Sleeve type rod-shaped fuel assembly and supercritical water-cooling nuclear reactor utilizing same

A fuel assembly and nuclear reactor technology, which is applied in the assembly of fuel elements, reactors, reactor fuel elements, etc., can solve the problems of increasing the complexity of components, and achieve the effects of improving reliability and safety, good economy, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

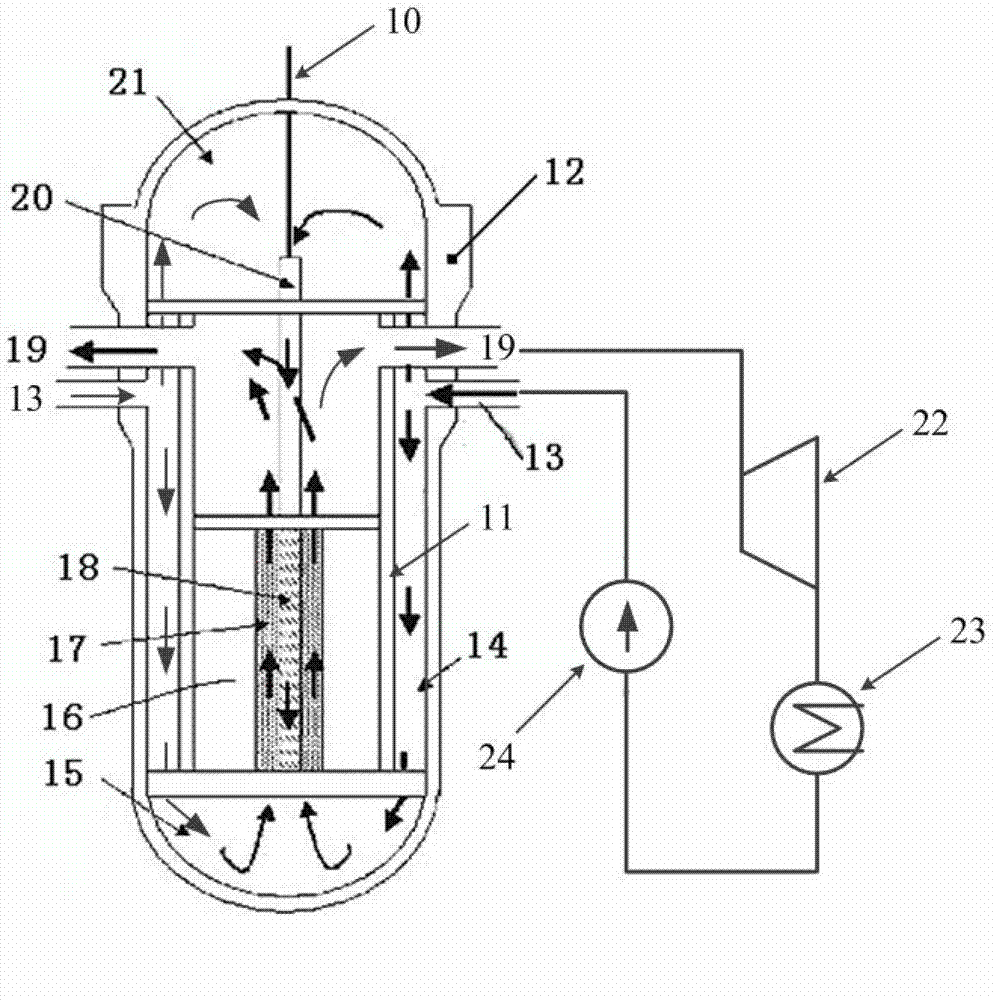

[0031] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

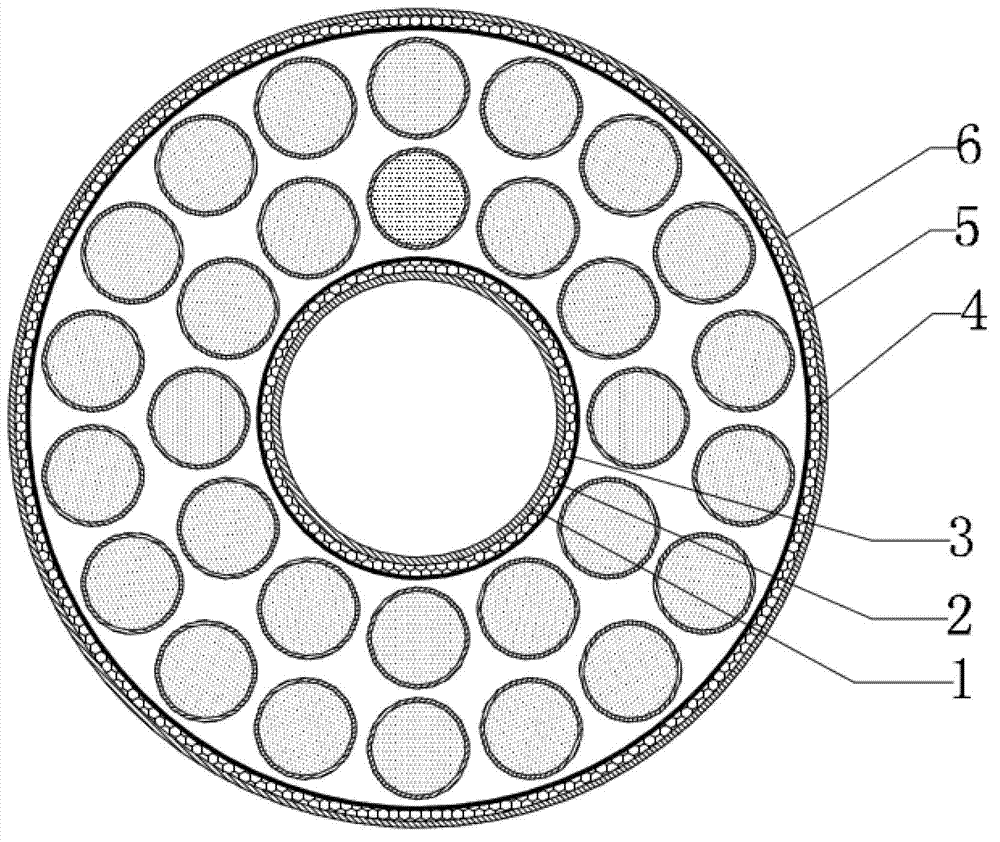

[0032] Such as figure 1 As shown, the present invention is a casing-type rod-shaped fuel assembly. The fuel assembly is in the form of an annular casing, and there are six