Charging and heating method and system of charging-type hybrid electric vehicle power battery

A technology for hybrid electric vehicles and power batteries, applied in electric vehicles, battery/fuel cell control devices, vehicle energy storage, etc., can solve problems such as insufficient charging performance, failure to consider the maximum output charging power of the charger, and waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

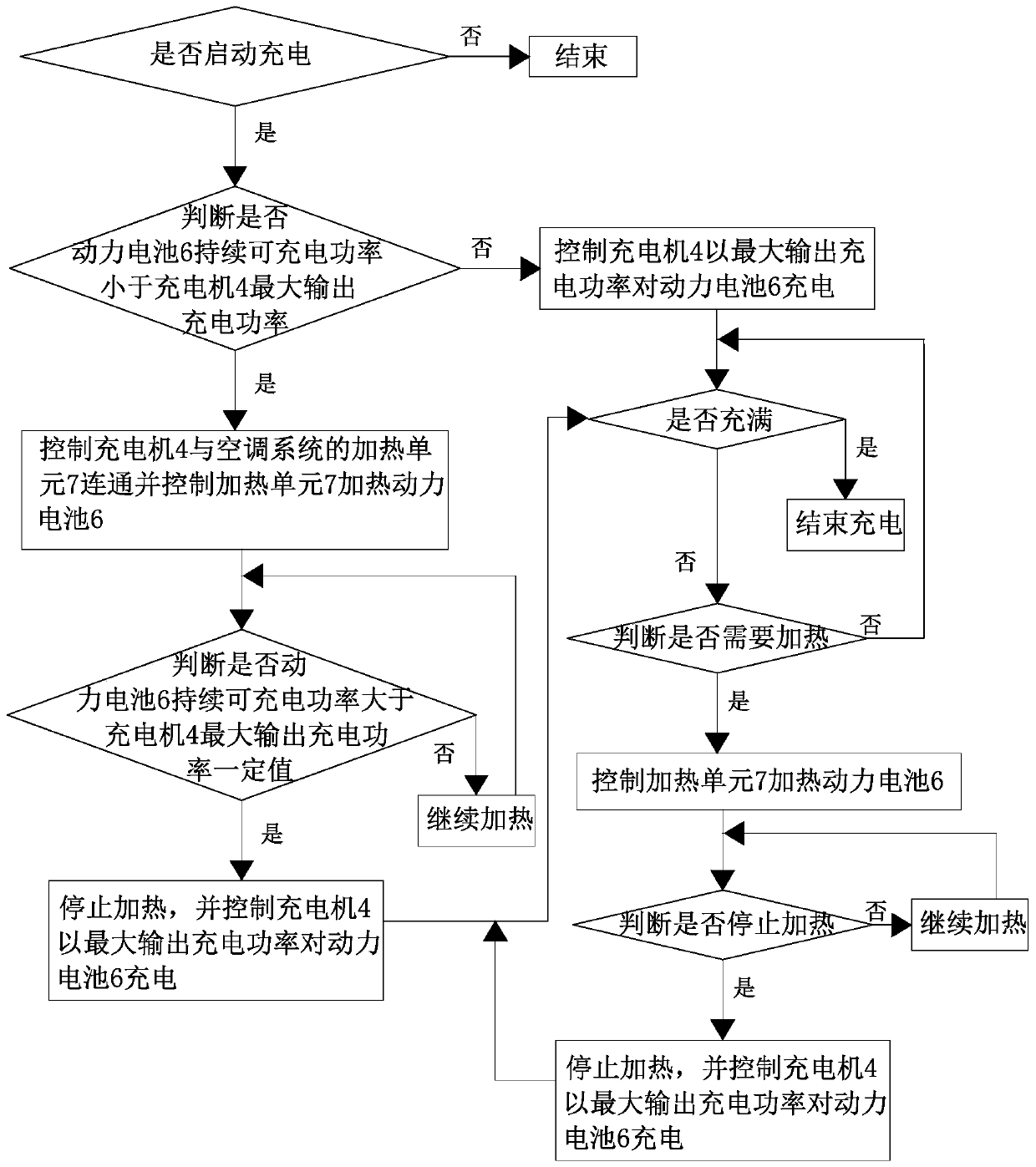

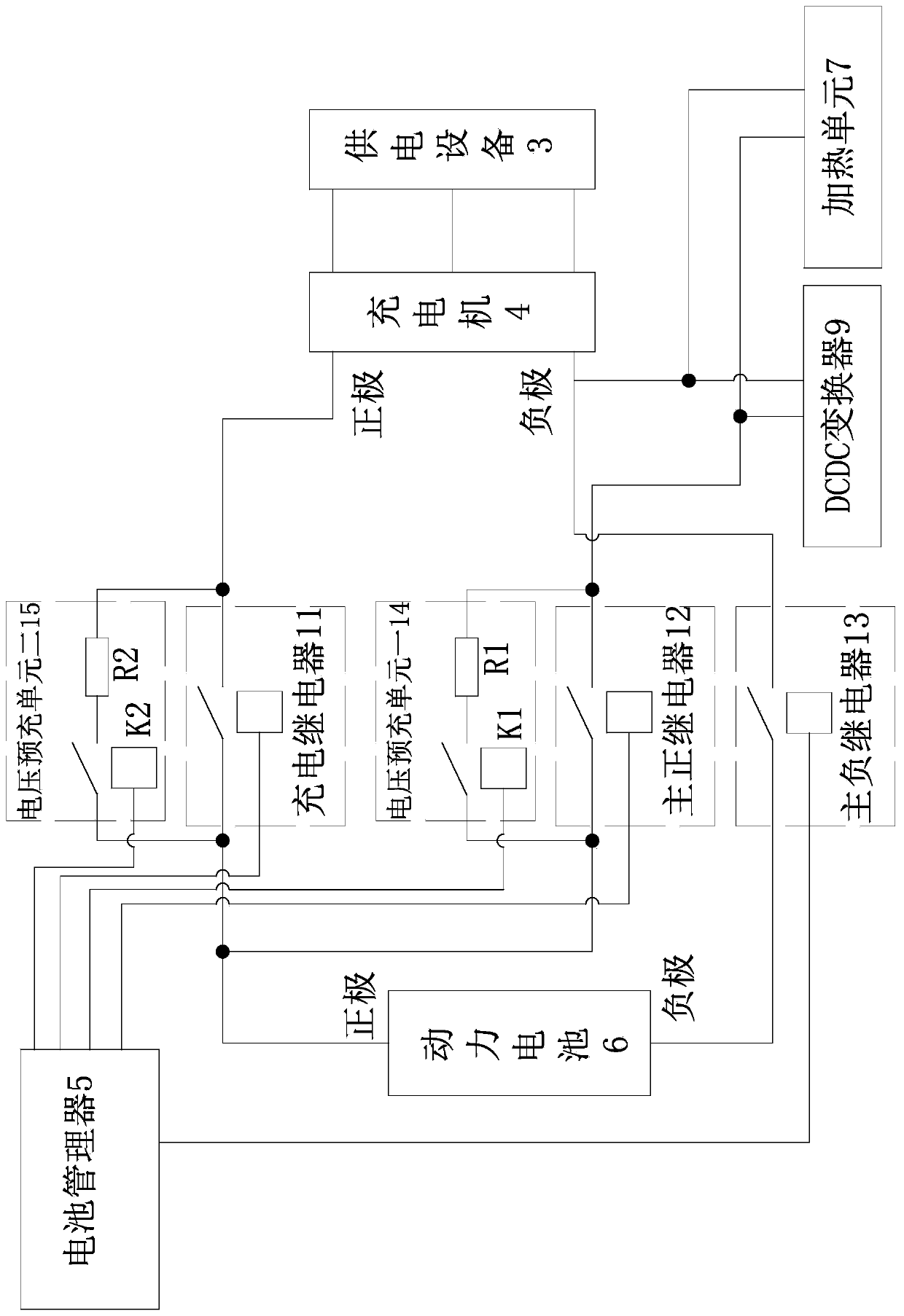

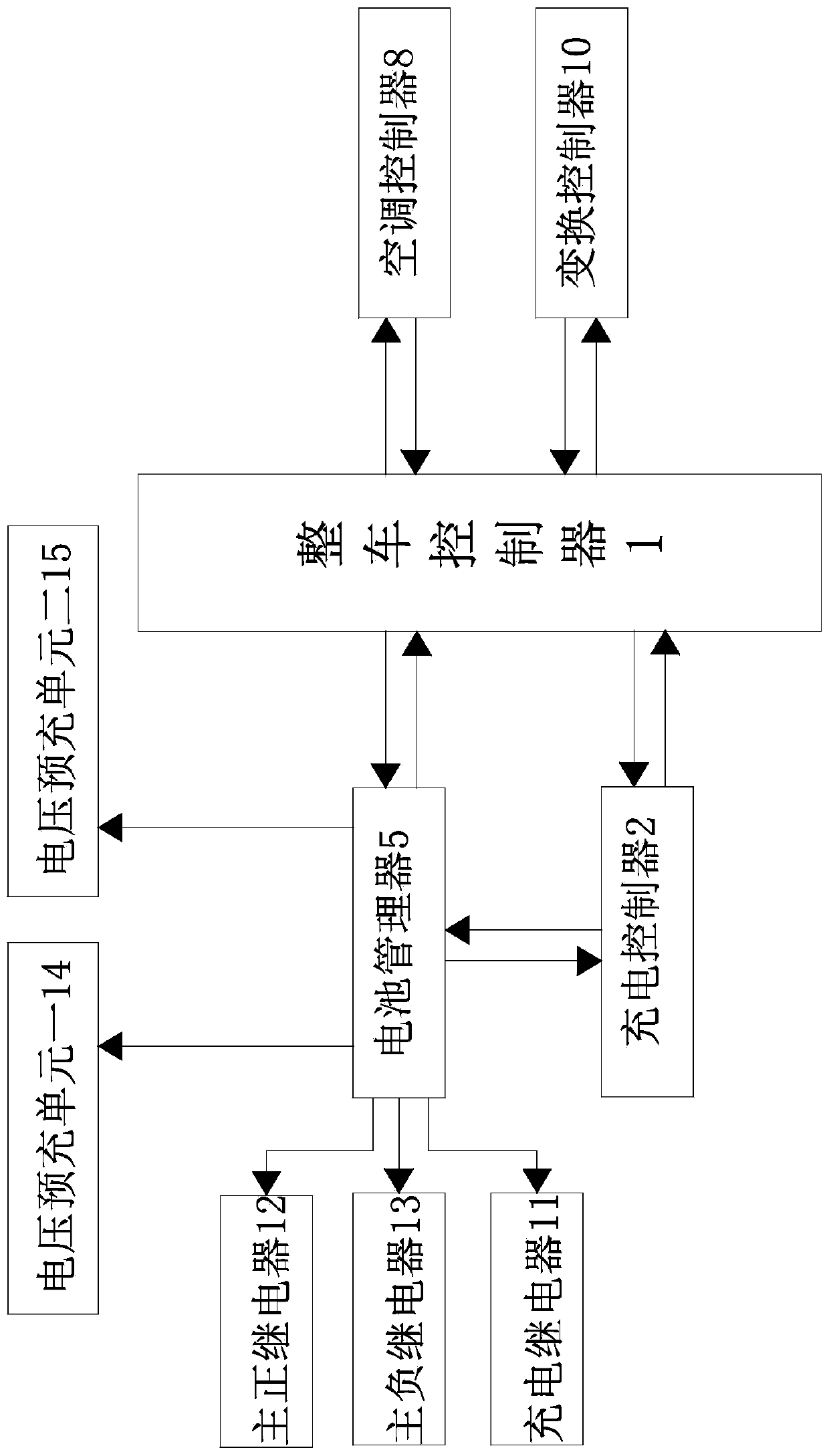

[0036] Such as figure 1 , figure 2 and image 3 As shown, a method for charging and heating a power battery of a plug-in hybrid electric vehicle, the method comprises the following steps:

[0037]Step A, start charging: the charge controller 2 calculates the maximum output charging power of the charger 4 in real time after the power supply device 3 is connected to the charger 4, and outputs the charging insertion signal and the maximum output charging power of the charger 4 to the battery manager 5 and the whole Car controller 1. The charging controller 2 receives the signal sent by the power supply device 3 to identify the maximum available current of the power supply device 3, and obtains the input voltage of the power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com