Patents

Literature

30results about How to "Reduce collapse accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shield tunneling construction method for n-shaped underground diaphragm wall

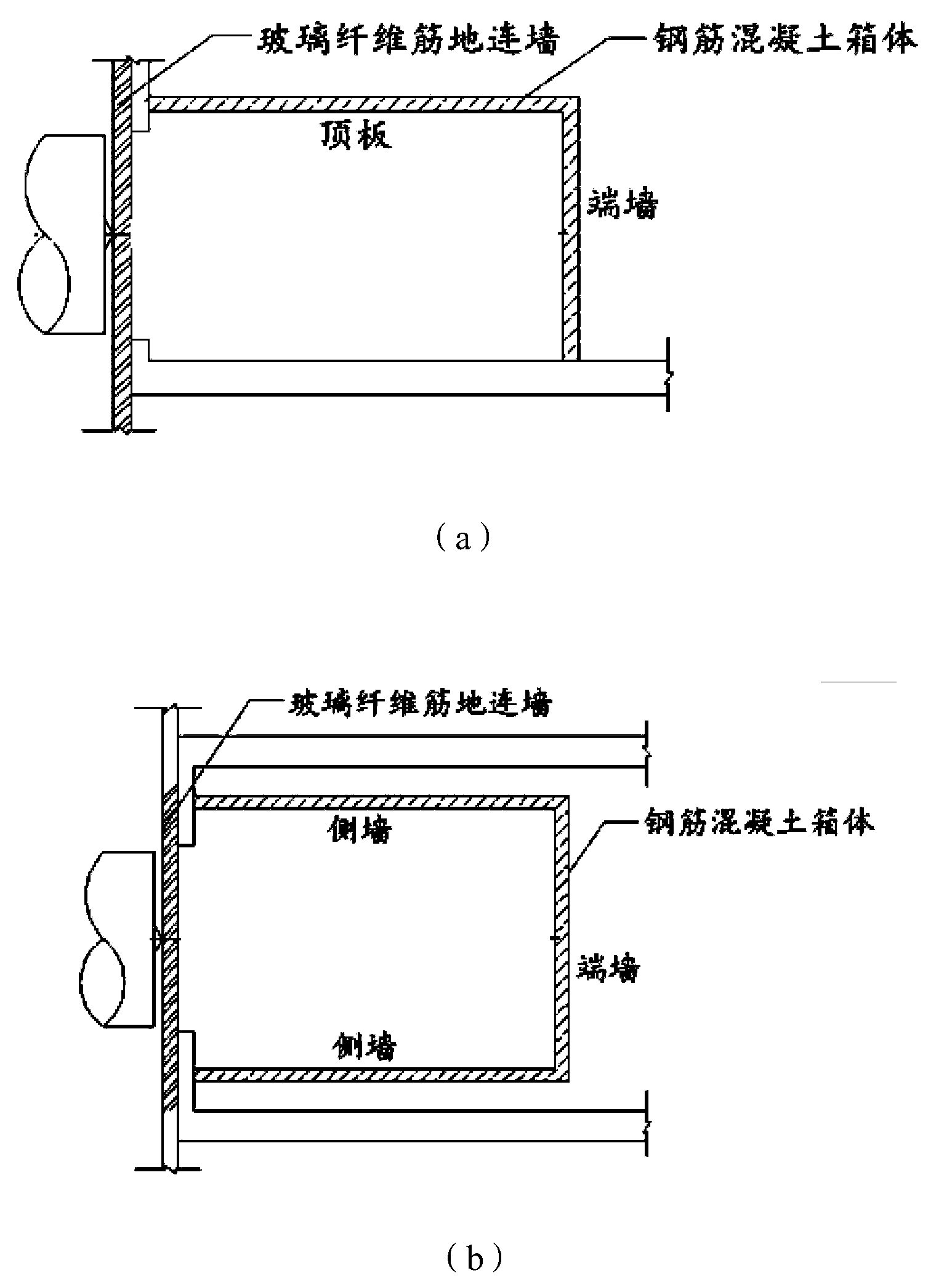

The invention discloses a shield tunneling construction method for an n-shaped underground diaphragm wall. The shield tunneling construction method comprises the following steps of step I, formulating a construction process flow; step II, performing the specific construction process: firstly, measuring and setting out; secondly, manufacturing a guide wall; thirdly, preparing and adjusting slurry; fourthly, trenching the underground diaphragm wall and performing bottom-clearing replacement; fifthly, manufacturing and hanging a GFRP (Glass Fiber Reinforced Plastic) reinforcement cage; sixthly, manufacturing and setting a bamboo reinforcement cage; seventhly, grouting underwater concrete; eighthly, constructing joints; ninthly, topping a joint pipe. The shield tunneling construction method disclosed by the invention has the beneficial effects that a tunnel door is not needed to be manually chiseled, so the construction period is greatly shortened; a soil body on the outer side of an envelope structure is not needed to be reinforced, so the construction cost of engineering is reduced; the envelope structure directly plays roles of retaining soil and stopping water at the shield tunneling stage, and the safety of the shield tunneling is greatly guaranteed.

Owner:HAINAN UNIVERSITY

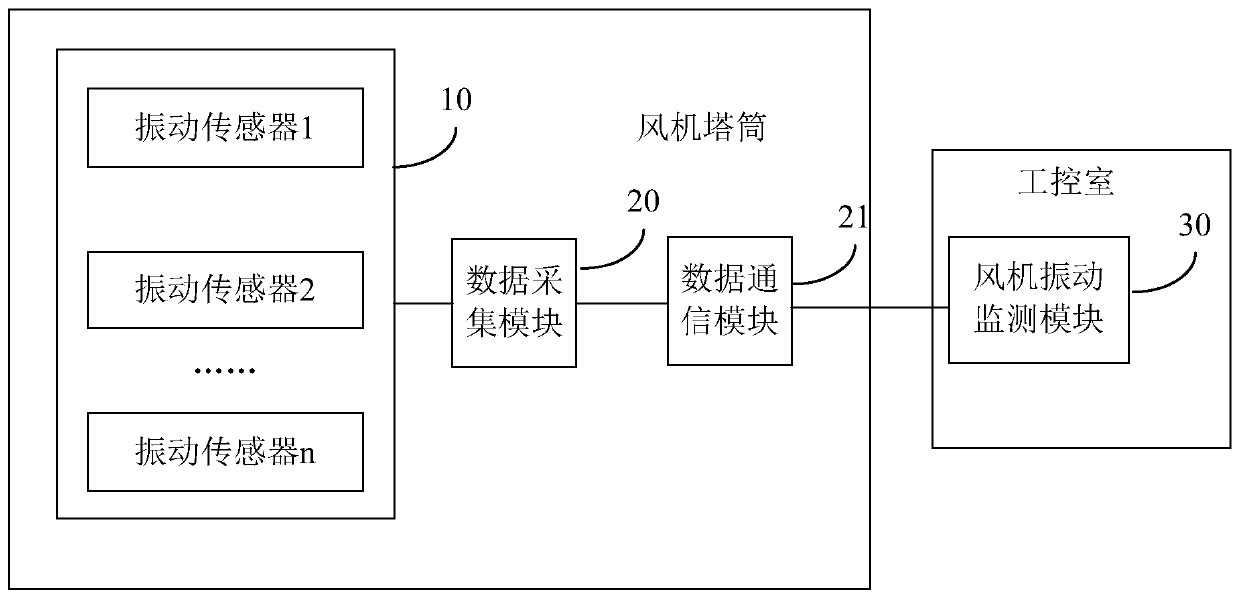

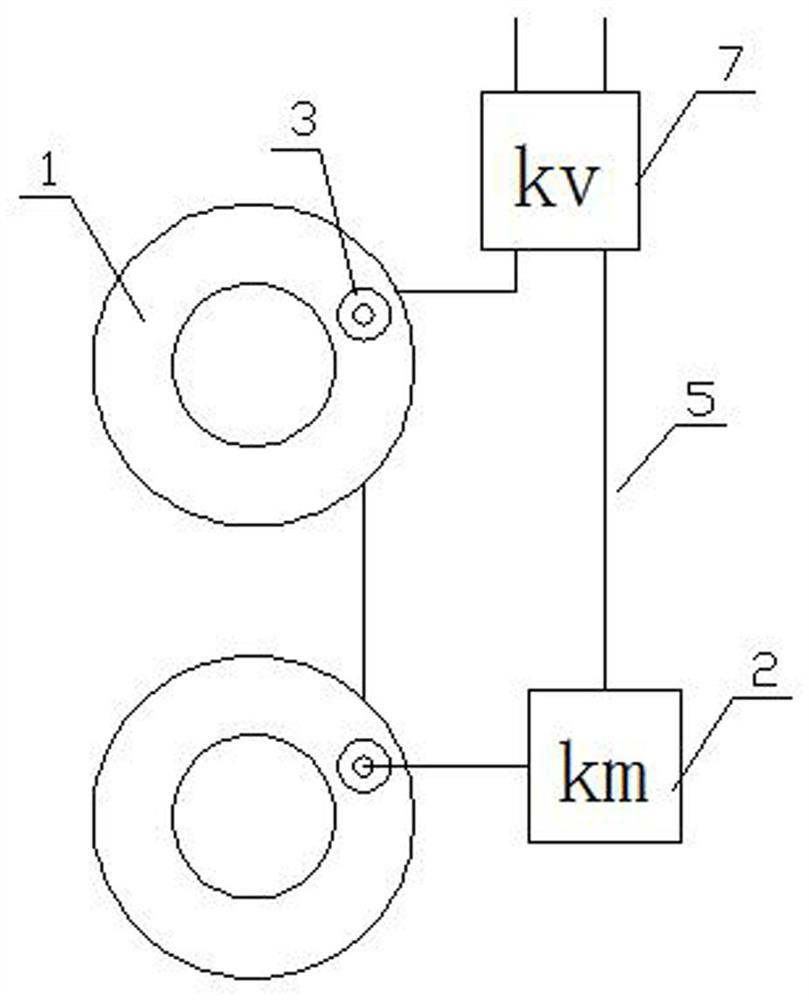

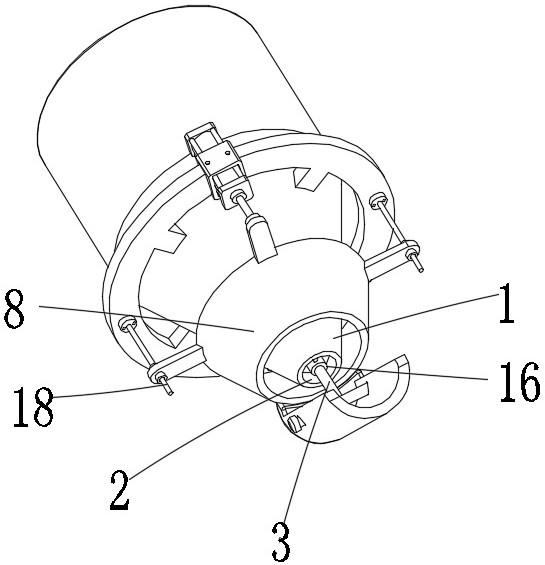

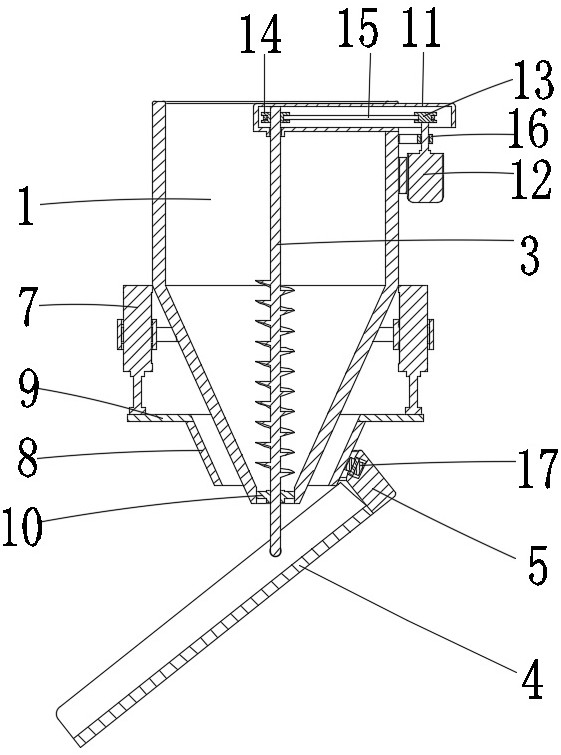

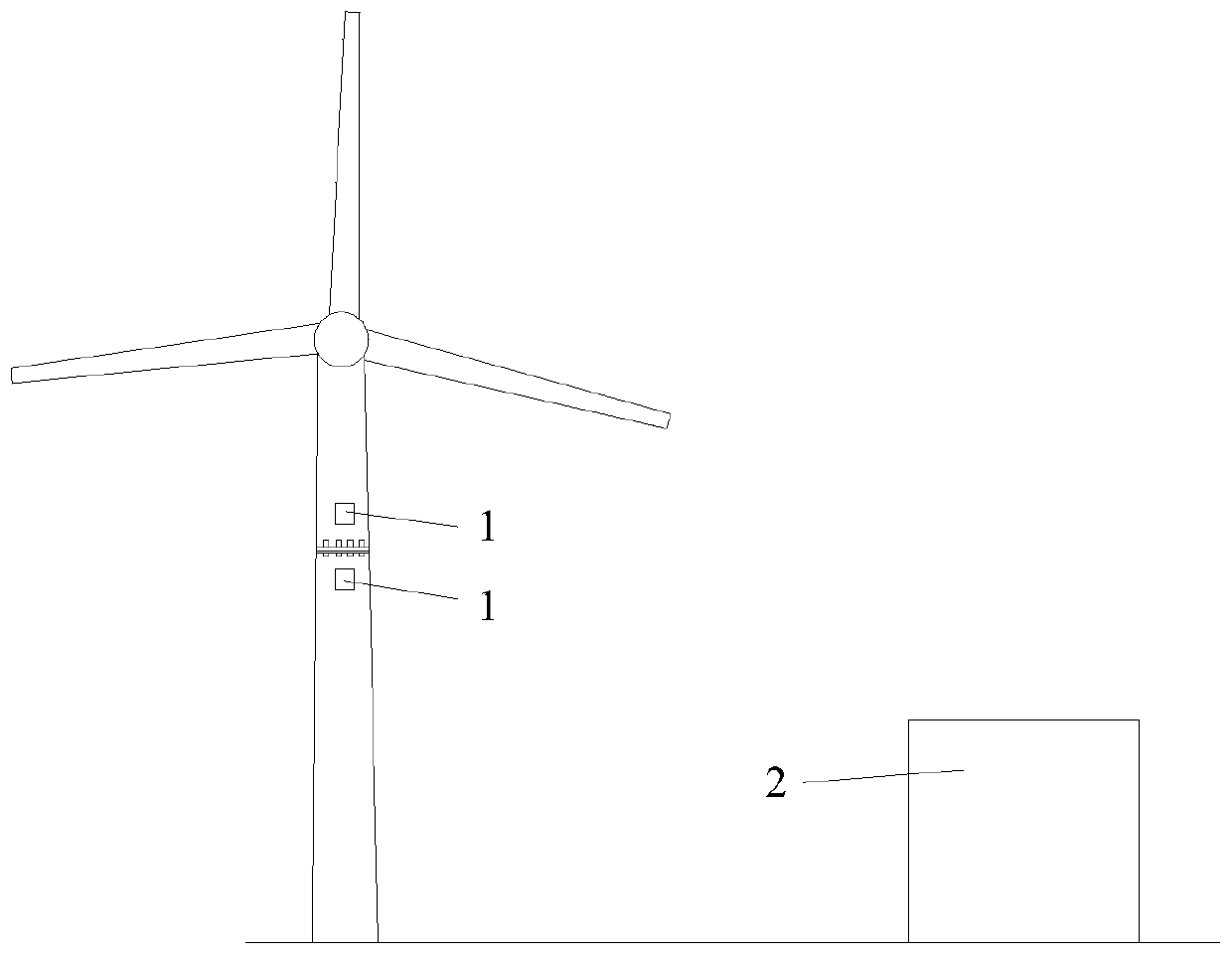

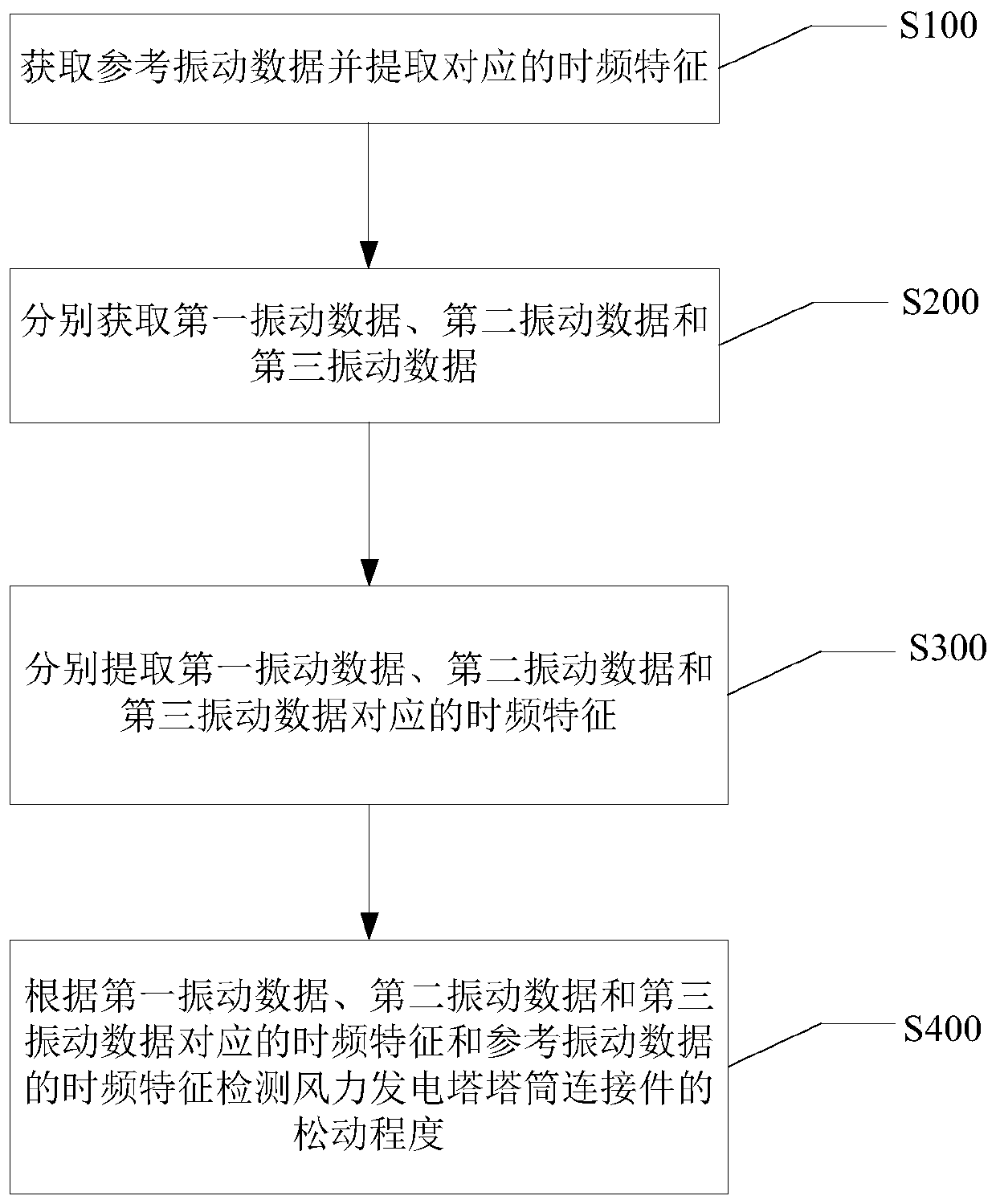

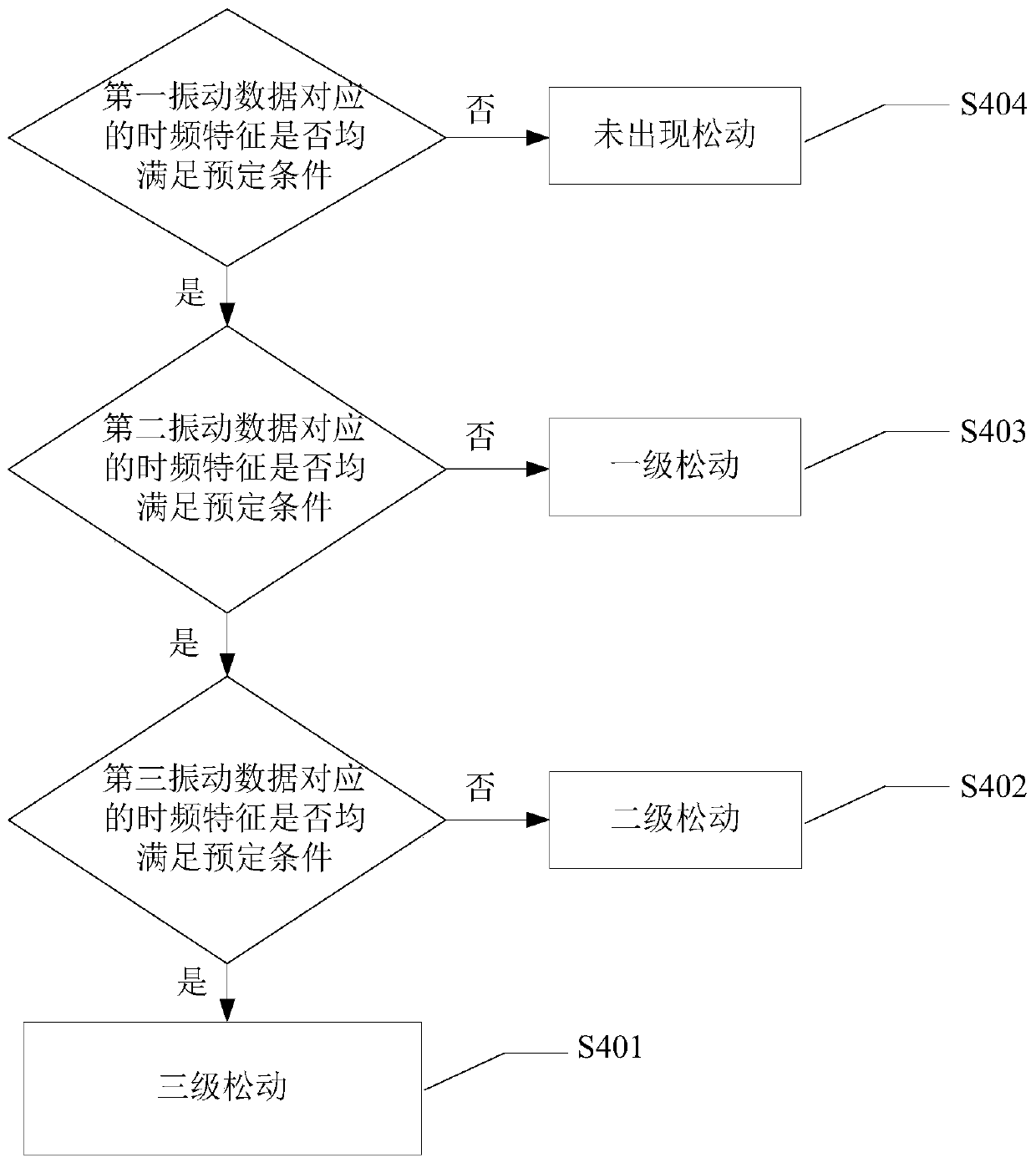

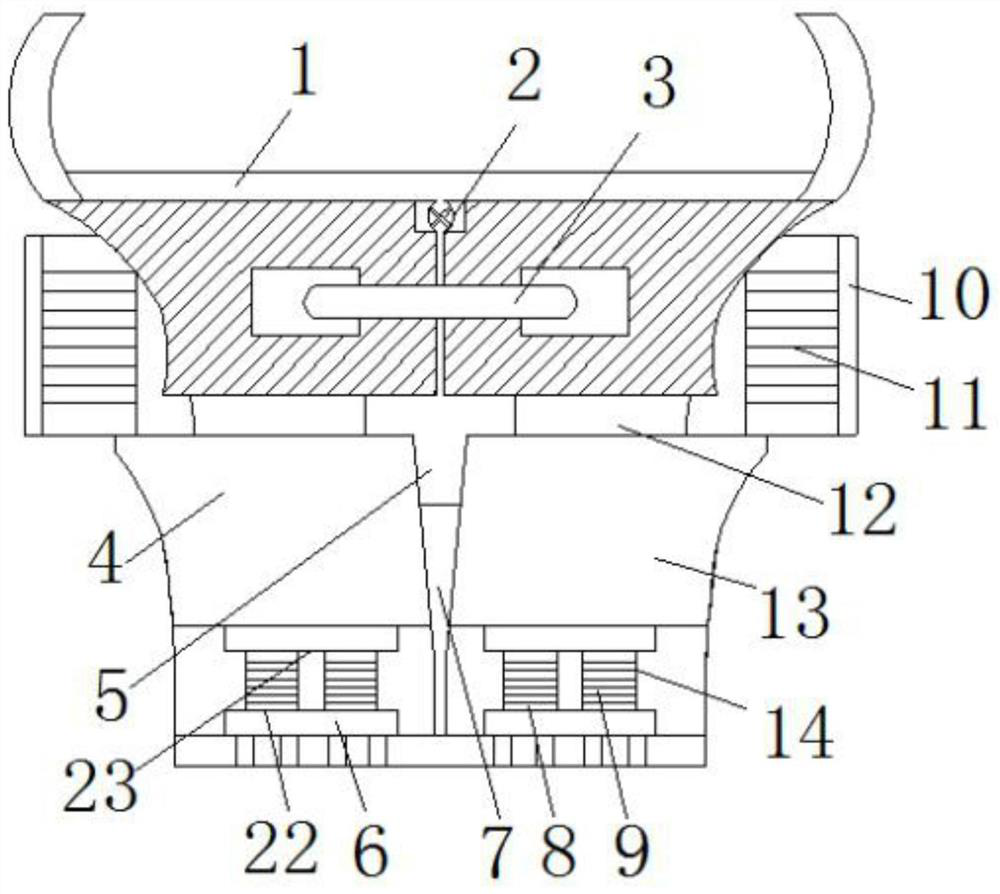

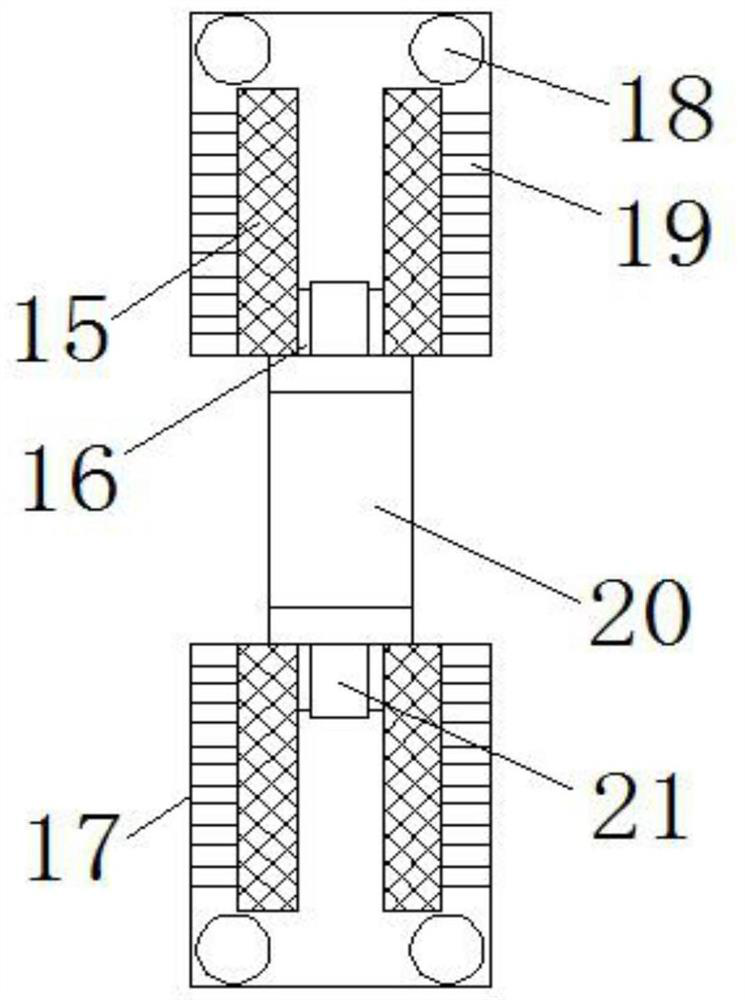

Method and device for detecting loosening degree of connecting part of wind power generation tower

