Segmented fixed-point hydraulic fracturing device and method for underground coal mine drilling

A technology of hydraulic fracturing and hole solidification, which is applied in the direction of earthwork drilling, wellbore/well components, and mining fluids, etc. It can solve the problem of unsatisfactory porosity and drainage effect, poor effect of coal seam fracture network reconstruction, and gas blockage Drainage channels and other issues, to achieve the effect of adapting to the conditions of underground roadways, reducing collapse accidents in holes, and increasing the strength of coal and rock formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

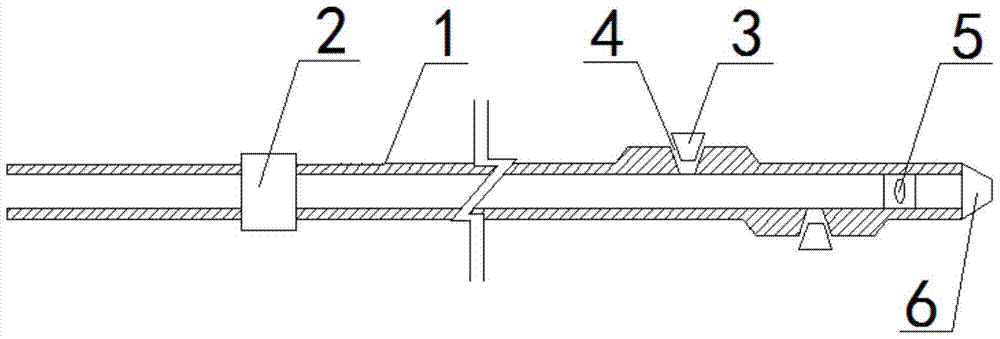

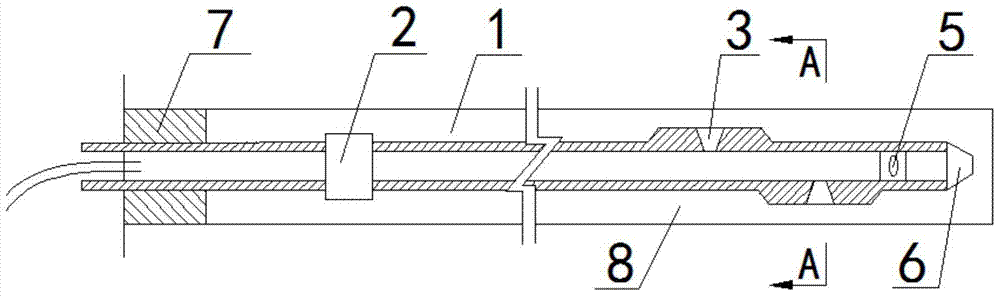

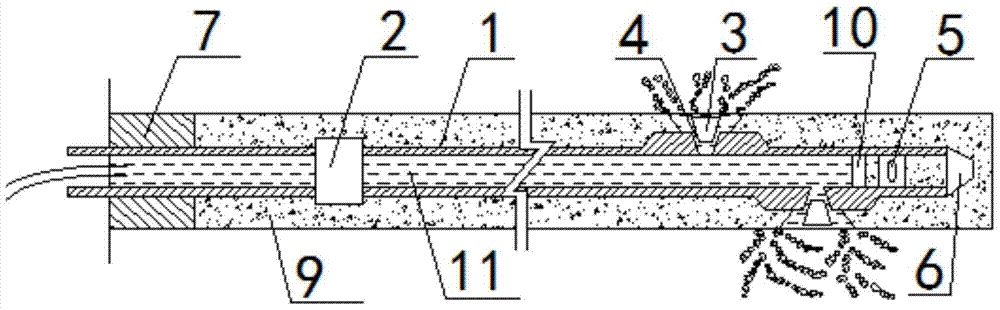

[0029] Such as Figure 1-3 As shown, the present invention provides a device for segmental fixed-point hydraulic fracturing of underground drilling in coal mines. The segmental fixed-point hydraulic fracturing device for underground coal mines includes a casing centralizer 2 and a check valve 5 sequentially connected by a casing 1 , there is a through hole in the middle of the check valve 5, a guide shoe 6 is connected to the end of the casing 1, and a water outlet hole 4 is opened on the casing wall near the check valve 5. Under the action of pre-tightening force, the water outlet hole 4 The size is just enough to embed the one-way valve 3 . Such as Figure 4 , 5 As shown, there are three pairs of one-way valves 3 and water outlet holes 4 on the same circumference of the casing wall of the staged fixed-point fracturing device in the lower coal mine, and they are 120° from each other, and they are arranged in a spiral in the axial direction of the casing 1. , the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com