Three-dimensional environmentally-friendly fermentation system

A fermentation system, three-dimensional technology, applied in the field of three-dimensional environmental protection fermentation machine, to achieve the effect of shortening the fermentation cycle, increasing the contact area, and fully fermenting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For further elaborating the technical means and effects that the present invention takes to reach the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to its specific implementation, structure, feature and its specific implementation mode, structure, feature and Efficacy, detailed as follows.

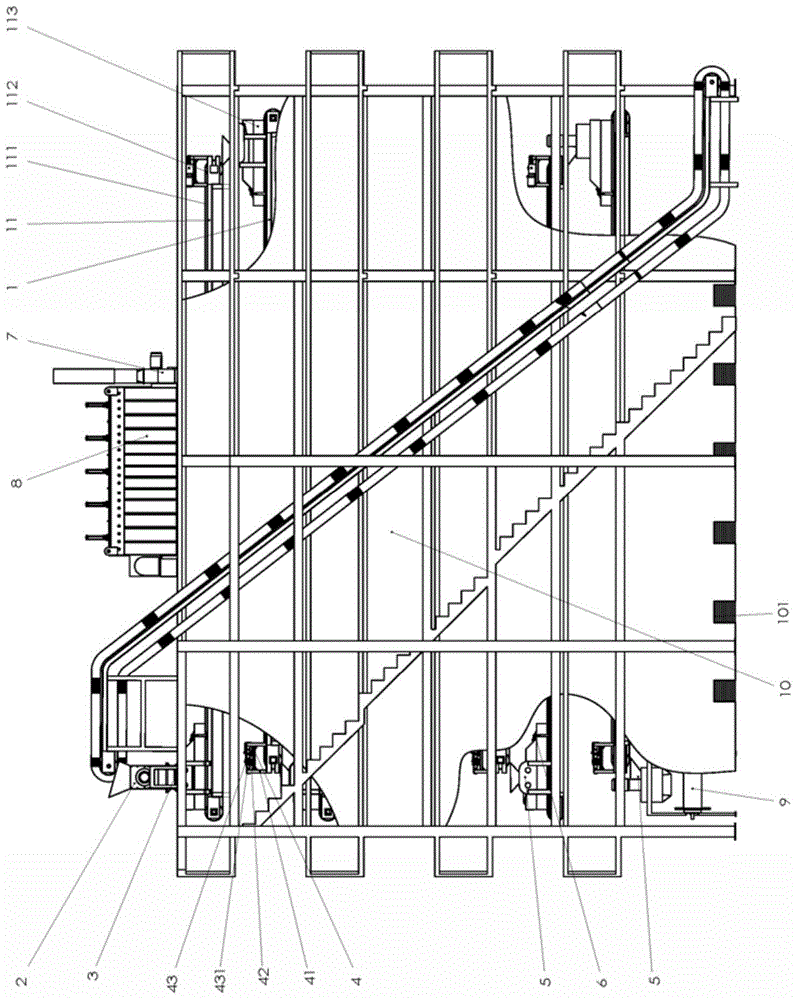

