Tailing filling sand bin device

A technology for sand silo and tailings, which is applied in the field of tailings filling sand silo device, can solve the problems such as the collapse of blocked tailings, the influence of tailings falling out, and the blockage of filling and falling openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

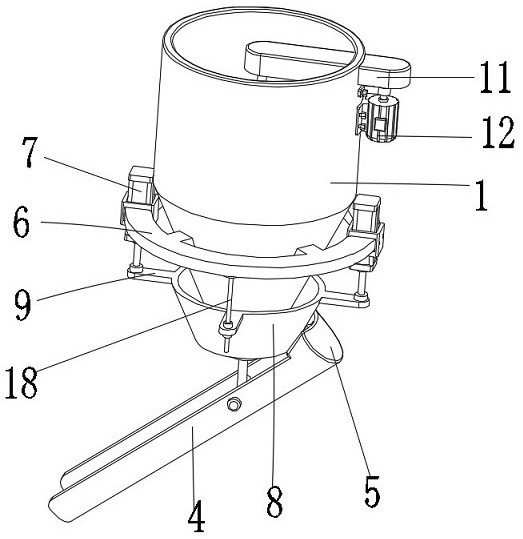

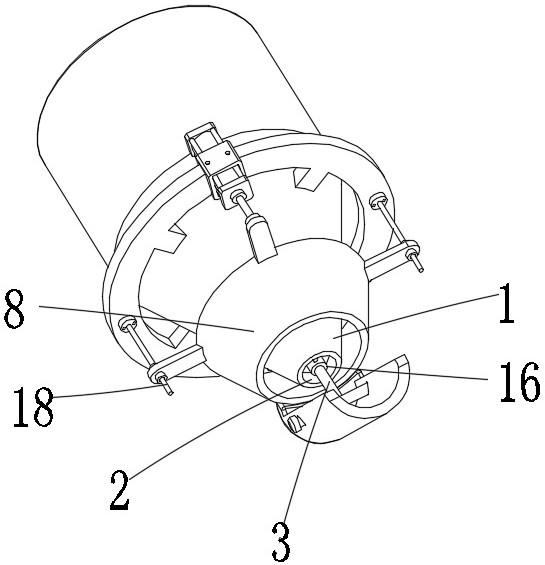

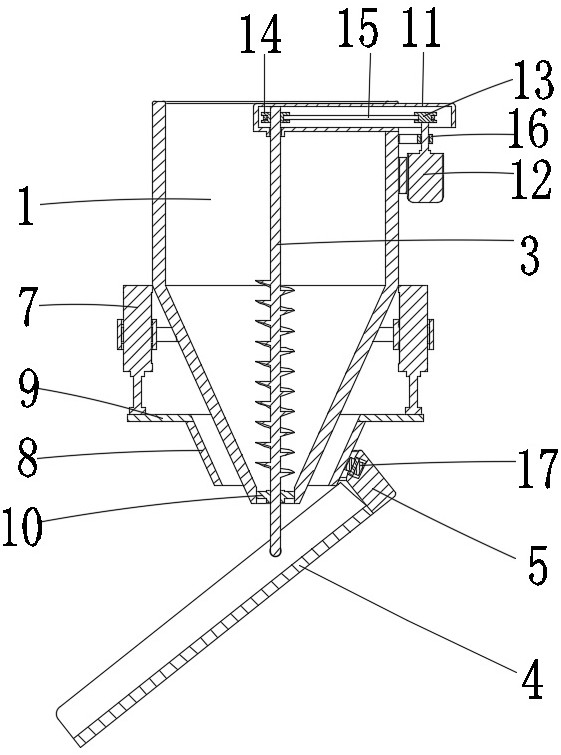

[0027] A kind of tailing sand filling sand bin device of the present embodiment, refer to Figure 1-4 : Including the sand bin 1 and the drop opening 2 arranged on the bottom side of the sand bin 1, the middle part of the sand bin 1 is rotationally connected with the auger shaft 3, the peripheral side wall of the lower part of the auger shaft 3 is provided with an auger piece, and the lower end of the auger shaft 3 It passes through the drop opening 2 and is hinged with a sliding sand tank 4. The right end of the sliding sand tank 4 is provided with an adjustment member 5, and the left side of the adjustment member 5 is provided with an arc-shaped surface. The upper part of the sand bin 1 is provided with a driving assembly that drives the auger shaft 3 to rotate. The outside of the middle part of the sand bin 1 is symmetrically fixed and connected with the cylinder 7 through the ring frame 6, and the lower part of the sand bin 1 is provided with a conical ring 8 which is in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com