InactiveCN107153002AReduce collapse accidentsEasy to detectMachine part testingNatural disasterEngineering

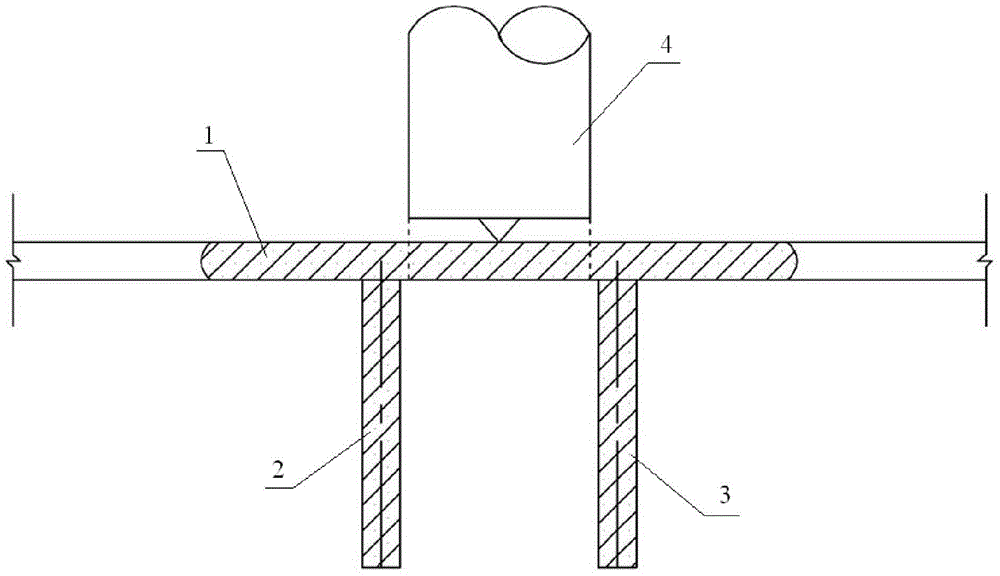

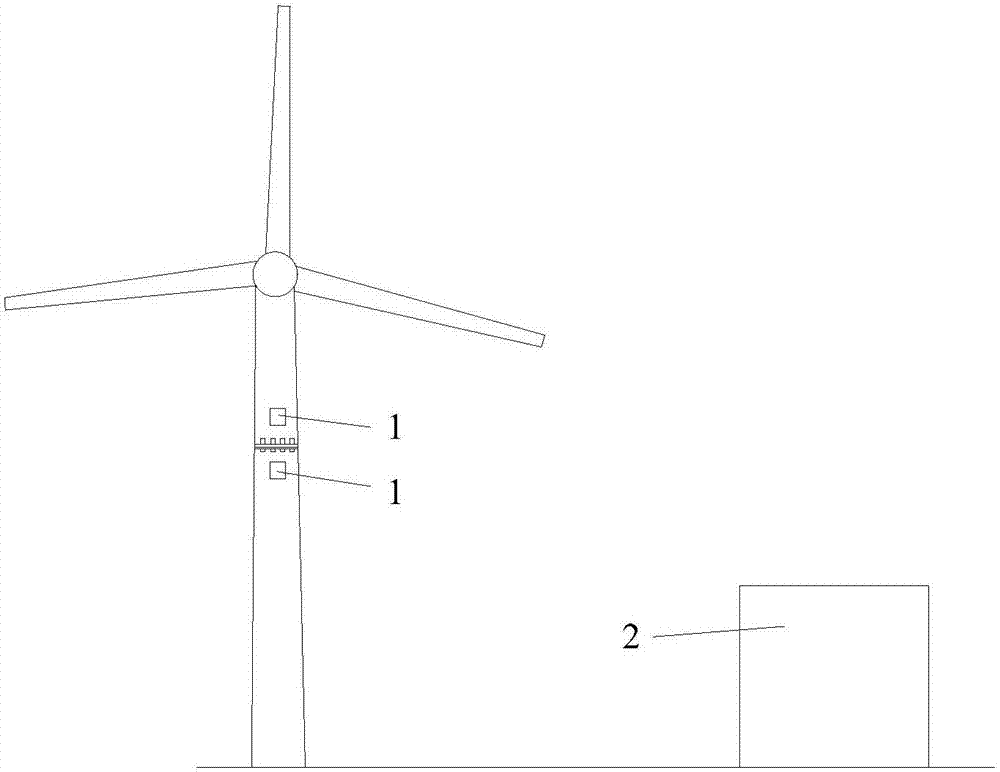

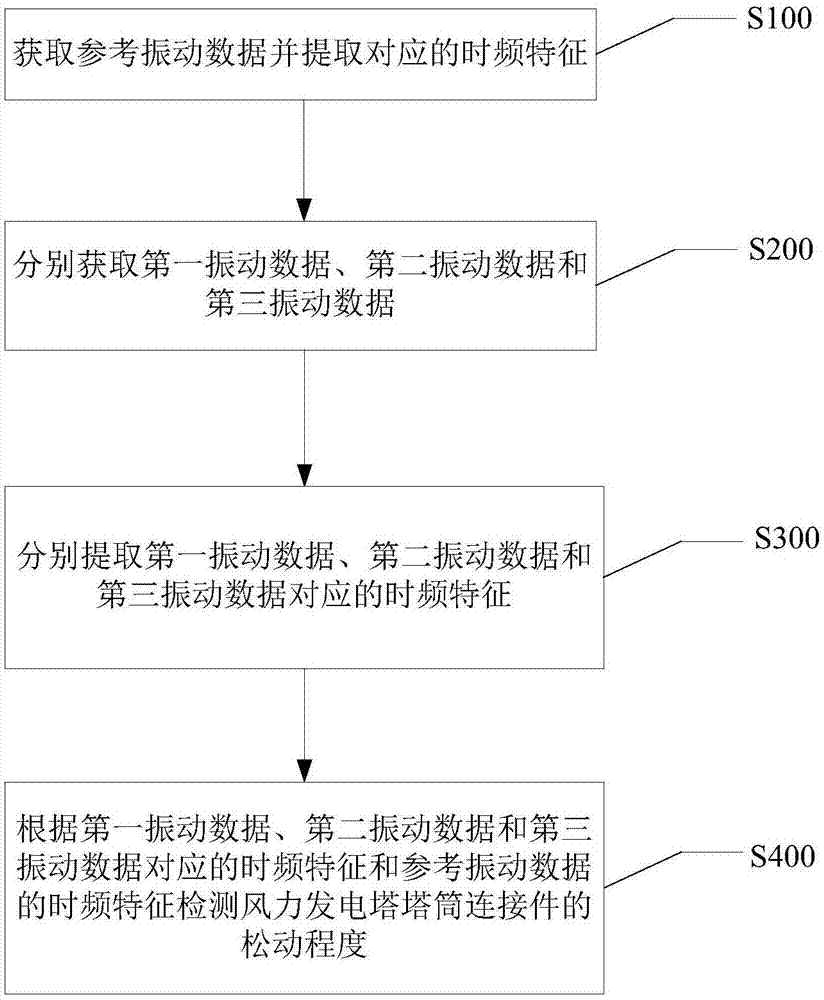

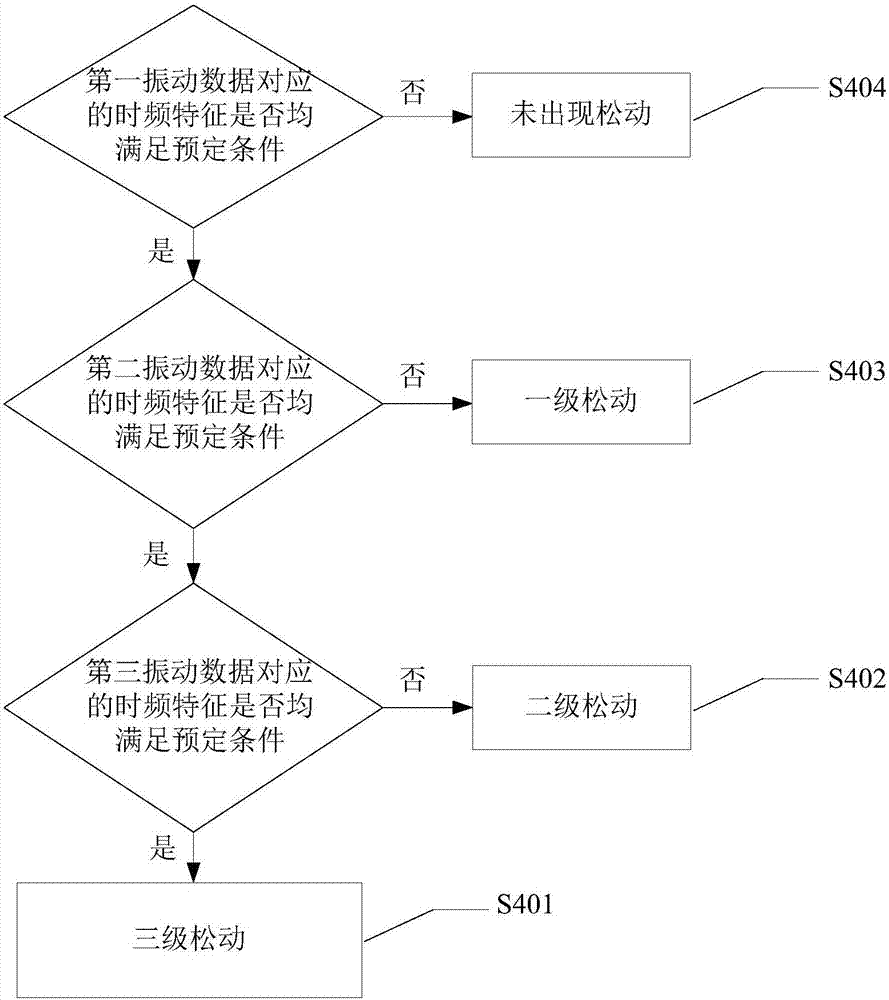

The invention discloses a method and device for detecting the loosening degree of a connecting part of a wind power generation tower, and the method comprises the steps: setting a sensor at each of two sides of the connecting part of the wind power generation tower, and obtaining the vibration data of the wind power generation tower in a first wind speed section after the arrival of typhoon at each time, the vibration data in a second speed section and the vibration data in a third wind speed section; comparing the three pieces of obtained vibration data with the reference vibration data of the initial wind speed of the wind power generation tower in the first section, and judging the loosening degree of the connecting part of the wind power generation tower after the typhoon at each time. Therefore, the method achieves the automatic detection and recognition of the loosening degree of the connecting part of the wind power generation tower, improves the maintenance efficiency of the loosening damage of the connecting part of the wind power generation tower, reduces the collapse accidents of the wind power generation tower, and has the important significance in prevention and reduction of natural disasters.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION +1

Shield excess hole construction method

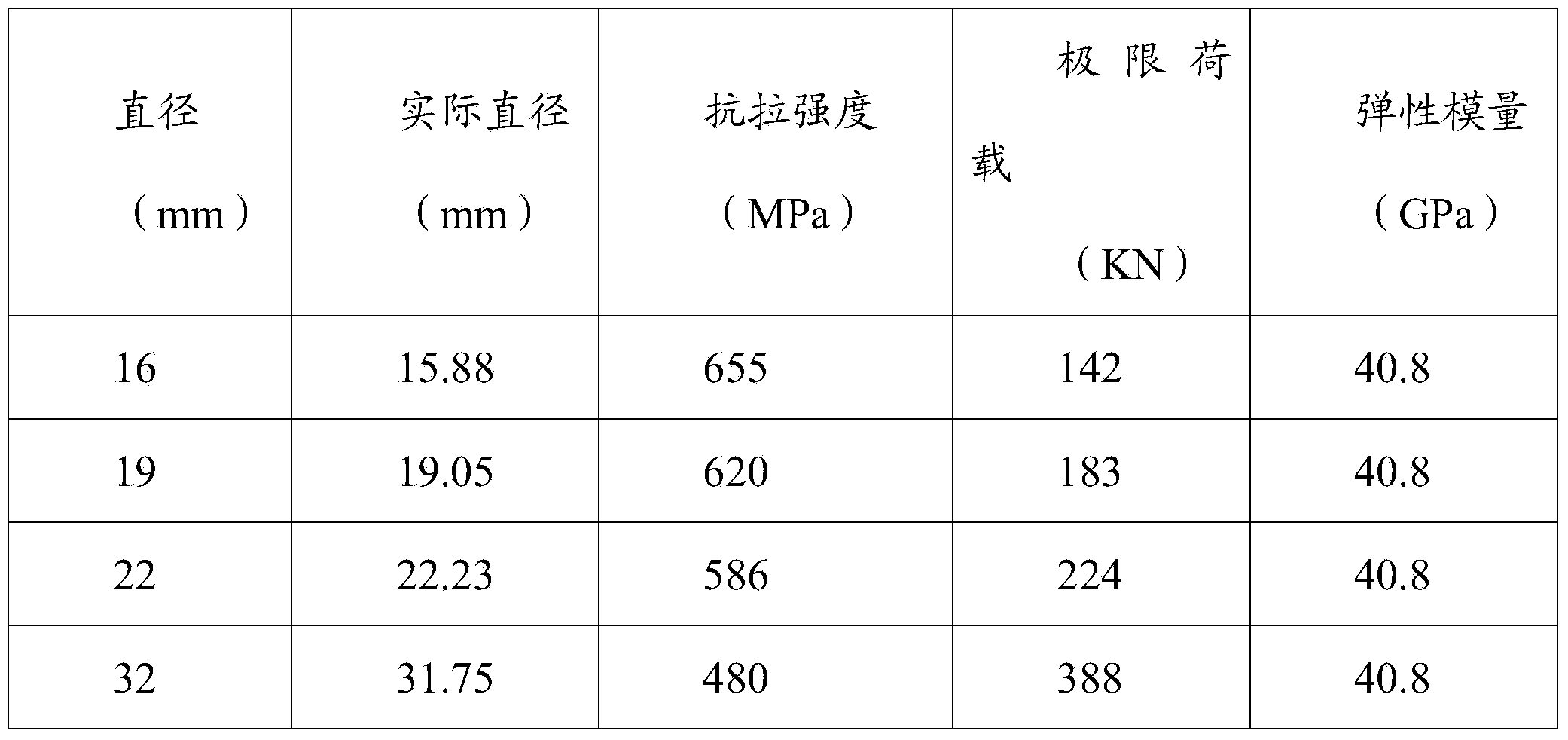

The invention provides a shield excess hole construction method. After a body structure of a shield well is finished, an underground continuous wall serves as an enclosing structure; glass fiber ribs are used for replacing reinforcements in the position of a shield tunneling machine crossing through a hole door of a groove wall of the underground continuous wall; a reinforcement concrete box is cast before the hole door, and is filled with soil for sealing; when the shield is started, the shield tunneling machine is closed in the reinforcement concrete box by the filled soil; when the shield is arrived, the whole reinforcement concrete box is fully filled with the filled soil; the shield tunneling machine directly cuts off the hole door to finish the starting or the arrival; when the shield is started, the shield tunneling machine directly cuts off the hole door in the closed reinforcement concrete box to finish the starting; and when the shield is arrived, the shield tunneling machine enters the closed reinforcement concrete box to finish the arrival after directly cutting off the hole door.

