Method for quantitatively analyzing material interface properties by combining non-destructive testing and definite element modelling

A quantitative analysis and non-destructive testing technology, which is applied in the direction of analyzing materials, measuring devices, and material analysis through optical means, can solve problems such as differences in analysis results and unreliable results, and achieve high sensitivity and reliable quantitative values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

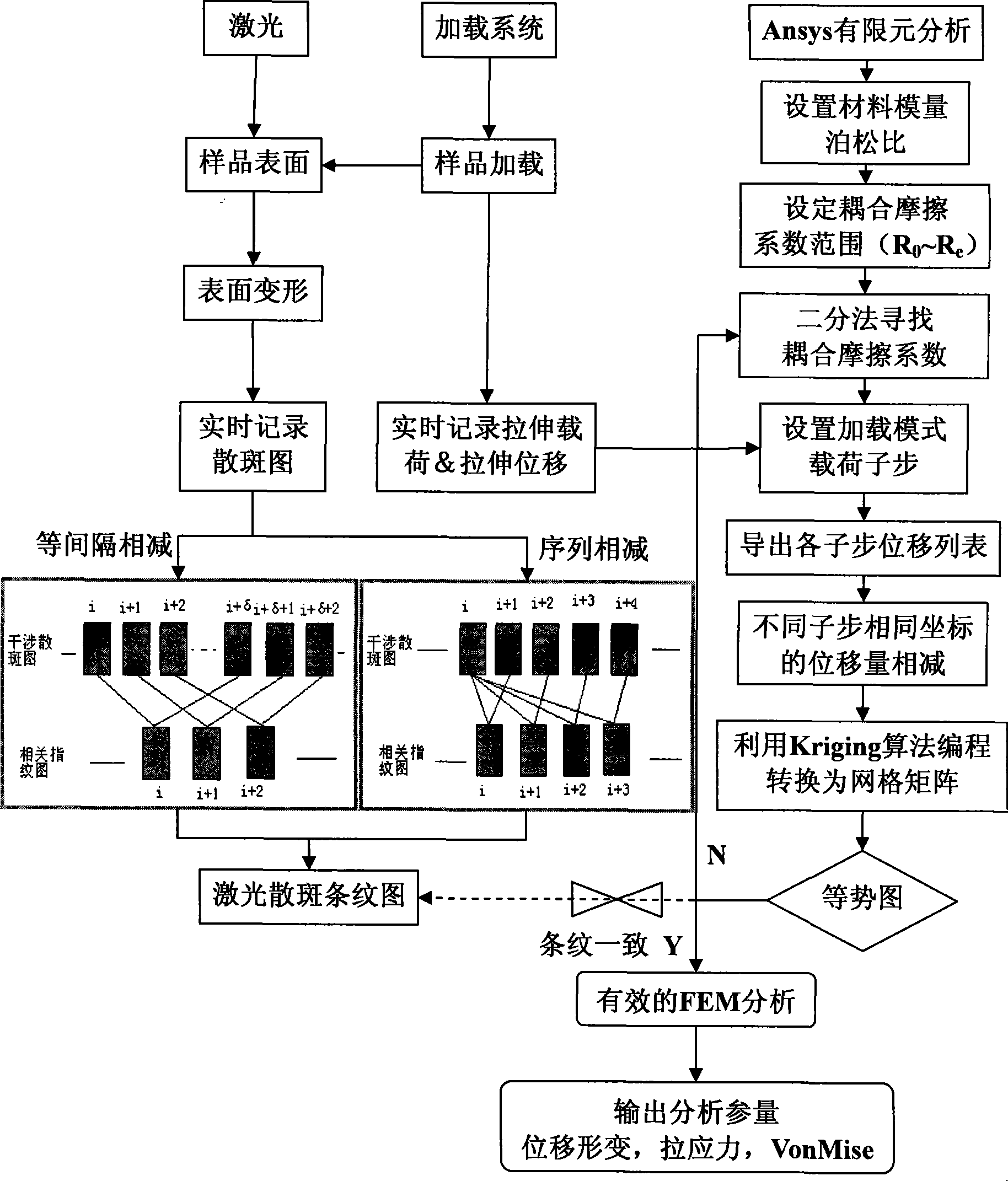