rings from the inside to the outside. The ring liner 4 , the outer heat insulation layer 5 and the assembly wall 6 are filled with fuel between the inner ring liner 3 and the outer ring liner 4 , and the fuel filled is the inner and outer circles of fuel rods.

[0033] Preferably, the material of the inner heat insulation layer 2 and the outer heat insulation layer 5 is zirconia.

[0034] Preferably, the material of the water tunnel wall 1 and the assembly wall 6 is silicon carbide.

[0035] Preferably, the inner ring liner 3 and the outer ring liner 4 are made of stainless steel or nickel-based alloy.

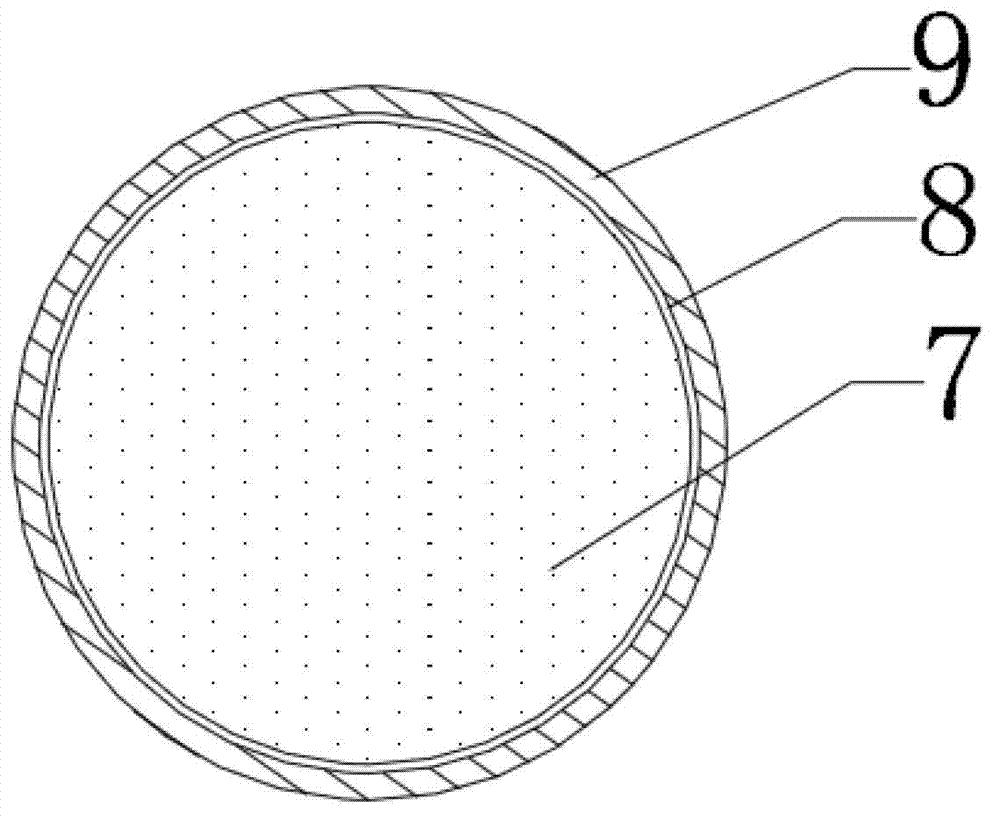

[0036] Such as figure 2 As shown, the fuel rod is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com