Owner:HAINAN UNIVERSITY

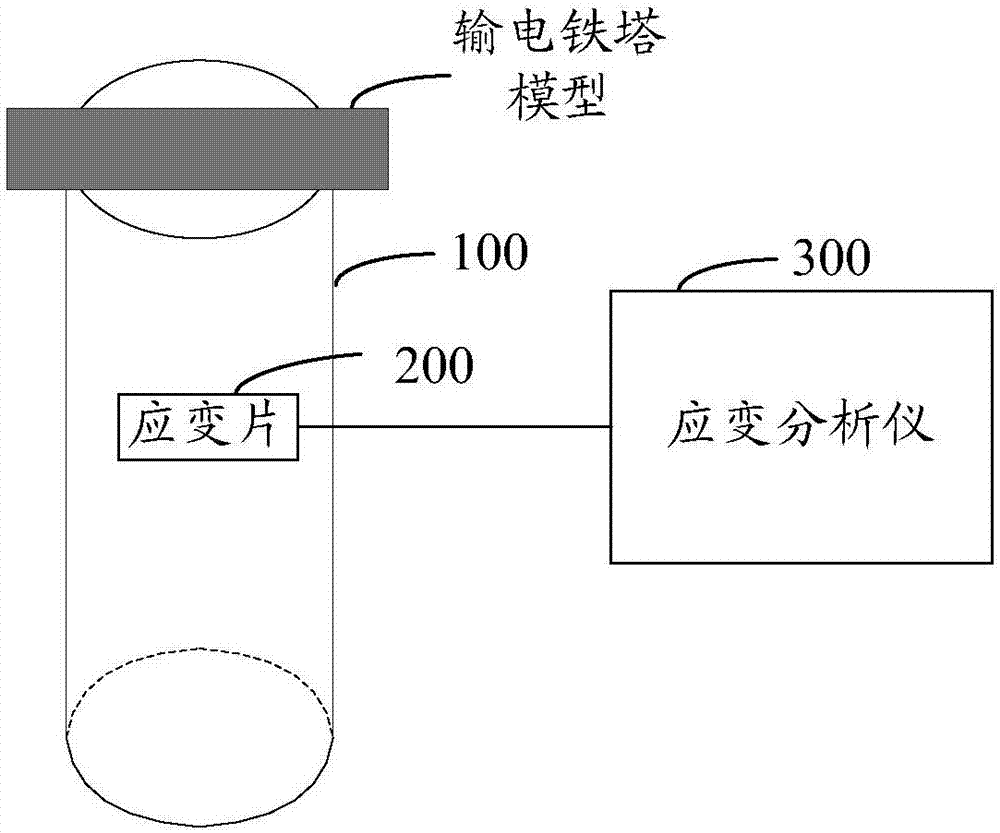

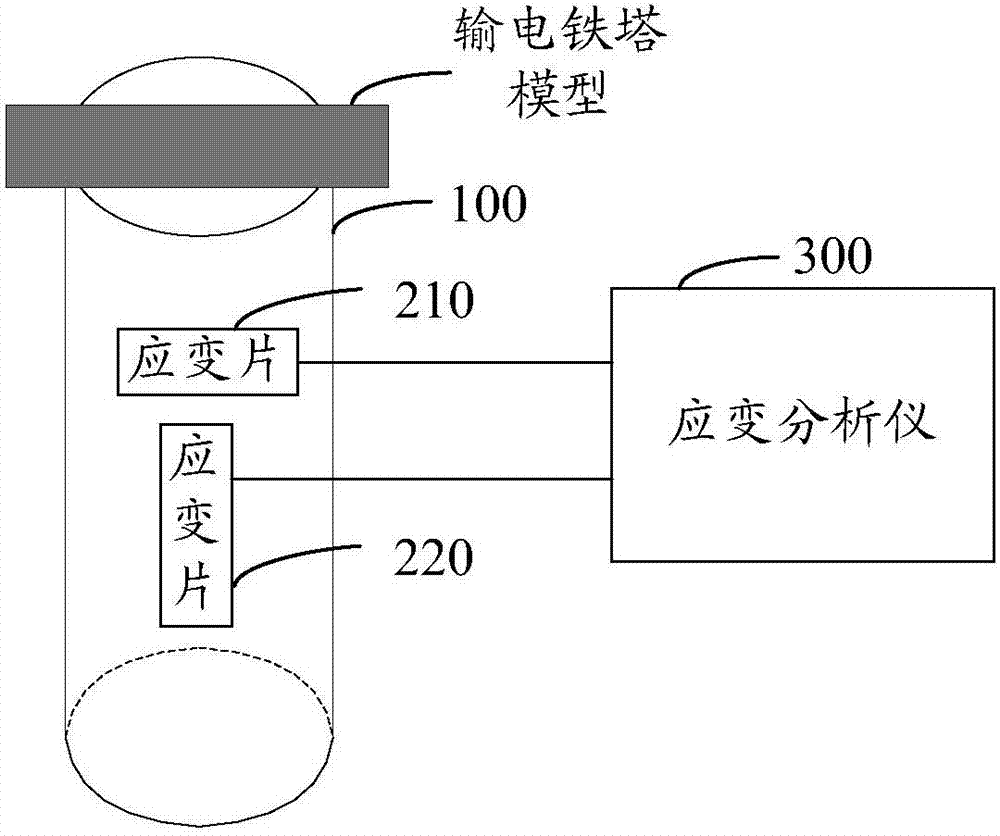

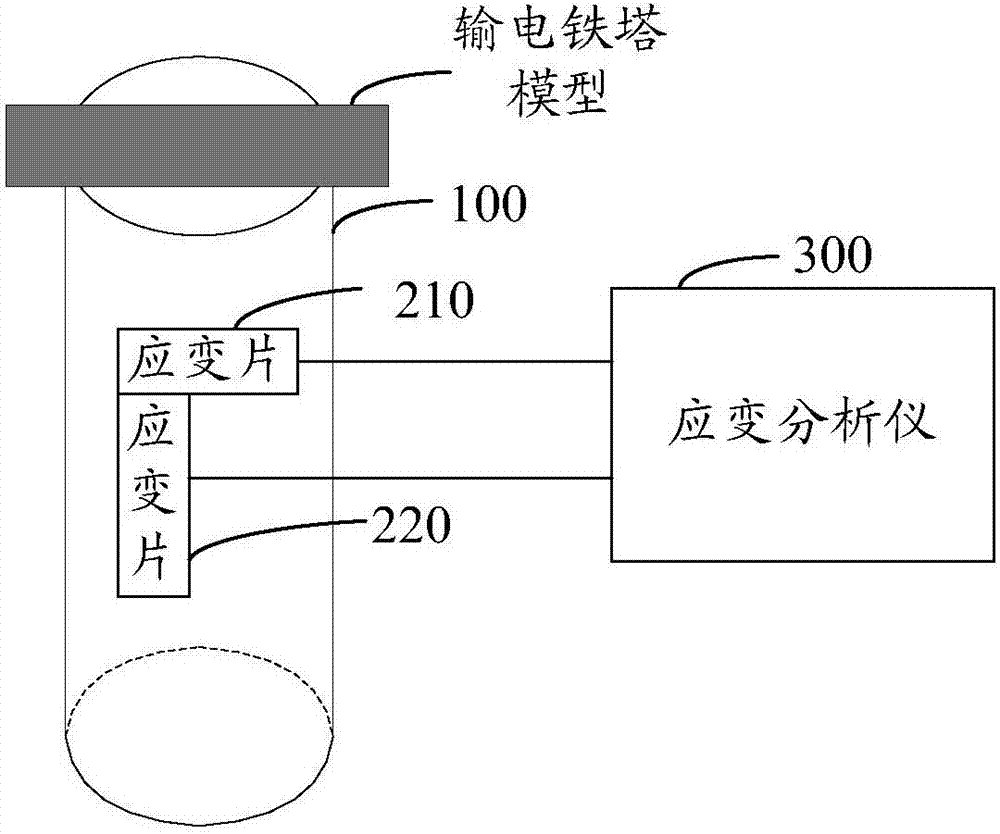

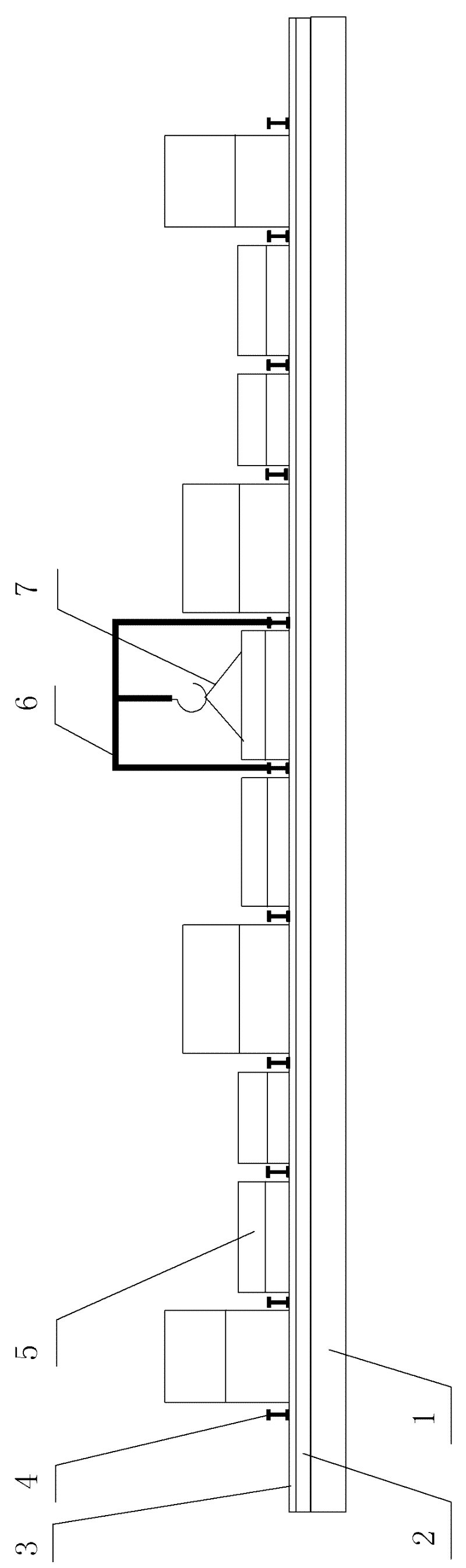

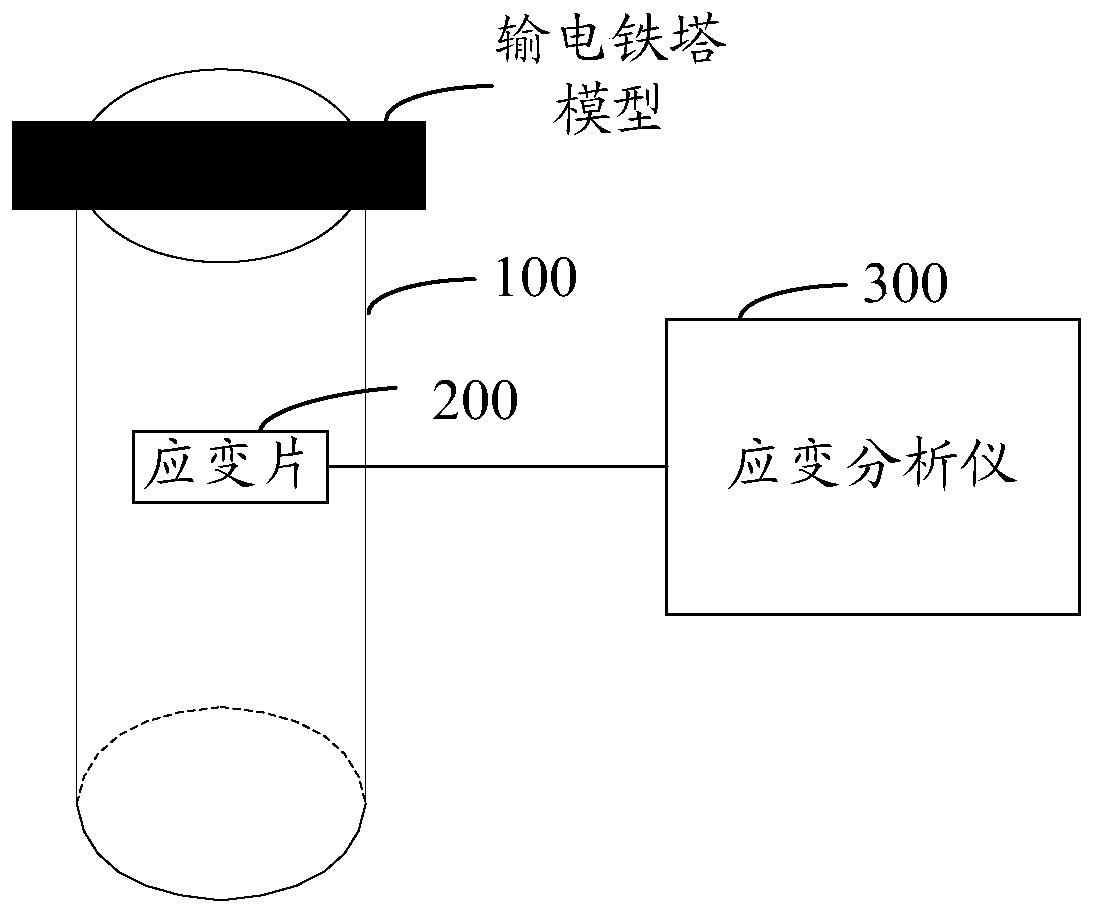

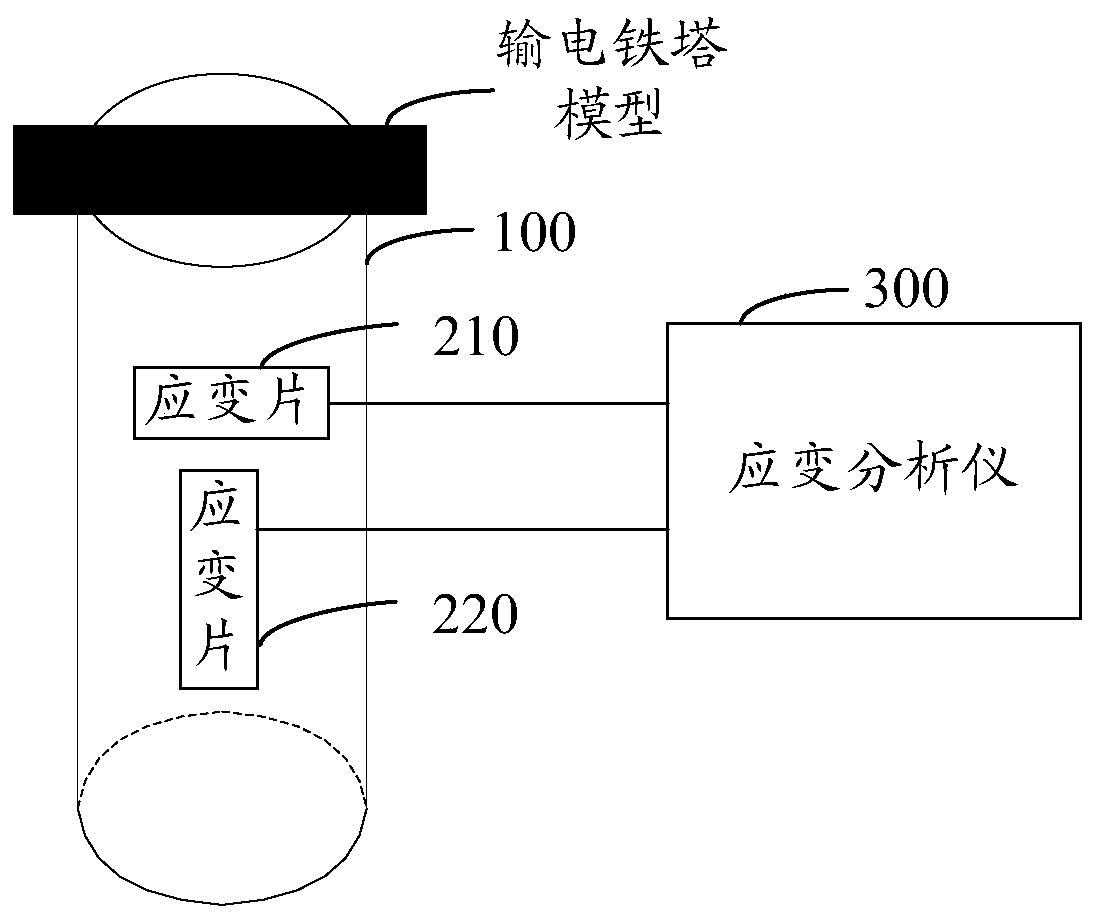

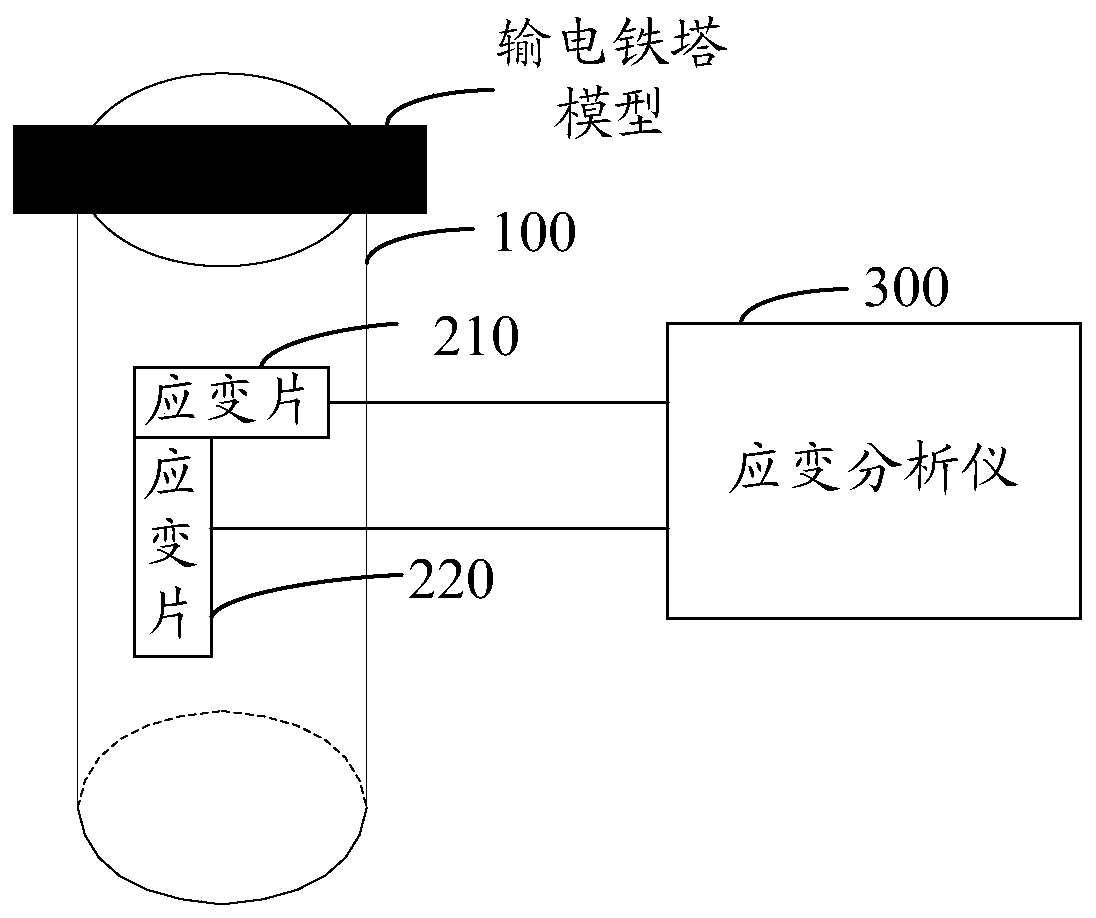

Transmission tower model wind power measurement device and measurement method thereof

ActiveCN107101800AImprove securityReduce collapse accidentsAerodynamic testingTransmission towerMeasurement device

The present invention relates to a transmission tower model wind power measurement device and a measurement method thereof. The wind power measurement device comprises a transmission tower model measurement cylinder, a strain gauge pasted on the wall of the measurement cylinder and a strain analyzer connected with the strain gauge; when measurement, the measurement cylinder is vertically arranged to allow one end of the measurement cylinder to face upwards, the transmission tower model is arranged on this end, the strain analyzer collects strain value data of the strain gauge, and the size of wind power of the model is obtained according to the corresponding relation of model force and the strain value of the strain gauge and the change of the strain value of the strain gauge before and after application of wind power. The transmission tower model wind power measurement device and the measurement method thereof measure the strain gauge on the measurement cylinder to measure the wind power of the transmission tower model, and the size of the measurement cylinder can be designed according to the concrete shape of the transmission tower model, so that the transmission tower model wind power measurement device and the measurement method thereof are suitable for large-volume, heavy and complex transmission tower model wind power measurement and are simple in measurement process and easy to realize.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

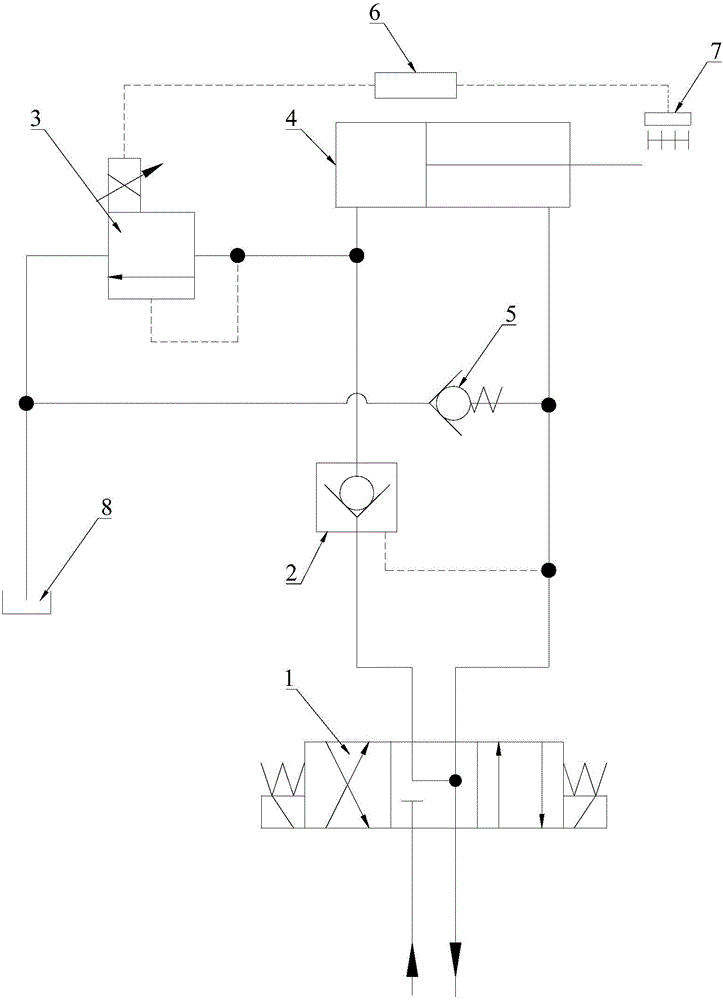

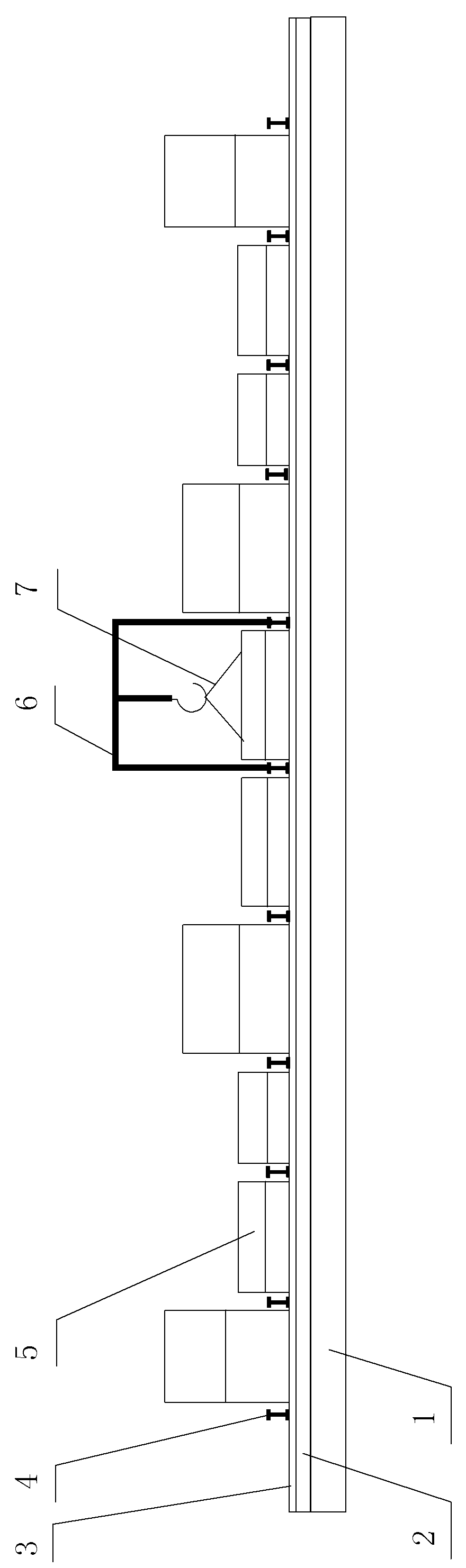

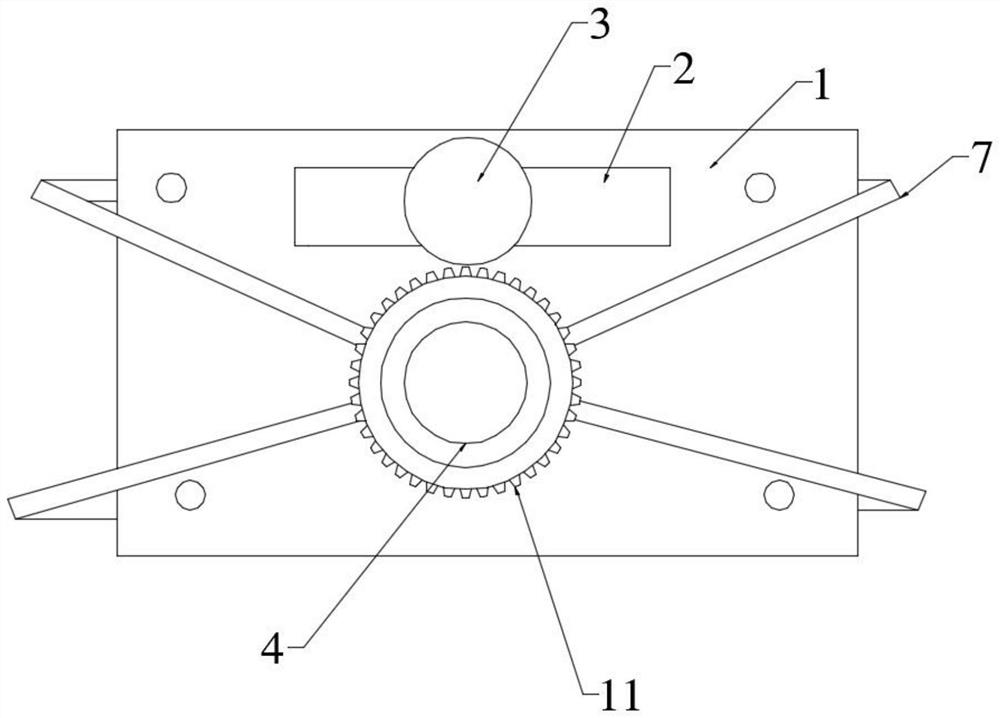

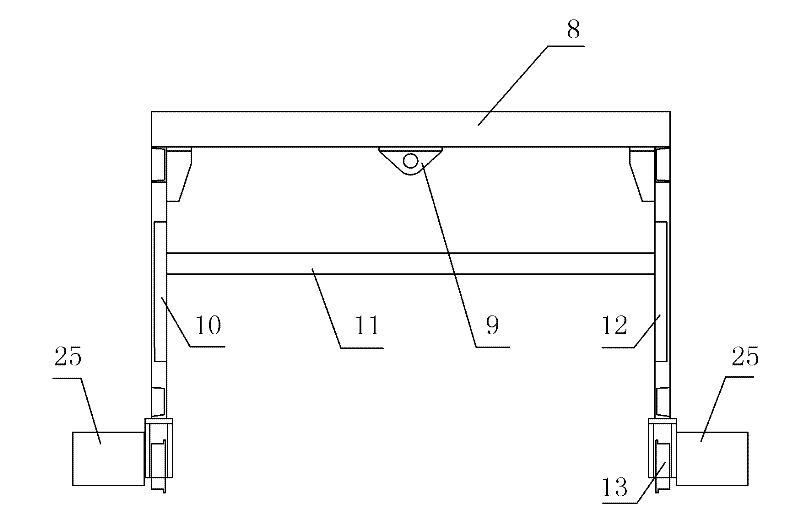

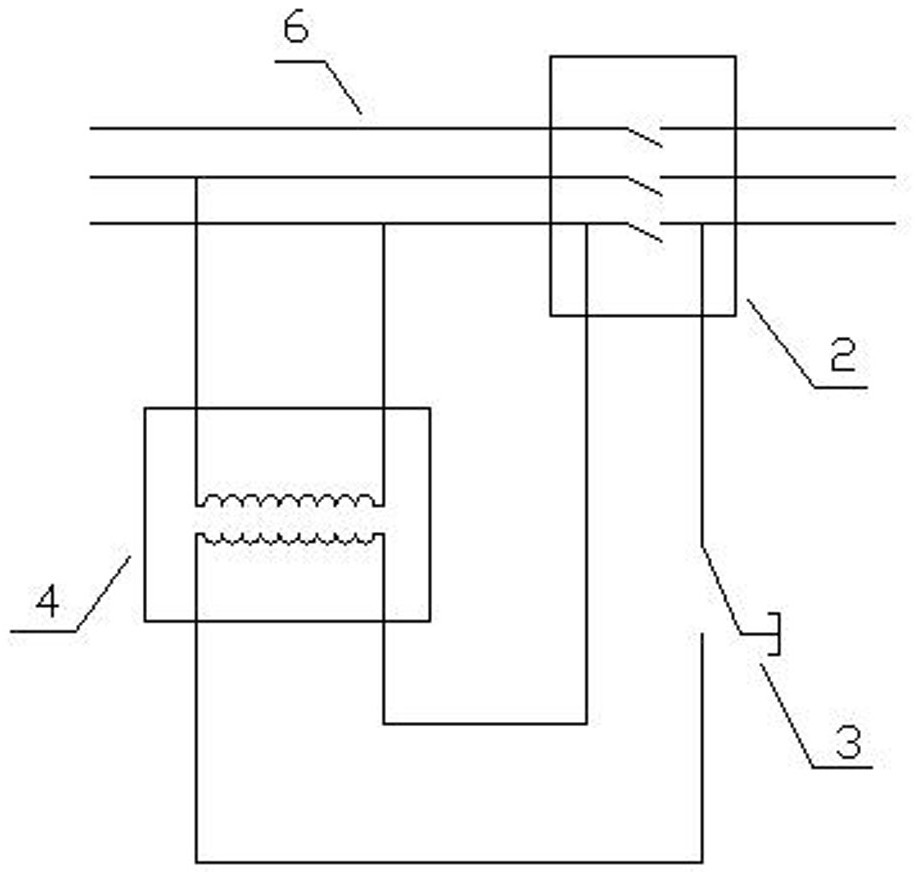

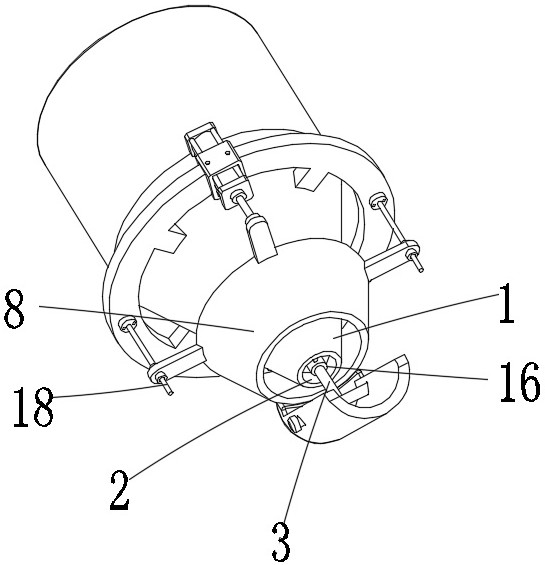

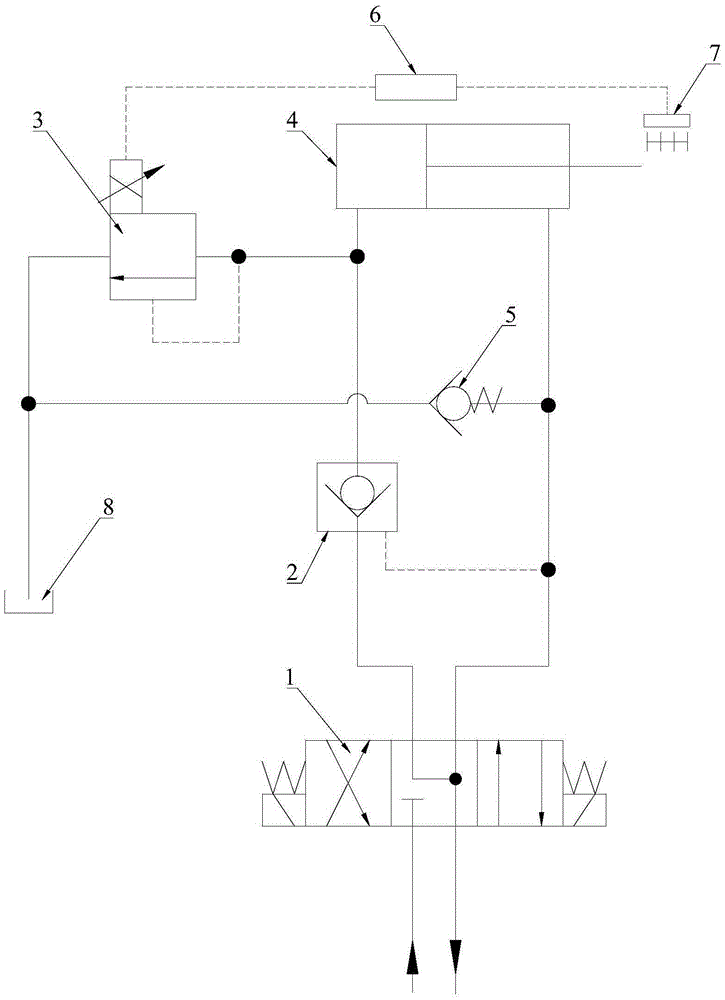

Open type shield machine, support device and control system and control method of support device

InactiveCN103953356AReduce labor intensityReduce collapse accidentsServomotorsTunnelsControl systemFuel tank

The invention discloses an open type shield machine, a support device and a control system and a control method of the support device. The control system can be used for controlling passive retraction of a slotting tool of the support device, and comprises a slotting tool oil cylinder with the slotting tool on a piston rod, a proportional overflow valve with an oil inlet communicated with a rodless cavity of the slotting tool oil cylinder and an oil outlet connected with an oil tank, a controller used for adjusting the pressure of the proportional overflow valve, and a displacement sensor which is used for detecting the extending displacement of the slotting tool and is connected with the controller. According to the control system, the passive retraction of the slotting tool can be achieved, so that the retraction speed of the slotting tool is basically the same as the forward speed of the shield machine and the stability of a soil body supported by the support device is kept; in addition, the control system does not need to be monitored in real time and operated by an operator, so that the labor intensity of the operator is reduced and the accident of soil body collapse caused by improper manual operation is reduced.