Method used

Image

Examples

Embodiment 1

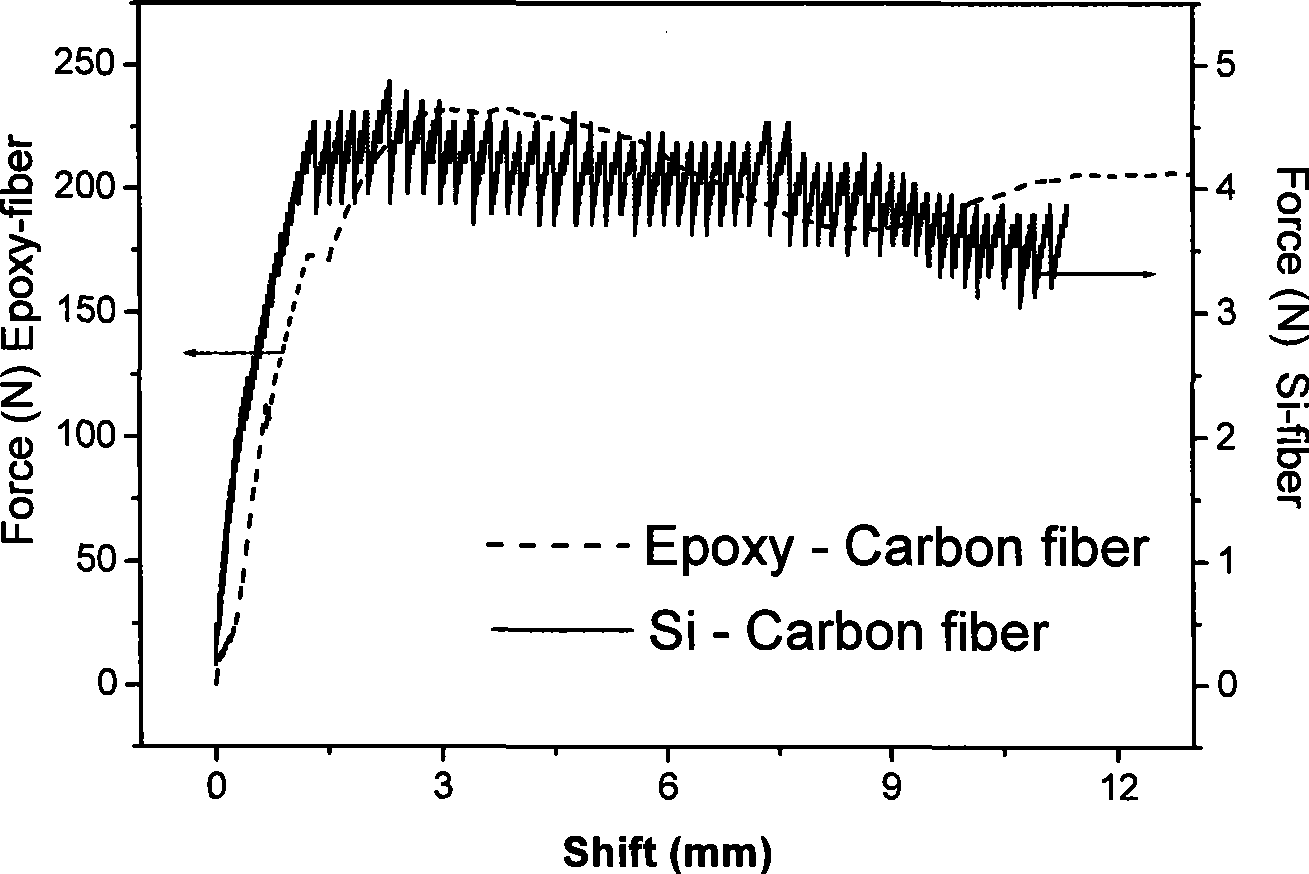

[0034] Embodiment 1, the detection of single-bundle carbon fiber reinforced epoxy resin composite material interface

[0035] The matrix material is epoxy resin (bisphenol A type epoxy resin model is E-51, curing agent low molecular weight polyamide resin model is 651, Wuxi Alz Chemical Co., Ltd.), the reinforcement is a single diameter of 7 μm, each bundle 1000 carbon fiber tows with a length of 150 mm (Dalian Xingke Carbon Fiber Co., Ltd.).

