Pretreatment method of anaerobic digestion treatment of kitchen garbage

A technology for kitchen waste and anaerobic digestion, which is applied in anaerobic digestion treatment, solid waste removal, fat oil/fat production, etc. The effect of maintenance workload, small footprint and uniform cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

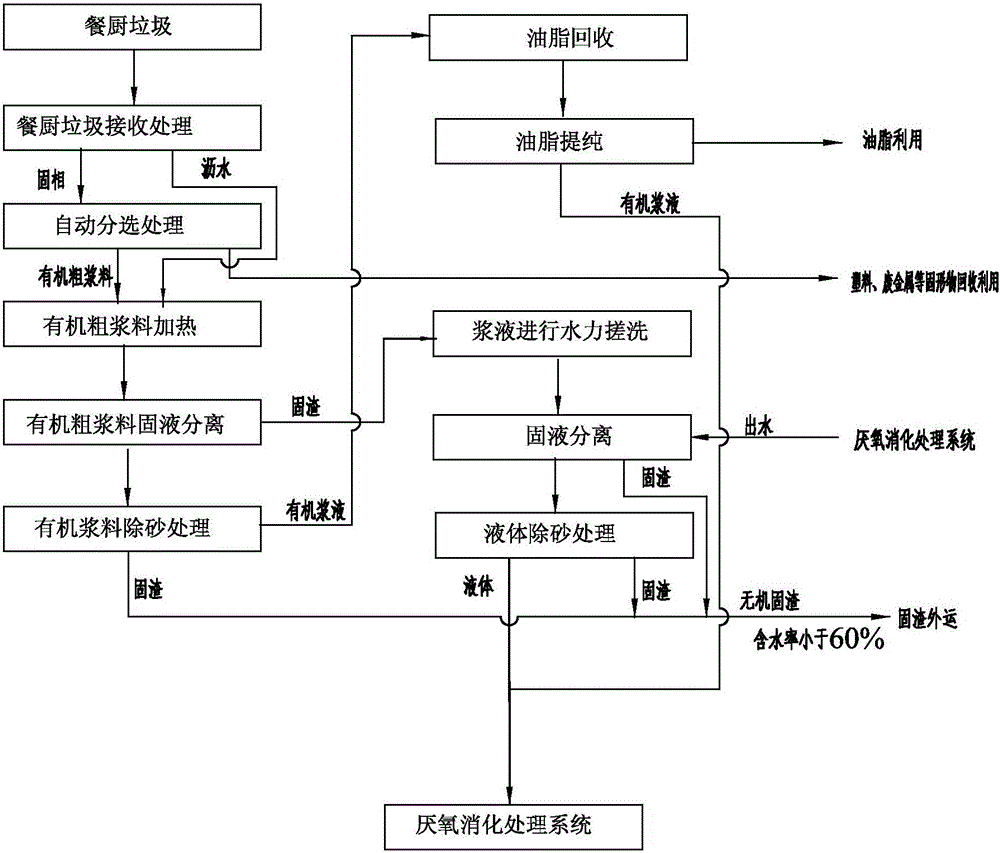

[0029] The pretreatment method of kitchen waste anaerobic digestion of the present invention is carried out according to the following steps,

[0030] (1) Receiving and disposing of kitchen waste.

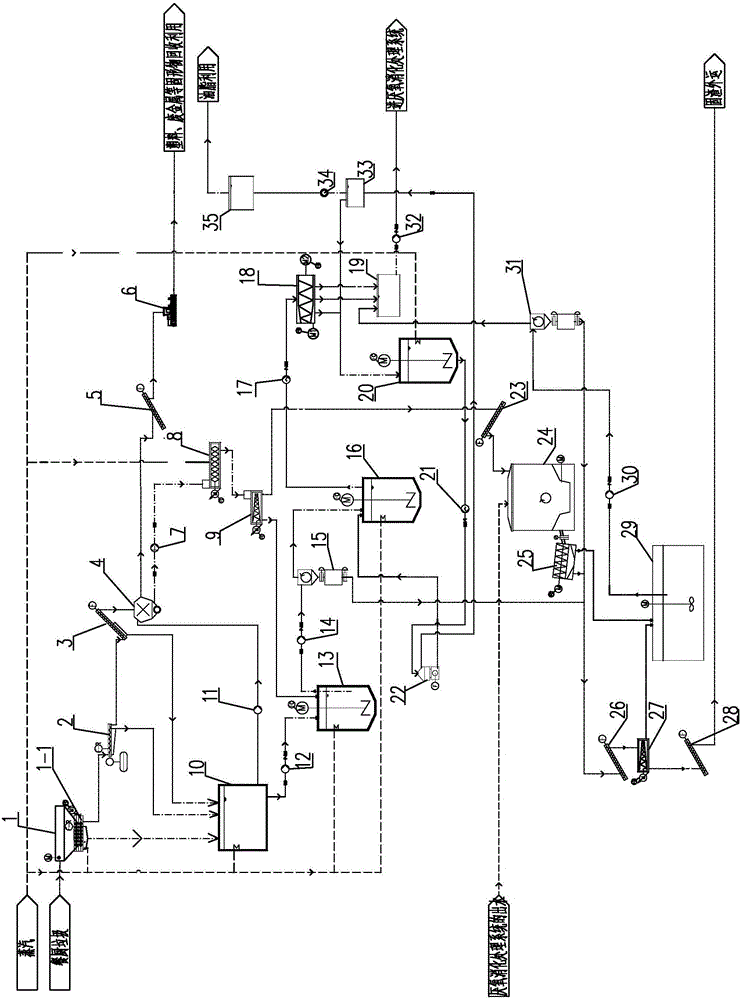

[0031] See figure 1 , 2 As shown, the present invention unloads the kitchen waste onto the grid frame on the upper part of the hopper 1. The grid frame is a frame structure and is installed on the top of the hopper 1 through a rotating shaft. The rotating shaft is connected to the motor, and the grid frame is controlled by the motor. Drive the overturn and put it to a horizontal position, pick out the large materials that cause blockage to the subsequent equipment, sort large-scale miscellaneous materials such as large tablecloths, large cutting boards, large plastics, and large woven bags in the raw materials of food waste, and can clean up at the source The large materials in the kitchen waste raw materials are pre-sorted, which can effectively prevent the stoppage of subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com