Foundation pile static test loading counterforce test method and weight boxes used by same

A technology of static load test and test method, which is applied in the test of basic structure, the use of stable tension/pressure test material strength, basic structure engineering, etc., which can solve the problem of increased test cost, long stacking time, and transportation of counterweights Large volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

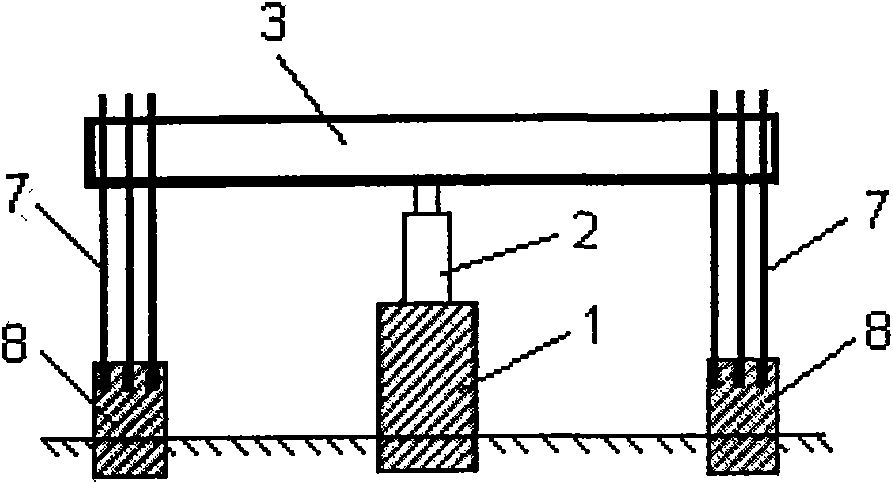

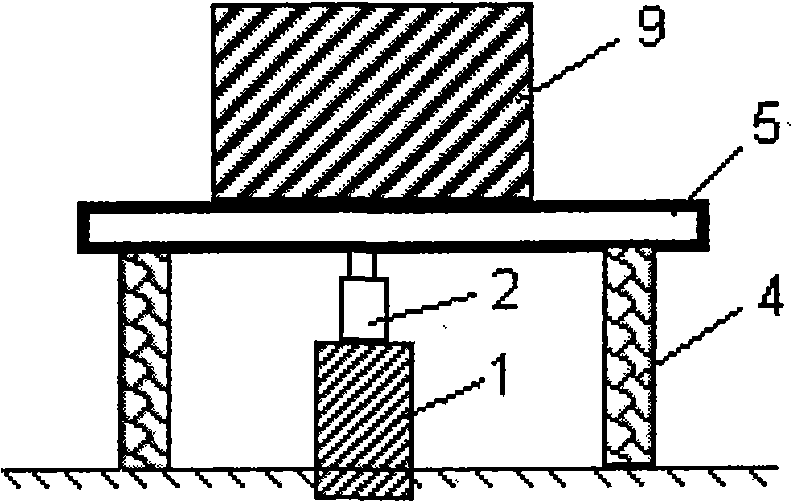

[0017] figure 1 with figure 2 Shown are the basic principles and processes of the currently used test method of the anchor pile beam reaction device system and the test method of the surcharge reaction beam device system.

