Rope type mycelia and production method thereof

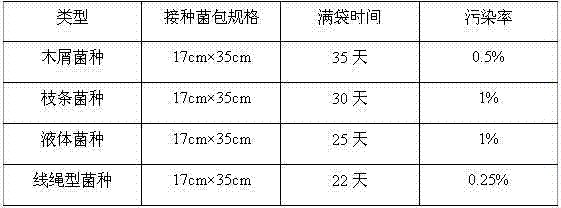

A production method and a rope-type technology, applied in the field of edible fungus mycelium growth substrate, can solve the problems of large wood consumption, unstable output, easy pollution cycle, etc., and achieve reduced production costs, fast and consistent growth of bacteria Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] is obtained by the following steps:

[0019] (1) Prepare nutrient solution, formula: 300g potato, 20g glucose, 2g peptone, 2g potassium dihydrogen phosphate, 1g magnesium sulfate, 1000ml water; specific operation:

[0020] Cut the accurately weighed potatoes into slices with a thickness of about 0.3cm, put the water into the pot and heat until boiling, put the cut potato slices into boiling water, boil for 15 minutes, filter and keep the filtrate to continue heating until the liquid boils again Add glucose, peptone, potassium dihydrogen phosphate, and magnesium sulfate to the liquid in sequence; pour the nutrient solution into the container for later use;

[0021] (2) Cord treatment: process the cord according to the production needs and the specifications of the mushroom bag. It is required that there is one cord in each bag. Wind the cord on a plastic shaft with a diameter of 0.5 cm, and put the wrapped cord in the Soak in the nutrient solution, the soaking time depe...

Embodiment 2

[0027] is obtained by the following steps:

[0028] (1) Prepare nutrient solution, formula: 300g potato, 20g glucose, 2g peptone, 2g potassium dihydrogen phosphate, 1g magnesium sulfate, 1000ml water; specific operation:

[0029] Cut the accurately weighed potatoes into slices with a thickness of about 0.3cm, put the water into the pot and heat until boiling, put the cut potato slices into boiling water, boil for 15 minutes, filter and keep the filtrate to continue heating until the liquid boils again Add glucose, peptone, potassium dihydrogen phosphate, and magnesium sulfate to the liquid in sequence; pour the nutrient solution into the container for later use;

[0030] (2) Cord treatment: process the cord according to the production needs and the specifications of the mushroom bag. It is required that there is one cord in each bag. Wind the cord on a plastic shaft with a diameter of 0.5 cm, and put the wrapped cord in the Soak in the nutrient solution, the soaking time depe...

Embodiment 3

[0036] is obtained by the following steps:

[0037] (1) Prepare nutrient solution, formula: 300g potato, 20g glucose, 2g peptone, 2g potassium dihydrogen phosphate, 1g magnesium sulfate, 1000ml water; specific operation:

[0038] Cut the accurately weighed potatoes into slices with a thickness of about 0.3cm, put the water into the pot and heat until boiling, put the cut potato slices into boiling water, boil for 15 minutes, filter and keep the filtrate to continue heating until the liquid boils again Add glucose, peptone, potassium dihydrogen phosphate, and magnesium sulfate to the liquid in sequence; pour the nutrient solution into the container for later use;

[0039] (2) Cord treatment: process the cord according to the production needs and the specifications of the mushroom bag. It is required that there is one cord in each bag. Wind the cord on a plastic shaft with a diameter of 0.5 cm, and put the wrapped cord in the Soak in the nutrient solution, the soaking time depe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com