Garden plant waste composting method

A plant waste and composting method technology, which is applied in the direction of organic fertilizer, fertilization device, combined biological treatment, etc., can solve the problems that the quality of compost products has not been greatly improved, the storage of grass clippings is large, and the quality of compost products is low. Achieve the effect of harmless treatment, low production cost and fast fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

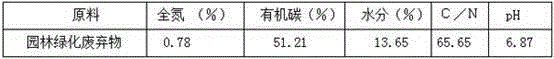

[0027] A garden plant waste composting method, comprising the following steps:

[0028] 1. Collection: Collect garden plant waste litter, lawn trimmings, street tree trimmings, weed seeds, and plant residues, sort the wastes, and cut branches;

[0029] 2. Chipping: the above-mentioned garden plant waste is chipped into pieces, and the particle size of the fragments is 4-9cm in length, 2-5cm in width, and 0.5-2cm in thickness;

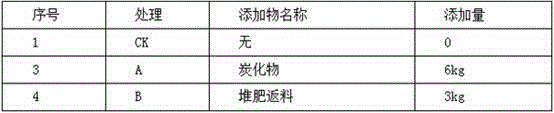

[0030] 3. One compost fermentation: put the above-mentioned sliced garden plant waste in the fermentation tank, add compost return material and EM inoculant, mix evenly and carry out a compost fermentation, the compost moisture mass fraction is 45%, and the compost oxygen concentration is 10%, the C / N ratio is 30:1, the fermentation temperature is 55°C, and the fermentation time is 10d to obtain a compost; the weight ratio of the EM inoculum and the compost return material is 1:5, and the compost during fermentation The length is 1.2m, the width is 1...

Embodiment 2

[0034] A garden plant waste composting method, comprising the following steps:

[0035] 1. Collection: Collect garden plant waste lawn trimmers, sort the waste, and cut branches;

[0036] 2. Chipping: the above-mentioned garden plant waste is chipped into fragments, and the particle size of the fragments is 4-9 cm in length, 2-5 cm in width, and 0.5-2 cm in thickness;

[0037] 3. One-time composting fermentation: put the above-mentioned sliced garden plant waste in the fermentation tank, add carbide and EM inoculant, mix evenly, and carry out one-time composting fermentation, the compost moisture content is 60%, and the stack oxygen concentration is 13%, the C / N ratio is 35:1, the fermentation temperature is 65°C, and the fermentation time is 13d to obtain a compost; wherein, the weight ratio of EM bacterial agent and carbide is 1:8; the length of the compost during fermentation 2m, width 1.8m, height 1.5m;

[0038] 4. Pulverization: The primary compost is pulverized into ...

Embodiment 3

[0041] A garden plant waste composting method, which comprises the following steps:

[0042] 1. Collection: Collect garden plant waste, street tree trimmings, weed seeds, and plant remnants, sort the waste, and cut branches;

[0043] 2. Chipping: the above-mentioned garden plant waste is chipped into pieces, and the particle size of the fragments is 4-9cm in length, 2-5cm in width, and 0.5-2cm in thickness;

[0044] 3. One-time composting fermentation: put the above-mentioned sliced garden plant waste in the fermentation tank, add composting material and EM inoculum, and perform a composting fermentation after mixing evenly. It is 15%, the C / N ratio is 32:1, the fermentation temperature is 58°C, and the fermentation time is 15d to obtain a compost; wherein, the weight ratio of the EM bacterial agent and the compost return material is 1:3, and during fermentation The length of the stack is 1.5m, the width is 1.3m, and the height is 1m;

[0045] 4. Pulverization: The primary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com