Patents

Literature

47results about How to "Inoculation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast manufacture method for liquid strain

ActiveCN103168613AModerate viscosityVigorousHorticultureFertilizer mixturesLiquid mediumMonopotassium phosphate

The invention belongs to the technical field of biology deep fermentation technology and particularly relates to a fast manufacture method for liquid strain. The method comprises the steps that for a culture medium, rice powder serves as a carbon source, sugar serves as an auxiliary carbon source, corn powder serves as a nitrogen source, peptone and yeast extract (powder) serve as auxiliary nitrogen sources, monopotassium phosphate and magnesium sulfate serve as inorganic salts, and water serves as a carrier; a glass container serves as a culture container; inoculation is performed after a liquid medium is sterilized, and the liquid strain is obtained through a rotary type shaking table. The fast manufacture method for the liquid strain has the advantages that cheap plant starch is used as the main carbon source and the nitrogen sources, and nutrition-allocated proportion is reasonable and comprehensive; the prepared liquid medium is appropriate in viscosity; a culture period is short, and the liquid strain with good quality, strong vitality and different sizes can be cultured in 2-3 days; at the time of inoculation, the fast manufacture method for the liquid strain is simple, convenient and fast; when a solid culture material is inoculated, the material flows fast and is easy to scatter, many strain running points appear and germinate fast and the like.

Owner:酒泉百山农业开发有限公司

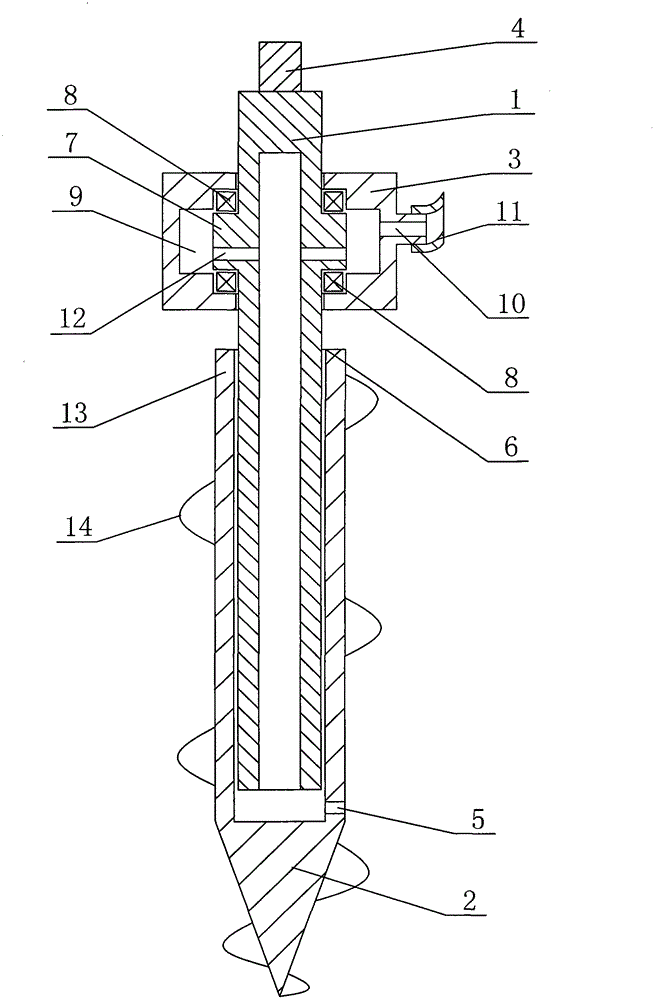

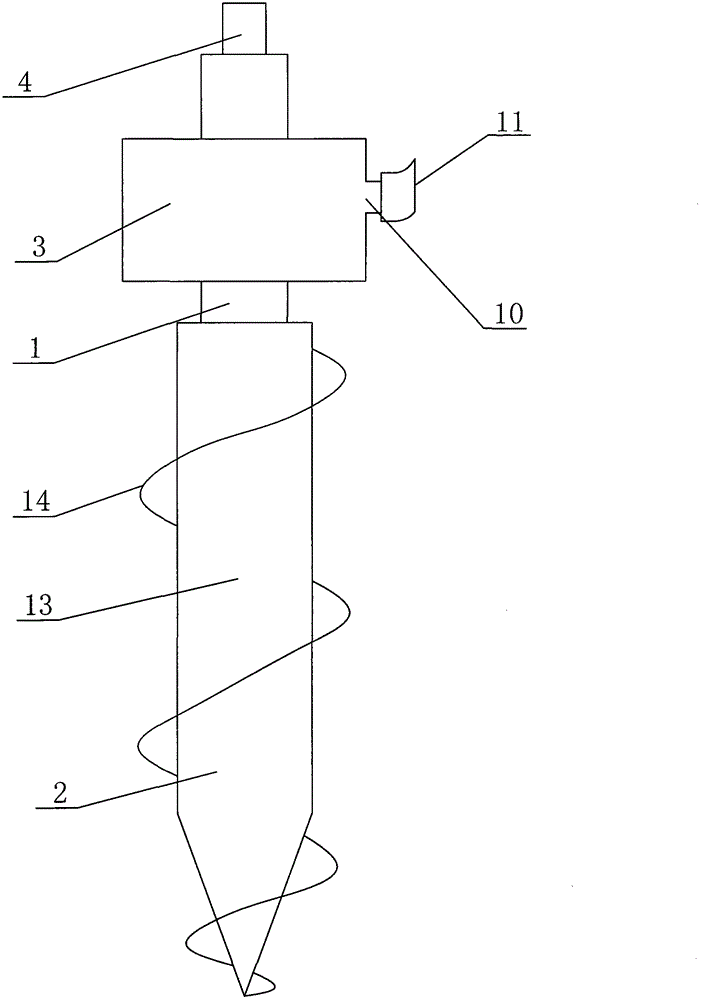

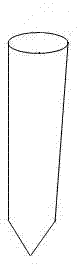

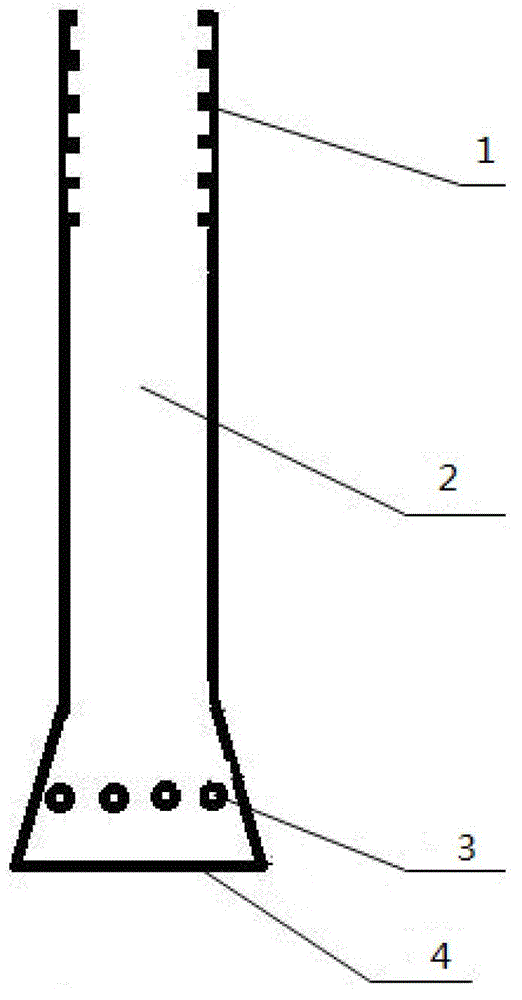

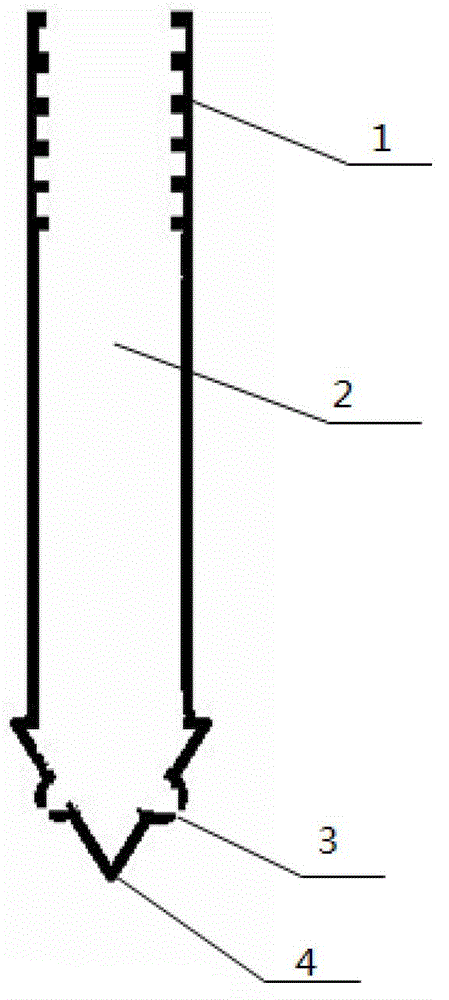

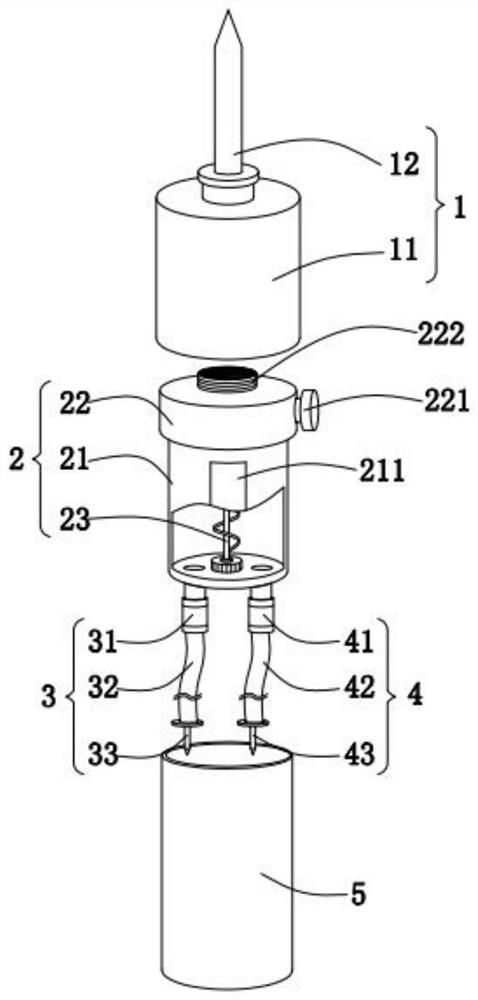

Efficient manual cistanche inoculation method and hollow drill for manual cistanche inoculation

The invention discloses an efficient manual cistanche inoculation method and a hollow drill for manual cistanche inoculation. The efficient manual cistanche inoculation method comprises the following steps of: (1) processing and carrying out quality detection of cistanche seeds; (2) preparing special nutritional soil containing cistanche; (3) preparing seed serous; and (4) drilling on soil, pressurizing and injecting the seed serous into soil holes, and compacting the soil in the holes, thus completing plantation. The hollow drill for the manual cistanche inoculation comprises a hollow drill shaft, a spiral drill coat, a feeding coat and a fixed drill handle. The efficient manual cistanche inoculation method has the advantages of extremely small soil excavation volume, small damage on root systems of host plants, high inoculation speed, low labor cost, irrigation water saving and high inoculation survival rate, thus being applicable to the condition of industrialization and scale plantation of haloxylon ammodendron and the cistanche.

