Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

A prefabricated component, loading test technology, applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc., can solve the problems of easy breakage of the sling of the sand bag, affecting traffic, inaccurate measurement, etc., to improve reliability. safety and reliability, good reliability and safety, and the effect of reducing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

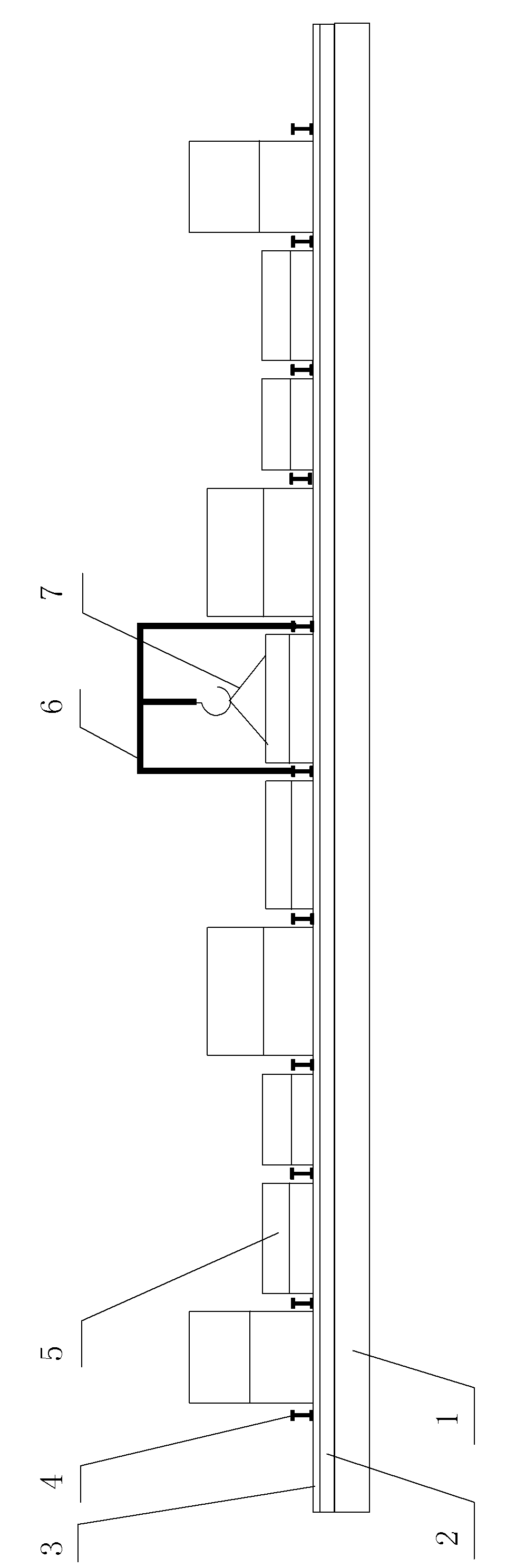

[0048] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the method for carrying out the loading test of the bridge support frame by towing and walking mobile prefabricated components includes the following steps:

[0049] 1) Place the loading special formwork 3 on the box girder formwork 2 on the bridge support frame 1 (the old formwork can be used for the loading special formwork 3);

