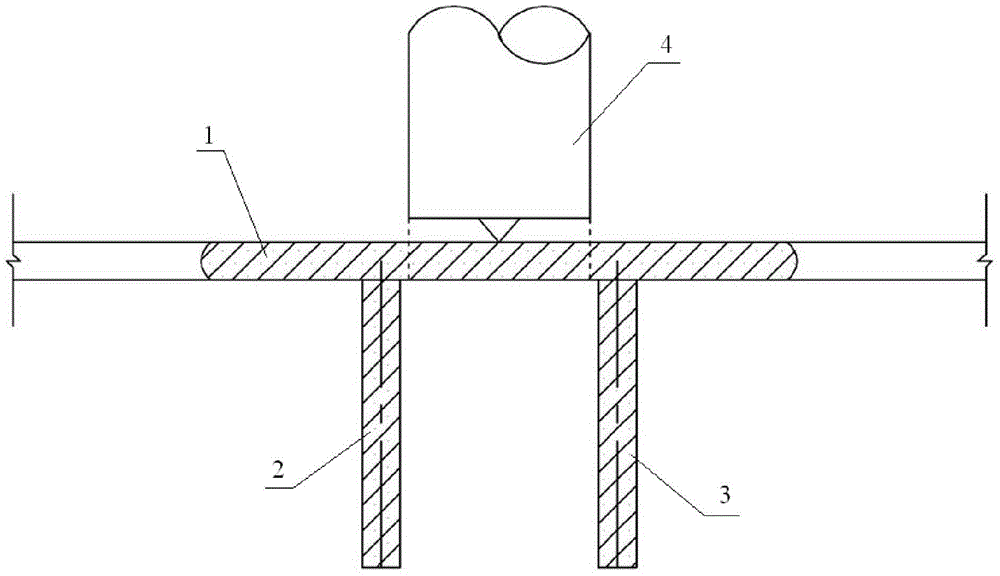

Shield tunneling construction method for n-shaped underground diaphragm wall

A technology of underground diaphragm wall and construction method, which is applied in the direction of foundation structure engineering, sheet pile wall, building, etc., can solve the problems of mud gushing and sand gushing and surface settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] What the present invention provides is a kind of Π-shaped underground diaphragm wall shield access hole construction method, and its specific method is as follows:

[0063] The first step is to formulate the construction process. The specific construction process is as follows:

[0064] Measurement and setting out → guide wall making → mud preparation and adjustment → ground wall formation and bottom cleaning replacement → GFRP reinforcement cage and bamboo reinforcement cage production and hanging → underwater concrete pouring → joint construction → joint pipe jacking → The entire construction is completed;

[0065] The second step, the specific construction process is as follows:

[0066] 1. Measurement and setting out:

[0067] According to the axis control piles, the axis control piles of the ground connection wall are measured, the control piles are protected piles, the elevation is introduced into the site, and the closed backtest method is used to set the bench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com