Owner:内蒙古宏魁生物药业有限公司

Edible mushroom cultivation bar high-efficiency inoculating method

The invention relates to an inoculation method of an edible fungus, particularly to a highly efficient inoculation method of the cultivated stems of the edible fungus. The method comprises steps of: construction of a solar greenhouse plastic fungus producing shed; preparation of bagged fungus stems; preparation of medium: 82 percent of saw dust, 17 percent of wheat bran and 1 percent of gypsum; mechanical bagging, sterilization under atmospheric pressure and then moving into the fungus producing shed for cooling; inoculation in the fungus producing shed: after routine sterilization, cooled fungus stems are piled in single layer from east to west, 4 pores are pricked on each stem, then inoculation is carried out and thin film is used for covering. After the first layer of the stems are inoculated, piling in single layer is carried out again from east to west and then inoculation is carried out, and repeat the operation; each pile has 10 to 12 layers; the fungus stems after being inoculated are kept immovable at original places for hypha growing, piles are shifted when the hypha seals the pores of strain or connects with each other, and turn into fungus growth management. The inoculation method of the invention has the advantages that: integrates the inoculation place and the hypha growing and fungus producing place, reduces costs of equipment and manpower, needs no externally sleeved bag, thus saving time, labor and cost; allows cooperation of a plurality of people, thus increasing production efficiency by 1 time; has high inoculation speed, thus reducing the settling probability of mixed bacterium and high rate of finished products. Therefore, the method is applicable to scaled cultivation or factory production.

Owner:TIANJIN JIYA ANIMAL HUSBANDRY GRP

Method for cultivating cistanche tubulosa in greenhouse

InactiveCN101946619AIncrease vaccination rateInoculation speedHorticultureWarm waterIntensive management

The invention discloses a method for cultivating cistanche tubulosa in a greenhouse, belonging to the technical field of plant cultivation. The method comprises the following steps: cutting tamarix chinensis in the greenhouse in spring in the first year, simultaneously inoculating the cistanche tubulosa, and carrying out reasonable light warm water fertilizer management after inoculating; and digging the cistanche tubulosa medicinal materials in autumn in the next year or harvesting seeds after the tamarix chinensis bears fruits in spring in the third year, wherein, the cultivation condition after inoculating is natural illumination, the indoor temperature is 18-32 DEG C, and the soil water content is 50-70%. The cultivation method carries out intensification management in the greenhouse, and has the advantages of simple and convenient operation, high cistanche tubulosa vaccination rate, rapid inoculation speed, short production period, high yield, and no freeze injury in winter.

Owner:CHINA AGRI UNIV

Pholiota nameko inoculation method

InactiveCN106212049AReduce manufacturing costIncrease productionHorticulturePholiotaInoculation methods

The invention discloses a pholiota nameko inoculation method, and the method comprises the steps of (1) bacterial strain preparation; (2) medium preparation; (3) medium packaging, namely packaging a medium in material bags, then sealing and punching holes, then pasting a sticker for oxygen supply, thereby obtaining a cultivation bag; (4) disinfection at normal pressure; (5) cooling; and (6) inoculation, namely pushing a pre-cooled cultivation bag into an inoculation chamber; then conducting aerosol disinfection again; making a hole on the bottom of the branch bacterial strain material bag; two person working together as a group, wherein one is responsible for inserting a branch bacterial strain in the cultivation bag rapidly and the other for pasting the sticker any time; culture management; bag opening; and accelerating germination management etc. According to the method, spawn running time can be shortened to 41-60d; the inoculation speed is fast; the pollution rate is greatly reduced; the produced pholiota nameko has a high yield and a complete and beautiful appearance; the production cost is low; and the method is suitable for scale production I factories.

Owner:莒县鑫垚食用菌研究所

Pholiota nameko three-grade seed production method taking amorpha fruticosa braches as base raw materials

ActiveCN104521558APromote growthPrevent agingGrowth substratesCulture mediaPholiotaAmorpha fruticosa

The invention discloses a pholiota nameko three-grade seed production method taking amorpha fruticosa braches as base raw materials. The pholiota nameko three-grade seed production method comprises the following steps: obtaining branch wood sections, treating the branch wood sections, distributing wheat bran on the branch wood sections, preparing an auxiliary culture base material, forming a strain material bag, sterilizing at high pressure and inoculating. The auxiliary culture base material is prepared from the following materials in percentage by mass: 72%-85% of saw dust, 15%-25% of wheat bran, 0.5%-2% of gypsum and 0.5%-2% of lime; water is added into the materials and is uniformly mixed, and the moisture content is controlled to be about 65%. By the aid of the method for preparing pholiota nameko three-grade seeds, the fungi growth time can be shortened for 20-30 days, the inoculating speed is rapid and the pollution rate is greatly reduced; mycelia are thick and dense and grow vigorous; strains on the upper part can be prevented from being aged and the strain preservation period is prolonged by more than 30-40 days.

Owner:RIZHAO HENGJIUFENG AGRI TECH CO LTD

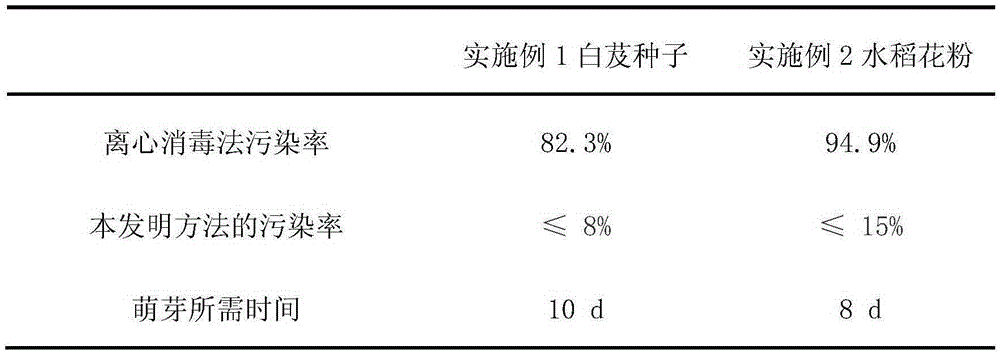

Disinfection and inoculation method of microphyte seeds and pollen

InactiveCN105325287AOvercoming major difficulties such as difficulty in inoculationConducive to cultivationPlant genotype modificationDisinfectantContamination rate

The invention discloses a disinfection and inoculation method of microphyte seeds and pollen. A special disinfection and inoculation technology for small seeds and plant pollen in a tissue culture process is designed by utilizing seeds and plant pollen of microphytes including orchids as materials in combination of a disinfection method of the tissue culture technology and tools such as an injector and the like; according to the technology, the problems that effective disinfection cannot be realized and a disinfectant cannot be completely removed due to too small orchid seeds and most plant pollen are solved, and the contamination rate in the tissue culture can be effectively reduced to be lower than 5%. Besides, with the adoption of the technology, disinfection and inoculation speeds can be greatly increased, meanwhile, due to the fact that a low-concentration sodium hypochlorite solution can effectively destroy seed coats of the microphyte seeds and cell walls of the pollen and cannot damage seed embryos and pollen cells, accordingly, the microphyte seeds of the plants such as the orchids and the like or the pollen cells of the plants can absorb nutrition of a culture medium more easily, and the seeds germinate 3-5 days in advance.

Owner:YANGTZE UNIVERSITY

Method for producing oyster mushroom strains from birch chopsticks

The invention discloses a method for producing oyster mushroom strains from birch chopsticks. The method comprises four steps of: performing pretreatment on the chopsticks, preparing a culture medium for the chopsticks, performing inoculation culture and transferring the strains. According to the method disclosed by the invention, by carrying out pretreatment on the birch chopsticks, on the one hand, harmful substances in the birch chopsticks can be fully decomposed, and on the other hand, convenience is brought to the insertion of the birch chopsticks into a mycelium mass during the inoculation. When a culture medium for the birch chopsticks is prepared, as birch contains a large number of nutrient components required for growth of oyster mushrooms, only sucrose, a compound fertilizer, wheat bran and corn flour need to be further added, therefore the components in a nutrient solution are greatly simplified and the preparation process is also trouble-saving and effort-saving. When the inoculation is performed, only the chopsticks need to be directly inserted into the mycelium mass for completion, the operation process is convenient, fast, effort-saving and labor-saving and the pollution rate is very low. Mycelia are fully grown all over the whole chopstick strains after culture, the cell ages after the inoculation are short and consistent, the strains are fast in growth speed, the mycelia are robust, and the strains are high in purity and strong in resistance to other fungi. The method disclosed by the invention further has the more prominent advantages of low production cost and very significant economic benefits.

