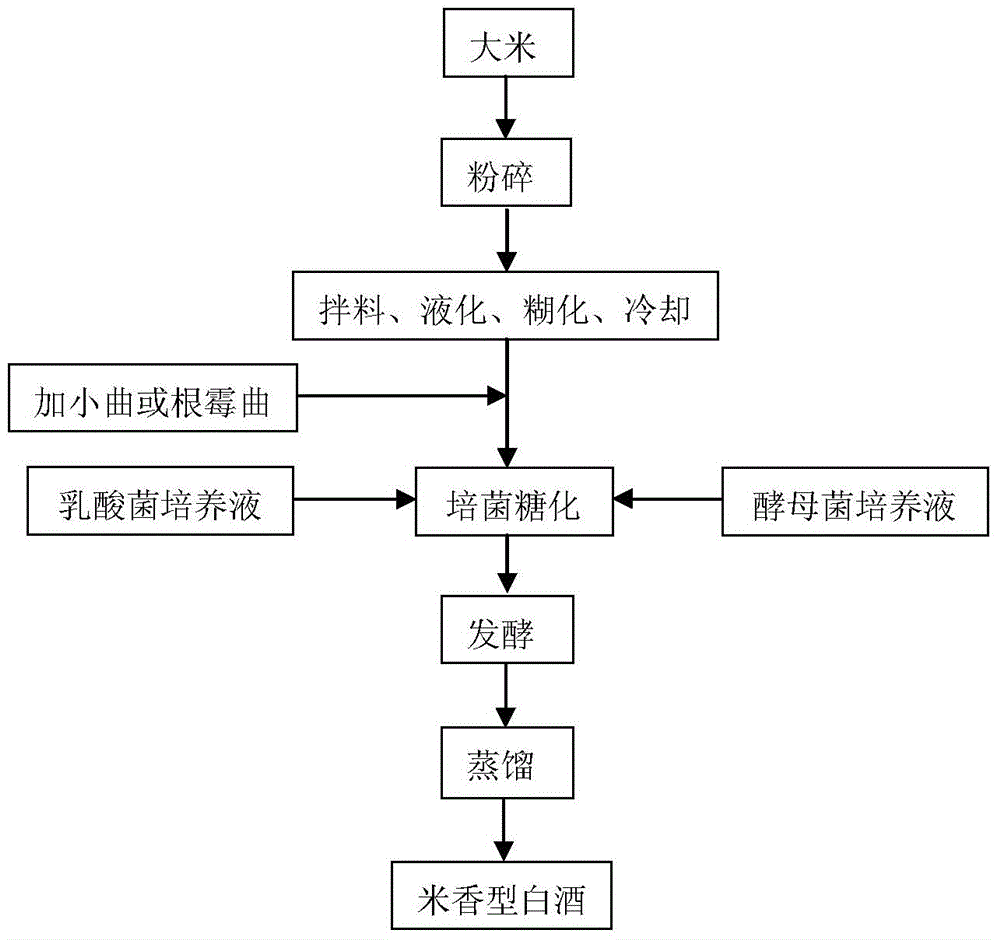

Method for producing rice-flavor liquor based on liquid fermentation

A liquid fermentation and rice-flavored technology, which is applied in the field of wine making, can solve the problems of high labor intensity, low content of ester aroma substances, and development restrictions, and achieve the effects of reducing labor intensity, pure rice aroma, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of yeast culture fluid

[0029] (1) Preparation of rice saccharification liquid medium

[0030] ① Gelatinization and liquefaction: After crushing the rice, beat it with 4 times the amount of water, add 4 U of high-temperature-resistant α-amylase per gram of rice flour, and start stirring to mix well. In the state of stirring, heat to 90°C, keep warm and liquefy at this temperature for 15 minutes, seal the can, continue to heat to gauge pressure 0.15MPa, keep the pressure for 25 minutes, cool naturally until the gauge pressure is zero, open the can and cool to about 60°C .

[0031] ②Saccharification: Add 120U of glucoamylase per gram of raw material, stir for 15 minutes, then keep warm at 60°C for 2.5 hours, stir once every half hour during this period, and the starch saccharification rate should be about 60%.

[0032] ③ Medium preparation: Dilute the saccharification solution with water to 13Bx, adjust the pH to 5.0, then warm the prepare...

Embodiment 2

[0038] Embodiment 2: the preparation of lactic acid bacteria culture fluid

[0039] (1) Primary seed cultivation

[0040] Lactobacillus acidophilus (CICC 6005) slant strains were inoculated into a 250mL Erlenmeyer flask filled with 50mL MRS liquid medium, cultured statically at 37°C for 30h, and the pH dropped to 4.0.

[0041] (2) Secondary seed cultivation

[0042] Dilute the rice saccharification liquid medium to 12Bx, add 1% barley root powder, sterilize at 110°C for 30 minutes, and obtain the lactic acid bacteria medium after cooling. Connect the first-grade seeds with 10% (V), culture statically at 37°C for 16 hours, and the lactic acid content reaches about 18g / L to obtain the lactic acid bacteria culture solution.

Embodiment 3

[0043] Example 3: Production of Rice-flavored Liquor by Liquid Fermentation of Xiaoqu Pure Grain

[0044] 1. Raw material crushing

[0045] 3.4kg of high-quality indica rice, crushed, of which more than 60% pass through a 20-mesh sieve.

[0046] 2. Liquefaction and gelatinization

[0047] Add 10L of water to the pulverized rice flour, stir well, add 4U of high temperature-resistant α-amylase per gram of rice flour, stir well, heat to 85°C while stirring, and maintain at this temperature for 1h. Continue heating and gelatinize at 0.1MPa and 121°C for 60 minutes to obtain rice gelatinized liquid.

[0048] 3. Bacteria saccharification

[0049]Cool the rice gelatinized liquid to 40°C, add 50U / g of glucoamylase preparation, keep at 40°C, cool to 30°C after 30 minutes, add water to a total volume of 12L, add Guilin Jiuqu pills with a raw material amount of 0.8%, and connect lactic acid bacteria according to the volume ratio Culture solution 1.0%, yeast culture solution inoculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com