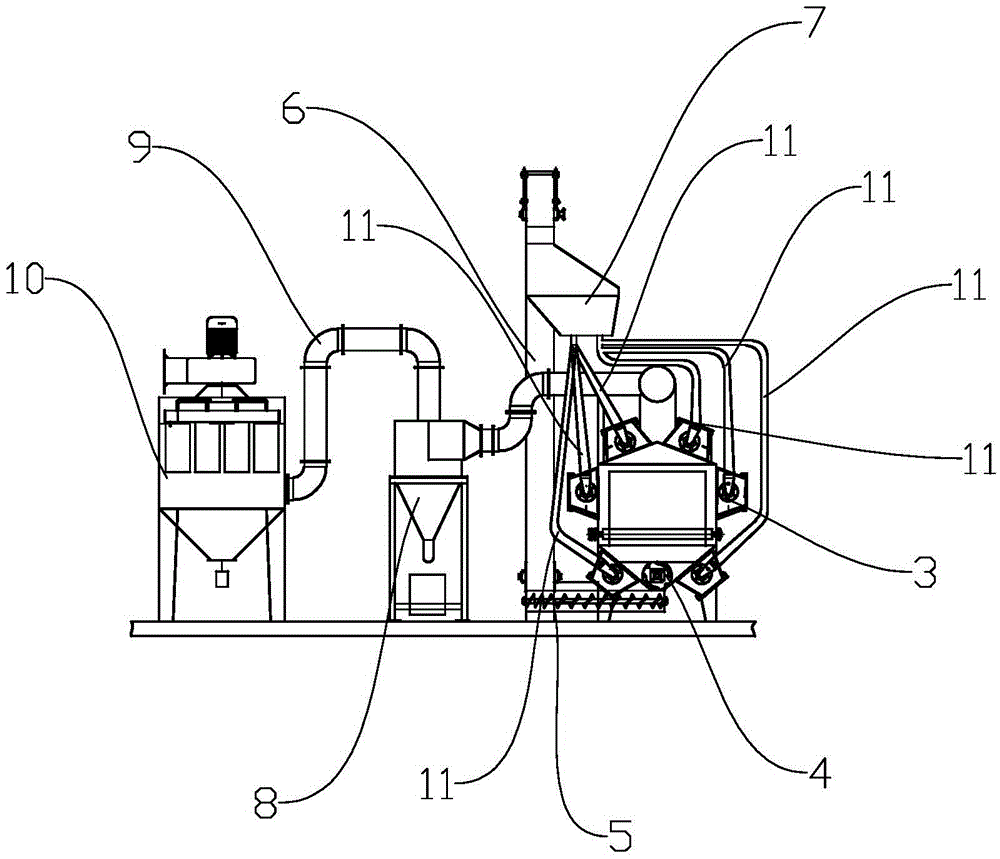

[0013] As shown in the figure: a special shot blasting machine for the outer wall of a steel cylinder steel pipe, including a shot blasting chamber 1, a steel cylinder steel pipe conveying mechanism passing through the front and rear ends of the shot blasting chamber 1, and a shot blaster installed in the shot blasting chamber 1 3. The steel shot recovery mechanism arranged at the bottom of the shot blasting chamber 1, the steel shot lifting device 6 arranged on one side of the shot blasting cleaning chamber 1, the shot sand separation device 7 connected to the top of the steel shot lifting device 6; the steel cylinder The steel pipe conveying mechanism is a parallel roller conveying mechanism 2, the end surface shape of the inner cavity of the shot blasting cleaning chamber 1 is a hexagonal structure, and a shot blasting device 3 is respectively installed on the six inner walls of the shot blasting cleaning chamber 1 .

[0014] The bottom of the shot blasting chamber 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com