Owner:顾环环

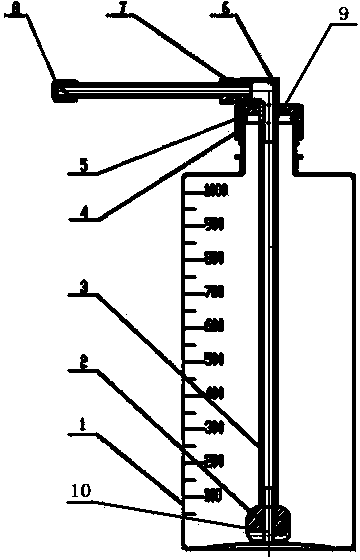

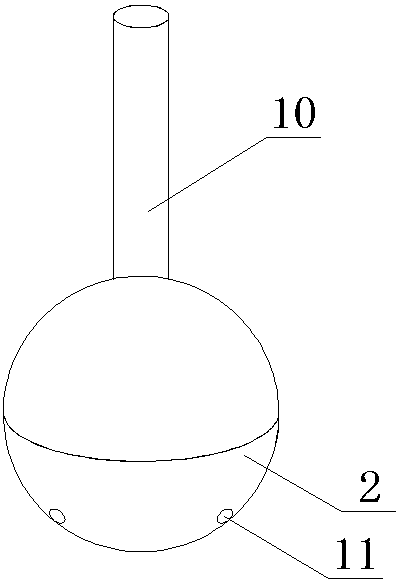

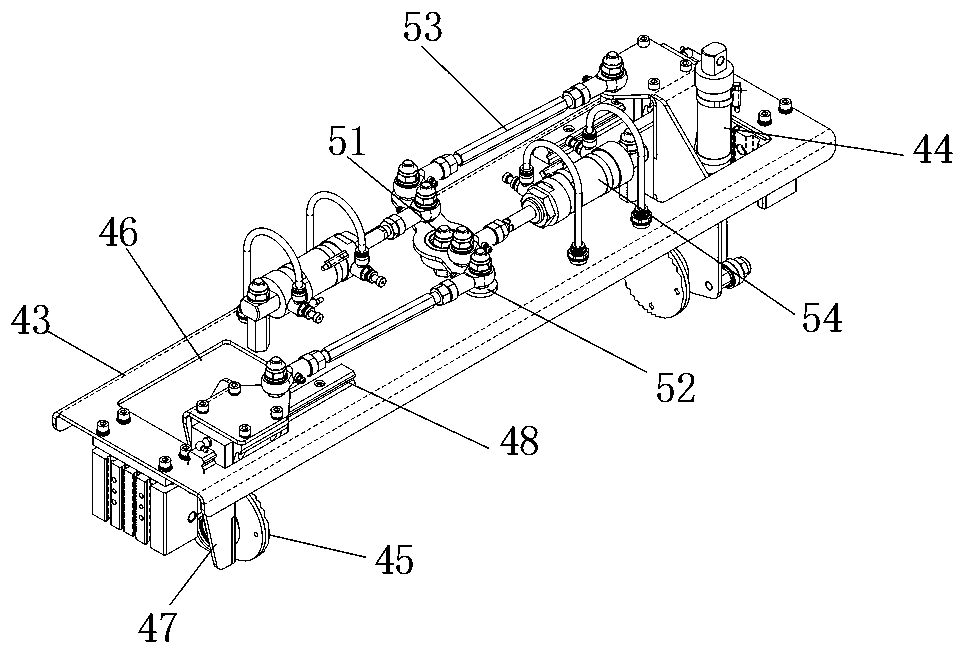

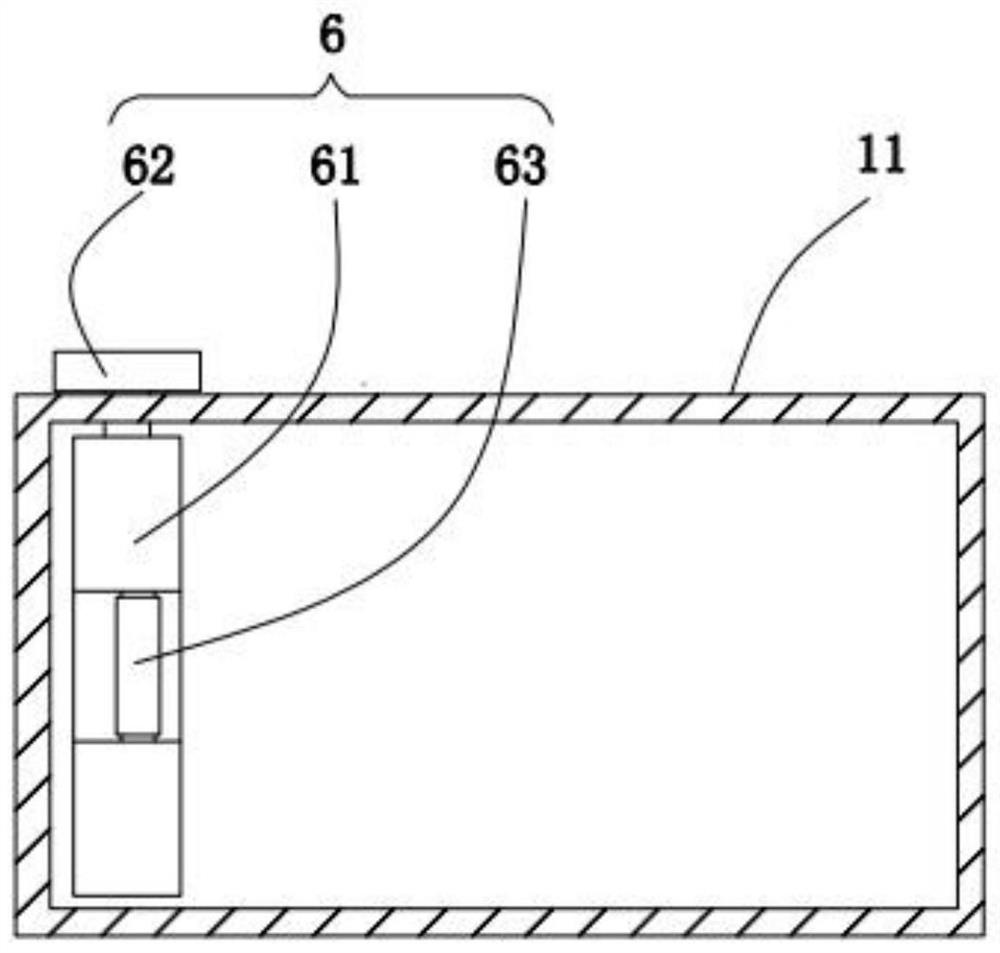

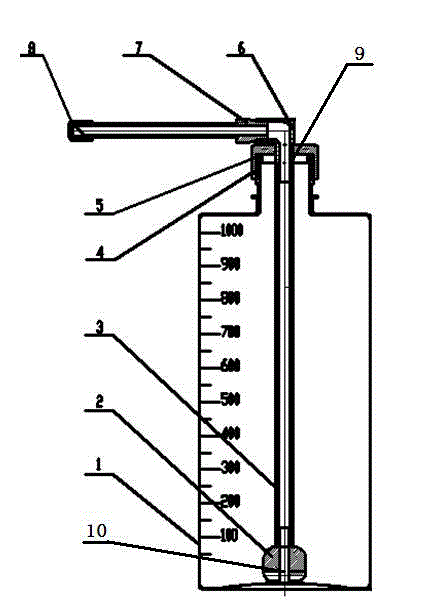

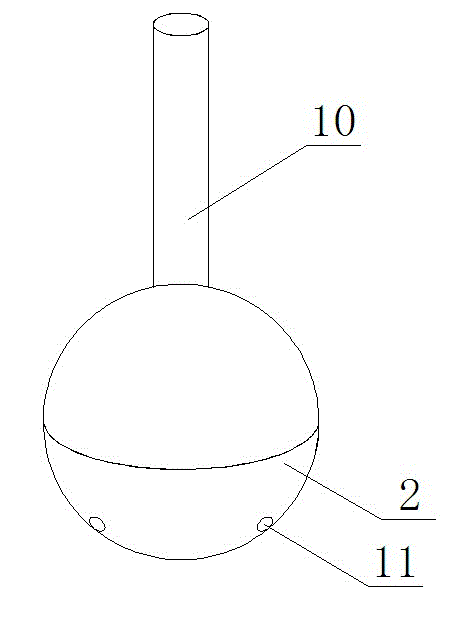

Edible fungus liquid strain storing and inoculating integrated machine

The invention discloses an edible fungus liquid strain storing and inoculating integrated machine. The edible fungus liquid strain storing and inoculating integrated machine is formed by connection of a storing device and an inoculating device. The storing device comprises a liquid strain storage bottle, a bottle cap and an O-shaped seal ring, wherein the O-shaped seal ring is arranged between the bottle neck and the bottle cap of the liquid strain storage bottle. The inoculating device comprises an inoculating syringe needle, a bend and a silicon rubber hose, wherein the inoculating syringe needle is connected with the silicon rubber hose through the bend, a hole is formed in the bottle cap, the bend and the silicon rubber hose penetrate through the hole to be inserted into the liquid strain storage bottle, and the external diameter of the bend is matched with the internal diameter of the hole. The edible fungus liquid strain storing and inoculating integrated machine has the advantages that the structure is simple, storing and inoculating of liquid strains are integrated, operation is simple and convenient, the inoculating speed is high, labor intensity of workers can be relieved obviously, and production efficiency is improved.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

