Heating method of preventing for high-carbon steel blank or steel ingot from decarbonizing

A heating method and billet technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as waste of energy, slow heating of billets, and insufficient oxygen, and achieve the effects of increased labor intensity, short heating time, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

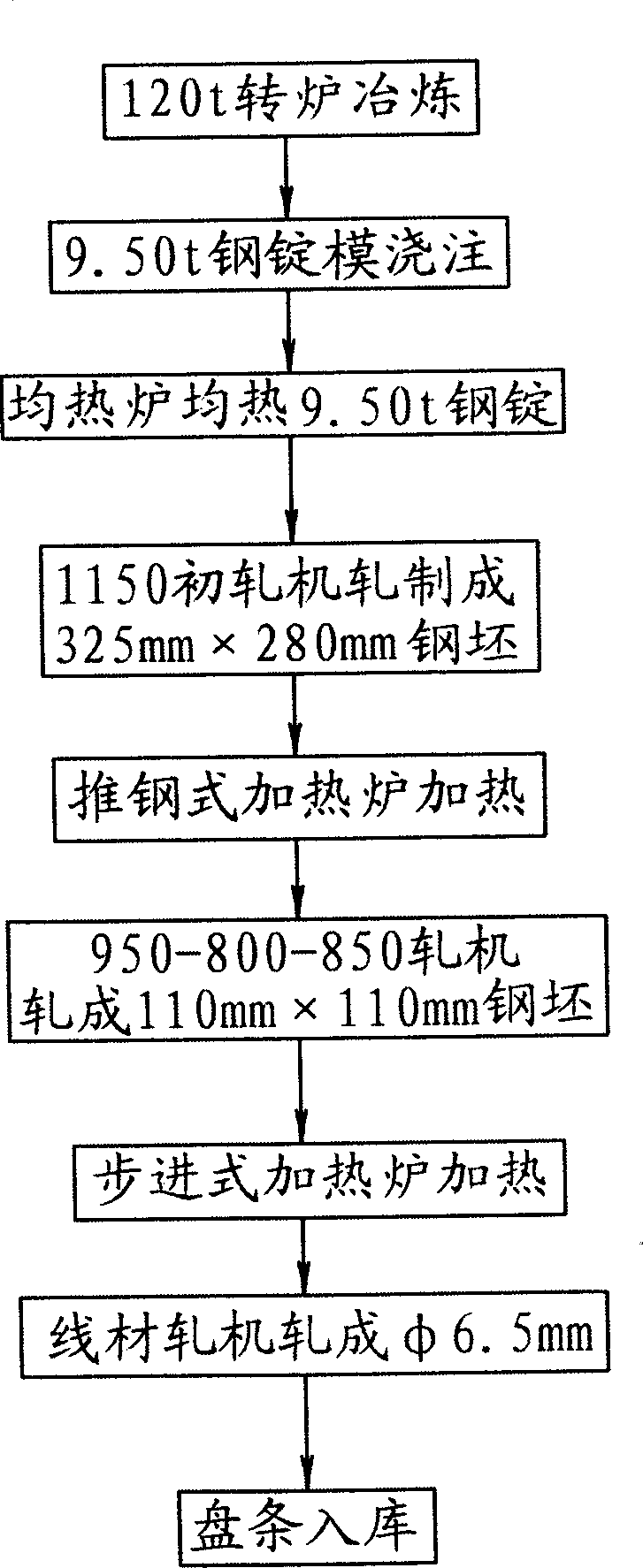

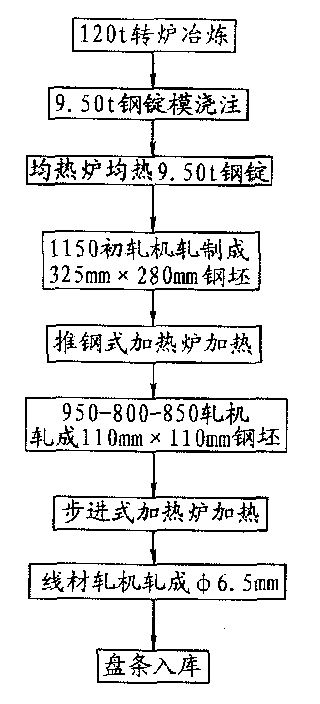

[0023] When producing T11A (carbon range 1.05~1.14%) φ6.5mm wire rod figure 1 process flow.

[0024] heating furnace

Maximum furnace temperature °C

Maximum billet temperature ℃

Air excess coefficient

Total heating time (min)

Preheating section

Heating section

soaking section

1050~1100

1200~1250

1150~1200

≤700

700~1250

1150~1180

1.2~1.4

50~70

[0025] The specific description for the above table is as follows:

[0026] ①When the walking heating furnace heats a 110mm×110mm steel billet, in the three stages of preheating, heating period and holding period of the whole heating process, the strong oxidizing oxygen atmosphere of the method of the present invention is used for heating, and the air in the strong oxidizing atmosphere is excessive The coefficient (the ratio of air to gas) is controlled between 1.2 and 1.4.

[0027] ②When the 110mm×110mm billet is in the preheating period ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com