A paint method for casting edge sealing edge of furniture components

A technology for components and furniture, applied in the field of edge-sealing paint for furniture components, can solve the problems of limited production scale, low production efficiency, and high production costs, and achieve high production efficiency, prolong service life, and solve the effects of easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below with reference to accompanying drawing, the present invention will be further described by example.

[0019] Refer to attached figure 1 , a kind of furniture member casting edge sealing edge painting method, this furniture component casting edge sealing edge painting method comprises the following steps:

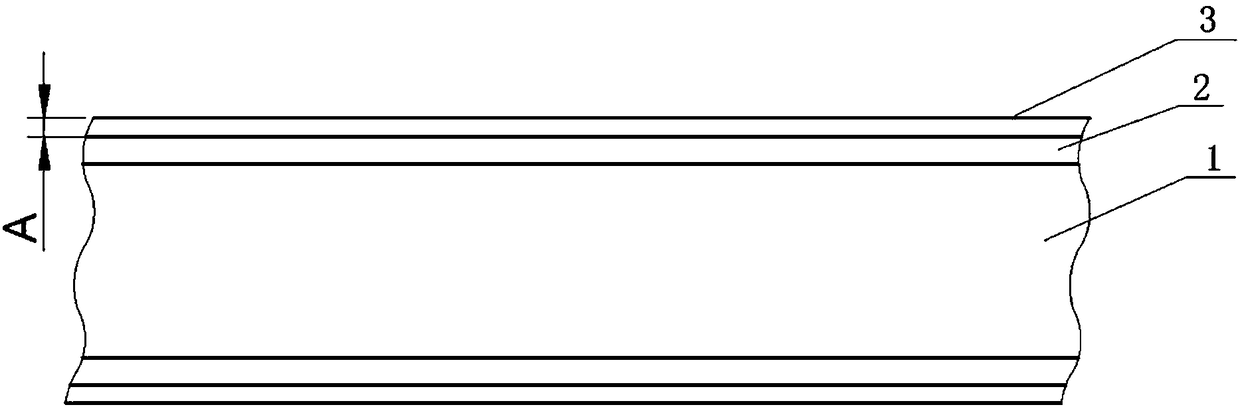

[0020] (1) Grooving: Slot 2 on the side 1 of the furniture component and at the edges and corners on both sides. There is a machining allowance A between the groove 2 and the end face 3 of the furniture component. The machining allowance A is 0.3 mm. In the component, the side 1 is a special-shaped surface, and the end surface 3 is a plane;

[0021] ⑵Painting: Stack and fix the furniture components neatly, expose the grooved special-shaped surface, and coat the high-hardness paint on the special-shaped surface. The coating uses unsaturated polyester resin, and turn the furniture components to make the paint Natural spreading and leveling on the special-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com