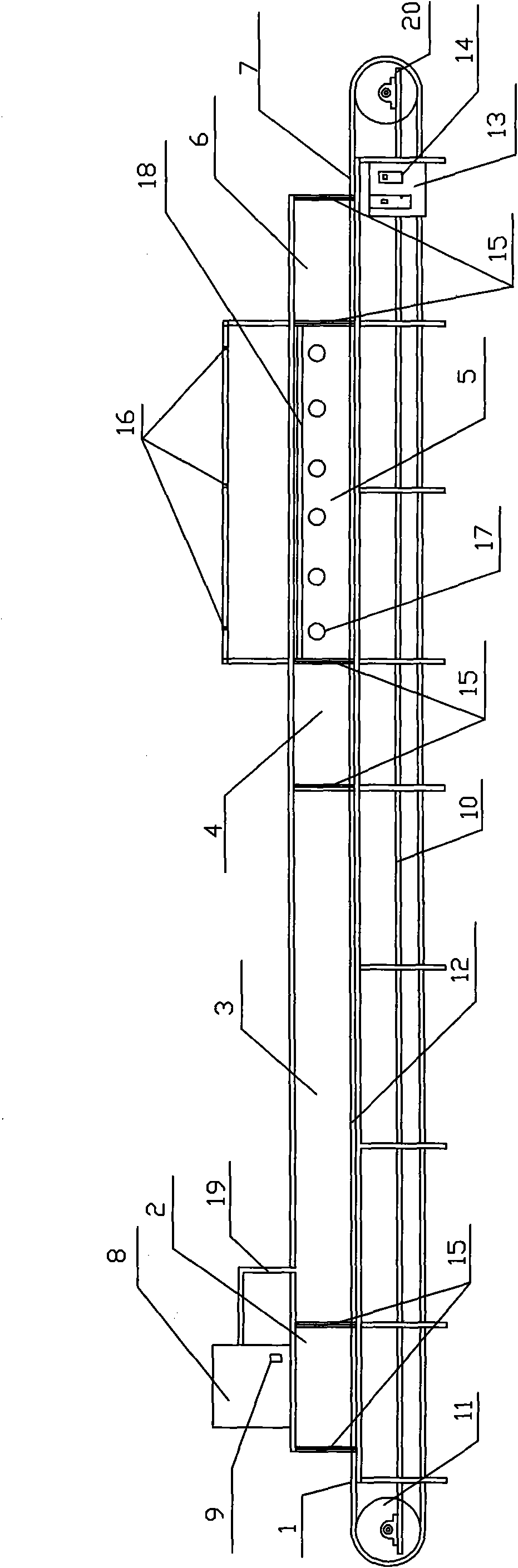

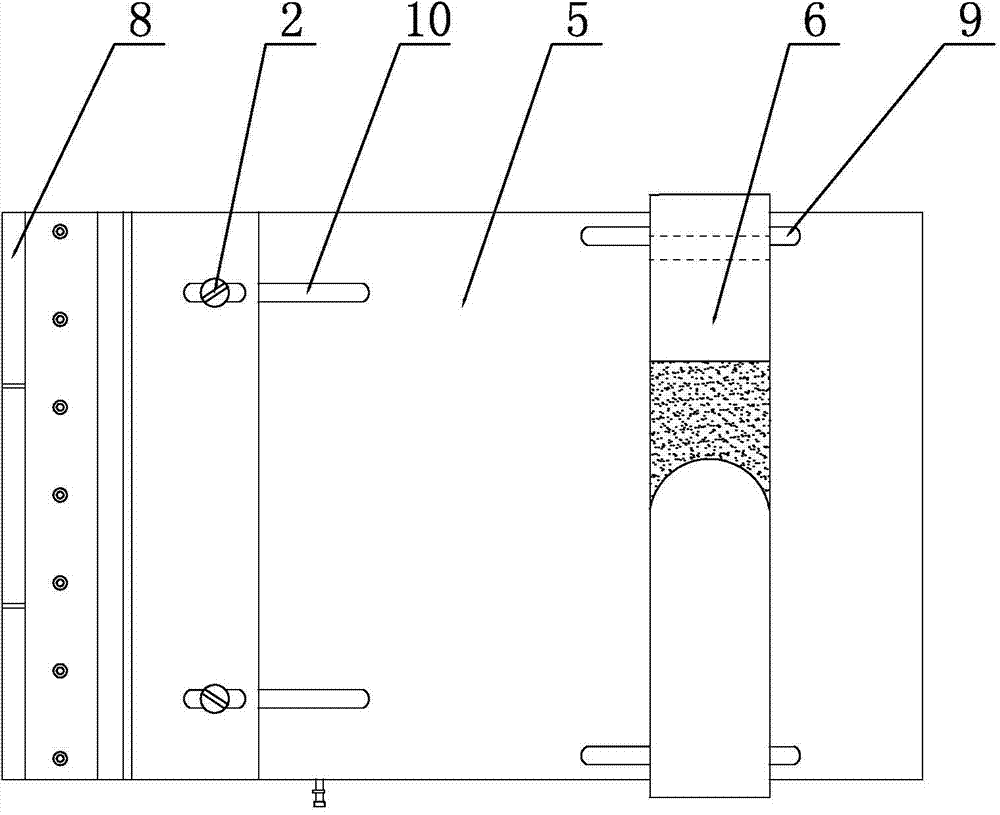

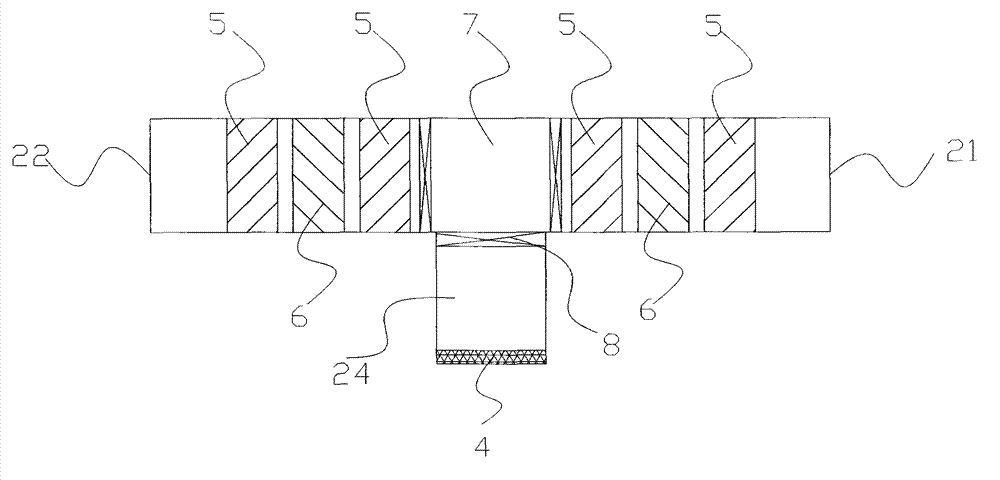

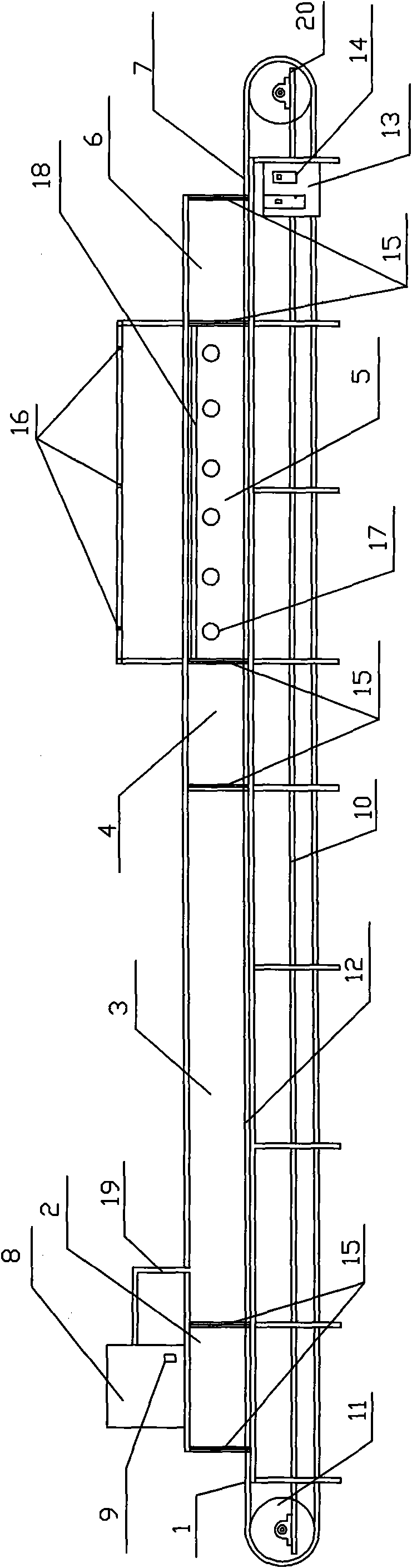

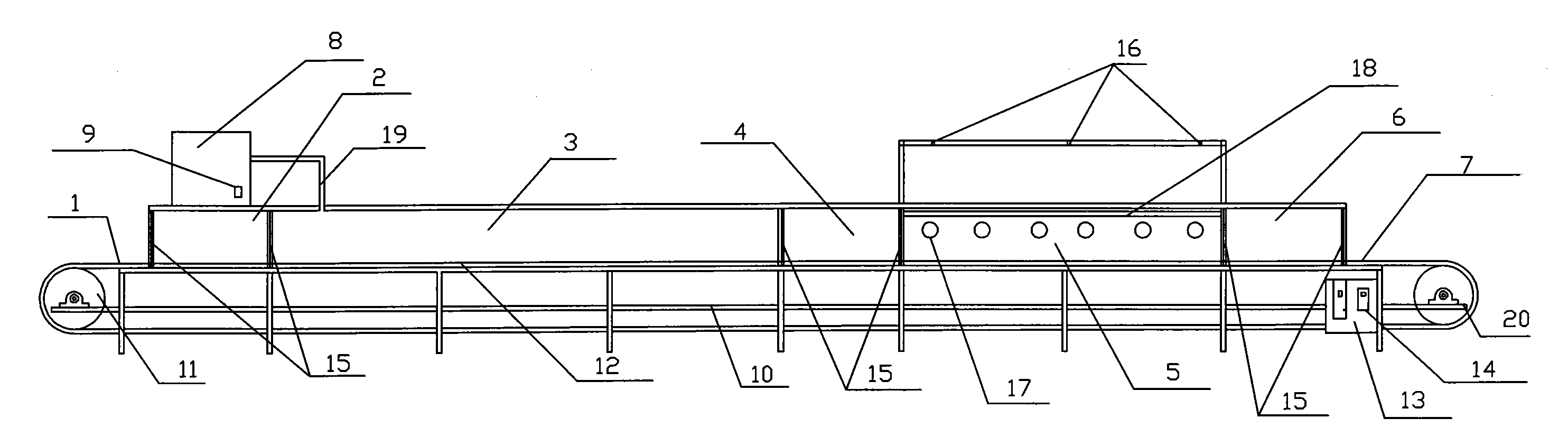

Large-scale aseptic-manipulation continuous production equipment

InactiveCN101663962AMaintain high efficiency and continuityInoculation speedHorticultureManufacturing lineContinuous production

The invention discloses a large-scale aseptic-manipulation continuous production equipment and relates to the technical field of structures of large-scale aseptic-manipulation continuous production lines. The production equipment has the structure that a conveyor is arranged on the frame; an inlet platform, an inlet buffering barn, a sterilizing barn, a middle buffering barn, an inoculation barn,an outlet buffering barn and an outlet platform are orderly arranged above the conveyor from left to right; an ozone generator is arranged above the inlet buffering barn and is connected with the sterilizing barn through a pipeline; the inlets and the outlets of the inlet buffering barn, the middle buffering barn and the outlet buffering barn are respectively provided with a movable curtain; a dehumidification window is arranged above the inoculation barn; both sides of the inoculation barn are respectively provided with three pairs of protective sleeves; and an object table is arranged in themiddle of the interior of the inoculation barn. The production equipment is an inoculation machine having the functions of environment sterilization, material conveying, oxygen enhancement, dehumidification and continuous inoculation, greatly increases the inoculation speed and the certified product rate, reduces the labor intensity and has the advantages of no sterilization residue, no damage and low cost.

Owner:YUNYANG MINGTIAN FUNGUS CO LTD

Branch strain cultivation method of dictyophora rubrovalvata

InactiveCN111448946AKeep activeInoculation speedCultivating equipmentsMushroom cultivationBiotechnologyInoculation methods

The invention discloses a branch strain cultivation method of dictyophora rubrovalvata. The cultivation method includes the following steps: (1) selecting raw materials; (2) selecting branches; (3) processing the branches; (4) preparing corn syrup; (5) performing primary boiling; (6) performing secondary boiling; (7) mixing raw materials; (8) performing sterilization; and (9) performing inoculation. Through the utilization of poplar branches as carriers of strains, scattered germination can be realized when the carriers are placed in culture mediums, so that the strains can grow at 360 degrees; the inoculation method is fast in inoculation, germination and feeding, good in uniform stability of germination, consistent in strain age, fast in inoculation speed and suitable for large-scale production, and can effectively shorten germination time and guarantee inoculation vitality; and the branch strains cultivated by the cultivation method can have the stability of solid strains and the inoculation speed of liquid strain.

