Steel-fiber high-performance concrete pipe and manufacturing method thereof

A technology for high-performance concrete and reinforced concrete pipes, applied in the field of pipelines, can solve the problems of high requirements for installation foundation, waste of national economy, and poor resistance to external pressure, so as to reduce operating costs, increase service life, and improve compression and resistance The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described in detail.

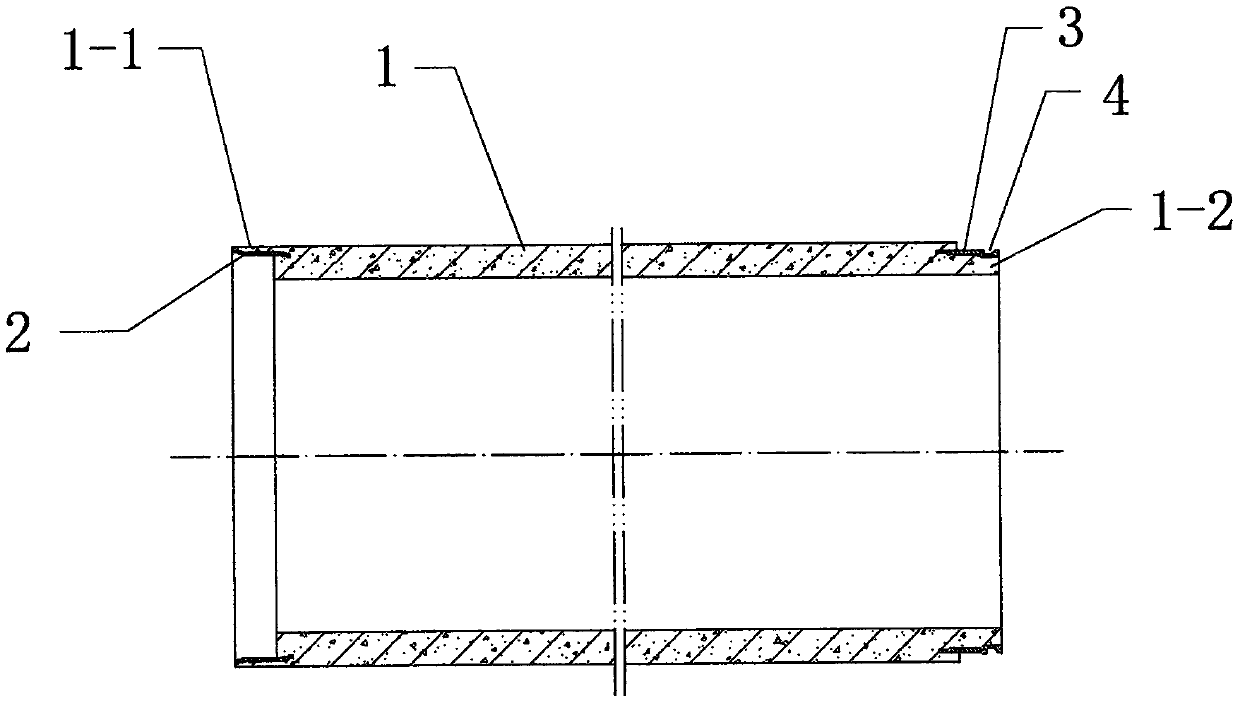

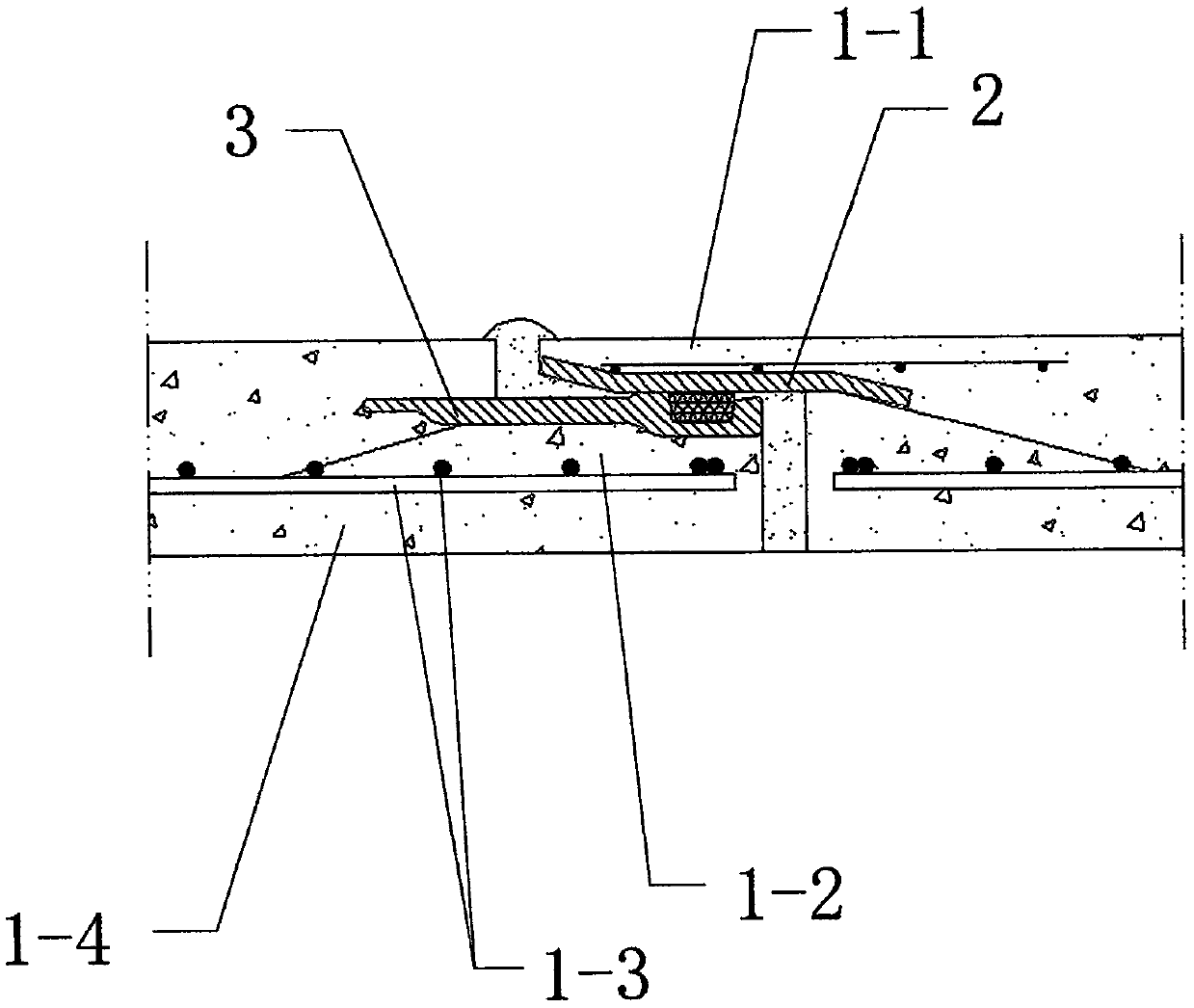

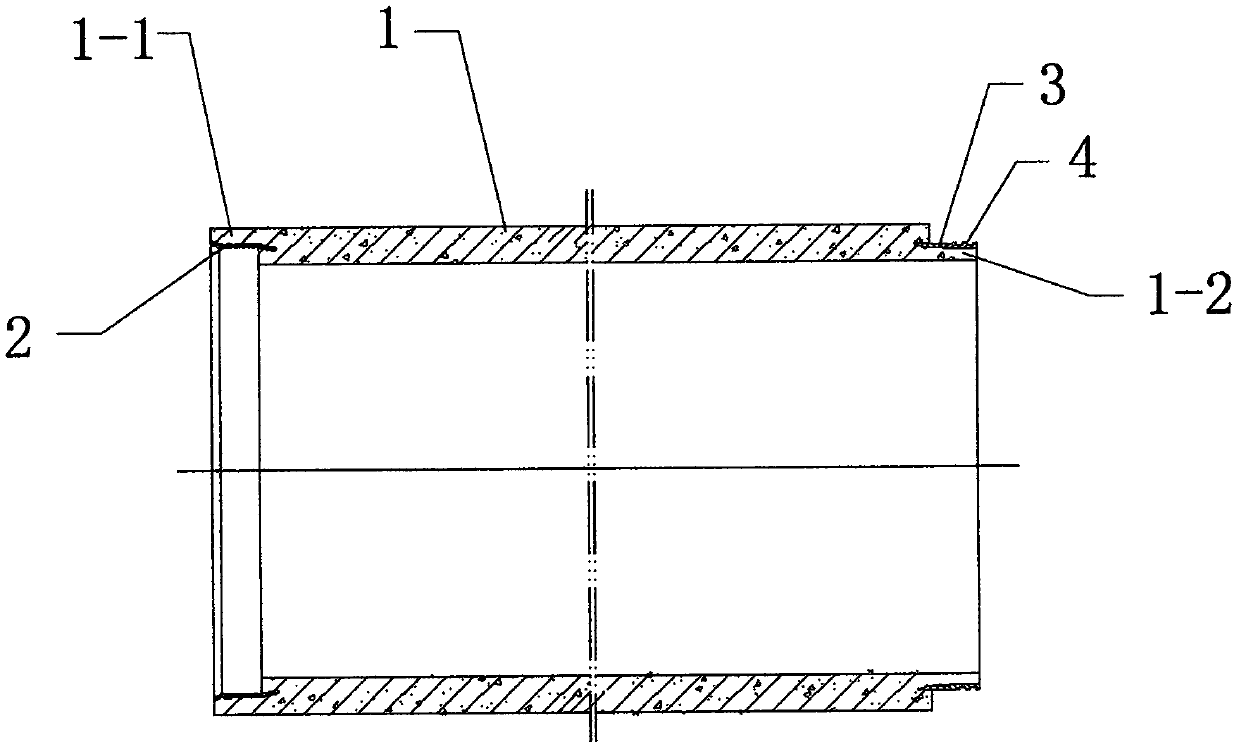

[0019] Such as Figure 1 to Figure 4 As shown, a steel fiber high-performance concrete pipe includes a reinforced concrete pipe body, the reinforced concrete pipe body 1, the two ends of the reinforced concrete pipe body 1 are provided with a socket part 1-1 and a socket part 1-2, and the socket part The part 1-1 and the socket part 1-2 are respectively fixed with a steel socket ring 2 and a steel socket ring 3, and the steel socket ring 3 is provided with a single / double annular groove 4, a single / double annular groove 4 An O-shaped rubber sealing ring is installed on the top; the steel socket ring 3 and the steel socket ring 2 of the adjacent reinforced concrete pipe body are plugged together.

[0020] The reinforced concrete pipe body includes a reinforcement cage 1-3 and a high-performance steel fiber concrete layer 1-4, and the high-performance steel fiber concrete layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com