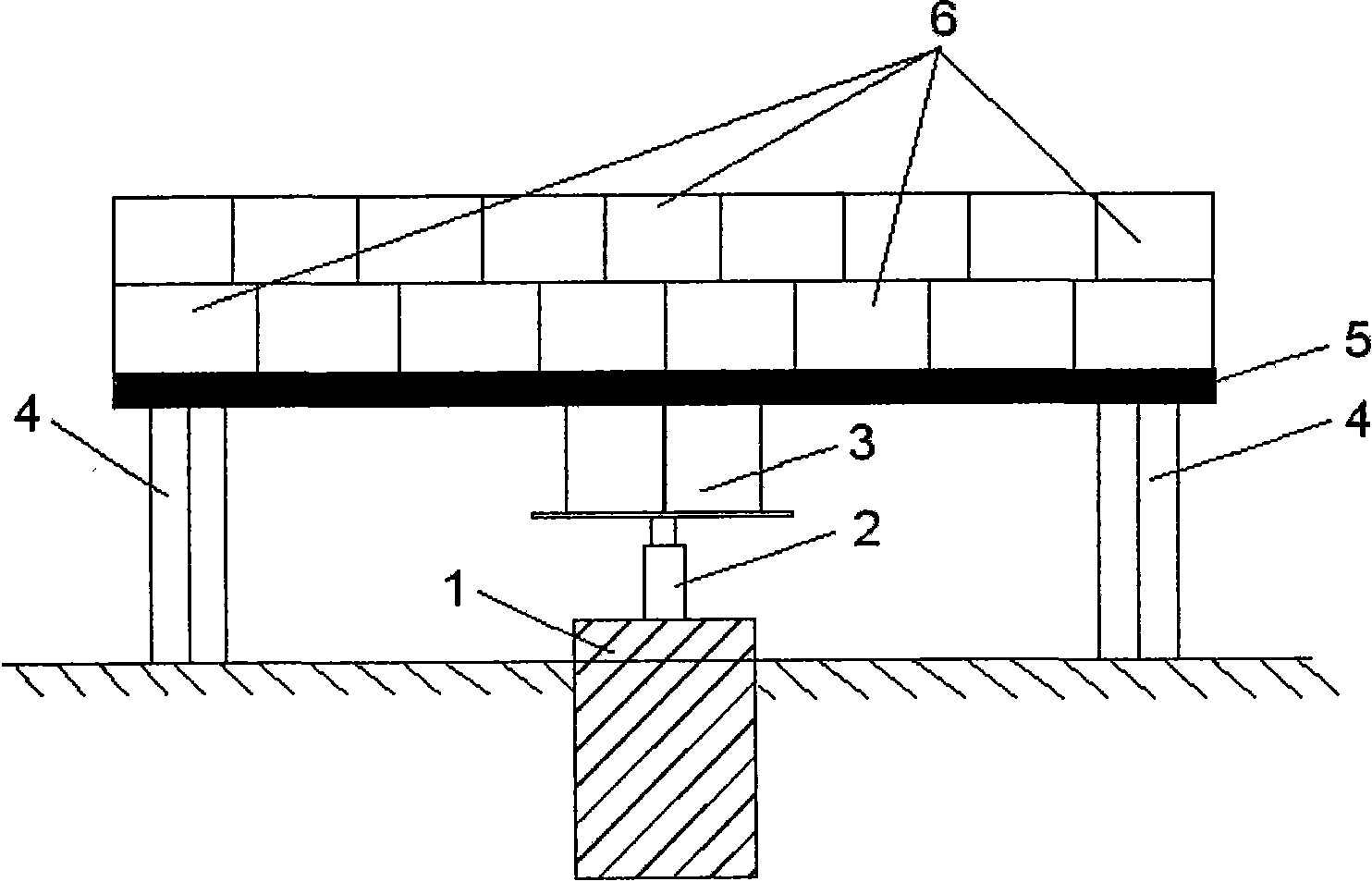

[0018] image 3 Shown is the method for testing the loading reaction force of the foundation pile static load test of the present invention. The jack 2 that is connected with the test instrument is arranged on the top of the foundation pile 1 in a conventional manner, and under the cooperation of the auxiliary support structure 4, the The load-bearing platform 5 constructed by a suitable form of beam structure is stacked with counterweights, and the load bearing capacity of the tested foundation pile 1 is tested when the load-bearing platform 5 is gradually jacked up by the jack 2 through the testing instrument connected with it. Wherein the counterweights stacked on the load-bearing platform 5 are counterweight materials such as sand and stones loaded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com