Method for preparing vanadium nitride and device

A vanadium nitride and fluidization technology, applied in chemical instruments and methods, nitrogen-metal/silicon/boron binary compounds, vanadium compounds, etc., can solve problems such as low efficiency and long production cycle, and achieve a simple process method. , High production efficiency, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

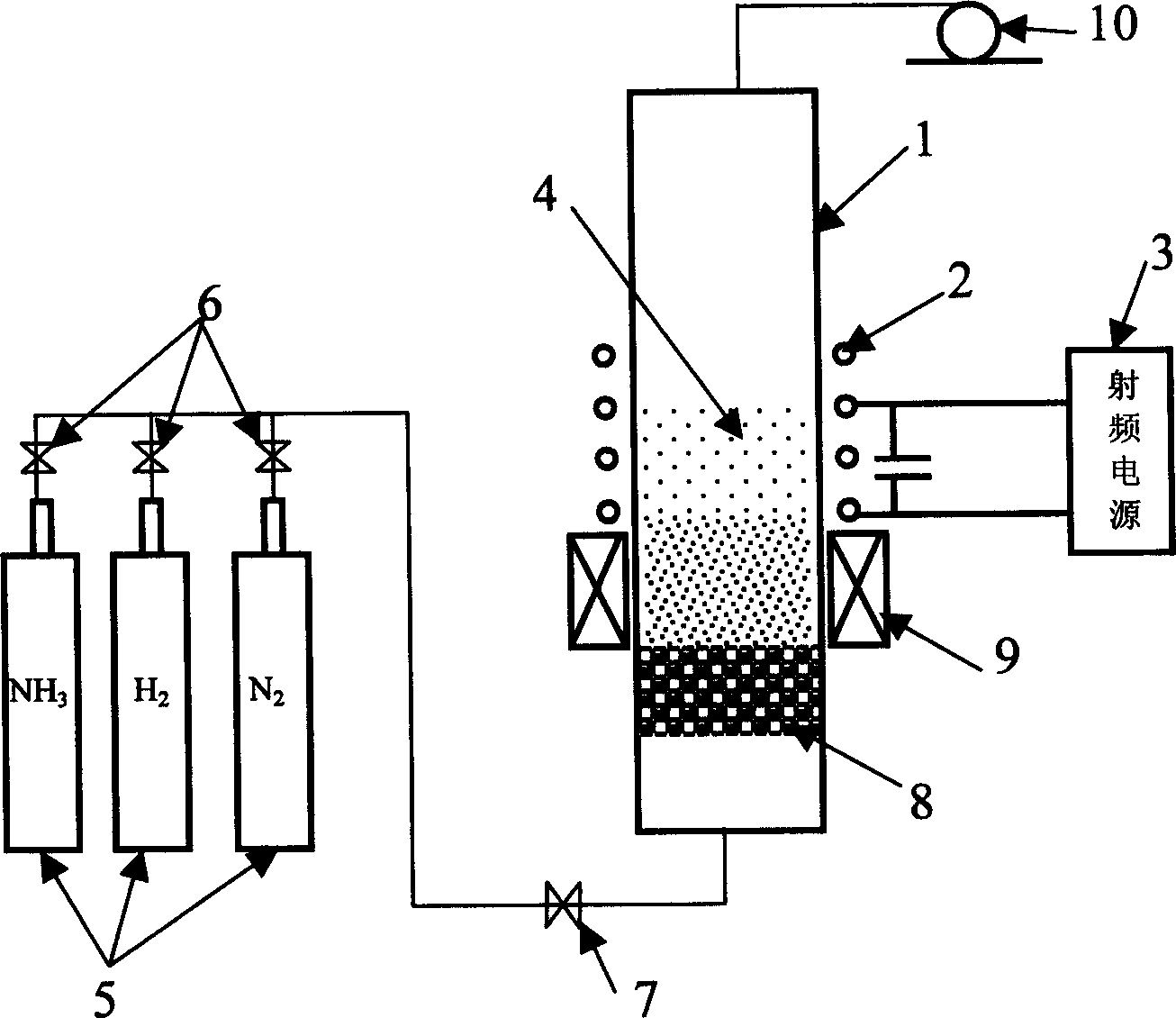

[0018] Embodiment 1: In this embodiment, the above-mentioned fluidized bed technology is adopted, and a radio frequency power supply is used to inductively excite the plasma in the reaction zone, and the gaseous molecules in the reaction gas are excited into active particles such as hydrogen and nitrogen ions with strong chemical activity. , so that these active particles interact with the vanadium oxide particles suspended in the reaction zone to form vanadium nitride.

[0019] The special device of the method of the present invention is as mentioned above, and this device has a fluidized bed 1 that airtight reaction vessel constitutes, and the radio frequency induction coil 2 is housed outside the fluidized zone position of reaction vessel, is arranged on the side of induction coil 2 There is a radio frequency power supply 3, which induces plasma in the reaction zone through the induction coil 2, and activates the reaction gas; on the other side of the fluidized bed 1, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com