Method for eliminating full-automatic two-layer steel coil stacking suspension

A fully automatic, steel coil technology, applied in the field of warehousing and automatic hoisting, can solve the hidden dangers of safety, there is no way to solve the problems of two-layer coil stacking in the air, two-layer steel coil collapse, etc., to improve the quality of hoisting and eliminate the hidden safety hazards of stacking and hanging. , the effect of high overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

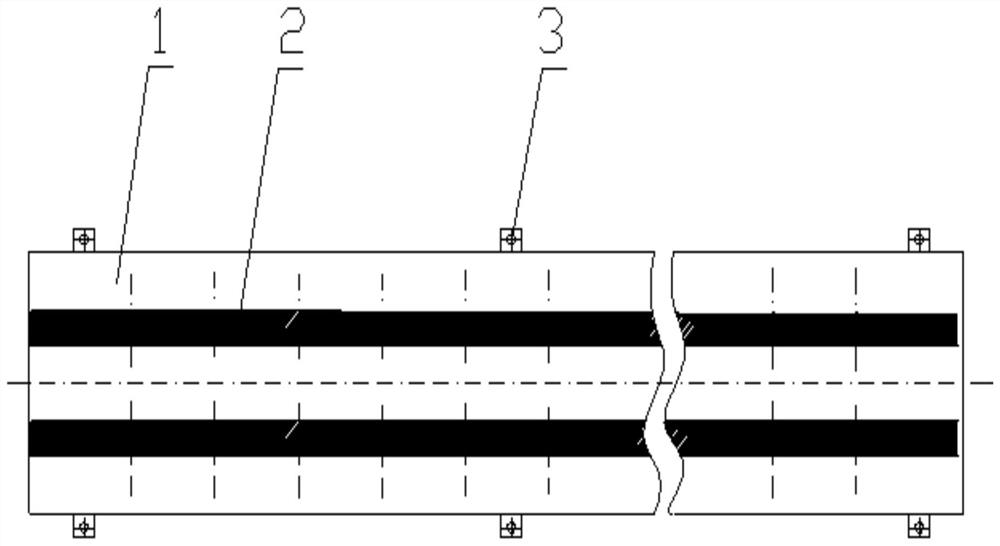

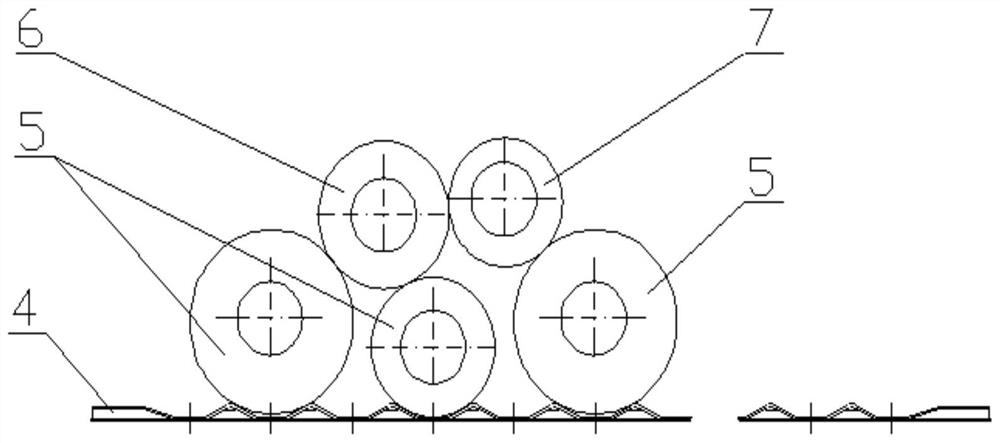

[0025] Embodiment 1: see Figure 1-Figure 4 , a method for eliminating full-automatic two-layer steel coil stacking and suspension, said method comprising the following steps:

[0026] Step 1) establish a kind of computing model that prevents two-layer rolls from stacking and hanging in the air;

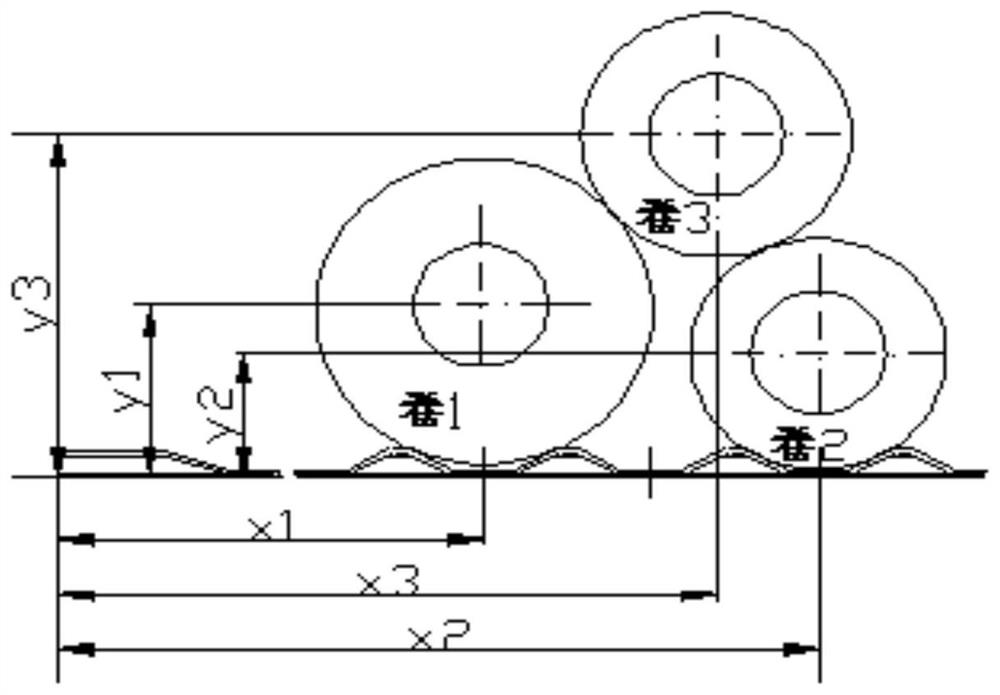

[0027] Step 2) Determine the non-interfering calculation method of two adjacent two-layer rolls through the calculation model;

[0028] Step 3) Summarize a reasonable β spacing value or correction rate based on on-site production practice or experience.

[0029] The step 1) establishes a calculation model for preventing double-layer rolls from being stacked and suspended, specifically as follows, building a calculation model for preventing double-layer rolls from being stacked and suspended with 3 bottom rolls and 2 layers of rolls.

[0030] The step 2) determines the non-interference calculation method of two adjacent two-layer rolls through the calculation model, specifically as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com