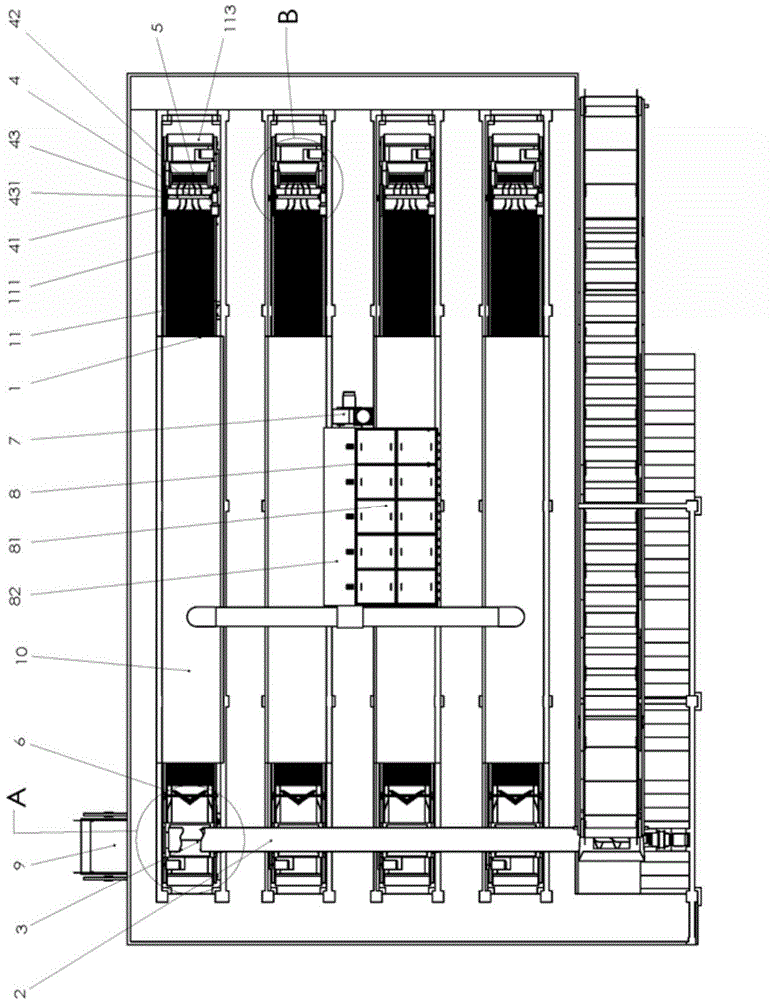

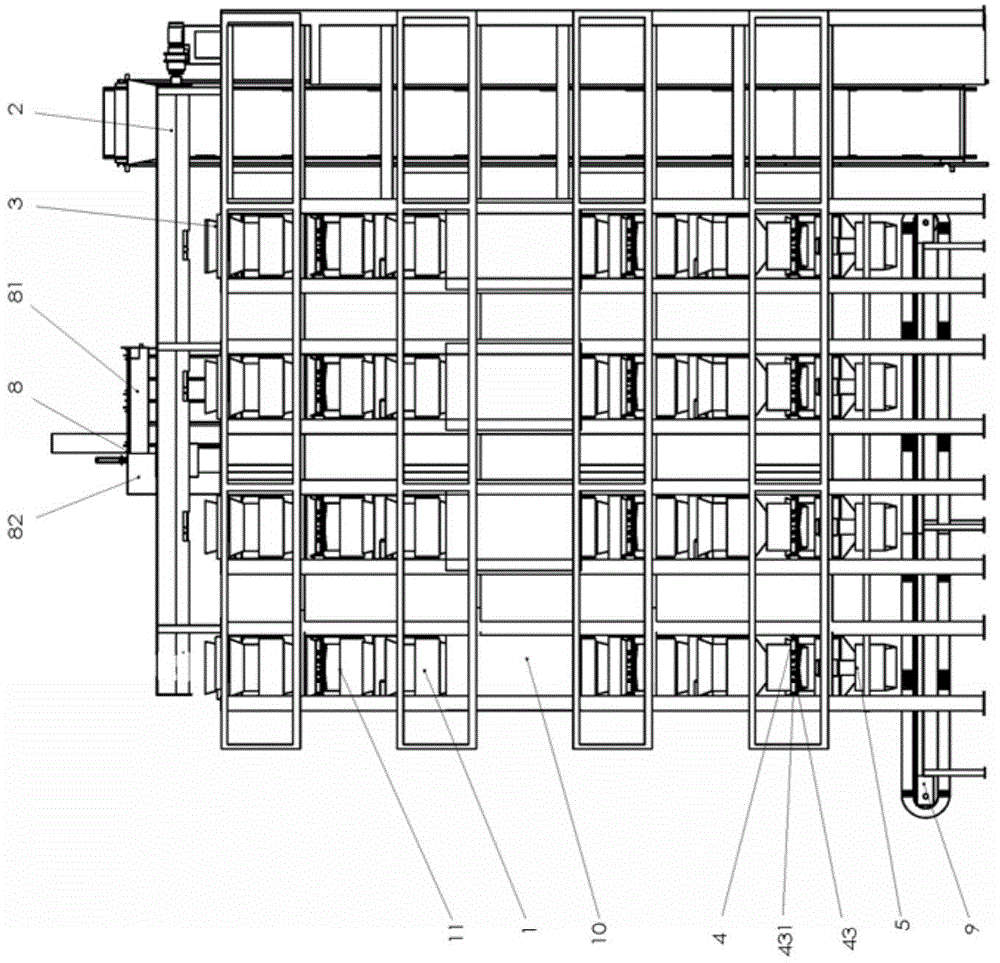

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7As shown, it is a three-dimensional environment-friendly fermentation system according to an embodiment of the present invention, which mainly consists of a conveyor unit 1, a feeding device 2, a material forming device 3, a material pre-crushing device 4, a crushing device 5, a horizontal material distribution device 6, and a ventilation device 7 , an exhaust gas purification device 8, a clinker conveyor 9, and a fermentation chamber 10; Each floor is provided with a conveyor 11, a material pre-crushing device 4, and a horizontal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com