Reliability test platform for frame and traction transmission system of bogie of bullet train

A traction drive and high-speed train technology, applied in the field of high-speed train bogies and traction drive system reliability test benches, can solve the problems of large differences in test results, low calculation accuracy, etc., to reduce costs and risks, adjust flexibility, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the drawings:

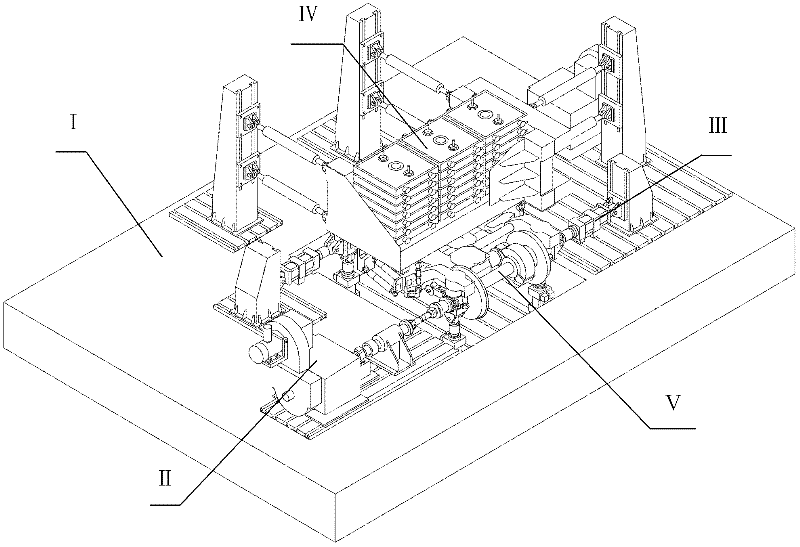

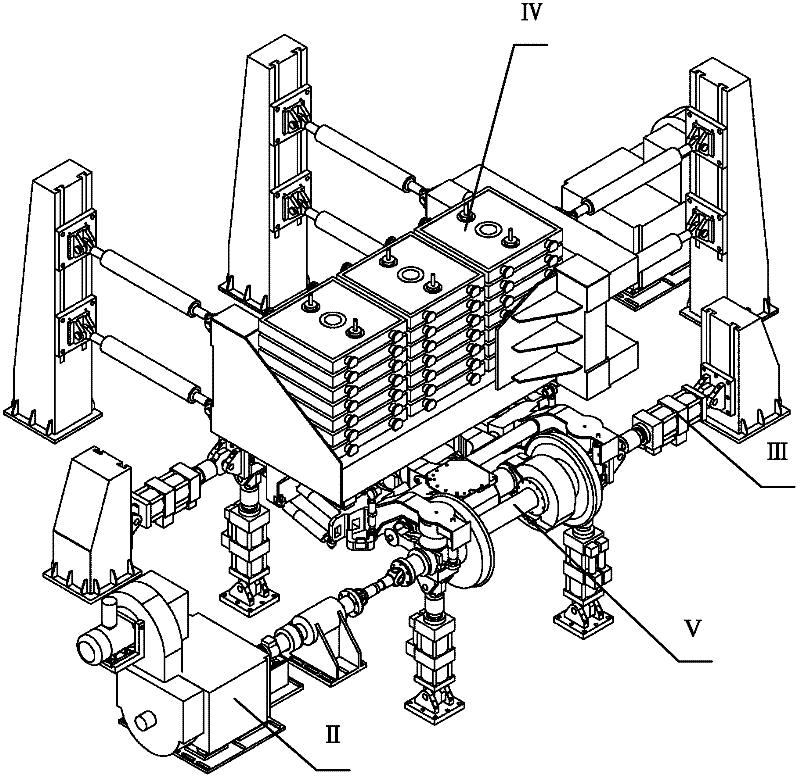

[0040] See figure 1 The high-speed train bogie frame and traction drive system reliability test bed of the present invention is composed of a mechanical assembly part, a test bed foundation I, a hydraulic pump station and an electronic control system.

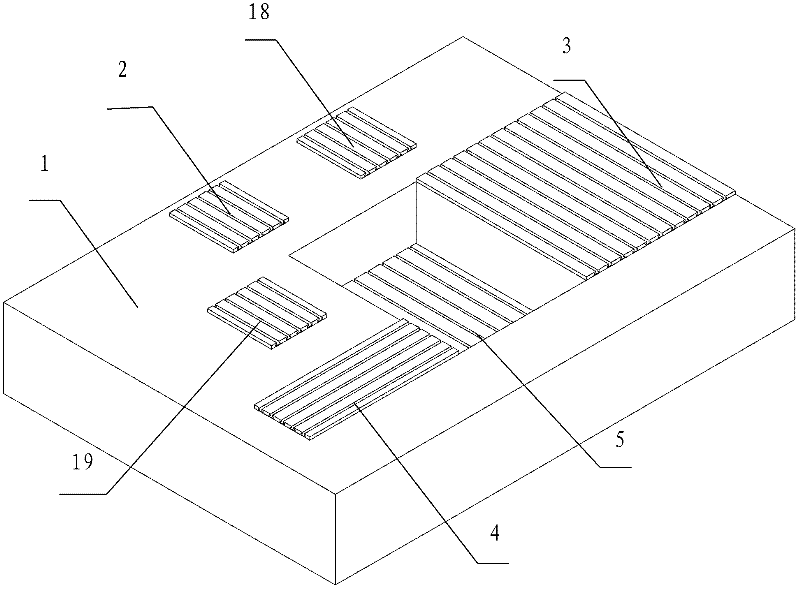

[0041] The said mechanical assembly part is composed of loading device II, excitation system assembly III, semi-vehicle quality simulation device IV and test bench tooling V. The loading device II, the excitation system assembly III and the semi-vehicle quality simulation device IV are installed on the foundation I of the test bench. A cast iron platform is arranged on the test bench foundation I to fix the loading device II, the excitation system assembly III and the semi-car quality simulation device IV.

[0042] See Figure 4 , 5 , The loading device II of the high-speed train bogie frame and traction drive system reliability test be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com