Owner:BEIJING SANY HEAVY MASCH CO LTD

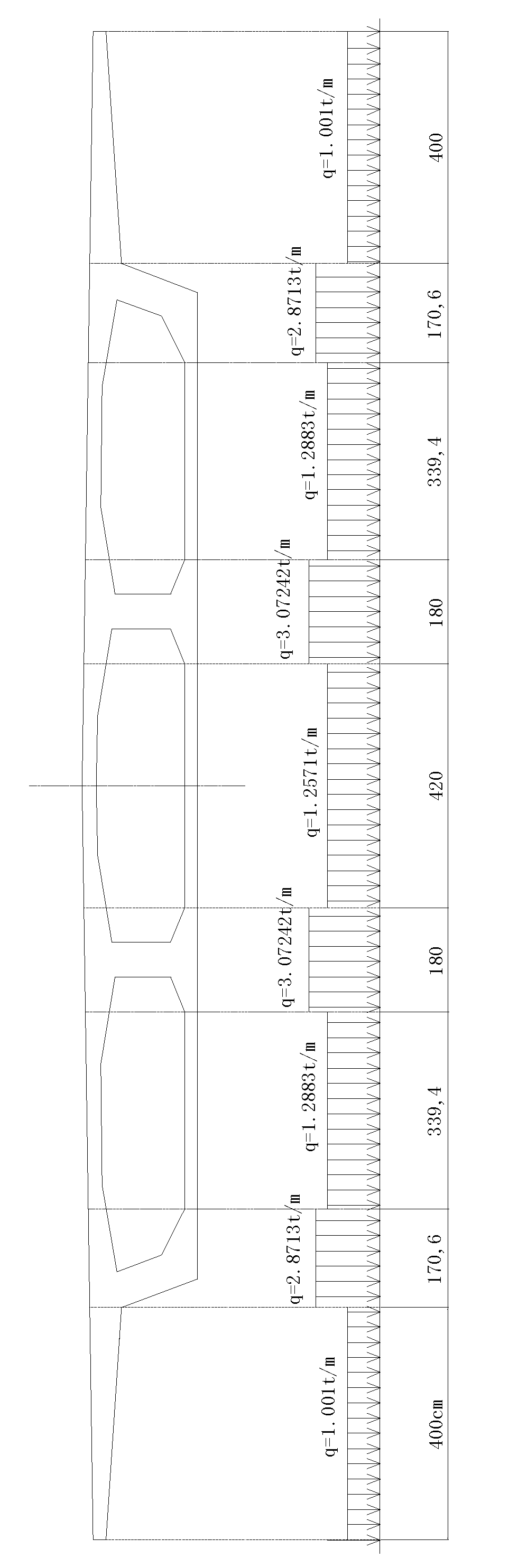

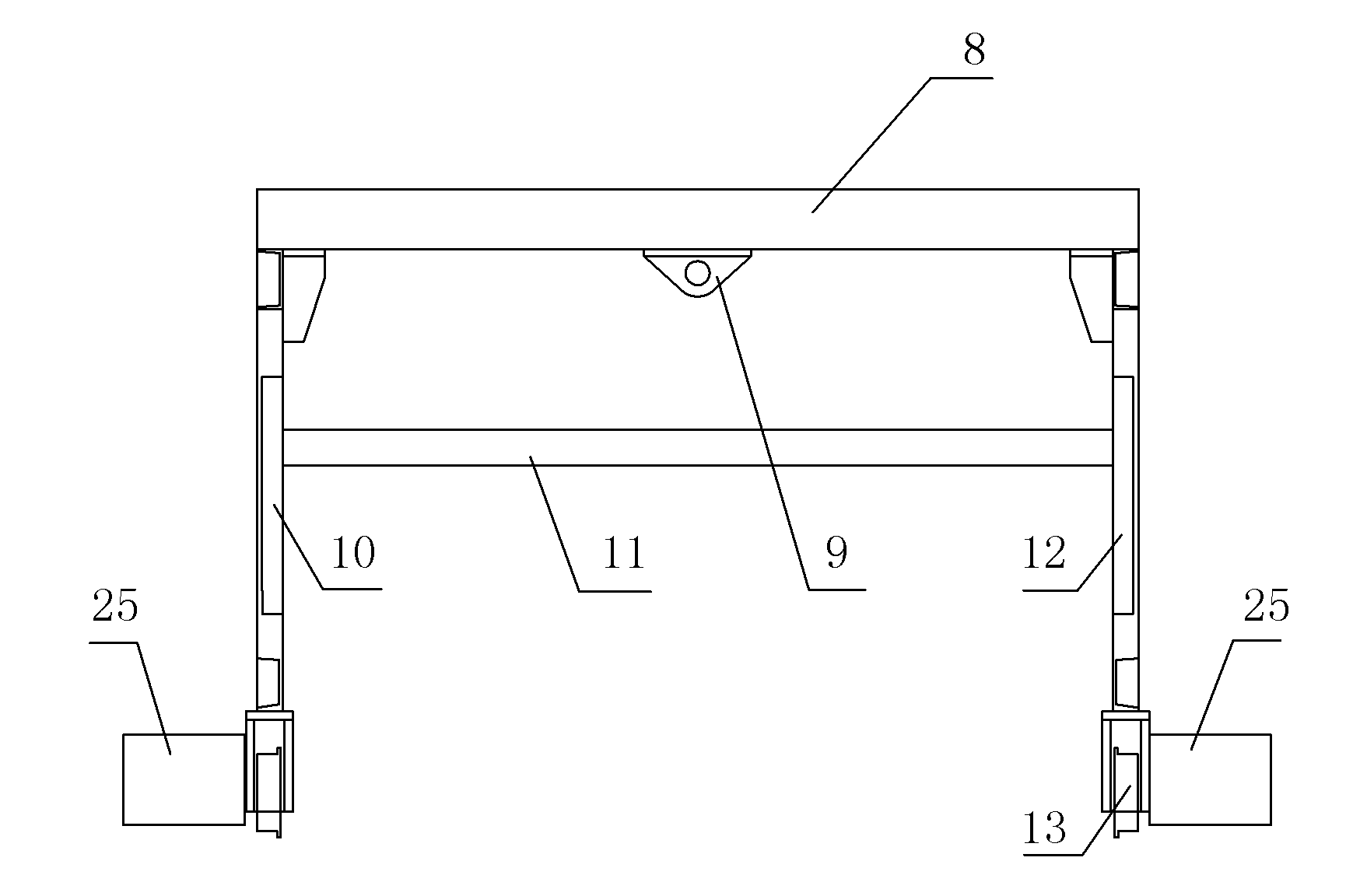

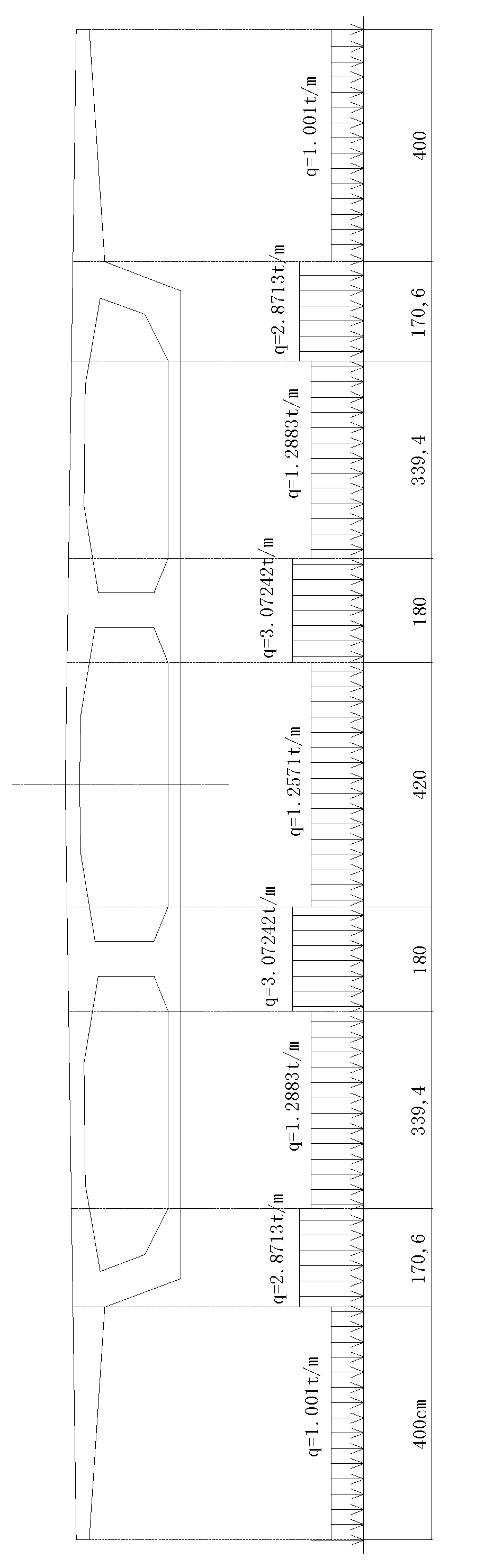

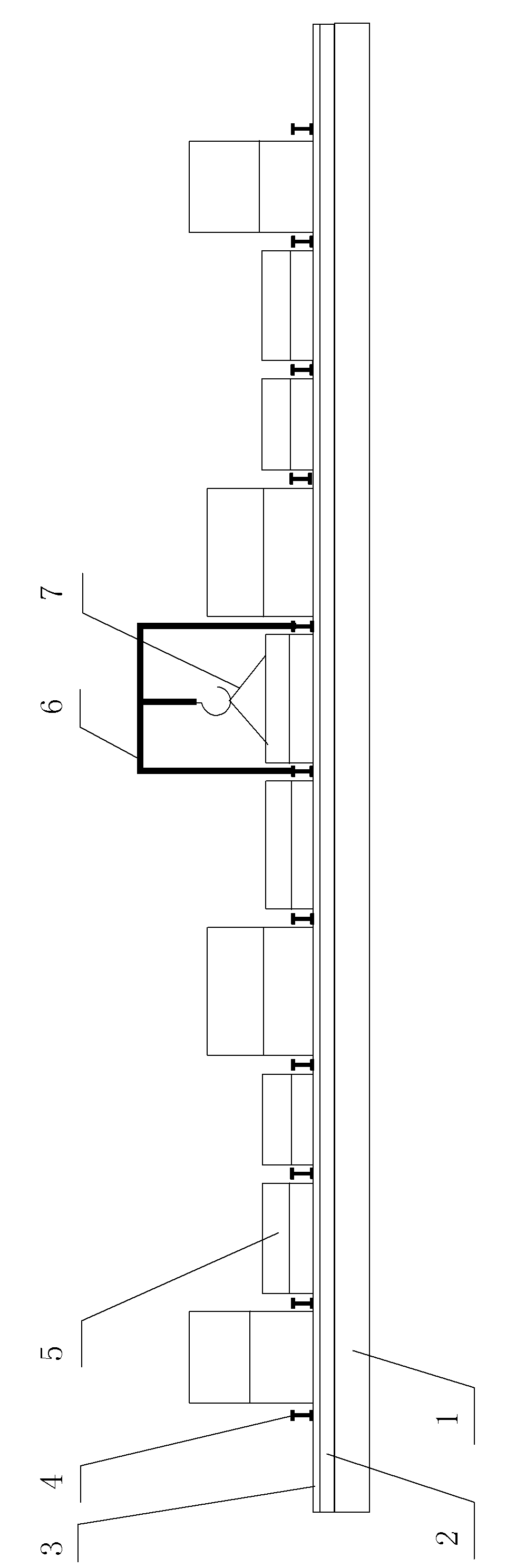

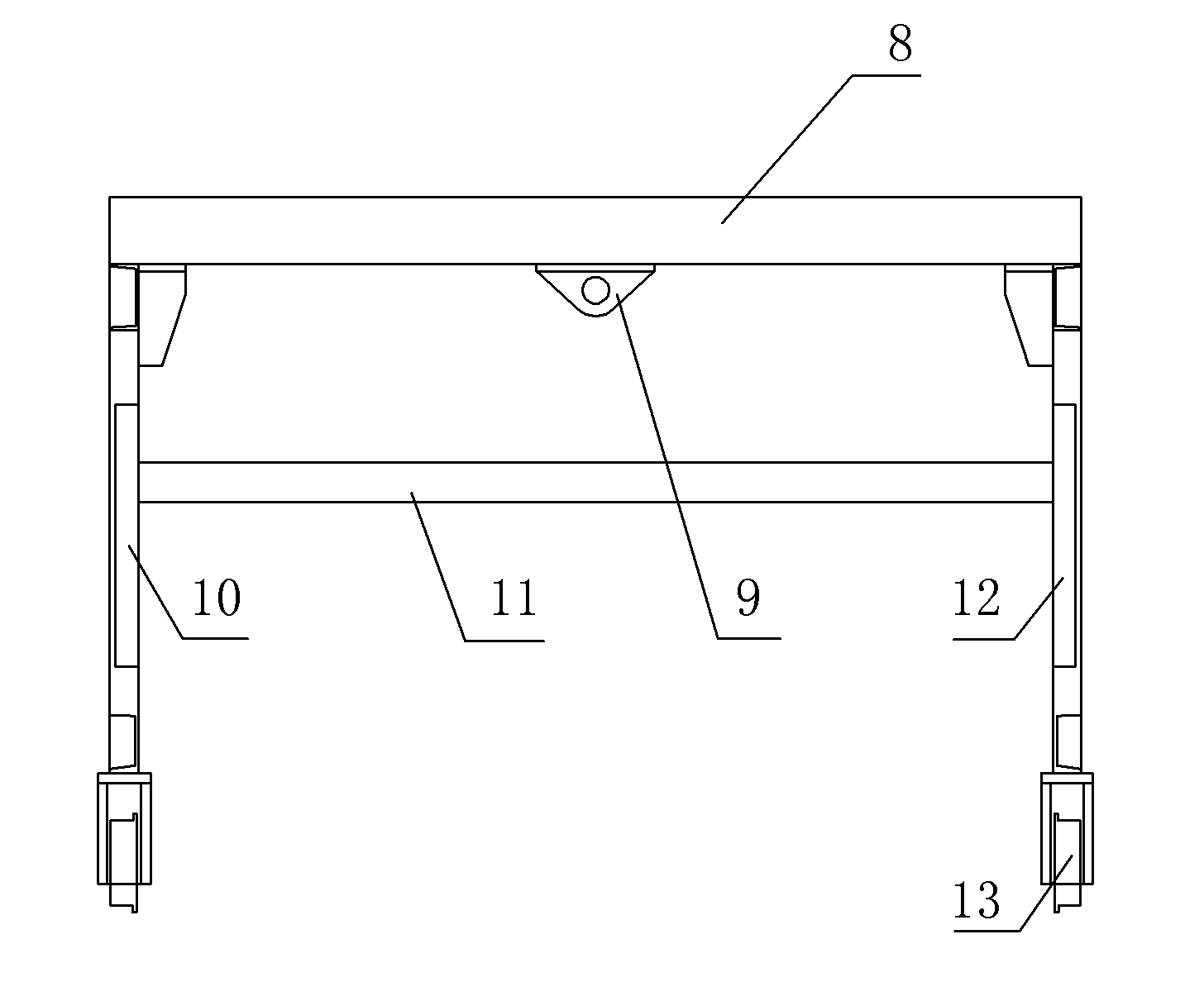

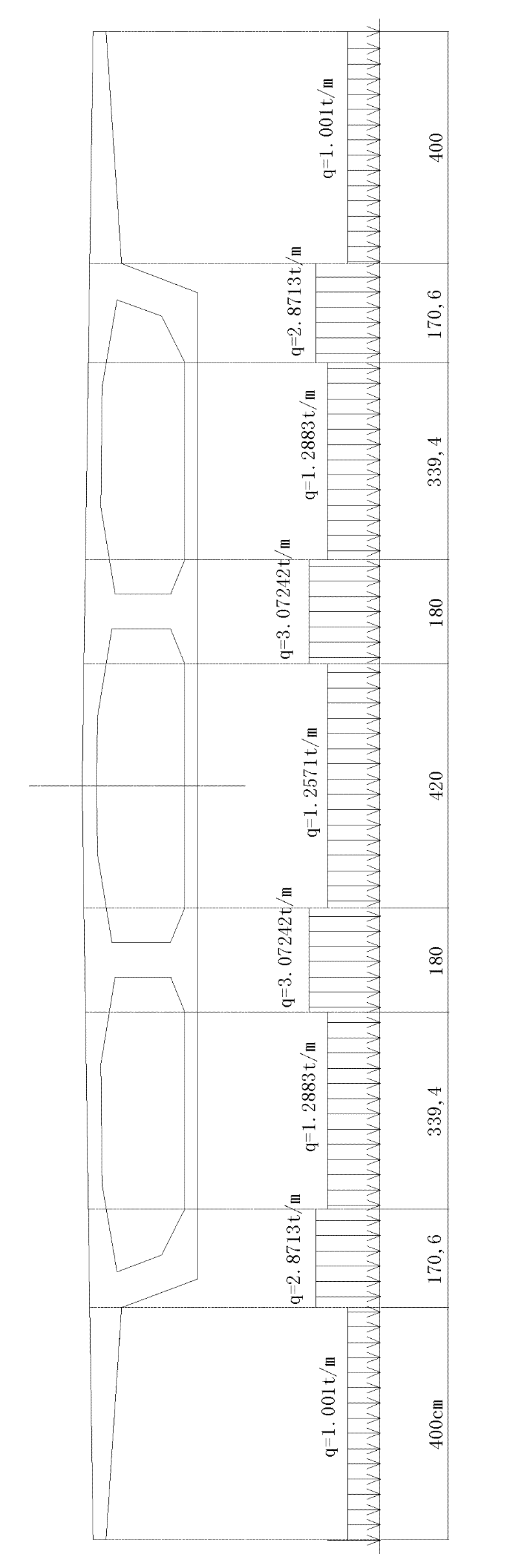

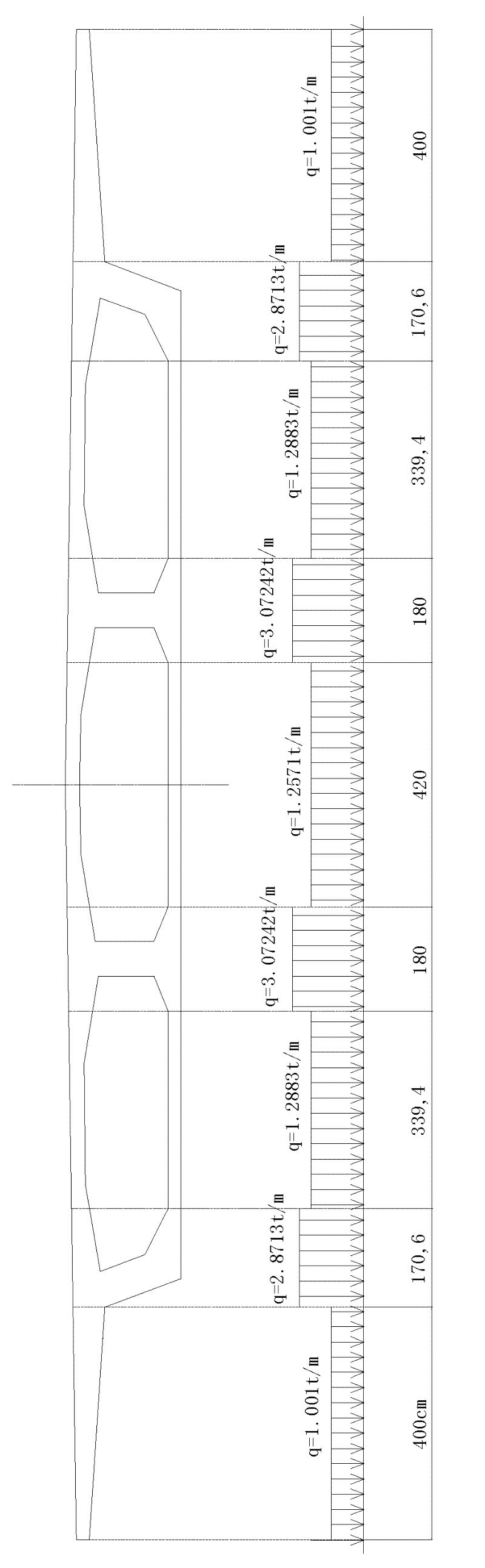

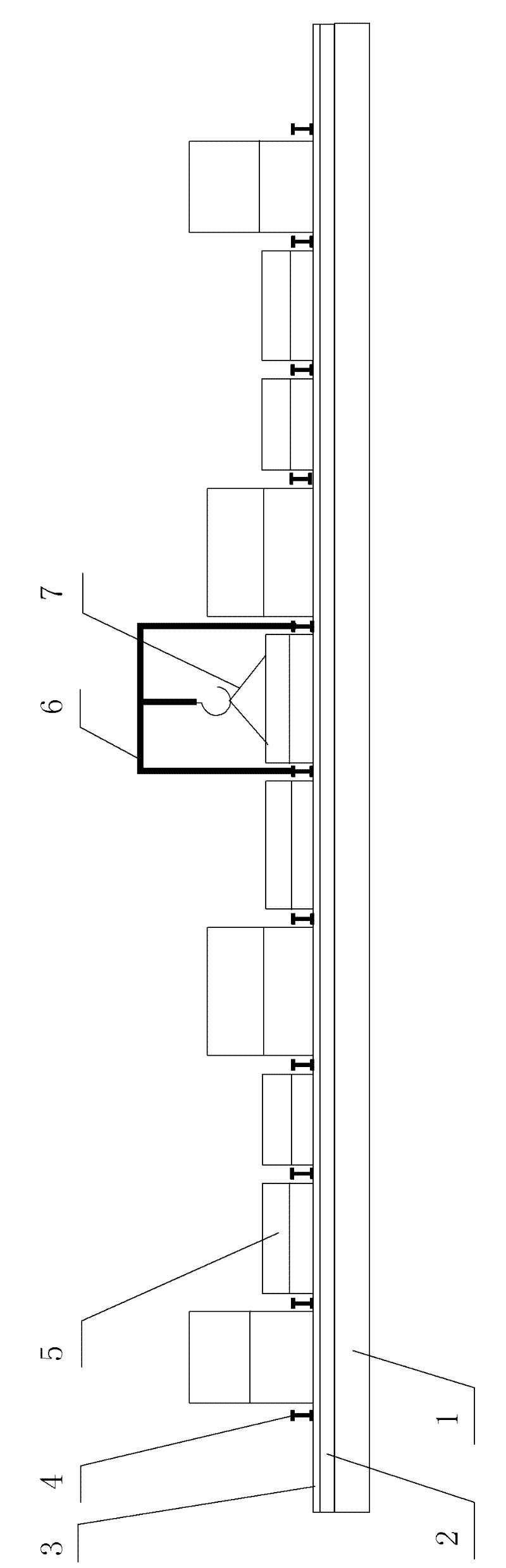

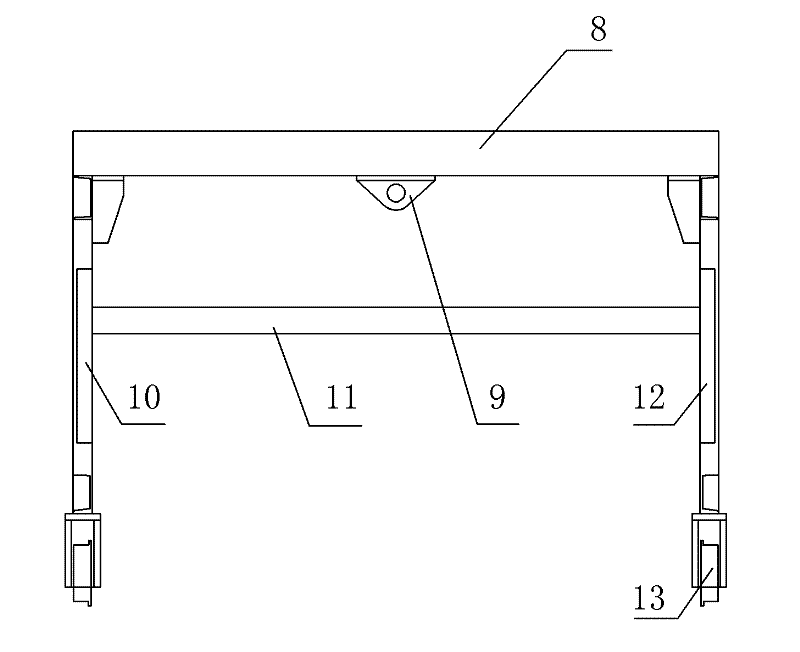

Method for carrying out load test on bridge support frame by prefabricated parts moved by electrically operated gallows frames

