Method for recycling waste SCR (Selective Catalytic Reduction) catalyst

A technology of SCR catalysts and blocks, which is applied in the field of waste catalyst recycling, can solve the problems of not effectively improving the separation rate and purity of compounds, prolonging the separation and purification process, and increasing processing costs, so as to reduce the enrichment of metal ions and shorten the process process, the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

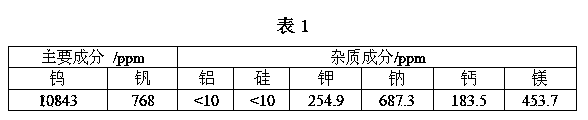

[0031] Take a waste honeycomb SCR catalyst from a power plant (size: 90 cm×15 cm×15 cm; service life: 36 months; the inlet end is severely worn; the middle part is cracked; the pore clogging rate is about 1 / 6), and use Blow the surface and pores with a compressed air gun for about 5 minutes, the air pressure is 0.5 MPa, and then use a high-pressure water gun to flush the catalyst pores from the inlet end. The water pressure is adjusted to 20 MPa, and the spraying time is 10 MPa. The catalyst was placed in a forced air drying oven, and the temperature was raised to 80 °C at a rate of 4 °C / min, and kept for 4 h. Take out the catalyst, cut out about 500 g of the catalyst block from the middle, crush it slightly with tweezers, put it into the trough of the rotary pulverizer, and after pulverizing for about 3 minutes, add 100 g of sodium carbonate, then turn on the pulverizer for about 3 minutes, and then Stop the pulverizer and take out the powder.

[0032] Put the mixed powder i...

Embodiment 2

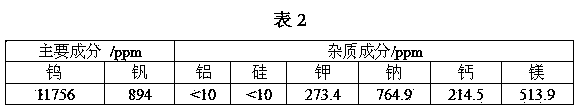

[0036]Take a waste honeycomb SCR catalyst from a power plant (size: 90 cm×15 cm×15 cm; service life: 36 months; the inlet end is severely worn; the middle part is cracked; the pore clogging rate is about 1 / 6), and use Blow the surface and pores with a compressed air gun for about 30 minutes at an air pressure of 0.1 MPa, then use a high-pressure water gun to flush the catalyst pores from the inlet end, adjust the water pressure to 5 MPa, and spray for 30 minutes. The catalyst was placed in a forced air drying oven, and the temperature was raised to 105 °C at a rate of 4 °C / min, and kept for 2 h. Take out the catalyst, cut out about 500 g of the catalyst block from the middle, crush it slightly with tweezers, put it into the trough of the rotary pulverizer, and after pulverizing for about 3 minutes, add 250 g of sodium carbonate, then turn on the pulverizer for about 3 minutes, and then Stop the pulverizer and take out the powder.

[0037] Put the mixed powder into an alumina ...

Embodiment 3

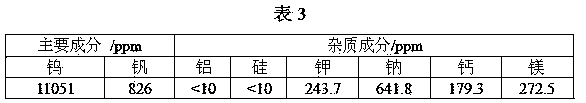

[0041] Take a waste honeycomb SCR catalyst from a power plant (size: 90 cm×15 cm×15 cm; service life: 36 months; the inlet end is severely worn; the middle part is cracked; the pore clogging rate is about 1 / 6), and use Blow the surface and pores with a compressed air gun for about 20 minutes at an air pressure of 0.3 MPa, then use a high-pressure water gun to flush the catalyst pores from the inlet end, adjust the water pressure to 20 MPa, and spray for 20 minutes. The catalyst was placed in a forced air drying oven, and the temperature was raised to 95 °C at a rate of 4 °C / min, and kept for 3 h. Take out the catalyst, cut out about 500 g of the catalyst block from the middle, crush it slightly with tweezers, put it into the trough of the rotary pulverizer, and after pulverizing for about 3 minutes, add 100 g of sodium carbonate, then turn on the pulverizer for about 3 minutes, and then Stop the pulverizer and take out the powder.

[0042] Put the mixed powder into an alumina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com