Method for extracting and separating high-purity cannabidiol from low-content industrial hemp floral leaves

A technology of cannabidiol and industrial hemp, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of poor separation effect of cannabinoids, poor production of complete sets, large investment in equipment, etc., and achieve improvement The effects of high sample load, increased content, and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

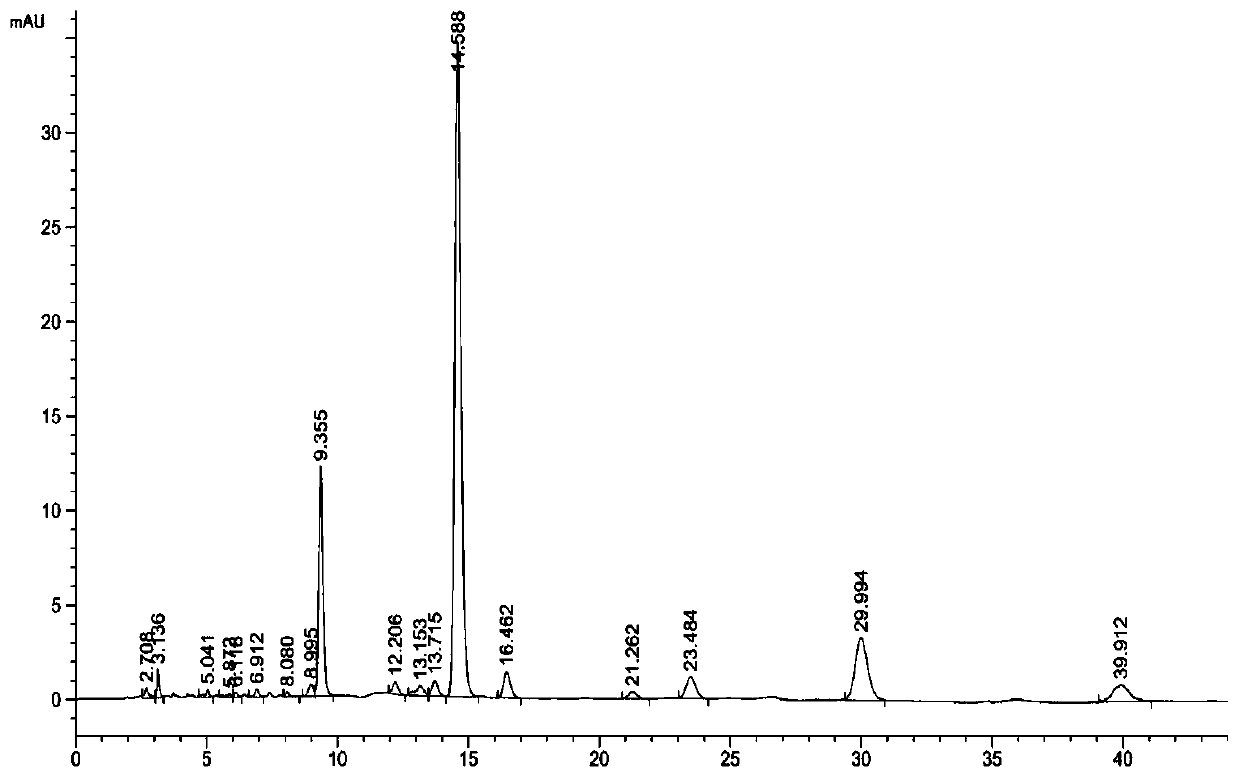

[0107] Extraction: 500g of industrial hemp flowers and leaves with a CBD content of 0.6% (w / w), crushed to an average particle size of 1mm, passed through a sieve to obtain 400g of powder, added 2.4L of pure water, stirred, heated to 70°C, and kept for 4h , filter; add 2.4L 30% (V / V) ethanol to the filter residue, stir, heat up to 70°C, keep warm for 4h, filter; add 2L 90% (V / V) ethanol to the filter residue, stir, heat up to 70°C , keep warm for 4 hours, filter, and collect the filtrate; then add 2L of 90% (V / V) ethanol to the filter residue, stir, heat up to 70°C, keep warm for 4 hours, filter, and combine the filtrates to obtain 4L of extract. 45°C, 100mbar, concentrated to 0.26L by rotary evaporation. The concentration of CBD in the suspension after liquid phase detection and concentration is 8.8g / L, and the extraction rate is 95.3%. figure 1 .