InactiveCN102012314AReduce collapse accidentsReduce casualtiesMachine part testingGallowsStandard test

The invention relates to a method for carrying out load test on a bridge support frame. The method for carrying out load test on the bridge support frame by prefabricated parts moved by electrically operated gallows frames is characterized by comprising the following steps: firstly placing a template special for loading on a box-beam template on the bridge support frame; installing a plurality of rails on the template special for loading along the longitudinal direction of the bridge support frame; placing the gallows frames on the rails, controlling the gallows frames to be electrically operated to walk to transport the prefabricated parts horizontally to lift and lower the prefabricated parts on the first layer, carrying out load test detection on the bridge support frame and then lifting and lowering the prefabricated parts on the second layer after meeting the requirement; carrying out detection again after completing all loading; after test detection meets the requirement, firstly unloading the prefabricated parts on the second layer and then unloading the prefabricated parts on the first layer after all the prefabricated parts on the second layer are unloaded. The method has good reliability and safety, standard test measurement and high precision of load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

InactiveCN102012313AReduce collapse accidentsReduce casualtiesMachine part testingTest efficiencyGallows

The invention relates to a method for carrying out load test on a bridge support frame. The method for carrying out load test on the bridge support frame by prefabricated parts moved through tractive walking is characterized by comprising the following steps: firstly placing a template special for loading on a box-beam template on the bridge support frame; installing a plurality of rails on the template special for loading along the longitudinal direction of the bridge support frame; placing gallows frames on the rails, using a tractor to tow the gallows frames to walk to transport the prefabricated parts horizontally to lift and lower the prefabricated parts on the first layer, carrying out load test detection on the bridge support frame and then lifting and lowering the prefabricated parts on the second layer after meeting the requirement; carrying out detection again after completing loading; after test detection meets the requirement, firstly unloading the prefabricated parts on the second layer and then unloading the prefabricated parts on the first layer after all the prefabricated parts on the second layer are unloaded. The method has good reliability and safety, high test efficiency, standard test measurement and high precision of load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

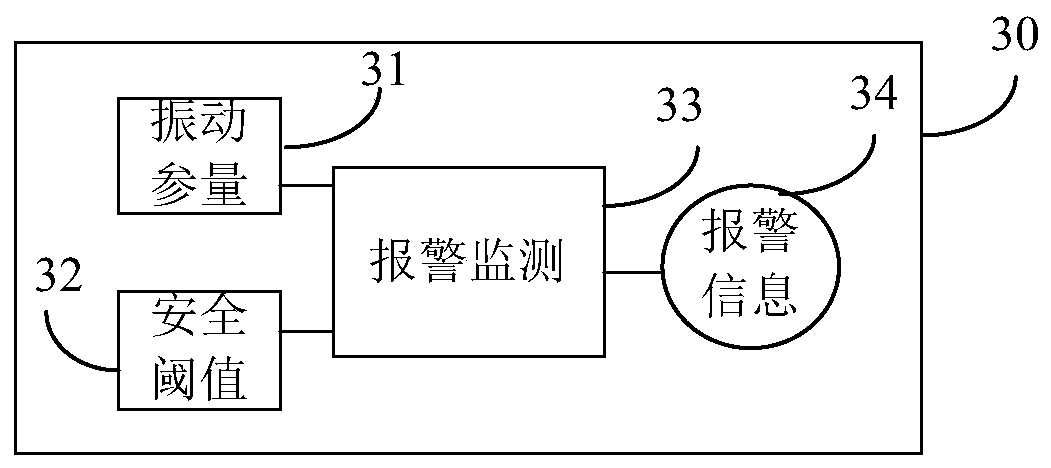

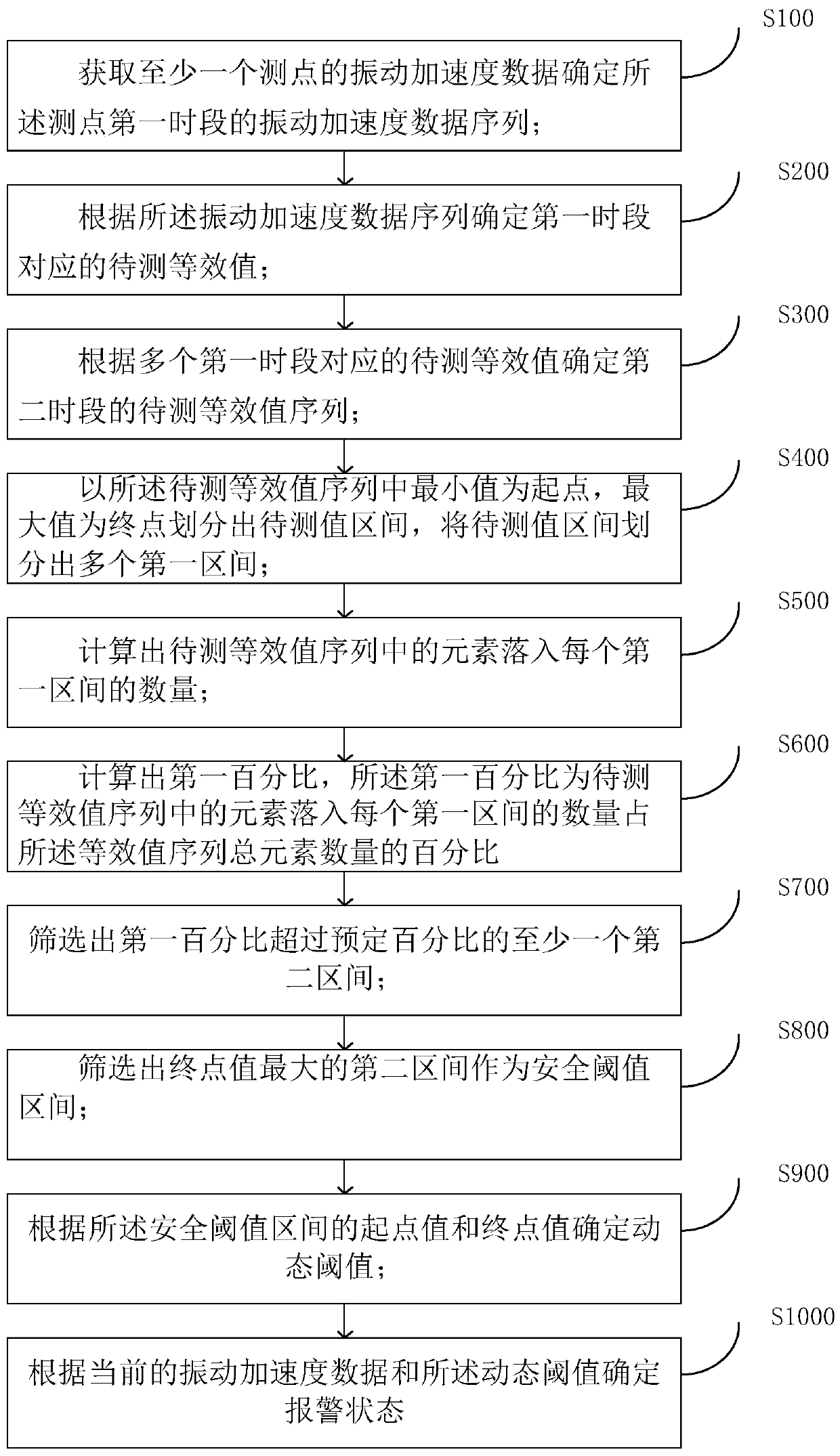

Vibration alarm method, storage medium and electronic equipment

PendingCN111259538AImprove accuracyReduce collapse accidentsDesign optimisation/simulationCAD numerical modellingAlarm stateVibration acceleration

The embodiment of the invention provides a vibration alarm method, a storage medium and electronic equipment, and the method comprises the steps: determining a corresponding equivalent value accordingto the vibration acceleration data of a measurement point, and determining a dynamic safety threshold value according to the equivalent values accumulated one by one; determining a vibration acceleration over-limit probability value according to the maximum vibration acceleration data of the measuring point, and further determining an over-limit probability development trend coefficient accordingto the vibration acceleration over-limit probability value; and determining an alarm state according to a vibration acceleration equivalent value of the measuring point, a dynamic threshold operationresult, an effective value development trend coefficient and an over-limit probability development trend coefficient. The vibration alarm method provided by the embodiment of the invention solves theproblem of false alarm or untimely alarm easily caused by using the design allowable value as the alarm threshold.

Owner:河北振创电子科技有限公司

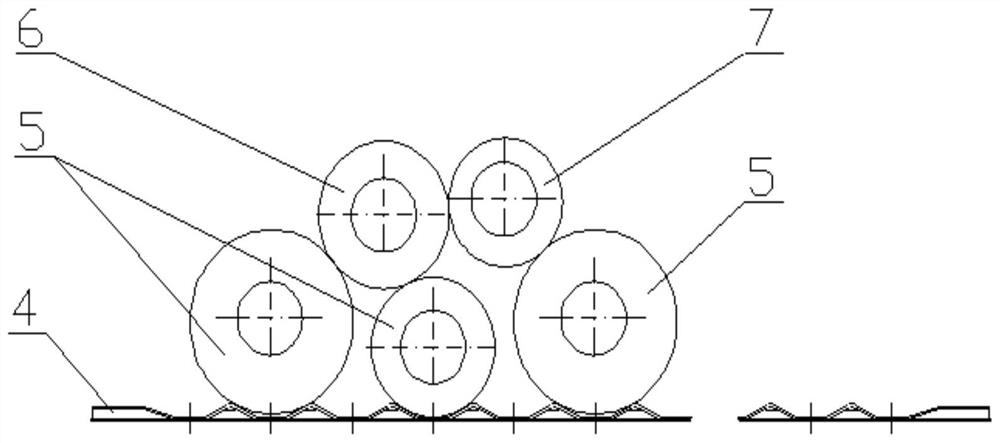

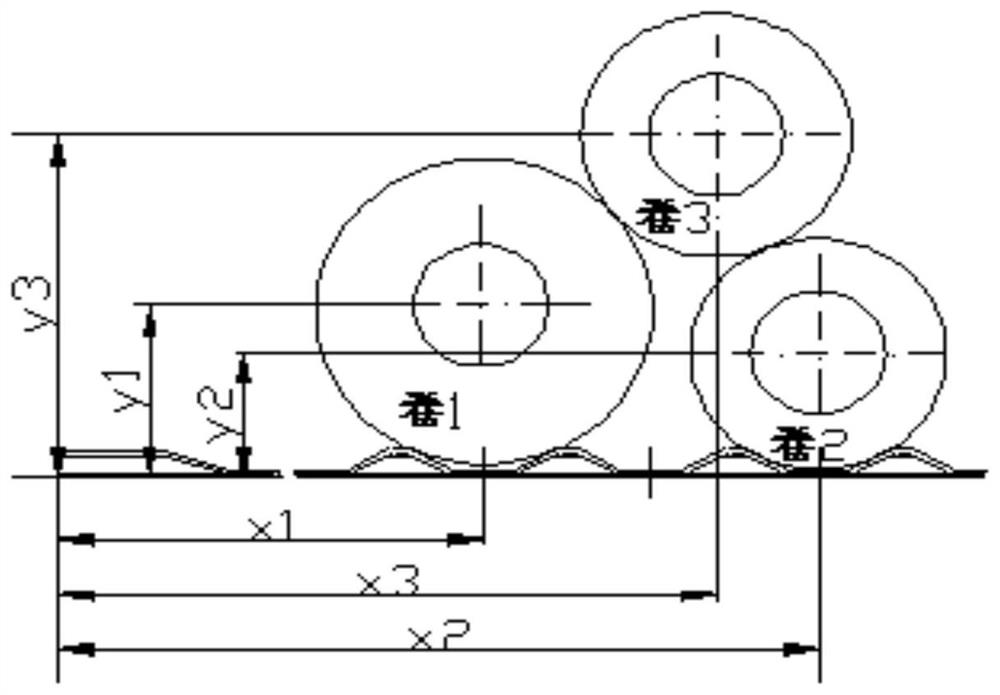

Method for eliminating full-automatic two-layer steel coil stacking suspension

PendingCN111737843AEliminate potential safety hazardsReduce collapse accidentsDesign optimisation/simulationUsing optical meansStructural engineeringMechanical engineering

The invention relates to a method for eliminating full-automatic two-layer steel coil stacking suspension. The method comprises the following steps that 1, a calculation model for preventing two-layersteel coil stacking suspension is established; 2) determining a non-interference calculation method of two adjacent layers of rolls through a calculation model; and 3) summarizing a reasonable beta interval value or correction rate according to field production practice or experience. The technical scheme is applied to highly-intelligent integrated equipment of a full-automatic large warehouse, double-layer stacking of a finished product warehouse is achieved, the potential safety hazard of stacking suspension caused by mutual position interference of two layers of adjacent steel coils due tovarious reasons is completely eliminated, and the use efficiency of the warehouse and the equipment is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

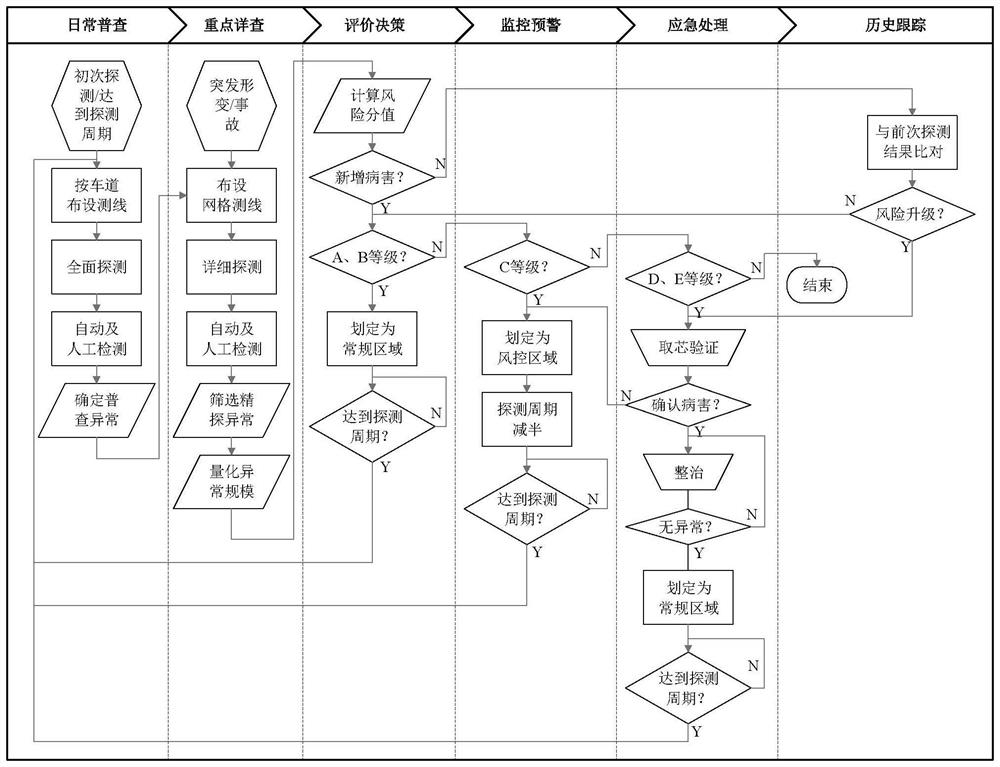

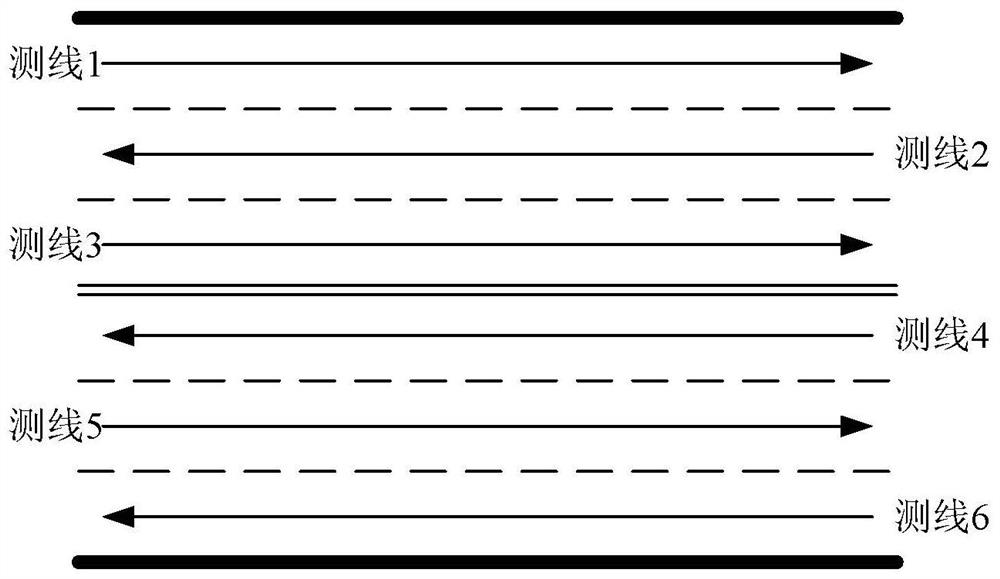

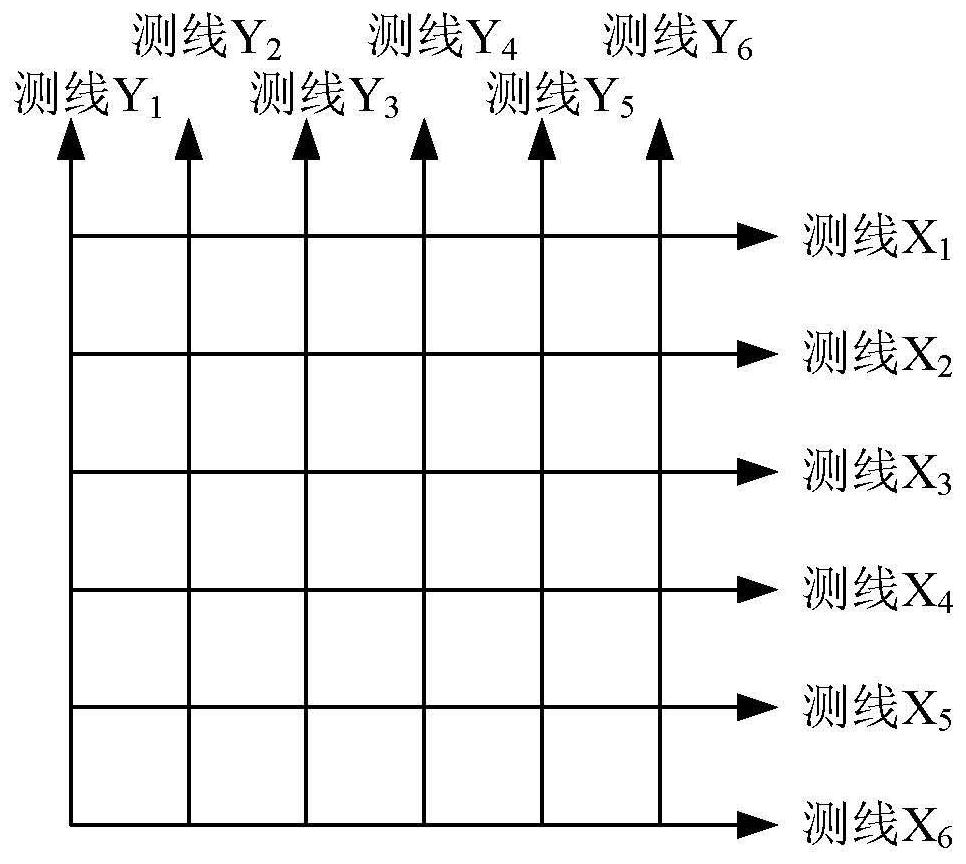

Urban underground disease body full life cycle management method based on ground penetrating radar

PendingCN114675261AImprove underground security early warning capabilitiesReduce collapse accidentsRadio wave reradiation/reflectionEnvironmental resource managementFull life cycle

The invention discloses an urban underground disease body full life cycle management method based on a ground penetrating radar, and the method comprises the following steps: 1, carrying out the comprehensive detection of an area which is detected for the first time and reaches a detection cycle through a rapid vehicle-mounted ground penetrating radar, and processing the data of the ground penetrating radar; 2, processing ground penetrating radar data in a region corresponding to general survey abnormity, screening fine detection abnormity, and quantifying the sizes of voids, cavities, loose bodies and water-rich bodies; 3, calculating risk occurrence possibility scores according to the scale of the fine detection abnormity, and dividing risk possibility grades; step 4, classifying the evaluation areas; and step 5, distinguishing and confirming abnormal regions as disease regions and conventional regions. Based on the technical means of the ground penetrating radar, the full-life-cycle management method for detection, evaluation, early warning, treatment and maintenance of the urban road underground disease bodies is established, and the management process and mechanism are perfected, so that the road underground safety early warning capability is improved, and the occurrence of road surface collapse accidents is reduced.

