Organic waste dry anaerobic high-temperature fermentation system and fermentation process

A dry-type anaerobic fermentation and organic waste technology, applied in fermentation, organic fertilizer, waste fuel, etc., can solve the problems of poor heat transfer effect, poor fluidity, increased process cost, etc., and achieve low energy consumption and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

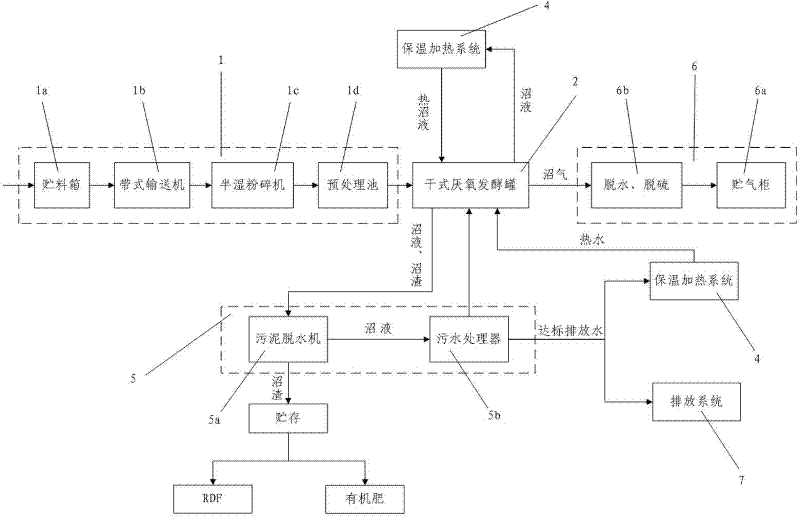

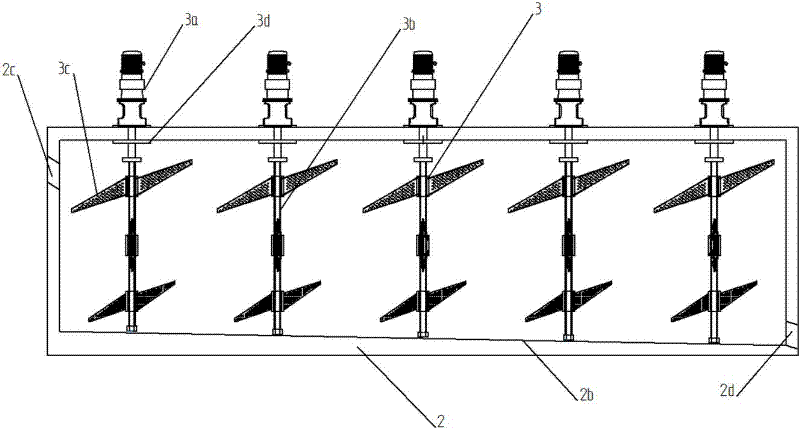

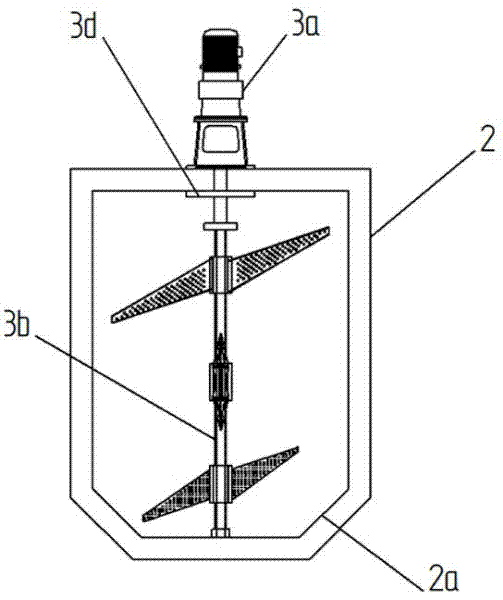

[0028] Such as figure 1 As shown, the organic waste dry-type anaerobic high-temperature fermentation system of the present invention includes a feed system 1, a dry-type anaerobic fermentation tank 2 with a stirring system 3, a thermal insulation heating system 4, a biogas slurry and residue treatment system 5, and an exhaust gas System 6 and control systems. The feeding system 1 includes a storage box 1a, a conveyor 1b, a semi-wet pulverizer 1c, and a pretreatment tank 1d arranged in sequence. The biogas slurry and residue treatment system 5 includes a sludge dehydrator 5a and a sewage processor 5b connected to each other through a pipeline 5c; the exhaust system 6 includes a gas holder connected with a dry anaerobic fermentation tank through a pipeline 6a; the pretreatment tank 1d of the feed system is connected to the feed port of the dry anaerobic fermentation tank 2 through pipelines, and the dry anaerobic fermentation tank 2 is connected to the thermal insulation heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com