Owner:安徽省百麓现代农业科技有限公司

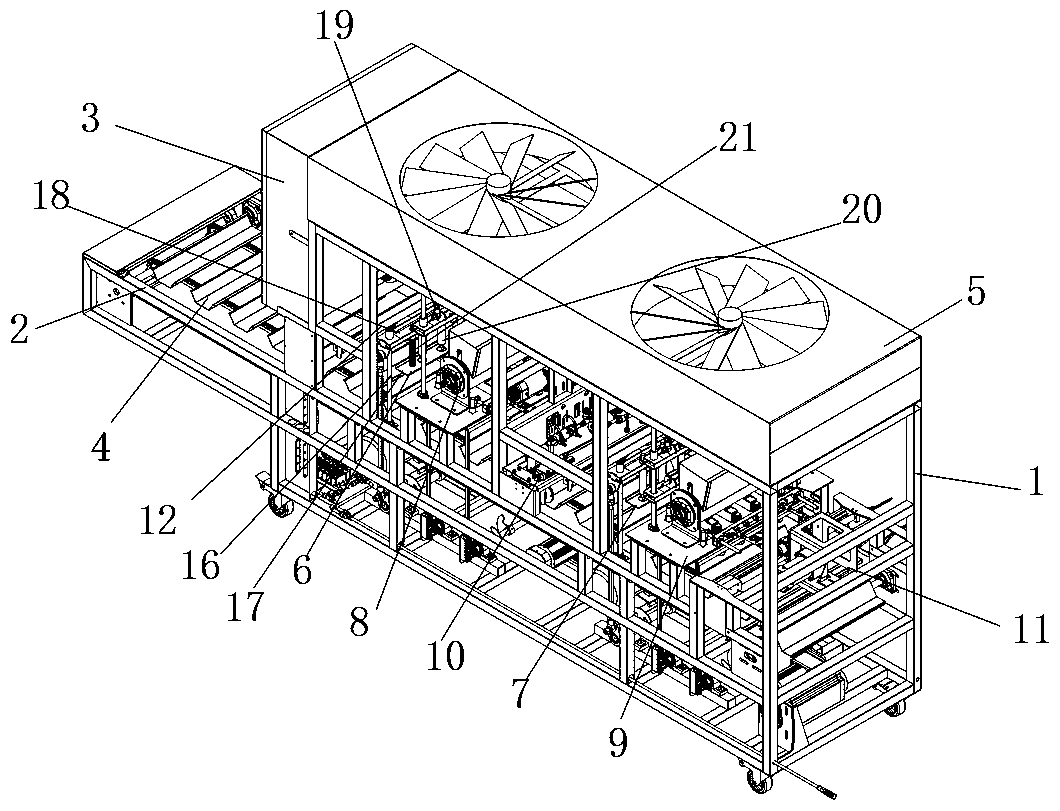

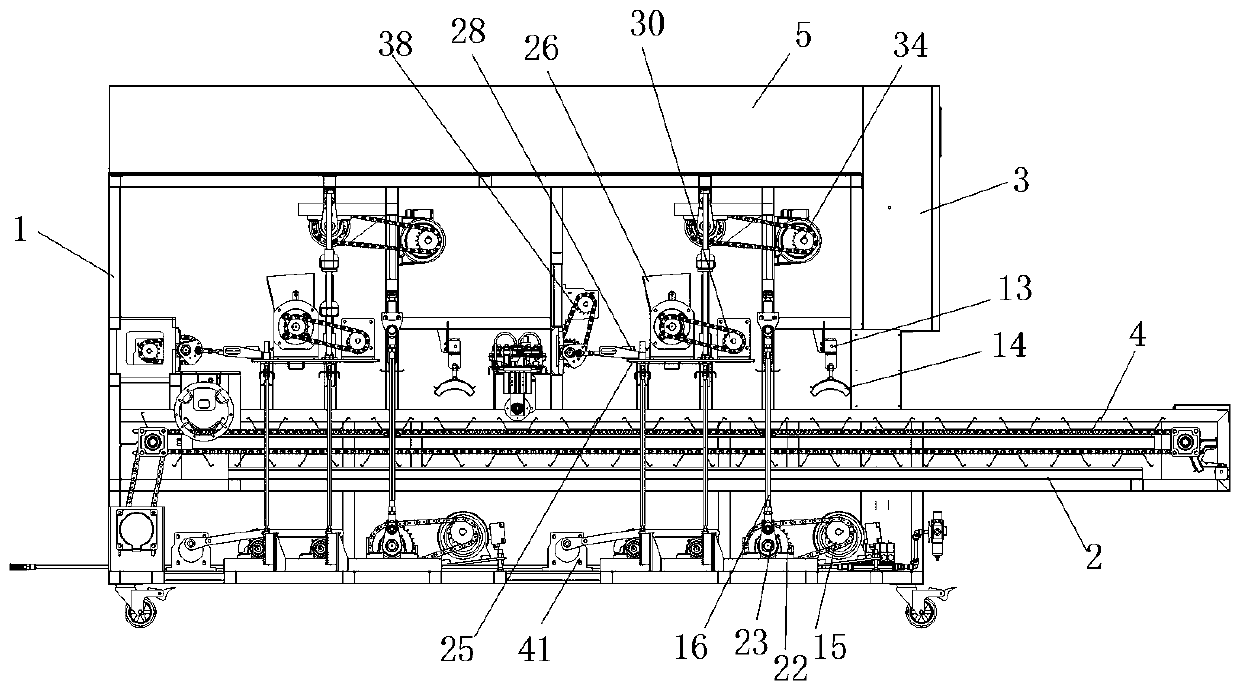

Mushroom double-sided solid inoculation machine

PendingCN109964738AAvoid infectionSimple structureCultivating equipmentsMushroom cultivationPunchingAgricultural engineering

The invention relates to the technical field of edible mushroom production, in particular to a mushroom double-sided solid inoculation machine. The machine comprises a frame and a chain conveying mechanism mounted on the frame and a main control cabinet, the chain conveying mechanism is provided with a bacteria pack trough for placing a bacteria pack, a rack is fixed to a purification and disinfection mechanism, the rack is further provided with a first punching mechanism, a second punching mechanism, a first inoculation seed pressing mechanism, a second inoculation seed pressing mechanism, apack turning mechanism and a pack discharging mechanism, the first punching mechanism, the first inoculation seed pressing mechanism, the pack turning mechanism, the second punching mechanism, the second inoculation seed pressing mechanism and the pack discharging mechanism are sequentially arranged in the chain conveying mechanism, and the front ends of the first punching mechanism and the secondpunching mechanism are all provided with bacteria pack disinfection mechanisms; the machine has the advantages of simple structure, convenient use, double-sided inoculation and high work efficiency.

Owner:ZHANGZHOU CITY XINGBAO MACHINERY

Pleurotus edible fungus rapid proliferation nutrient solution and pretreatment method of cultivated species of nutrient solution

ActiveCN106187448AInoculation speedLow input costCalcareous fertilisersSuperphosphatesSaccharumChlorogenic acid

The invention discloses a pleurotus edible fungus rapid proliferation nutrient solution, each 1,000 ml of hyphae rapid proliferation nutrient solution comprises 5 g of saccharose, 5 g of trehalose, 1 g of glucose, 0.05 g of chlorogenic acid, 0.05 g of VB2, 0.05 g of VB6 and the balance of water, and the PH is 7.0. Accordingly, the invention further discloses a pretreatment method of corresponding cultivated species. The proliferation nutrient solution added with different sugars, the vitamins and the antibacterial agent is used for pretreatment on cultivated specie mycelium, the fungus vigor is enhanced, the setting time of mycelium is shortened, the anti-bacterial capability of the mycelium is improved, and therefore, and the sundry fungus pollution rate is reduced while an open type inoculation method is ensured to be adopted. At the same time, a stapler breathable type sealing manner is adopted, oxygen supply during out-of fungus bag culture is enhanced, and the mycelial growth cycle is shortened. Rapid culture, high yield and harmlessness of the pleurotus edible fungus can be realized.

Owner:MICROBIOLOGY RES INST GUANGXI ZHUANG AUTONOMOUS REGION ACADEMY OF AGRI SCI +1

Method for culturing strains by using wooden pegs

InactiveCN103833491AWidely qualifiedEligibility convenienceFertiliser formsFertilizer mixturesOxygenRunning time

An object of the invention is to provide a method for culturing strains by using wooden pegs. By adopting the method, a spawn running time can be shortened by about 15 days; and cost is reduced. The method comprises the steps of making braches, waster wood, defective food pick sticks, teak sticks and apricot sticks into wooden peg shapes with the thickness of 0.5 cm; immersing the wooden pegs by using normal temperature white sugar water with a concentration of 5%; fishing the wooden pegs out; mixing a nutritional material with an amount accounting for 10% of the volume of the strain pegs; loading into bags; and pulling the wooden pegs out when inoculation points are largely connected together to form vent oxygen permeable holes naturally. 800 wooden pegs are loaded in a 15*55 cm strain bag. The length of the wooden pegs is 4-5 cm or 5-7 cm. Raw materials are wide and sufficient in resources; and wastes can be changed into treasure. By adopting the wooden pegs to culture the strains, preparation is convenient; the method is simple; transformation amount is large; and production cost is reduced by about 30%.