Owner:中国电波传播研究所

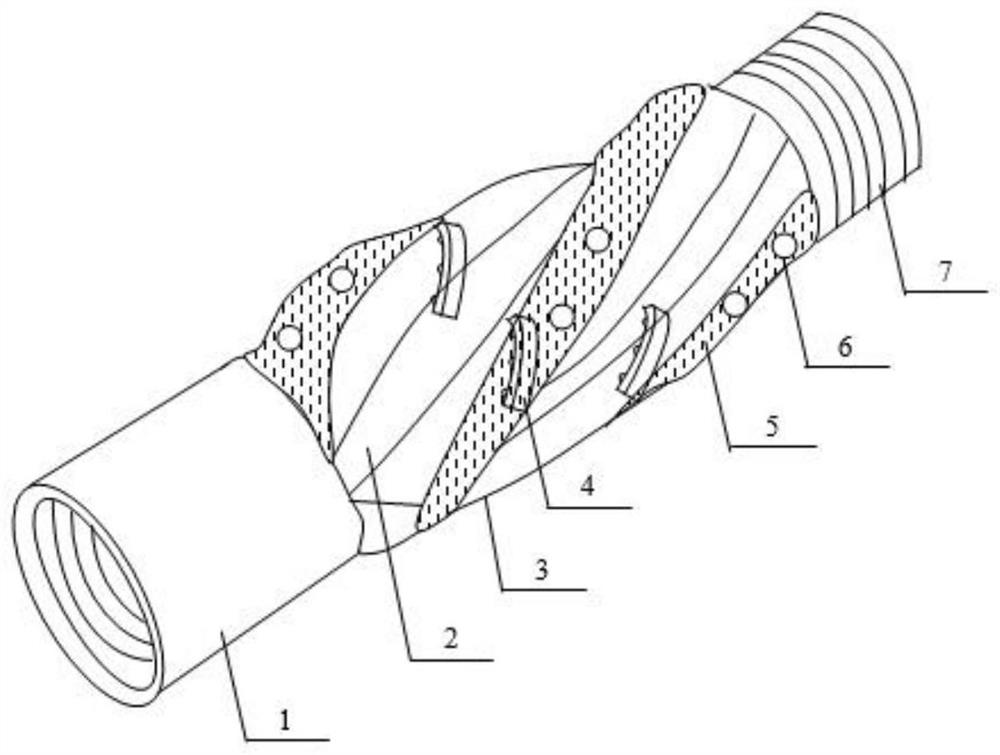

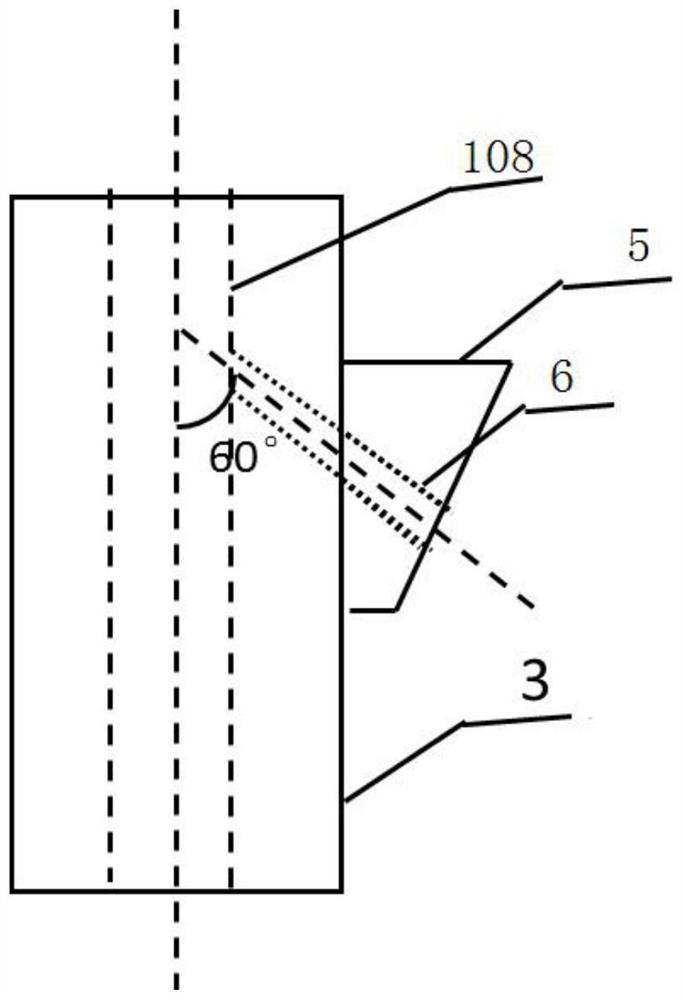

Irregular shaft cleaning and drifting device based on deflection angle flow dividing and drifting method

PendingCN112282699AImprove cleanlinessEasy to carry aroundCleaning apparatusEngineeringStructural engineering

The invention relates to an irregular shaft cleaning and drifting device based on deflection angle flow dividing and a drifting method. The irregular shaft cleaning and drifting device comprises a female connector, a drainage groove, a drifting body, scraping teeth, drifting strips, deflection angle flow dividing holes and a male connector. The female connector is connected with a drill bit, the male connector is connected with a drill rod, the scraping teeth are welded to the drifting strips, the drifting strips are welded to the drifting body, the deflection angle flow dividing holes are holes formed in the drifting strips, the holes penetrate through the drifting body all the time and communicate with a water hole of the drifting body, and the drainage groove is formed in a gap betweenthe two drifting strips. The irregular shaft cleaning and drifting device has the advantages of being suitable for deposition of rock debris in irregular boreholes in a deep well drifting process, capable of enabling the rock debris to be more easily carried to a wellhead in a circulating mode, reducing well wall collapse accidents and trimming the well wall, the borehole cleanliness can be improved, and the irregular shaft cleaning and drifting device is suitable for being widely used.

Owner:CHINA PETROCHEMICAL CORP +2

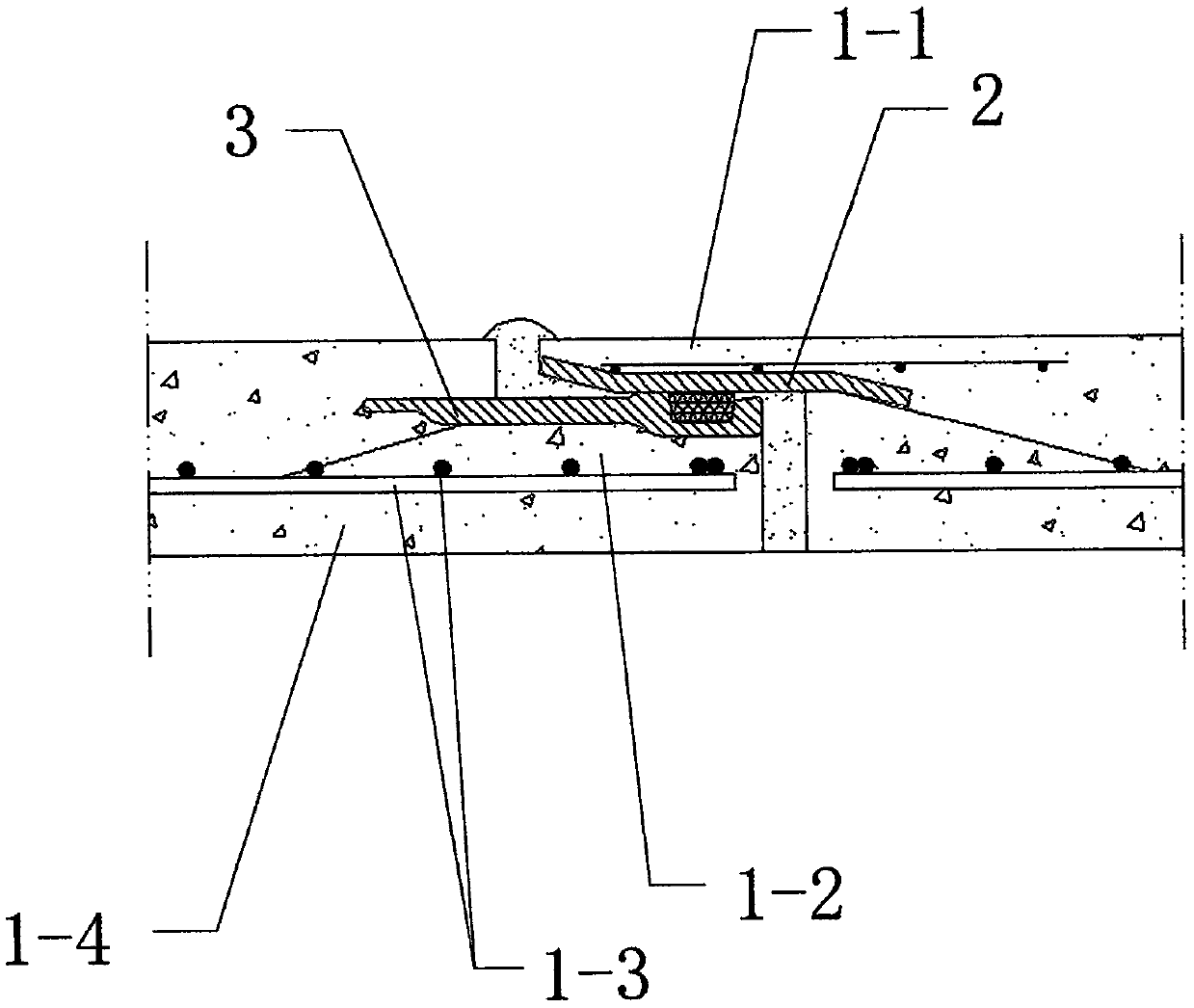

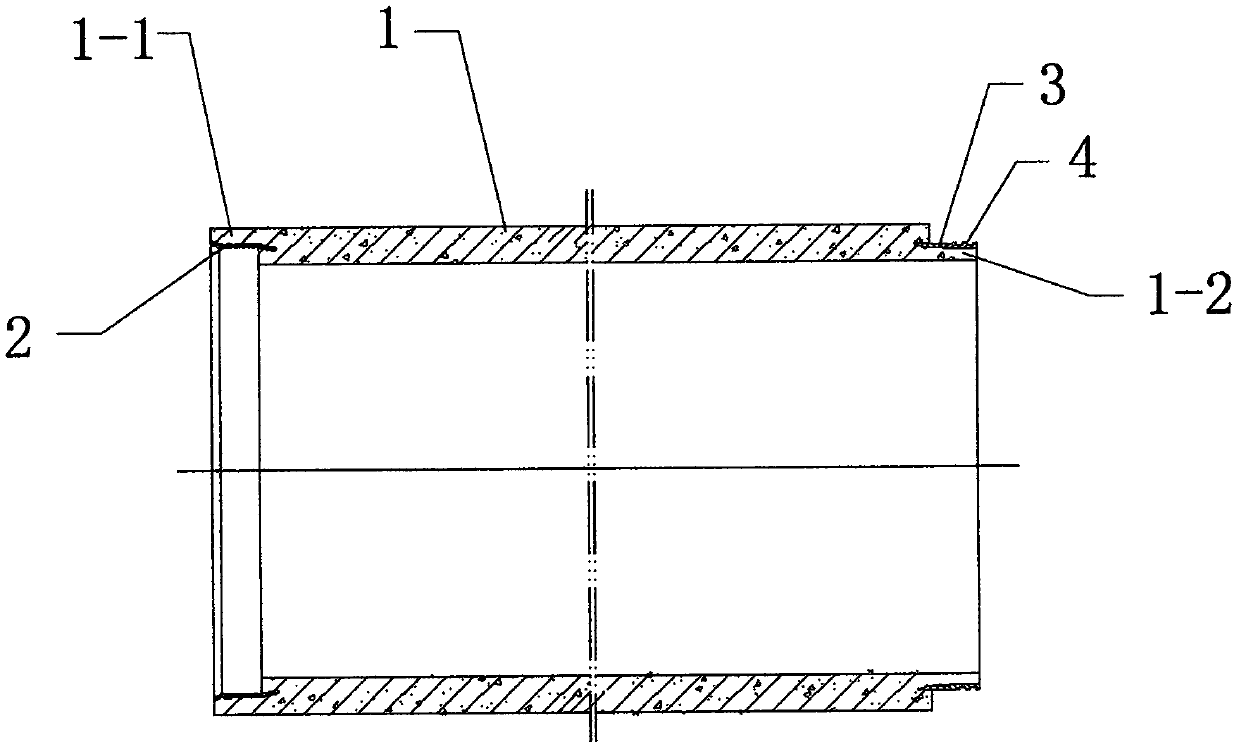

A π-shaped underground diaphragm wall shield tunnel construction method

The invention discloses a shield tunneling construction method for an n-shaped underground diaphragm wall. The shield tunneling construction method comprises the following steps of step I, formulating a construction process flow; step II, performing the specific construction process: firstly, measuring and setting out; secondly, manufacturing a guide wall; thirdly, preparing and adjusting slurry; fourthly, trenching the underground diaphragm wall and performing bottom-clearing replacement; fifthly, manufacturing and hanging a GFRP (Glass Fiber Reinforced Plastic) reinforcement cage; sixthly, manufacturing and setting a bamboo reinforcement cage; seventhly, grouting underwater concrete; eighthly, constructing joints; ninthly, topping a joint pipe. The shield tunneling construction method disclosed by the invention has the beneficial effects that a tunnel door is not needed to be manually chiseled, so the construction period is greatly shortened; a soil body on the outer side of an envelope structure is not needed to be reinforced, so the construction cost of engineering is reduced; the envelope structure directly plays roles of retaining soil and stopping water at the shield tunneling stage, and the safety of the shield tunneling is greatly guaranteed.

Owner:HAINAN UNIV

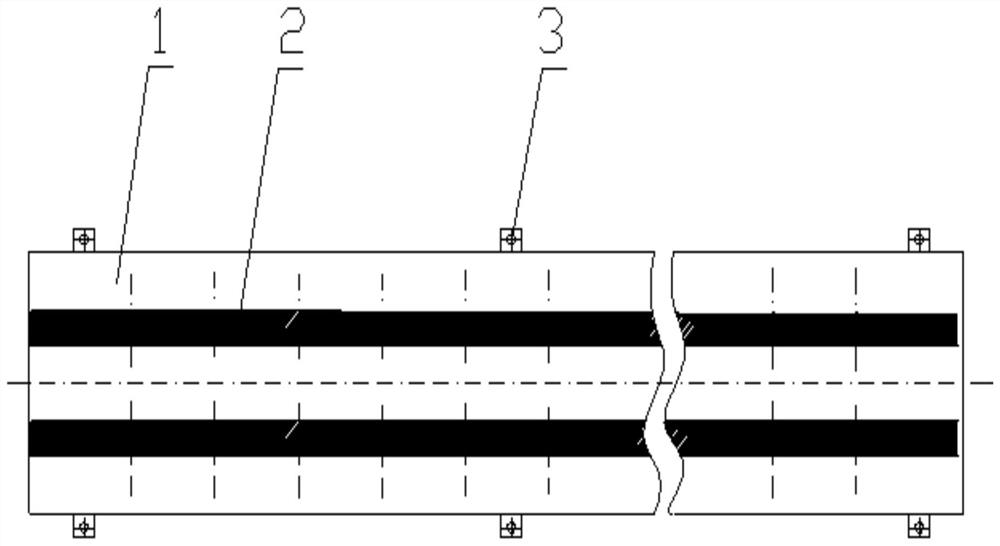

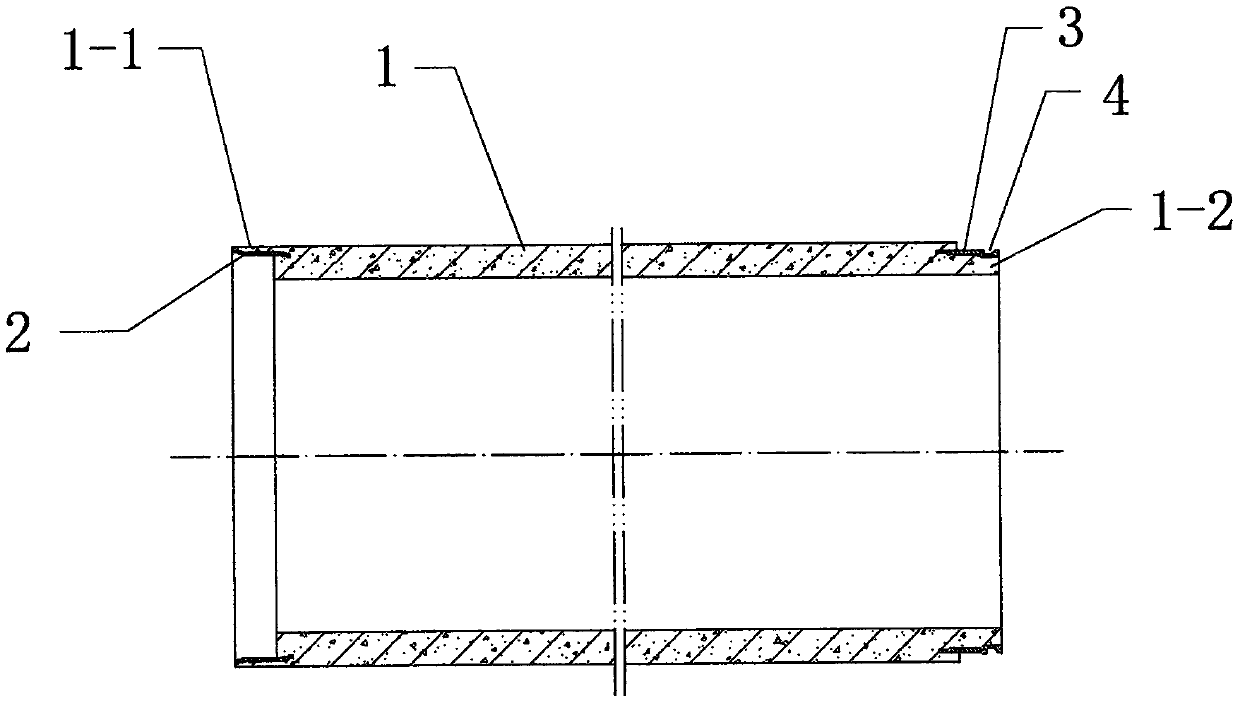

Steel-fiber high-performance concrete pipe and manufacturing method thereof

InactiveCN110142868AImprove compressive and tensile strengthExtended service lifeShaping reinforcementsRigid pipesRebarHigh performance concrete

The invention discloses a steel-fiber high-performance concrete pipe comprising a reinforced concrete pipe body. The two ends of the reinforced concrete pipe body are provided with a socket portion and a spigot portion, the socket portion and the spigot portion are fixedly provided with a steel socket ring and a steel spigot ring correspondingly, a single / double annular groove is formed in the steel spigot ring, and an O-type rubber sealing ring is arranged on the single / double annular groove; and the steel socket rings and the steel spigot rings on adjacent reinforced concrete pipe bodies areconnected in an inserted manner. The steel-fiber high-performance concrete pipe reduces the occurrence of ground collapse accidents, the service life of the pipe is prolonged, the installation efficiency is improved, the operation cost is reduced, and the national economic benefits are improved.

Owner:深圳市三新水环境科技有限公司

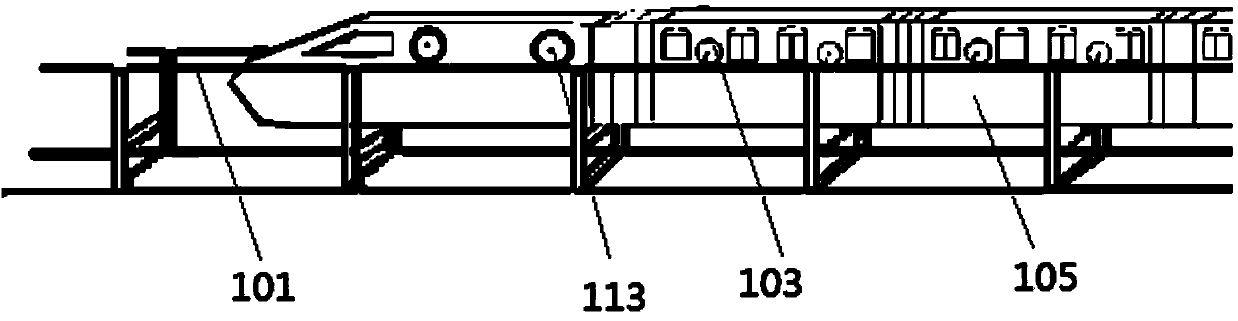

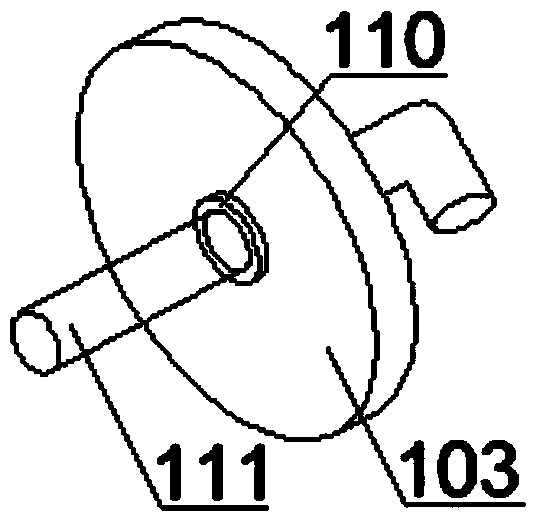

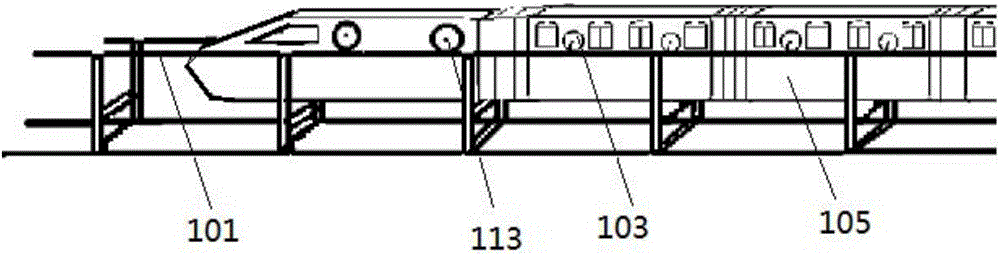

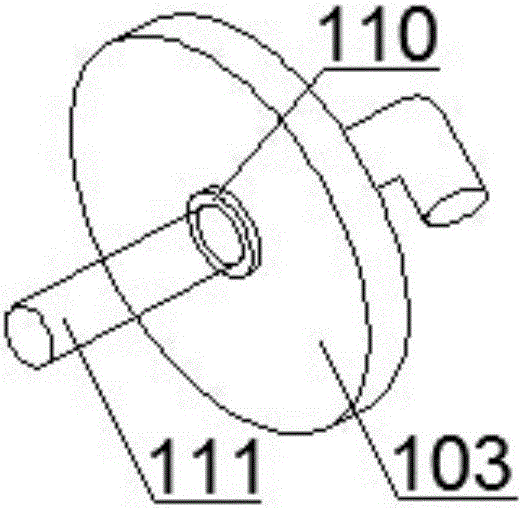

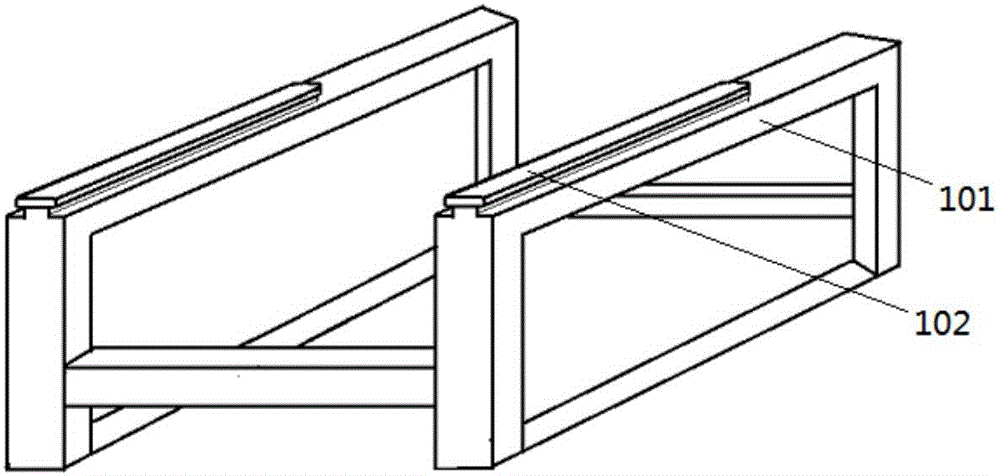

Train system

ActiveCN104192150AStrong enduranceTake advantage ofBallastwayRailway transportReinforced concreteStub axle

The invention provides a train system and relates to the field of transportation. The train system comprises a train rail set and a train running on the train rail set. The train rail set comprises two parallel reinforced concrete rails and a supporting structure which is used for supporting the reinforced concrete rails and arranged on the ground and connected with the reinforced concrete rails. The train comprises a train head and carriages. The train head is provided with train head wheels. The carriages are provided with carriage wheels. The train head wheels and the carriage wheels correspond to the train rails. Bearings are arranged in the centers of the carriage wheels. Short shafts fixed on the train penetrate the bearings. A power plant is arranged on the train head and connected with the train head wheels. The train system has good stability and requires fewer land sources.

