Method and device for laser pulse and electromagnetic pulse composite forming of metal sheet

An electromagnetic pulse and metal sheet technology is applied in the field of metal sheet laser shock wave and electromagnetic pulse composite forming method and device, which can solve the problems of difficult popularization, high cost, and high energy consumption of equipment, and achieve localization and inhomogeneity. The effect of expanding the deformation area and deformation amount and improving the uniformity of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

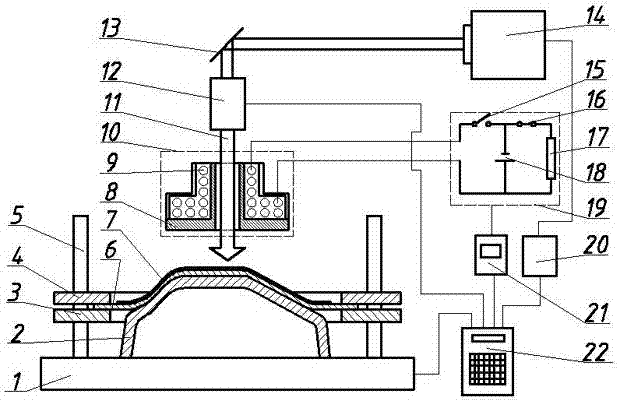

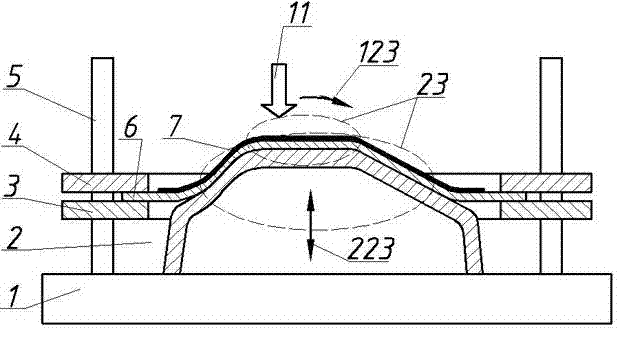

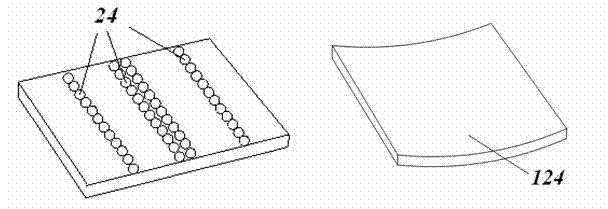

[0034] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Describe in detail the details and working conditions of the specific device proposed by the present invention.

[0035] Such as figure 1 As shown, the device of the present invention includes: a three-axis numerical control workbench 1, a bottom mold 2, a test piece supporting plate 3, a test piece pressing plate 4, a guide post 5, a flexible film 7 (constraining layer + absorbing layer), and an electromagnetic pulse device 10 , spot adjustment device 12, 45 ° total reflection mirror 13, high-power pulse laser 14, electromagnetic force generation system 19, laser power supply 20, electromagnetic pulse controller 21, computer control system 22; Described electromagnetic pulse device 10 comprises: electromagnetic pulse Coil 9, magnetic collector 8; the electromagnetic force generation system 19 includes: discharge switch 15, charging switch 16, charging device 17, pulse energy storage capacitor ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser pulse width | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com