Owner:XINBIN MANCHU AUTONOMOUS COUNTY HONGSHENG MUSHROOM

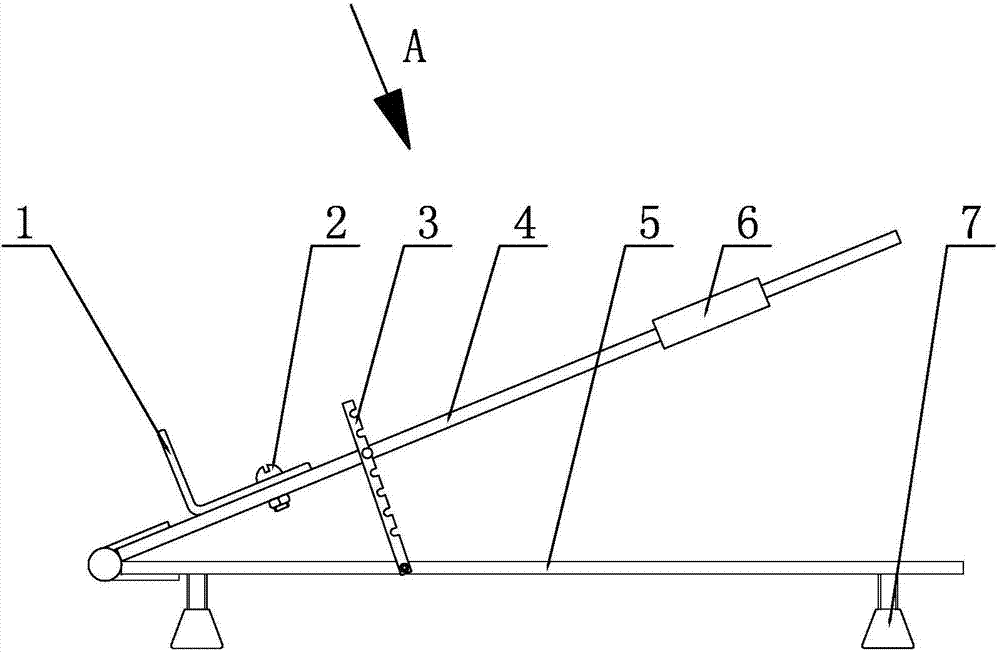

Special inoculation frame for liquid cell culture

InactiveCN104762198AAvoid germsThe supporting structure is stable and reliableBiological material testing procedures3D cell cultureLiquid cell

The invention relates to microbial culture and in particular relates to a special inoculation frame special for liquid cell culture. The inoculation frame comprises a base plate and a supporting plate of which the bottom is in running fit with the base plate, wherein a baffle plate is arranged at the rear part of the upper surface of the supporting plate, a bottleneck fixing mechanism is arranged at the front part of the upper surface of the supporting plate, and an angle adjusting device is arranged between the supporting plate and the base plate. The inoculation frame provided by the invention can be used for solving the technical problems of low inoculation speed, high operation strength, high contamination probability and the like of the prior art, and has the advantages of being stable in supporting structure, suitable for clamping fixation of triangular flasks with different specifications, high in inoculation speed, high in effect, saving in labor and the like.

Owner:RUNKE BIOENG FUJIAN

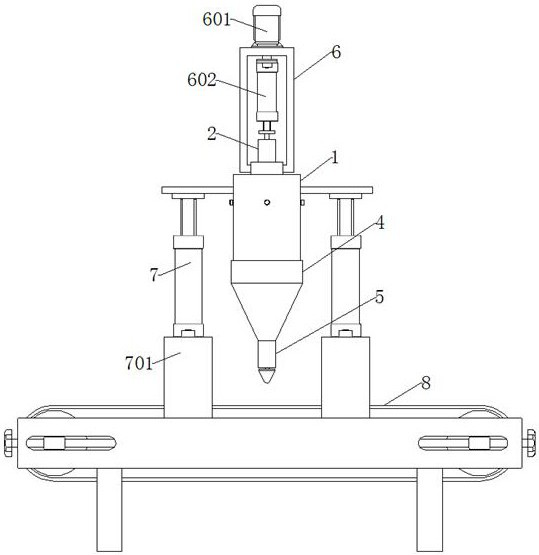

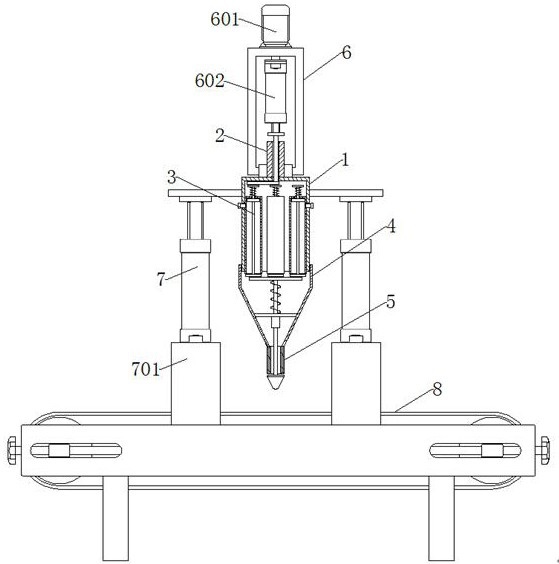

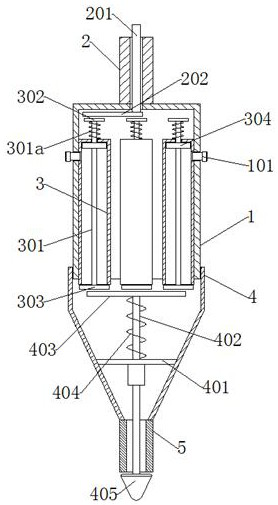

Automatic liquid strain inoculation device for edible fungus cultivation

ActiveCN112400614AInoculation speedReduce laborBio-organic fraction processingCultivating equipmentsEngineeringStructural engineering

The invention discloses an automatic liquid strain inoculation device for edible fungus cultivation. The device comprises a mounting cylinder and a guide pipe, wherein the mounting cylinder is of a cylinder structure with an opening in the bottom end, the guide pipe is vertically fixed to the center of the top of the mounting cylinder, a plurality of sets of liquid storage cylinders are evenly arranged in the mounting cylinder around the inner side wall of the mounting cylinder, the liquid storage cylinder is of a cylinder structure with an opening in the bottom end, a supporting rod vertically penetrates through the top end of the liquid storage cylinder, the supporting rod is in clearance fit with the liquid storage cylinder, a limiting block is arranged at the top end of the supportingrod, and a first spring is connected to the portion, between the limiting block and the liquid storage cylinder, of the supporting rod in a sleeving mode. The device has the beneficial effects that the multiple sets of liquid storage cylinders for storing liquid strains are arranged in the mounting cylinder, and the liquid strains are sequentially discharged to a plug through the multiple sets ofliquid storage cylinders, so that continuous operation of edible fungus inoculation is achieved, the strain inoculation speed is increased, manual inoculation is replaced with mechanical full-automatic inoculation, labor amount of personnel is reduced, and operation is easy.

Owner:东宁市互利山产品有限公司

Pollution-free inoculating machine

InactiveCN102870596AIncrease success rateReasonable structural designDispersed particle filtrationHorticultureActivated carbon filtrationPulp and paper industry

The invention relates to a pollution-free inoculating machine and relates to the technical field of inoculating machines. The pollution-free inoculating machine comprises a frame and a body fixed on the same. The pollution-free inoculating machine is characterized in that the left end of the body is provided with a discharge hole, the right end of the body is provided with a feed hole, an air distribution chamber is arranged in the center of the body and is connected with an air inlet, the bottom of the air inlet is provided with an aerosol smoldering hole, gauze filter layers are disposed at the end of the air inlet and the end of the aerosol smoldering hole, activated carbon filter layers are disposed on left and right sides of the air distribution chamber, each activated carbon filter layer is provided with a raw cotton filter layer, and each of two sides of the air distribution chamber and the inner end of the air inlet is provided with a fan. The pollution-free inoculating machine is reasonable in structural design. Airflow is filtered layer by layer by means of the deseeded and not degreased raw cotton and the activated carbon layers, so that pollution-free inoculation is achieved. Inoculating is easy, so that inoculating process is simplified, and inoculating speed and inoculating success rate are increased.

Owner:吴永玉

Highly effective cultivating method for Chinese caterpillar fungus

The invention discloses a highly effective culture method of Chinese caterpillar fungus. The method is that with the liquid fermentation of Chinese caterpillar fungus strain, a large number of Chinese caterpillar fungus mycelium are cultivated after a few days; the cultivated species of Chinese caterpillar fungus can be produced in a large scale; then the Chinese caterpillar fungus mycelium produced after fermentation are inoculated on silkworm chrysalis or rice medium which is treated by surface sterilization; the further cultivation of the Chinese caterpillar fungus mycelium are processed at a certain appropriate temperature and humidity with necessary ventilation and light management; a large amount of artificial cordyceps militaris which has same form and similar function with the wild Chinese caterpillar fungus is obtained after a few days. The highly effective culture method of Chinese caterpillar fungus of the invention has not only rapidness and effectiveness but also low culture cost. The invention has important significance and popularization and application value for the development of precious Chinese medicine resource, the extension of novel application of .silkworm industry resource and the improvement of additional value.

Owner:JIANGSU UNIV OF SCI & TECH

Tissue culture method for rapid expanding propagation of tissue culture seedlings for field planting in production process of virus-free minitubers of potatoes

InactiveCN111937745AImprove inoculation efficiencyImprove production efficiencyHorticulture methodsPlant tissue cultureBiotechnologyCarrageenan

The invention provides a tissue culture method for rapid expanding propagation of tissue culture seedlings for field planting in the production process of virus-free minitubers of potatoes. The tissueculture method comprises the steps: (1) ammonium nitrate in an MS culture medium formula is replaced with ammonium chloride, and calcium chloride is replaced with calcium nitrate; (2) carrageenan isreplaced with ginned cotton; (3) the using amount of each mother liquor and white sugar is decreased by 10-30%; (4) at 100 DEG C, after two or more minutes, direct filling is conducted, and the filling amount of a 240-type culture bottle is 20-25ml; (5) expanding propagation is conducted, specifically, mother seedlings are shorn into sections each with 1-2 leaves, after the completion of shearing,cutting is not needed, and gentle scattering and even shaking are conducted; and tissue culture is conducted, specifically, the illumination intensity of tissue culture is 3300 Lx. According to the method, the expanding propagation speed is increased by 30% or above, the tissue culture time is shortened by 7 days, and the cost is reduced by 35% or above.

Owner:江苏宝德农业科技有限公司

Edible mushroom cultivation bar high-efficiency inoculating method

The invention relates to an inoculation method of an edible fungus, particularly to a highly efficient inoculation method of the cultivated stems of the edible fungus. The method comprises steps of: construction of a solar greenhouse plastic fungus producing shed; preparation of bagged fungus stems; preparation of medium: 82 percent of saw dust, 17 percent of wheat bran and 1 percent of gypsum; mechanical bagging, sterilization under atmospheric pressure and then moving into the fungus producing shed for cooling; inoculation in the fungus producing shed: after routine sterilization, cooled fungus stems are piled in single layer from east to west, 4 pores are pricked on each stem, then inoculation is carried out and thin film is used for covering. After the first layer of the stems are inoculated, piling in single layer is carried out again from east to west and then inoculation is carried out, and repeat the operation; each pile has 10 to 12 layers; the fungus stems after being inoculated are kept immovable at original places for hypha growing, piles are shifted when the hypha seals the pores of strain or connects with each other, and turn into fungus growth management. The inoculation method of the invention has the advantages that: integrates the inoculation place and the hypha growing and fungus producing place, reduces costs of equipment and manpower, needs no externally sleeved bag, thus saving time, labor and cost; allows cooperation of a plurality of people, thus increasing production efficiency by 1 time; has high inoculation speed, thus reducing the settling probability of mixed bacterium and high rate of finished products. Therefore, the method is applicable to scaled cultivation or factory production.