Owner:张向东

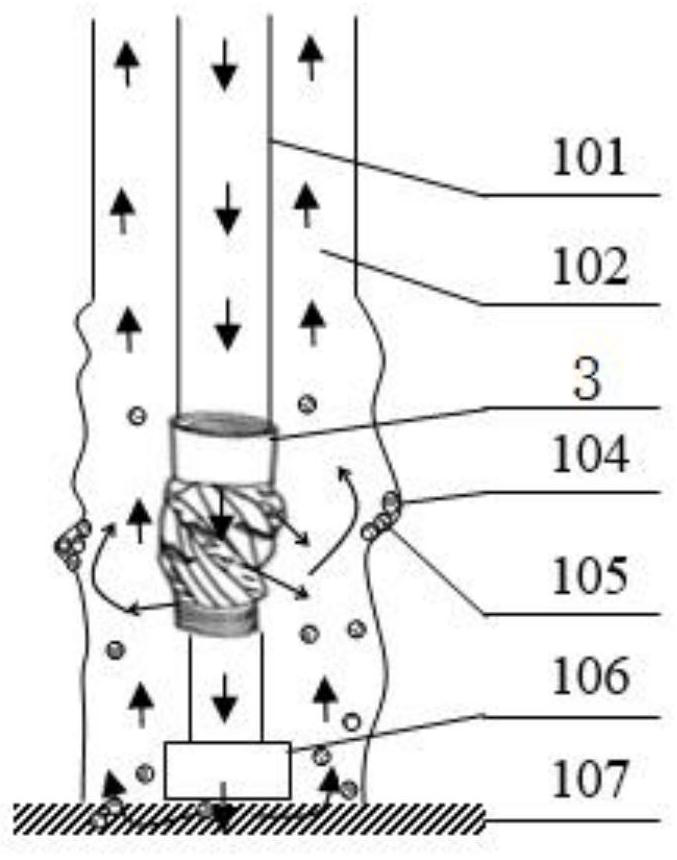

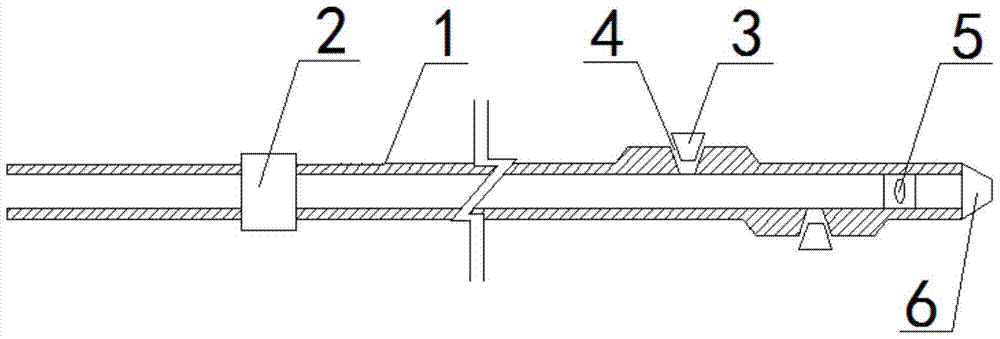

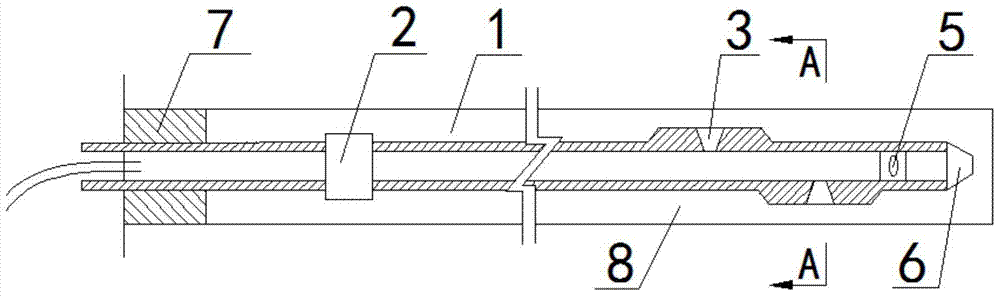

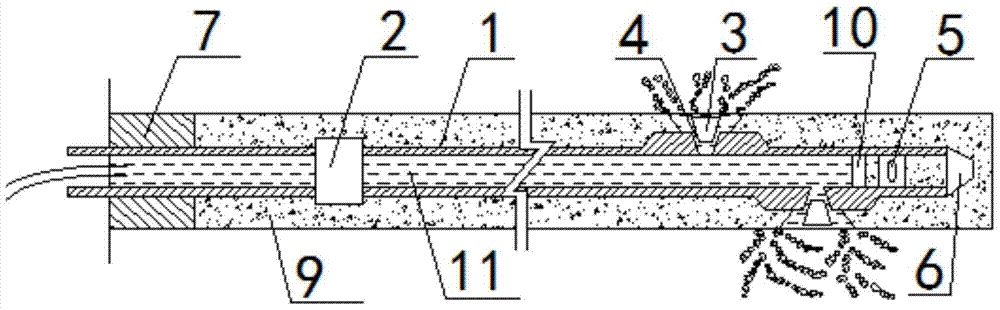

Segmented fixed-point hydraulic fracturing device and method for underground coal mine drilling

A segmented fixed-point hydraulic fracturing device and method for underground drilling in a coal mine, wherein the method mainly includes a segmented fixed-point hydraulic fracturing device in an underground coal mine: installing a segmented fixed-point fracturing device in an open hole until the predetermined fracturing Target layer; 2 Grouting and fixing holes: After using the plug to seal the orifice annulus, use the grouting pump to inject cement slurry into the segmented fixed-point fracturing device, and then return to the Orifice; 3. Pressure displacement fluid: press the rubber pad and displacement fluid into the casing, and keep the pressure until the rubber pad is pressed against the check valve and wait for coagulation; 4. Fracturing: inject fracturing fluid into the casing, press The fracturing fluid breaks through the cement weak surface of the one-way valve structure and then fractures the target layer. The invention provides a device and method for segmental fixed-point hydraulic fracturing and hole fixing for underground drilling in coal mines, which solves the problem of complex and cumbersome steps in the existing pore forming and segmental hydraulic fracturing technology, and improves the hole fixing and segmental hydraulic fracturing. The quality of fracturing has realized the integration of hole fixing and segmented fixed-point hydraulic fracturing.

Owner:HENAN POLYTECHNIC UNIV

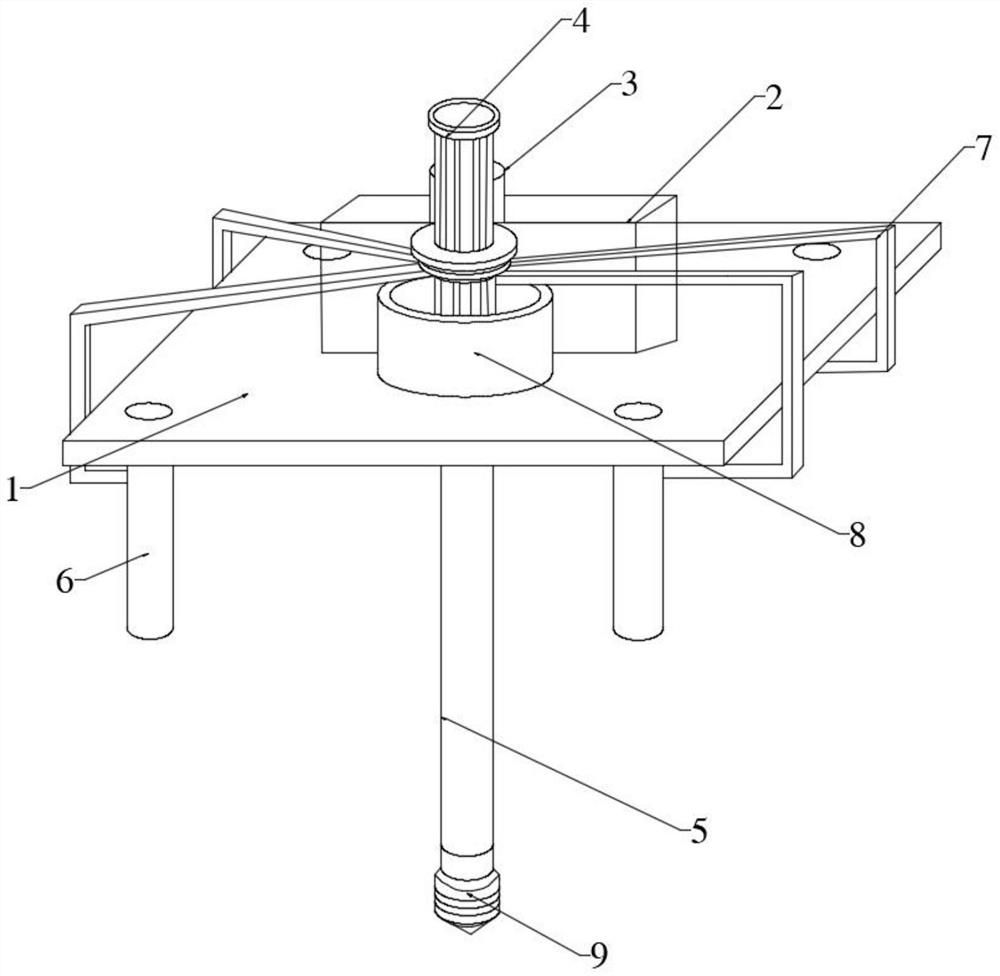

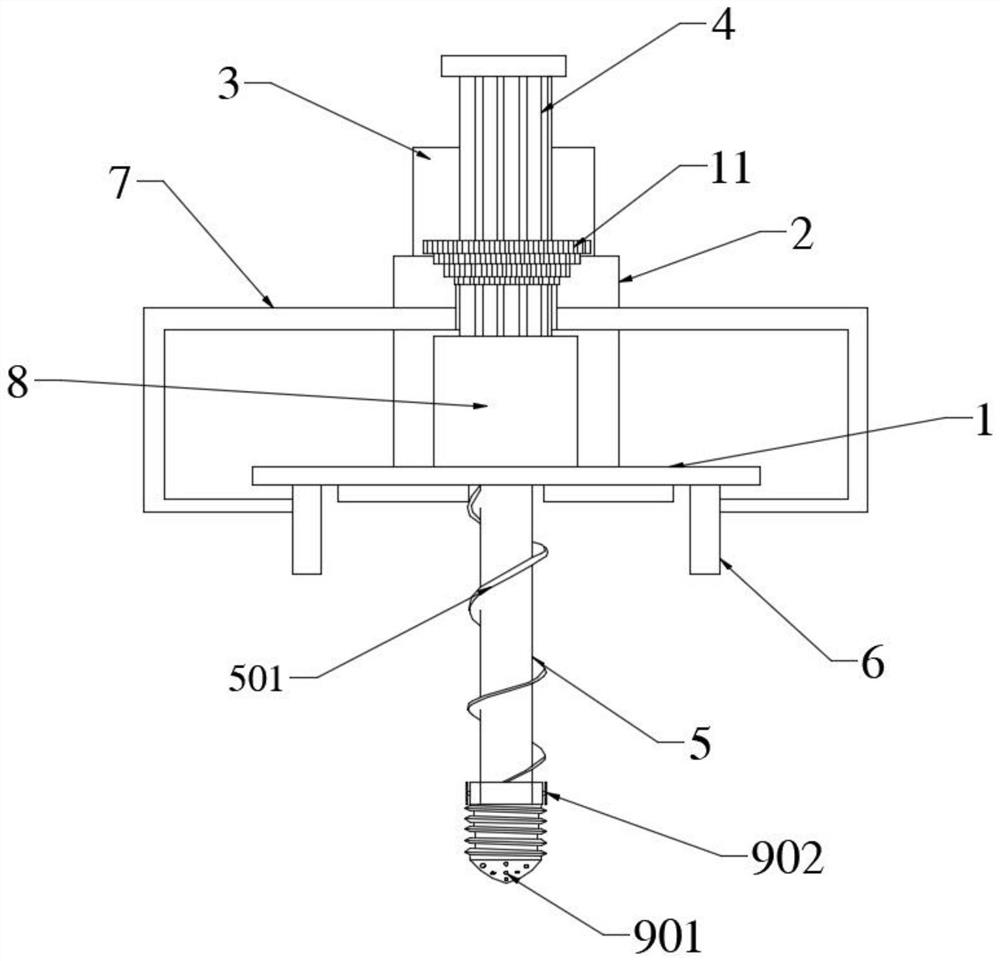

Oil drilling equipment capable of automatically adjusting rotating speed based on geology

PendingCN114776227ABest output rateIncrease flexibilityConstructionsDerricks/mastsWell drillingElectric machinery

The invention discloses oil drilling equipment capable of automatically adjusting the rotating speed based on geology, and belongs to the technical field of oil drilling. The drilling equipment comprises a drilling platform, a drilling support is arranged on the drilling platform, a drilling motor is arranged on the drilling support and connected with a first drilling connecting rod, the first drilling connecting rod is connected with a second drilling connecting rod, a drilling sleeve is arranged on the drilling platform, and the first drilling connecting rod and the second drilling connecting rod penetrate through the drilling sleeve. A plurality of fixing feet are arranged below the drilling platform and connected with the first drilling connecting rod through a transmission box, an excavating drill bit is arranged at the end, away from the first drilling connecting rod, of the second drilling connecting rod, and a water guide pipe is arranged in the excavating drill bit, penetrates through the second drilling connecting rod and communicates with the first drilling connecting rod. The device has the effect of automatically exploring the rotating speed according to the specific geology, and collapse accidents are avoided while the service life is prolonged.

Owner:JIANGSU RUIYI PETROLEUM MASCH CO LTD

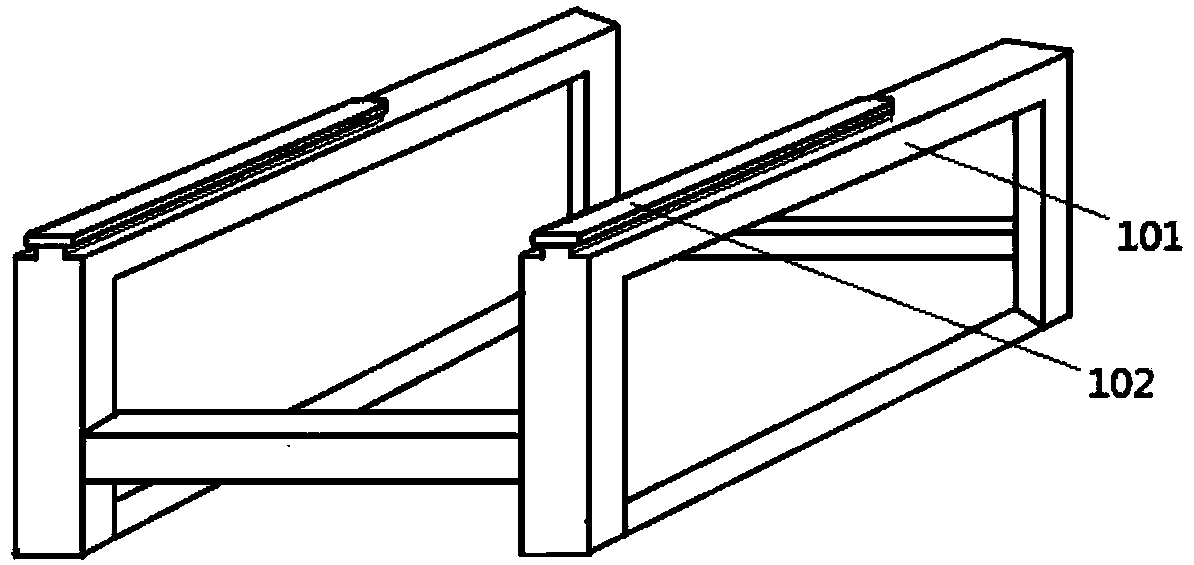

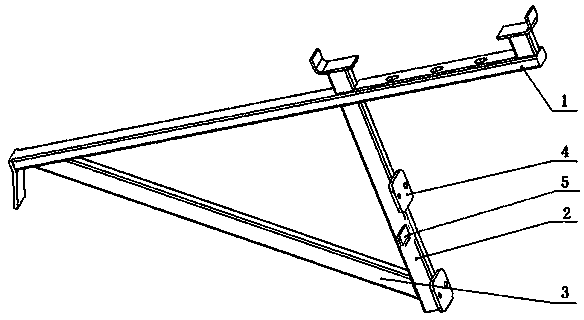

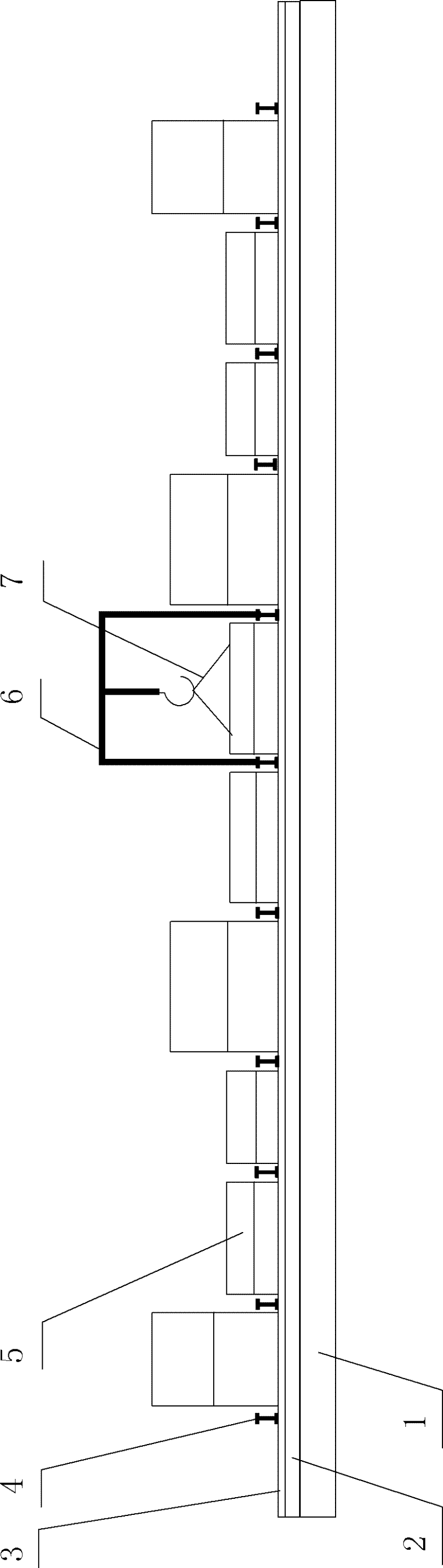

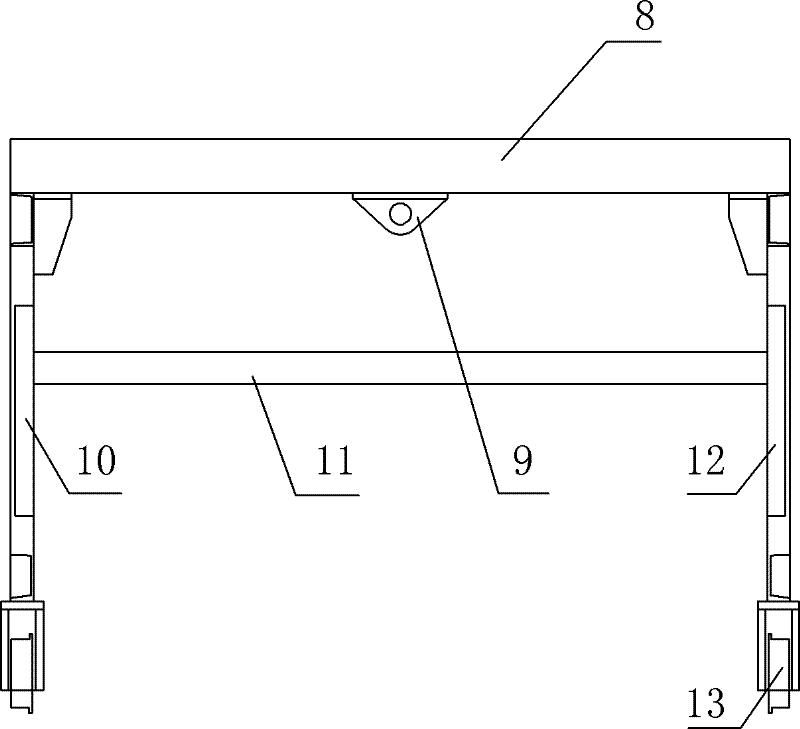

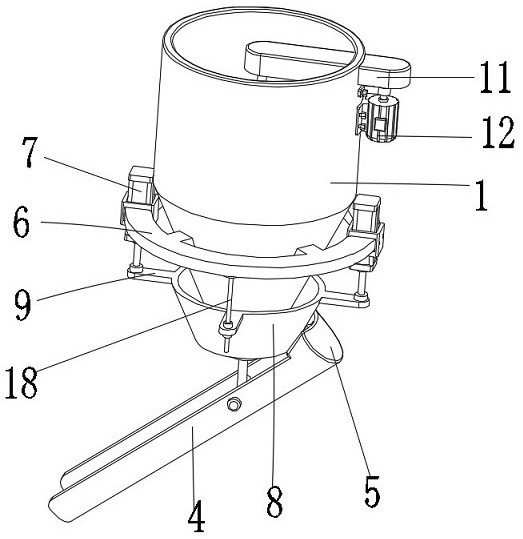

Support

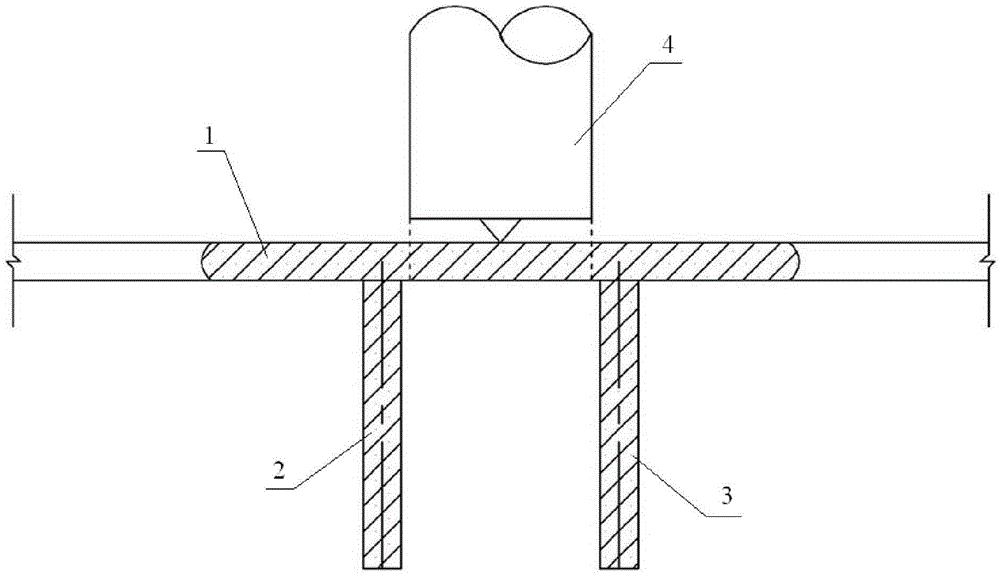

The invention discloses a support, and belongs to the technical field of engineering machinery. The support comprises a transverse beam (1), a stand column (2) and an inclined support (3), wherein the inclined support (3) is used for supporting the transverse beam (1) and the stand column (2). The support further comprises a balancer (4) and a reminding device (5), wherein the balancer (4) and a reminding device (5) are arranged on the stand column (2) and electrically connected. According to the support, the balancer and the reminding device are additionally arranged on an existing support, the balance degree of the support can be measured within a certain time period, the reminding device does not work if a value displayed on the balancer is kept within a normal balance range, the reminding device works, makes a sound and reminds people to decompress the support or transfer goods on the support if the value displayed on the balancer exceeds the balance value range, the collapse probability of the support is reduced, and the support is simple in structure and convenient to operate.

Owner:徐州天龙回转支承有限公司

Method for carrying out load test on bridge support frame by prefabricated parts moved by electrically operated gallows frames

InactiveCN102012314BReduce collapse accidentsReduce casualtiesMachine part testingGallowsStandard test

Owner:CHINA FIRST METALLURGICAL GROUP

Method for performing load test for bridge support frame with hand-propelled movable prefabricated part

InactiveCN102023092BReduce collapse accidentsReduce casualtiesMachine part testingEngineeringStandardization

The invention relates to a method for performing a load test for a bridge support frame. The method for performing the load test for the bridge support frame with a hand-propelled movable prefabricated part is characterized in that the method comprises the following steps of: firstly installing a load special mould on a box girder mould arranged on the bridge support frame; installing a pluralityof tracks on the load special mould along the vertical direction of the bridge support frame; installing door-shaped hangs on the tracks; pushing the door-shaped hangs with hands to realize the horizontal transportation of the prefabricated part for carrying out the hanging and release of a first layer of prefabricated part, performing load test detection for the bridge support frame, and then carrying out the hanging and release of a second layer of prefabricated part after the requirement of load test detection is reached; and carrying out the detection again after finishing loading; unloading after requirements of testing and detecting are reached, wherein the second layer of prefabricated part is unloaded firstly, and the first layer of prefabricated part is unloaded after the second layer of prefabricated part is completely unloaded. The method has good reliability and safety, and also has high accuracy for test measure standardization and load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

InactiveCN102012313BReduce collapse accidentsReduce casualtiesMachine part testingTest efficiencyGallows

Owner:CHINA FIRST METALLURGICAL GROUP

Wind force measurement equipment and measurement method for transmission tower model

ActiveCN107101800BImprove securityReduce collapse accidentsAerodynamic testingTransmission towerEngineering

The present invention relates to a transmission tower model wind power measurement device and a measurement method thereof. The wind power measurement device comprises a transmission tower model measurement cylinder, a strain gauge pasted on the wall of the measurement cylinder and a strain analyzer connected with the strain gauge; when measurement, the measurement cylinder is vertically arranged to allow one end of the measurement cylinder to face upwards, the transmission tower model is arranged on this end, the strain analyzer collects strain value data of the strain gauge, and the size of wind power of the model is obtained according to the corresponding relation of model force and the strain value of the strain gauge and the change of the strain value of the strain gauge before and after application of wind power. The transmission tower model wind power measurement device and the measurement method thereof measure the strain gauge on the measurement cylinder to measure the wind power of the transmission tower model, and the size of the measurement cylinder can be designed according to the concrete shape of the transmission tower model, so that the transmission tower model wind power measurement device and the measurement method thereof are suitable for large-volume, heavy and complex transmission tower model wind power measurement and are simple in measurement process and easy to realize.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

Power-off protection system for loosening of foundation bolts of hoisting equipment

PendingCN113928995AReduce collapse accidentsImprove securityEmergency protective arrangements for automatic disconnectionCranesTransformerPush switch

The invention discloses a power-off protection system for loosening of foundation bolts of hoisting equipment, and relates to the technical field of power supply control of the hoisting equipment. The power-off protection system comprises bolt gaskets, a hole is formed in each bolt gasket, and an automatic reset push switch is arranged in each hole; when the foundation bolts are loosened or fractured, the push switches can automatically reset; the push switches are connected with and control an alternating current contactor with 24V coil voltage; a control electric box is additionally arranged on a power supply line of the hoisting equipment, a transformer is arranged in the control electric box, and the transformer is used for transforming 380V voltage into 24V voltage for control; a power supply inlet wire of the hoisting equipment is connected to a wire inlet end of the alternating current contactor, and a wire outlet end of the alternating current contactor supplies power to the hoisting equipment; and the bolt gaskets are arranged on the foundation bolts respectively, and a control line is connected with the push switches on the bolt gaskets in series. By means of the power-off protection system, the power supply of the hoisting equipment can be cut off in time after the foundation bolts of the hoisting equipment are loosened, and the operation of the equipment is stopped, so that the probability of collapse accidents of the hoisting equipment is reduced.