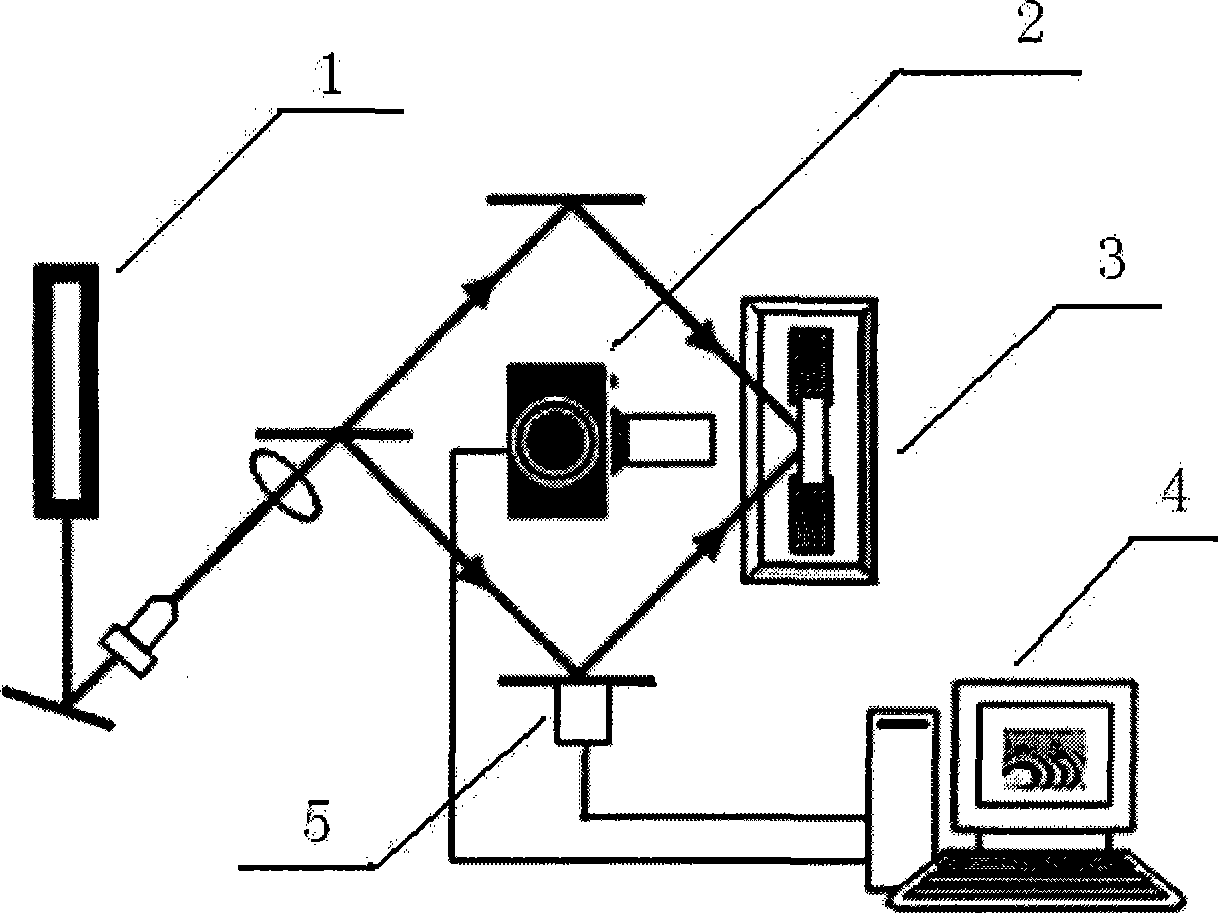

[0036] The detection method is carried out according to the following steps:

[0037] 1) Mix the epoxy resin and curing agent according to the mass ratio of 10:3 and pour it into 80×20×2mm 3 Insert a bundle of carbon fibers into the PTFE mold with a thickness of 1mm. Slowly heat up and cure in an oven according to the program: 60°C for 3 hours, 70°C for 3 hours, 80°C for 3 hours, 105°C for 3 hours, and 120°C for 3 hours until a golden yellow translucent sample is obtained. Take the sample out of the mold, spray white paint on the sur...

Embodiment 2

[0041] Embodiment 2, the detection of single-bundle carbon fiber reinforced silicone rubber composite material interface

[0042] Among the selected composite materials, the matrix material is silicone rubber (GN512, vinyl-terminated dimethylsiloxane catalytic addition, Hong Kong Advanced Technology Industries Co., Ltd.), the reinforcement is a single diameter of 7 μm, 1000 per bundle, and the length 150mm carbon fiber tow carbon fiber (Dalian Xingke Carbon Fiber Co., Ltd.).

[0043] The detection method is carried out according to the following steps:

[0044] 1) Silicone gel 5g is poured into 80×20×2mm 3 In the PTFE mold, a bundle of carbon fibers is inserted into it at a thickness of 1mm. Slowly heat up and vulcanize in an oven according to the program: 60°C for 3 hours, 70°C for 3 hours, 80°C for 3 hours, 105°C for 3 hours, and 120°C for 3 hours until a colorless and translucent sample is obtained. Take the sample out of the mold, spray white paint on the surface, and c...

Embodiment 3

[0047] Example 3, detection of carbon fiber sheet reinforced epoxy resin composite material interface

[0048] The matrix material is epoxy resin (bisphenol A type epoxy resin model is E-51, curing agent low molecular weight polyamide resin model is 651, Wuxi Alz Chemical Co., Ltd.), the reinforcement is a single diameter of 7 μm, each bundle 1000 carbon fibers with a length of 150 mm (Dalian Xingke Carbon Fiber Co., Ltd.).

[0049] The detection method is carried out according to the following steps:

[0050] 1) Mix epoxy resin and curing agent evenly at a mass ratio of 10:3 and pour into 80×20×2mm 3 In the PTFE mould, lay the fiber flat by winding, and brush a thin layer of epoxy resin to pre-cure to 100×20×0.2mm 3 After thinning, carefully place it at 1mm thickness. Slowly heat up and cure in an oven according to the program: 60°C for 3 hours, 70°C for 3 hours, 80°C for 3 hours, 105°C for 3 hours, and 120°C for 3 hours until a golden yellow translucent sample is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com