Owner:TIANJIN JIYA ANIMAL HUSBANDRY GRP

Inoculation method of tissue culture seedlings of potatoes

InactiveCN103548684AReduced Chances of ContaminationInoculation speedHorticulture methodsPlant tissue cultureInoculation methodsSolanum tuberosum

The invention discloses an inoculation method of tissue culture seedlings of potatoes. The inoculation method is characterized in that impact factors of the growth of the detoxified tissue culture seedlings of the potatoes are strictly controlled, and the tissue culture seedlings are subjected to integral cutting, dispersed tissue culture and cutting again after inoculation appliances, a culture room and an inoculation room are strictly disinfected and sterilized, so that the purposes of high speed, short cycle, low pollution, simple operation and low cost of the detoxified tissue culture and breeding of the potatoes are achieved.

Owner:GANSU KAIKAI AGRI TECH DEV

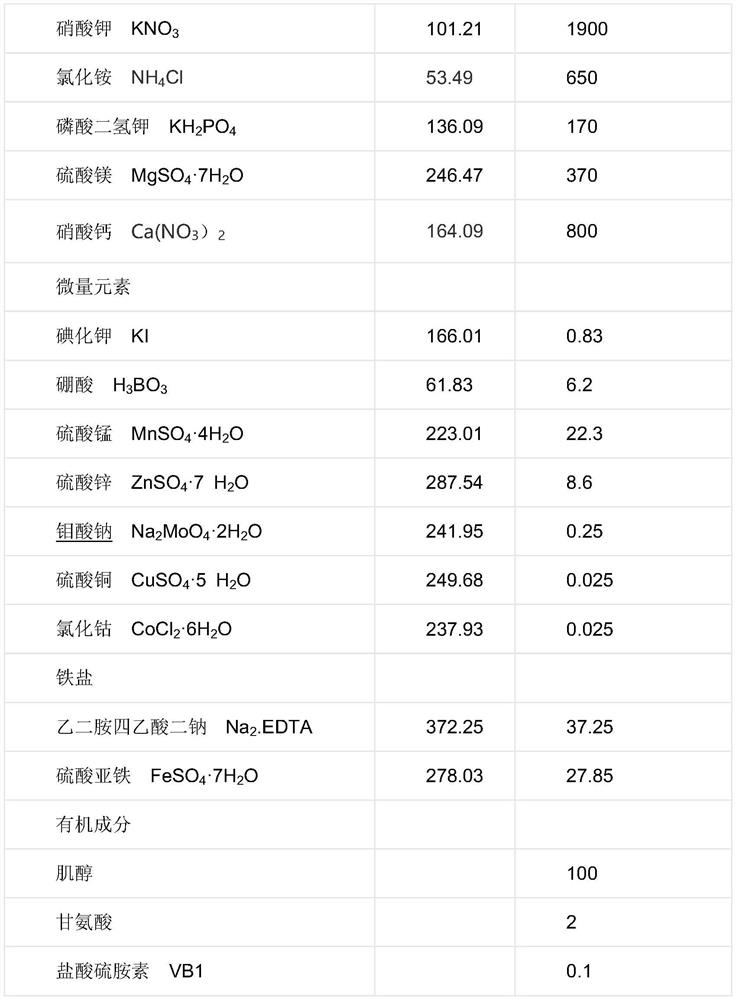

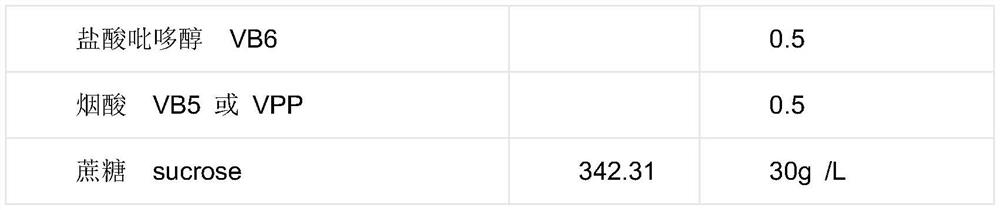

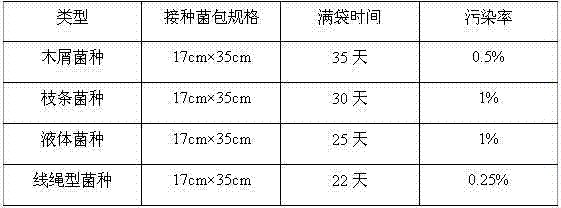

Rope type mycelia and production method thereof

InactiveCN104737814AFull of nutritionImprove water absorptionHorticultureFertilizer mixturesBobbinNutrient solution

The invention relates to rope type mycelia and a production method thereof and belongs to the field of edible fungus mycelia. A nutrient solution is prepared, wound ropes are placed in the nutrient solution to be soaked, totally soaked bobbins are directly arranged in ethene or propylene bags, subjected to high pressure or atmospheric pressure disinfection, and placed in a clean environment to be cooled, inoculation is conducted under aseptic conditions when the temperature of the mycelium bags decreases to 25 DEG C-30 DEG C, the inoculated mycelium bags are placed in a culture room at the temperature of 24 DEG C-26 DEG C to be cultured, and after the mycelium bags are full of mycelia and ripe for 7-10 days, the mycelium bags are stored in the environment of 4 DEG C. Quantitative mycelia are obtained, the mycelium bags conduct spawn running consistently, and management is facilitated; the rope type mycelia have simple requirements for the forms of the package bags, production efficiency is improved, and production cost is reduced. By the adoption of inoculation of the rope type mycelia, rapid and quantitative inoculation can be achieved, and the mycelium bags have a high spawn running speed and a low pollution rate.