Owner:陆锐

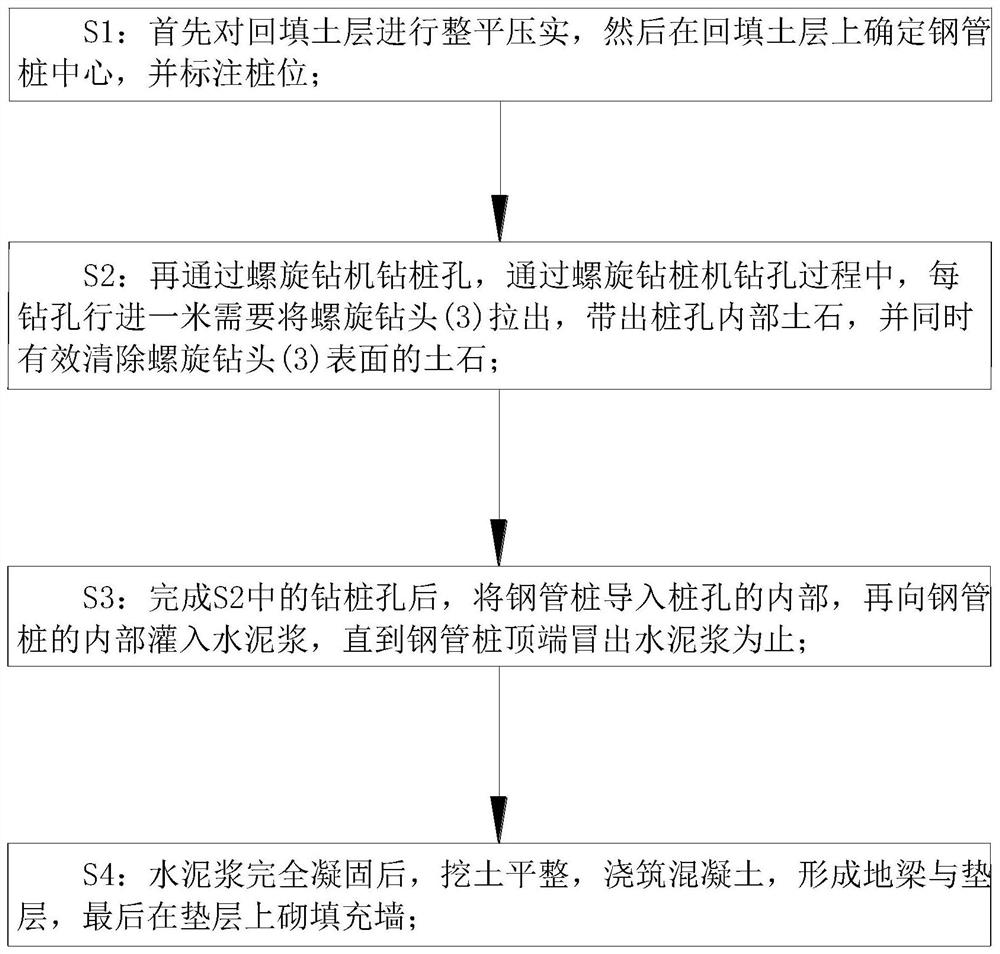

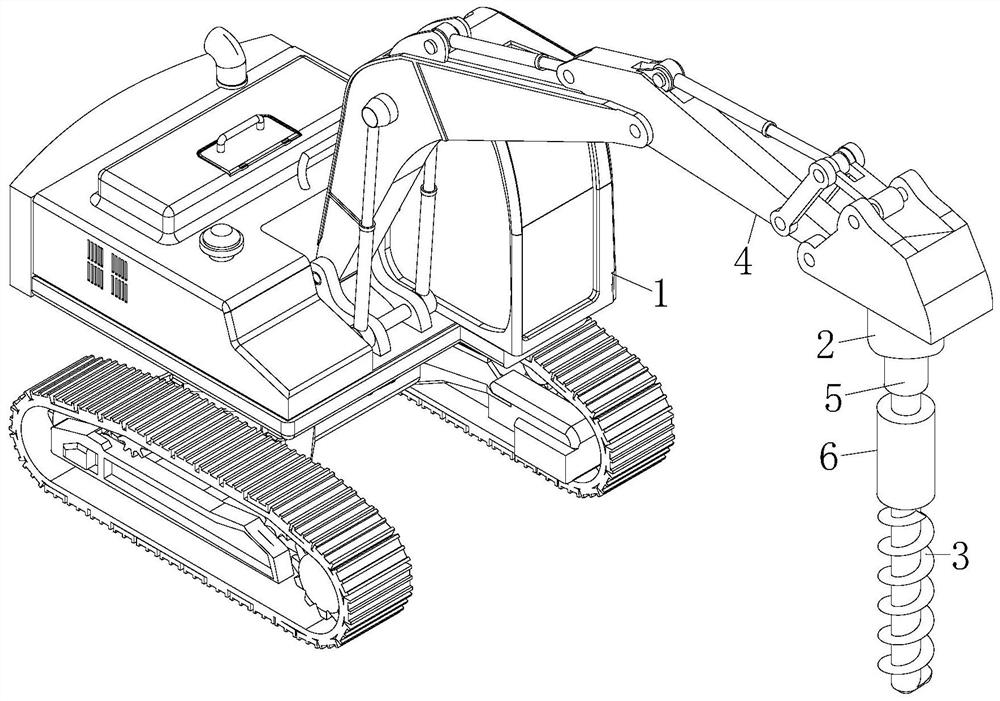

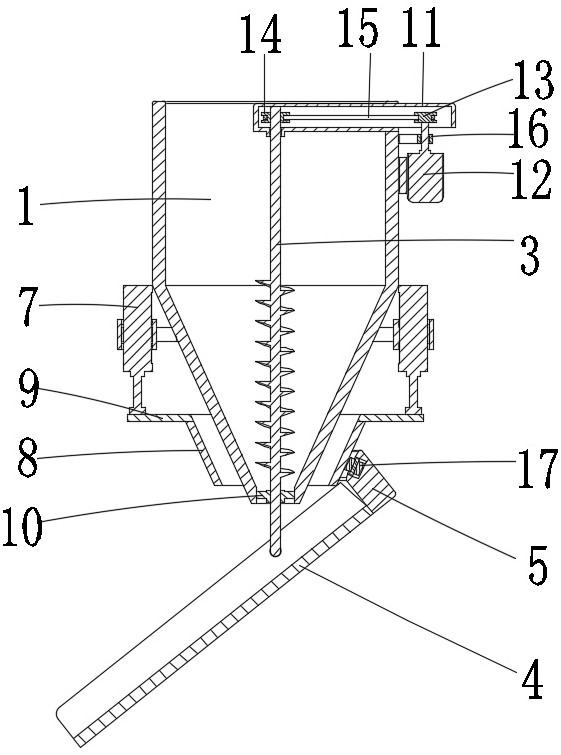

A Construction Method for Filling Wall Foundation with Deep Backfilling Soil

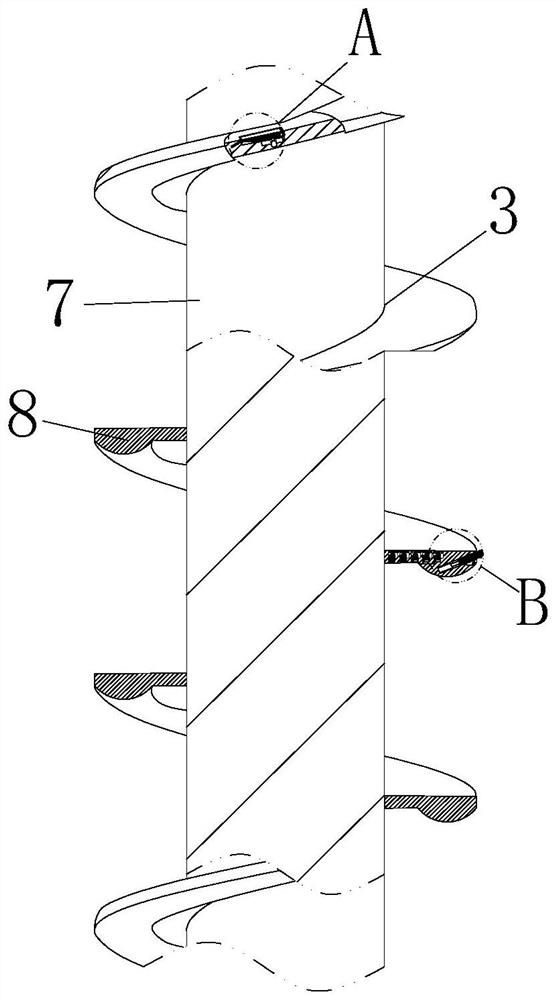

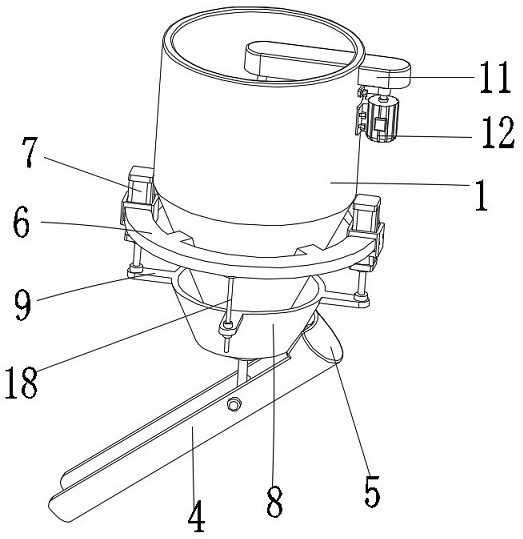

ActiveCN112921957BIncreased piling hole capacityPrevent fallingDrilling rodsDrilling casingsHydraulic cylinderAuger

The invention belongs to the technical field of building construction, and specifically relates to a construction method for filling a wall foundation with deep backfill soil. The auger drilling machine used in the construction method includes a body, a rotating column and an auger bit; the top of the body is provided with a The movement arm; the end of the movement arm is rotatably connected with a rotation column; the bottom surface of the rotation column is fixedly connected with a hydraulic cylinder; the bottom surface of the hydraulic cylinder is fixedly connected with a connecting column; the bottom surface of the connecting column is fixedly connected with a screw Drill bit; the auger bit includes a core column and a helical blade; the surface of the helical blade is provided with uniformly arranged rotating grooves; the internal rotation of the rotating groove is connected with a baffle plate; the present invention effectively improves the carrying capacity of the auger bit The ability of soil and rock avoids a large amount of soil and rock falling when the auger bit is exported to the pile hole, which reduces the drilling efficiency and affects the introduction of the steel pipe pile into the pile hole in the later stage, so as to improve the pile hole drilling capacity of the auger drill.

Owner:温州城建集团股份有限公司

A tailing sand filling sand bin device

The invention relates to the field of mining equipment, in particular to a sand bin filling device for tailing sand, which includes a sand bin and a drop opening arranged on the bottom side of the sand bin. An auger shaft is rotatably connected to the middle of the sand bin, and the circumferential side wall of the lower part of the auger shaft is An auger is provided, the lower end of the auger shaft passes through the outlet and is hinged with a sliding sand tank, the right end of the sliding sand tank is provided with an adjustment piece, the left side of the adjustment piece is provided with an arc surface, and the upper part of the sand bin is provided with a driving auger shaft to rotate The driving assembly of the sand bin is symmetrically fixed and connected with the cylinder through the ring frame outside the middle part of the sand bin; the invention prevents the tailing sand from blocking the drop opening by rotating the auger in the sand bin, and at the same time adjusts the vertical movement of the left end of the sand slide tank. Adjust the falling and accumulating area of the tailings to realize the expansion of the accumulation area of the tailings. At the same time, the rotation of the sliding sand tank is driven by the auger shaft to further expand the accumulation area, which can reduce the tailings caused by excessive tailings accumulation to a certain extent. Collapse accidents, and avoid tailings clogging too high at the drop opening, and improve the falling efficiency of tailings.

Owner:铜陵有色股份安庆月山矿业有限公司

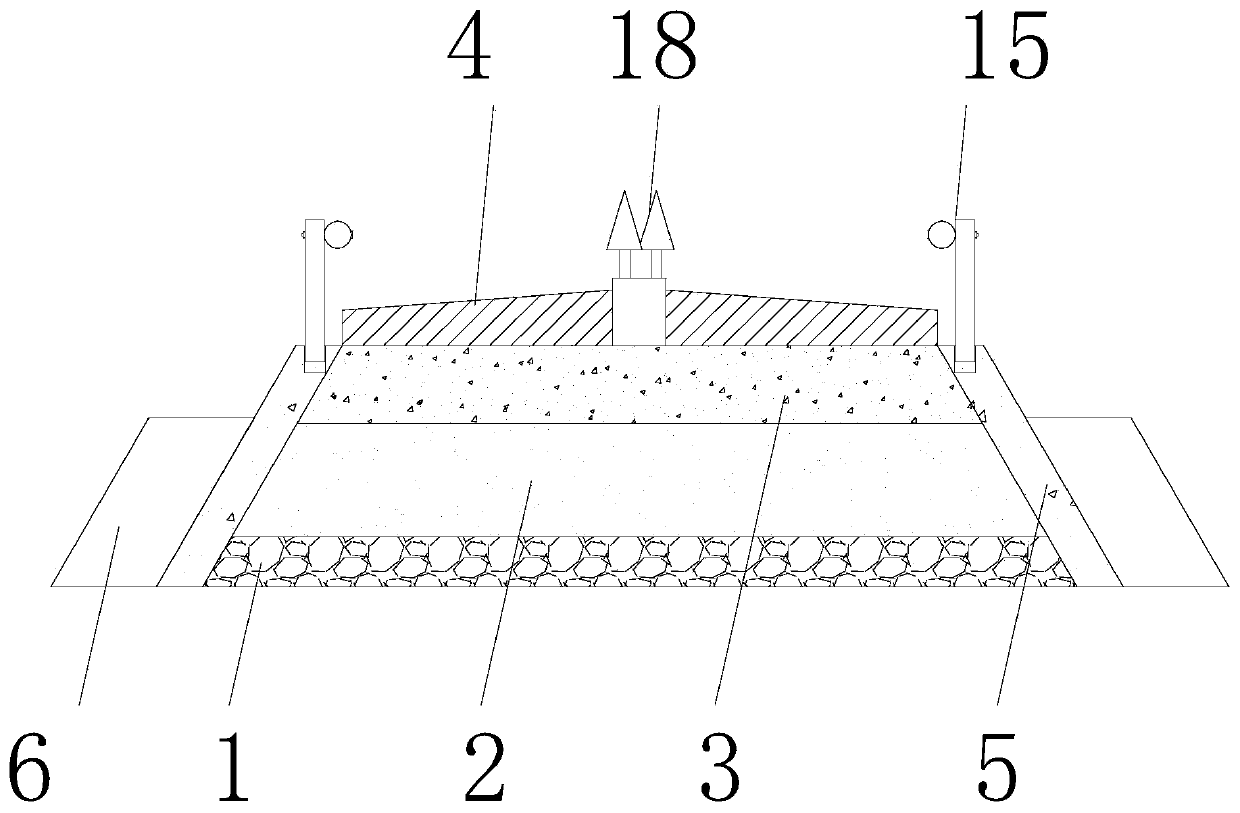

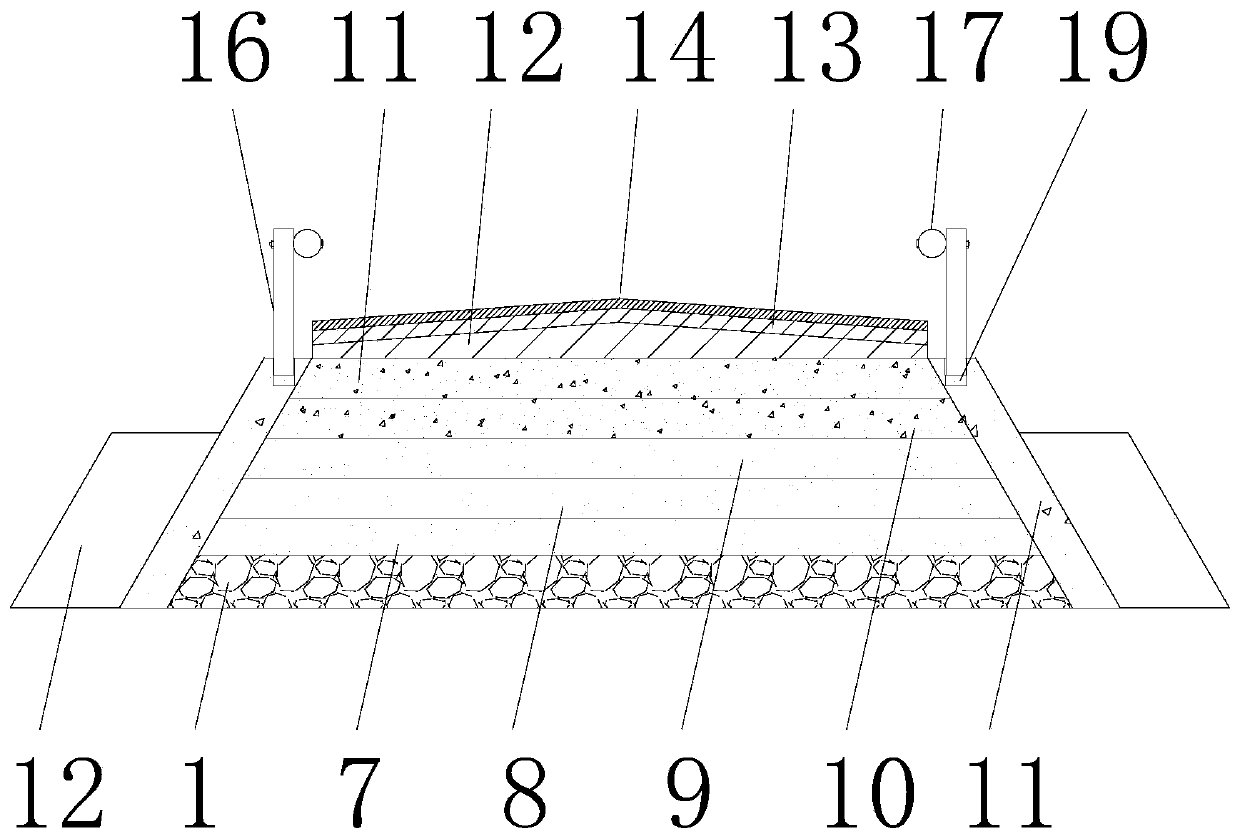

Expressway anti-scouring roadbed pavement and construction method

InactiveCN111041930APlay the role of diversionAct as a footholdIn situ pavingsPaving gutters/kerbsSoil scienceCrushed stone

The invention discloses an expressway anti-scouring roadbed pavement which comprises a broken stone hardcore, an lime-soil layer, a cement stabilized macadam layer, an asphalt layer, protection slopesand back pressure protection channels; the lime-soil layer is arranged at the upper end of the broken stone hardcore; the cement stabilized macadam layer is arranged at the upper end of the lime-soillayer; the asphalt layer is arranged at the upper end of the cement stabilized macadam layer; the protection slopes are arranged on the two sides of the broken stone hardcore, the ash soil layer andthe cement stabilized macadam layer; a back pressure protection channel is arranged on the outer side of each protection slope; the lime-soil layer comprise a first lime-soil layer, a second lime-soillayer and a third lime-soil layer, the first lime-soil layer is arranged on the broken stone hardcore, the second lime-soil layer is arranged on the first lime-soil layer, and the third lime-soil layer is arranged on the second lime-soil layer. By arranging the broken stone hardcore, the protection slopes and the back pressure protection channels, the problems that an existing expressway subgradeand pavement is poor in stability and prone to local collapse due to rain wash, and great hidden dangers are brought to driving are solved.

Owner:华润建筑有限公司

a train system

ActiveCN104192150BStrong enduranceTake advantage ofBallastwayRailway transportReinforced concreteStub axle

Owner:张向东

Tailing filling sand bin device

ActiveCN111828088AAvoid cloggingIncrease the accumulation areaMaterial fill-upAugerStructural engineering

The invention relates to the field of mining equipment, in particular to a tailing filling sand bin device. The tailing filling sand bin device comprises a sand bin and a falling opening arranged at the bottom side of the sand bin, wherein an auger shaft is rotationally connected in the middle of the sand bin, an auger piece is arranged on the circumferential side wall of the lower part of the auger shaft, the lower end of the auger shaft penetrates through the falling opening and is hinged with a sand sliding groove, an adjusting piece is arranged at the right end of the sand sliding groove,an arc-shaped surface is arranged on the left side of the adjusting piece, a driving assembly for driving the rotation of the auger shaft is arranged on the upper part of the sand bin, and air cylinders are symmetrically and fixedly connected outside the middle part of the sand bin through an annular frame. Tailings are prevented from blocking the falling opening by rotating the auger piece in thesand bin, and meanwhile, the falling accumulation area of the tailings is adjusted by adjusting the upward and downward movement of the left end of the sand sliding groove, so that the accumulation area of the tailings is enlarged; meanwhile, the sand sliding groove is driven by the auger shaft to rotate, the accumulation area is further enlarged, the tailing collapse accident caused by too highaccumulation height of the tailing is reduced to a certain extent, the tailings are prevented from blocking the falling opening too high, and the falling efficiency of the tailings is improved.

Owner:铜陵有色股份安庆月山矿业有限公司

Wind power tower connector looseness detection method and detection device

InactiveCN107153002BReduce collapse accidentsEasy to detectMachine part testingNatural disasterEngineering

The invention discloses a method and device for detecting the loosening degree of a connecting part of a wind power generation tower, and the method comprises the steps: setting a sensor at each of two sides of the connecting part of the wind power generation tower, and obtaining the vibration data of the wind power generation tower in a first wind speed section after the arrival of typhoon at each time, the vibration data in a second speed section and the vibration data in a third wind speed section; comparing the three pieces of obtained vibration data with the reference vibration data of the initial wind speed of the wind power generation tower in the first section, and judging the loosening degree of the connecting part of the wind power generation tower after the typhoon at each time. Therefore, the method achieves the automatic detection and recognition of the loosening degree of the connecting part of the wind power generation tower, improves the maintenance efficiency of the loosening damage of the connecting part of the wind power generation tower, reduces the collapse accidents of the wind power generation tower, and has the important significance in prevention and reduction of natural disasters.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION +1

A device for improving the seismic capacity of bridges

ActiveCN108978451BReduce wave damageAvoid damageBridge structural detailsExpansion jointSeismic resistance

The invention discloses a device for improving the seismic resistance of a bridge. The device includesthe bridge body, the bridge main body is laternally spaced with an expansion joint, the two e of the expansion joint are connected by connecting pieces, the two ends of the connecting piece are fixed with the outside of the bridge main body through a steel plate, a positioning plate is symmetrically welded in the middle of the steel plate, a reinforcing rib is integrally formed between the positioning plate and the edge side of the steel plate, a sleeve bar is fixed between the positioning plates, the outside of the sleeve bar is flush with one end of the positioning plate, and a column steel is connected between the sleeve bars; through the high-damping isolation rubber bearing arranged in the invention, by using the special damping formula to consume the horizontal vibration energy transmitted in the earthquake, when the earthquake comes, the vertical support to the bridge main bodywill not transfer all the energy to the bridge main body in the horizontal direction, and the vibration energy will be converted into heat consumption by using the lead core in the reciprocating seismic wave, so as to reduce the wave damage action of the horizontal seismic force on the bridge main body.

Owner:诸暨市岳都纺织有限公司

Open shield machine, support device, control system and control method thereof

InactiveCN103953356BReduce labor intensityReduce collapse accidentsServomotorsTunnelsControl systemFuel tank

The invention discloses an open type shield machine, a support device and a control system and a control method of the support device. The control system can be used for controlling passive retraction of a slotting tool of the support device, and comprises a slotting tool oil cylinder with the slotting tool on a piston rod, a proportional overflow valve with an oil inlet communicated with a rodless cavity of the slotting tool oil cylinder and an oil outlet connected with an oil tank, a controller used for adjusting the pressure of the proportional overflow valve, and a displacement sensor which is used for detecting the extending displacement of the slotting tool and is connected with the controller. According to the control system, the passive retraction of the slotting tool can be achieved, so that the retraction speed of the slotting tool is basically the same as the forward speed of the shield machine and the stability of a soil body supported by the support device is kept; in addition, the control system does not need to be monitored in real time and operated by an operator, so that the labor intensity of the operator is reduced and the accident of soil body collapse caused by improper manual operation is reduced.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com