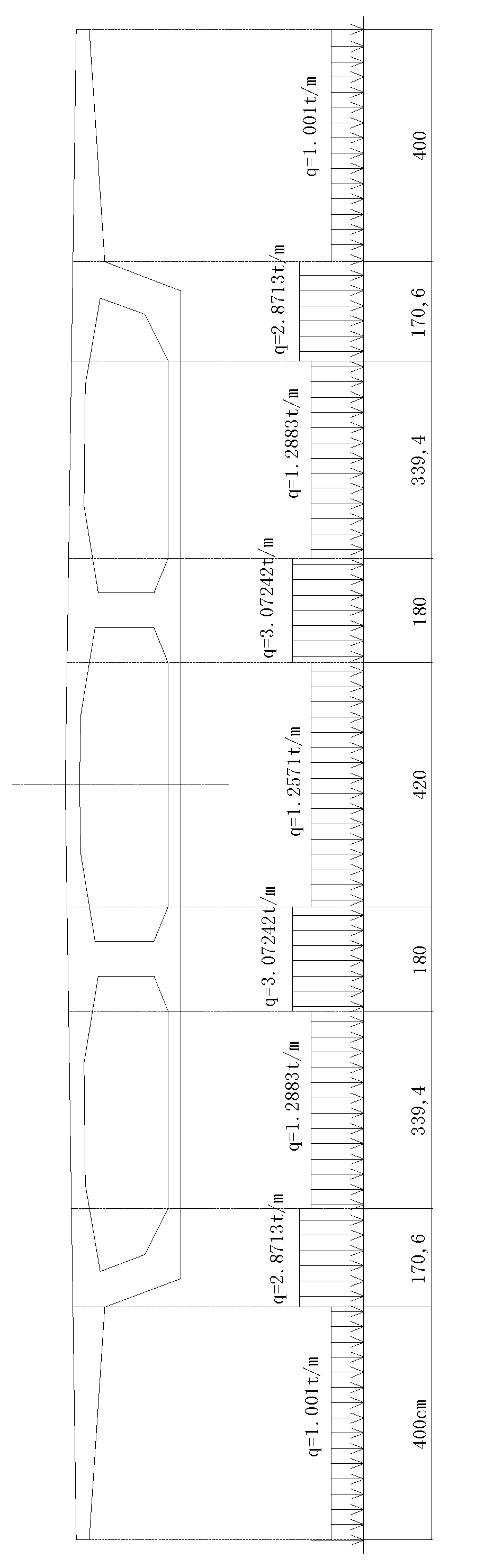

[0050] 2) Install a plurality of rails 4 (7-22) along the longitudinal direction (i.e. the length direction) of the bridge support frame 1 on the loading special template 3, and the rails 4 are fixed on the loading special template 3 with clamps, Adjacent tracks are connected by connectors (the width of the connectors is 60mm, and the connectors are steel strips; the tracks are equipped with double gears), and the distance between adjacent tracks is greater than the length of the prefabricated components by 10-1000mm;

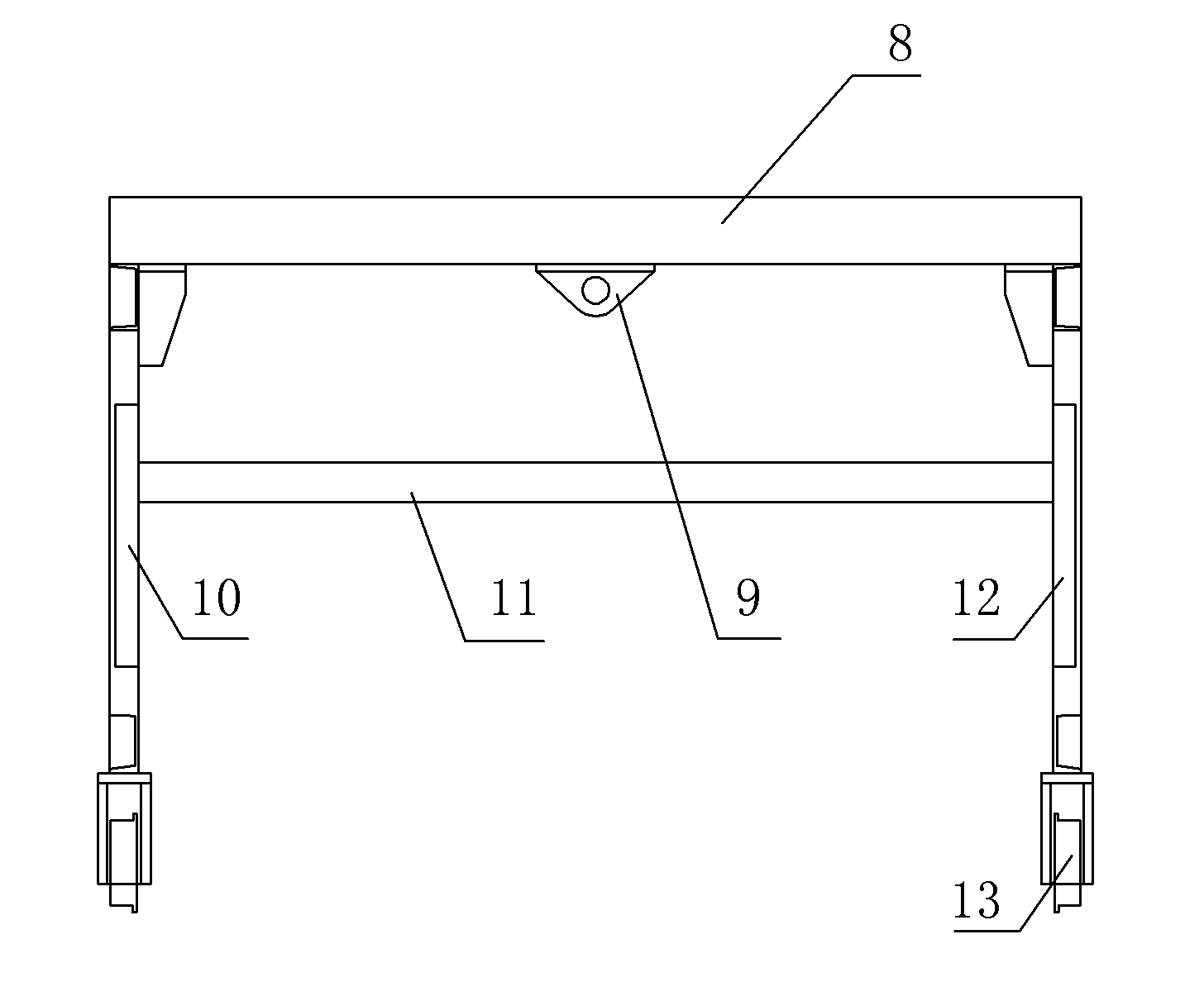

[0051] 3) Place several gantry c...

Embodiment 2

[0073] It is basically the same as Example 1, the difference is that the bridge support frame within a certain range in the same span is subjected to a partition loading test, that is, the prefabricated components of the second floor are laid in partitions and tested in partitions, and then the bridge supports in the same span are tested. The prefabricated components in the tested area are moved to the undetected area in the same span, so as to realize the complete loading test with fewer prefabricated components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com