Owner:JILIN AGRICULTURAL UNIV +1

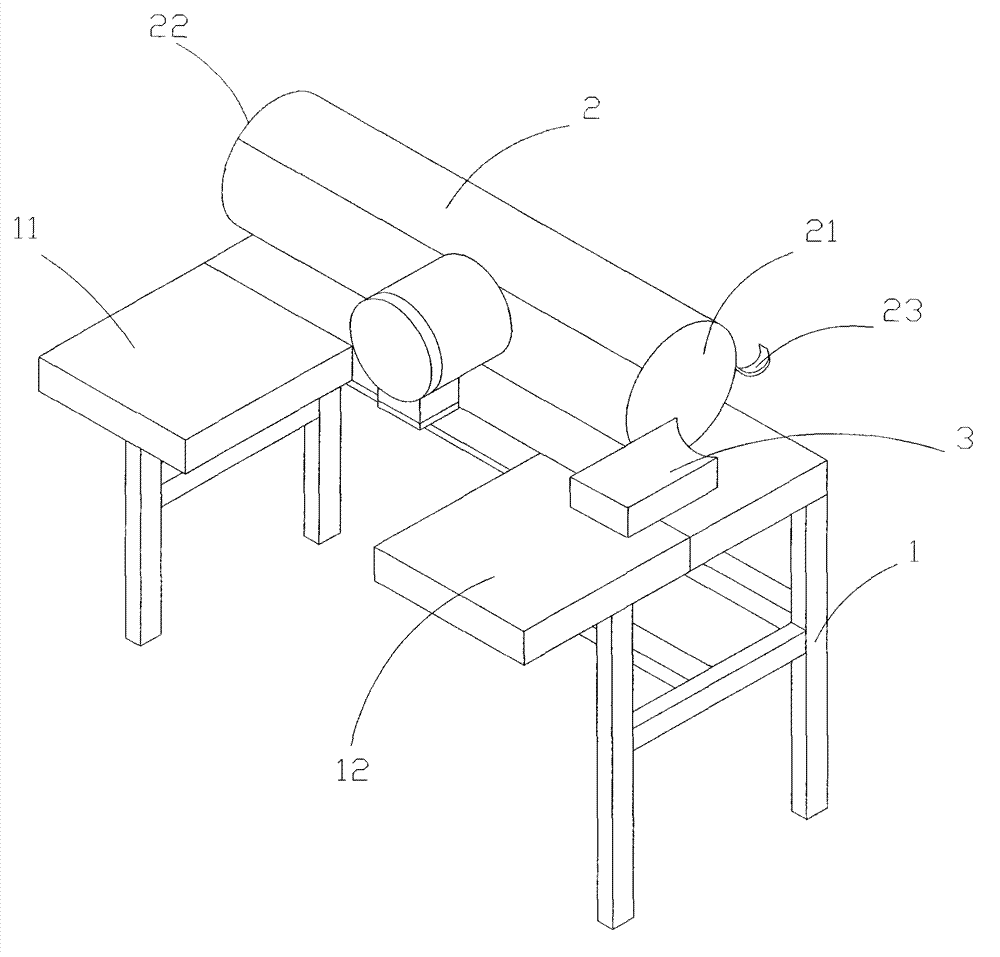

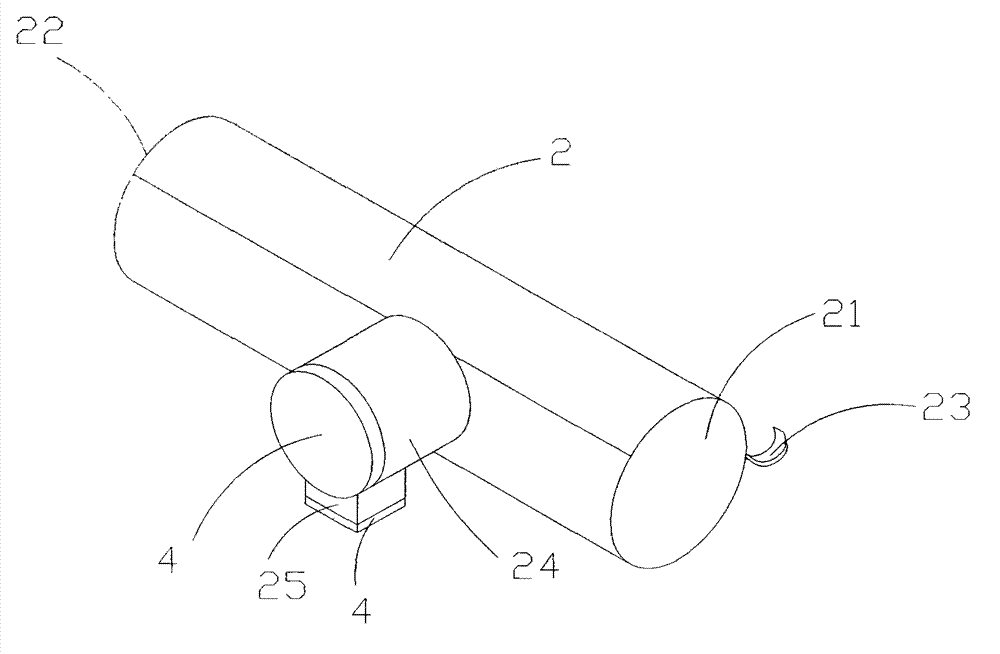

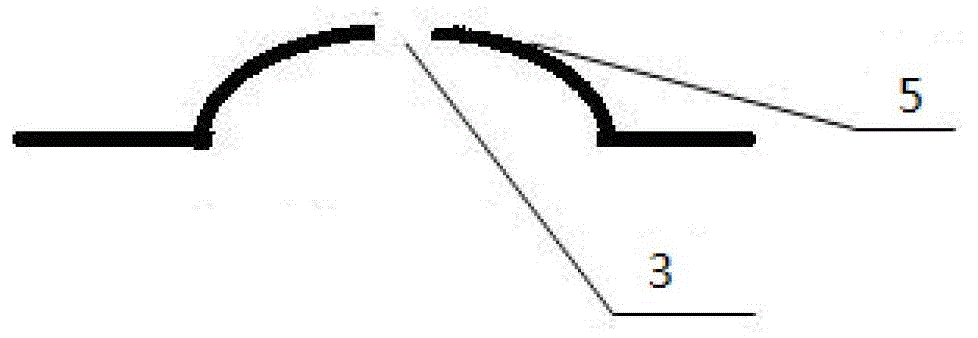

Device for inoculating wound roots of plants and application method thereof

The invention relates to a device for inoculating wound roots of plants and an application method thereof. The device is connected onto a spray rod of an agricultural sprayer, and is formed by a connecting rod, a cutting head and liquid outlet holes, wherein the connecting rod is of a hollow structure; one end of the connecting rod can be detachably connected with the spray rod of the agricultural sprayer; the other end of the connecting rod is connected with the cutting head; the cutting head is of a hollow structure; the front end of the cutting head is in a wedged shape; a plurality of liquid outlet holes are formed in a wedge-shaped slope; and opening parts of the liquid outlet holes are projected out of the surface of the wedge-shaped slope. According to the device, screws of the connecting rod and screws of the spray rod of the agricultural sprayer are matched, and the use method is simple and convenient. The device is directly fixed on the spray rod without a spray head and is used for inoculating plant endophytes and plant pathogens with infected roots.

Owner:NANJING NORMAL UNIVERSITY

A kind of formula and production process of edible fungus granules

The invention discloses a formula of edible mushroom granules and a production process. The formula of the culture medium of the fungus consists of the following components: 97.5% of sorghum grains, 1.5% of light calcium carbonate and 1% of glucose. Its main production process includes: material selection→rinsing→soaking→cooking→removal of free water→stirring→bottling→stopping→wrapping and tying→autoclaving→out of the pot, inoculation→mycelium cultivation→one shake flask → Secondary shake flask → Finished strain. In the production process of the present invention, a small bottle-mouth container bottle is used as the packaging material of the bacterial strain, and the film package of the sealed tampon can not only meet the oxygen demand for the growth of mycelia in the container bottle, but also reduce the contamination of the bacteria by bacteria; The shaking bottle process makes the mycelium filling speed more than double, and the upper and lower bacterial ages are the same when the mycelium is full. The strains produced by this production process have high purity, fast inoculation speed, fast germination, and good food, and are welcomed by the majority of mushroom farmers.

Owner:HEZE UNIV

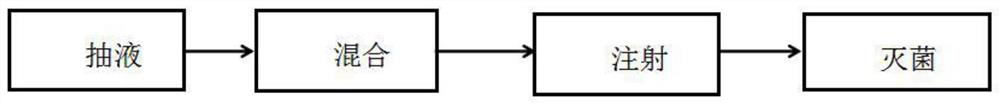

A rapid inoculator for animal vaccines

ActiveCN108618963BQuick drawFast preparationPharmaceutical containersMedical packagingAnimals vaccinesInoculation methods

The invention relates to the technical field of vaccines, in particular to a rapid inoculation method for animal vaccines. The method comprises the steps of liquid extracting, liquid mixing, injectingand sterilizing; the inoculation method adopts an inoculating device for inoculation, and the inoculating device comprises a needle-punching mechanism a mixing mechanism, a vaccine extraction mechanism, a vaccine adjuvant extraction mechanism, a protection mechanism and a pushing mechanism; the needle-punching mechanism is fixedly connected to one end of the mixing mechanism; the other end of themixing mechanism is communicated to the vaccine extraction mechanism and the vaccine adjuvant extraction mechanism; the vaccine extraction mechanism and the vaccine adjuvant extraction mechanism arearranged mutually independently; the mixing mechanism is fixedly connected to the protection mechanism; the vaccine extraction mechanism and the vaccine adjuvant extraction mechanism are disposed at the inside of the protection mechanism; the pushing mechanism is installed inside the needle-punching mechanism. The method has the advantages of rapid, safe and reliable inoculation.

Owner:库俊红 +2

Large-scale aseptic-manipulation continuous production equipment

InactiveCN101663962BMaintain high efficiency and continuityInoculation speedBiological material testing proceduresProduction lineProcess engineering

The invention discloses a large-scale aseptic-manipulation continuous production equipment and relates to the technical field of structures of large-scale aseptic-manipulation continuous production lines. The production equipment has the structure that a conveyor is arranged on the frame; an inlet platform, an inlet buffering barn, a sterilizing barn, a middle buffering barn, an inoculation barn,an outlet buffering barn and an outlet platform are orderly arranged above the conveyor from left to right; an ozone generator is arranged above the inlet buffering barn and is connected with the sterilizing barn through a pipeline; the inlets and the outlets of the inlet buffering barn, the middle buffering barn and the outlet buffering barn are respectively provided with a movable curtain; a dehumidification window is arranged above the inoculation barn; both sides of the inoculation barn are respectively provided with three pairs of protective sleeves; and an object table is arranged in the middle of the interior of the inoculation barn. The production equipment is an inoculation machine having the functions of environment sterilization, material conveying, oxygen enhancement, dehumidification and continuous inoculation, greatly increases the inoculation speed and the certified product rate, reduces the labor intensity and has the advantages of no sterilization residue, no damage and low cost.

Owner:YUNYANG MINGTIAN FUNGUS CO LTD

Novel method for preparing black fungus mushroom branched wood cultivars

InactiveCN103224426BHigh degree of anti-agingQuality improvementHorticultureFertilizer mixturesHyphaMushroom

The invention relates to black fungus mushroom branched wood cultivars which are characterized by using branched wood as a main raw material and adding auxiliary materials as fillers. The invention also comprises a preparation method for the cultivars. Compared with conventional wood dust cultivars, the branched wood cultivars have the advantages that 1. mycelia of the branched wood are not damaged during inoculation, strains can germinate in a short period, and the whole branched wood germinates at the same time, so that growth of infectious microbes is inhibited; 2. the branched wood mycelia have high anti-aging degree, so that the quality of the strains is increased; 3. cultivated fungus sticks are short and consistent in fungus age, so that the black fungus and mushroom are produced quickly, and production period is shorten and yield and quality of the product are increased; and 4. inoculation speed is fast, operations are simple and fast, and practical applicability is strong.

Owner:邬金飞

Method for cultivating cistanche tubulosa in greenhouse

InactiveCN101946619BIncrease vaccination rateInoculation speedHorticultureTamarix chinensisWarm water

The invention discloses a method for cultivating cistanche tubulosa in a greenhouse, belonging to the technical field of plant cultivation. The method comprises the following steps: cutting tamarix chinensis in the greenhouse in spring in the first year, simultaneously inoculating the cistanche tubulosa, and carrying out reasonable light warm water fertilizer management after inoculating; and digging the cistanche tubulosa medicinal materials in autumn in the next year or harvesting seeds after the tamarix chinensis bears fruits in spring in the third year, wherein, the cultivation condition after inoculating is natural illumination, the indoor temperature is 18-32 DEG C, and the soil water content is 50-70%. The cultivation method carries out intensification management in the greenhouse,and has the advantages of simple and convenient operation, high cistanche tubulosa vaccination rate, rapid inoculation speed, short production period, high yield, and no freeze injury in winter.

Owner:CHINA AGRI UNIV

Edible fungus liquid strain storing and inoculating integrated machine

The invention discloses an edible fungus liquid strain storing and inoculating integrated machine. The edible fungus liquid strain storing and inoculating integrated machine is formed by connection of a storing device and an inoculating device. The storing device comprises a liquid strain storage bottle, a bottle cap and an O-shaped seal ring, wherein the O-shaped seal ring is arranged between the bottle neck and the bottle cap of the liquid strain storage bottle. The inoculating device comprises an inoculating syringe needle, a bend and a silicon rubber hose, wherein the inoculating syringe needle is connected with the silicon rubber hose through the bend, a hole is formed in the bottle cap, the bend and the silicon rubber hose penetrate through the hole to be inserted into the liquid strain storage bottle, and the external diameter of the bend is matched with the internal diameter of the hole. The edible fungus liquid strain storing and inoculating integrated machine has the advantages that the structure is simple, storing and inoculating of liquid strains are integrated, operation is simple and convenient, the inoculating speed is high, labor intensity of workers can be relieved obviously, and production efficiency is improved.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Method for making three-level species of Pleurotus ostreatus using Amorpha fragrans branches as matrix material

ActiveCN104521558BPromote growthPrevent agingGrowth substratesCulture mediaPholiotaAmorpha fruticosa

The invention discloses a pholiota nameko three-grade seed production method taking amorpha fruticosa braches as base raw materials. The pholiota nameko three-grade seed production method comprises the following steps: obtaining branch wood sections, treating the branch wood sections, distributing wheat bran on the branch wood sections, preparing an auxiliary culture base material, forming a strain material bag, sterilizing at high pressure and inoculating. The auxiliary culture base material is prepared from the following materials in percentage by mass: 72%-85% of saw dust, 15%-25% of wheat bran, 0.5%-2% of gypsum and 0.5%-2% of lime; water is added into the materials and is uniformly mixed, and the moisture content is controlled to be about 65%. By the aid of the method for preparing pholiota nameko three-grade seeds, the fungi growth time can be shortened for 20-30 days, the inoculating speed is rapid and the pollution rate is greatly reduced; mycelia are thick and dense and grow vigorous; strains on the upper part can be prevented from being aged and the strain preservation period is prolonged by more than 30-40 days.

Owner:RIZHAO HENGJIUFENG AGRI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com