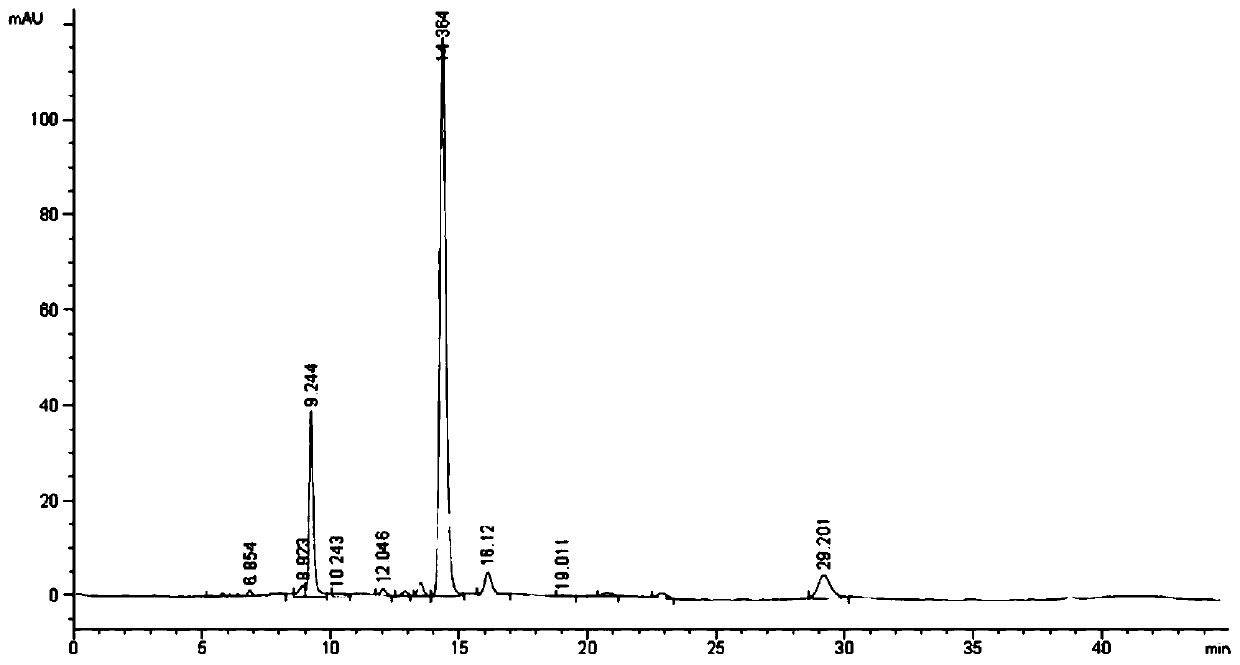

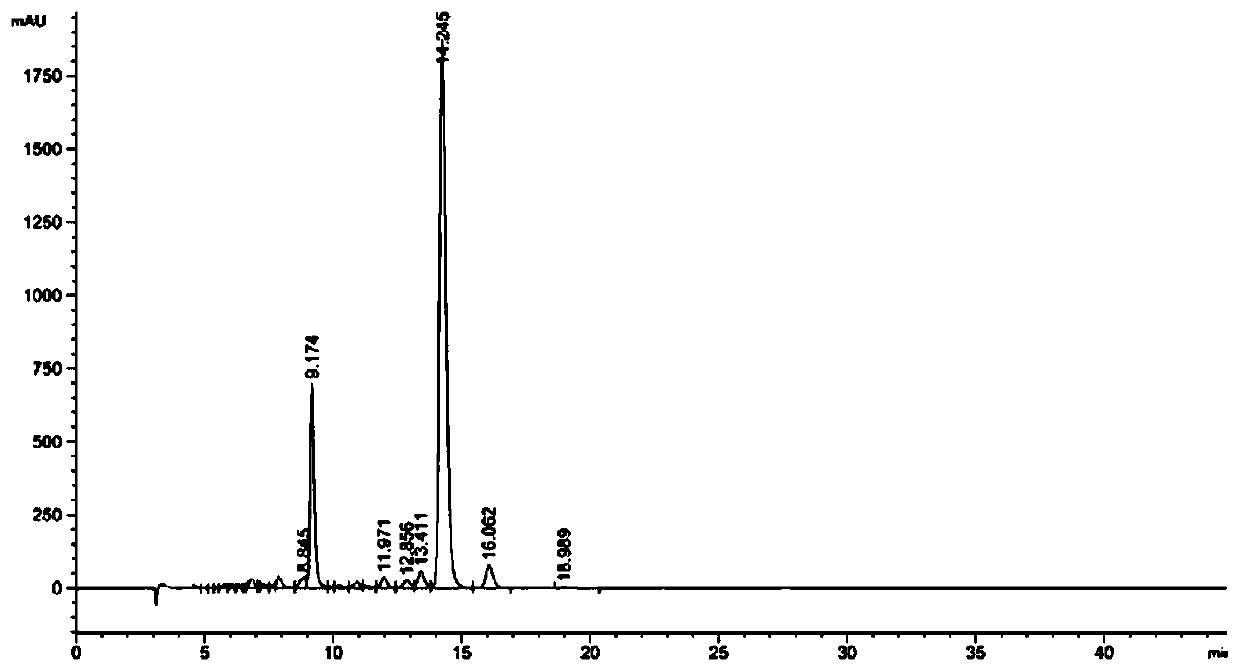

[0108] Adsorption and analysis of macroporous resin: 45mlLX-T83 (produced by Xi'an Lanxiao Technology New Materials Co., Ltd.)...

Embodiment 2

[0112] Extraction: 500g of industrial hemp leaves with CBD content of 0.5% (w / w), crushed to an average particle size of 0.5mm, added 3.2L of purified water, stirred, heated to 20°C, kept for 3.5h, filtered; poured into the filter residue Add 3.2L 10% (V / V) methanol, stir, heat up to 20°C, keep warm for 3.5h, filter; add 3.2L 90%(V / V) methanol to the filter residue, stir, heat up to 40°C, keep warm for 2h, Filter and collect the filtrate; then add 3.2L of 90% (V / V) methanol to the filter residue, stir, heat up to 40°C, keep warm for 2h, filter, and combine the filtrates to obtain 6.4L of extract. 45°C, 100mbar, concentrated to 0.52L by rotary evaporation. The concentration of CBD in the suspension after liquid phase detection was 4.6g / L, and the extraction rate was 96.2%.

[0113] Adsorption and analysis of macroporous resin: 45ml of LX-T83 (produced by Xi'an Lanxiao Technology New Material Co., Ltd.) macroporous resin is wet-packed with 40% (V / V) methanol aqueous solution, t...

Embodiment 3

[0117] Extraction: 500g of industrial hemp flowers and leaves with a CBD content of 1% (w / w), crushed to an average particle size of 1mm, add 4L of pure water, stir, heat up to 30°C, keep warm for 3h, filter; add 4L10 to the filter residue % (V / V) n-propanol, stir, heat up to 30°C, keep warm for 3h, filter; add 4L 95% (V / V) n-propanol to the filter residue, stir, heat up to 50°C, keep warm for 2h, filter, Collect the filtrate; add 4L of 95% (V / V) n-propanol to the filter residue, stir, heat up to 50°C, keep warm for 2h, filter, and combine the filtrates to obtain 8L of extract. 45°C, 100mbar, concentrated to 0.56L by rotary evaporation. The concentration of CBD in the suspension after liquid phase detection and concentration was 8.5g / L, and the extraction rate was 95.2%.

[0118] Adsorption analysis of macroporous resin: 45ml LX-22 (produced by Xi'an Lanxiao Technology New Materials Co., Ltd.) macroporous resin is wet-packed with 40% (V / V) n-propanol aqueous solution, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com