Foundation base model test device capable of bidirectional loading

A basic model, two-way loading technology, applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of only one-way loading, multiple simulation functions, single function, etc., to reduce the size effect and boundary effect, Comprehensive monitoring system and the effect of multiple simulation functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

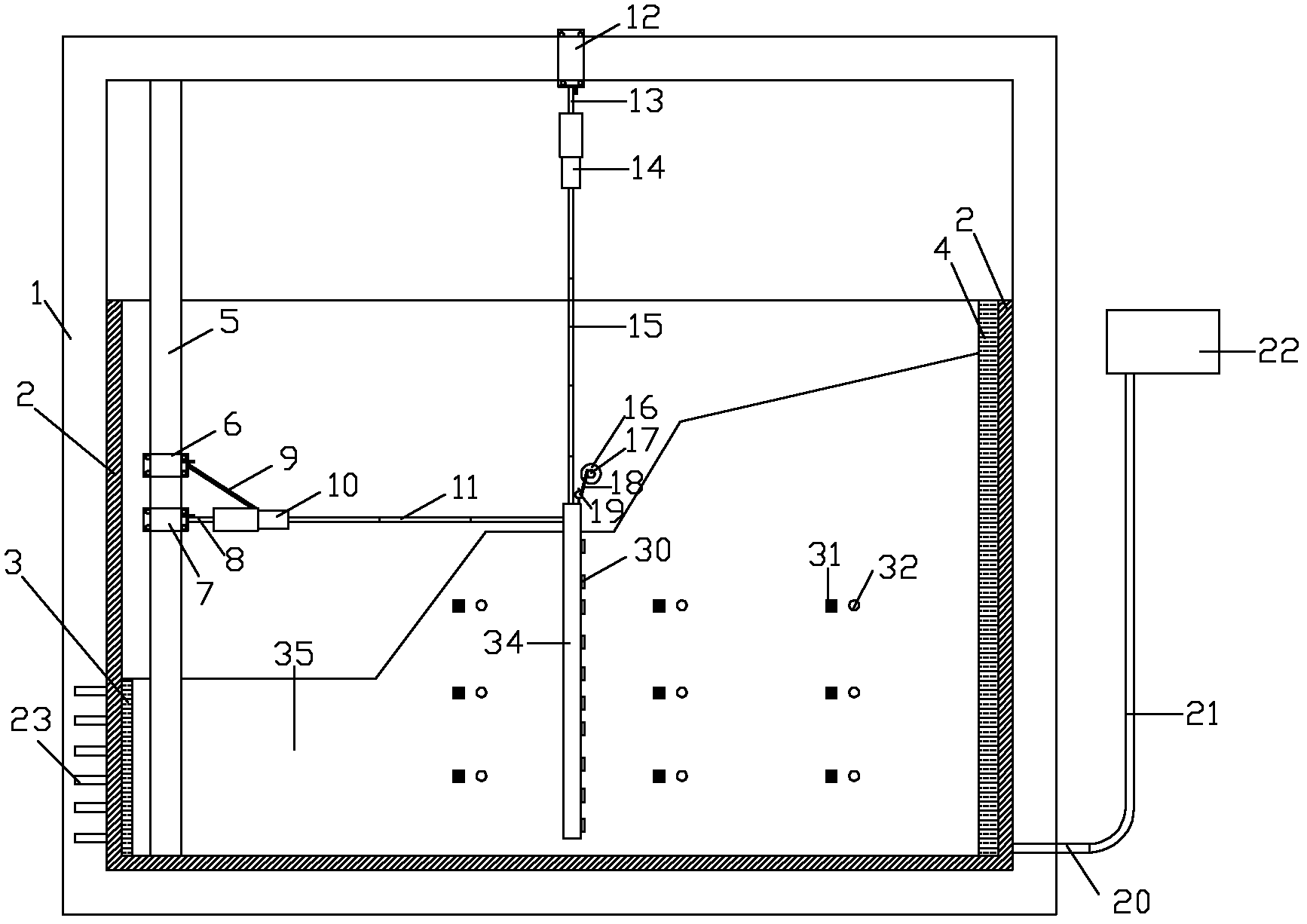

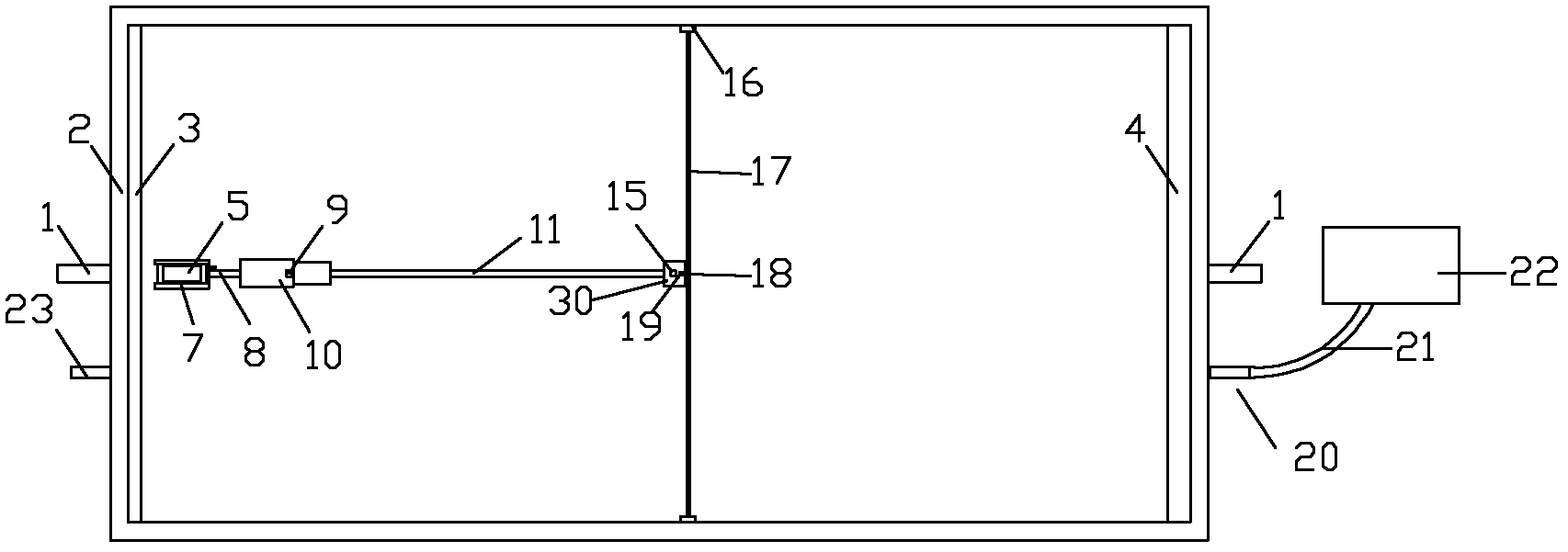

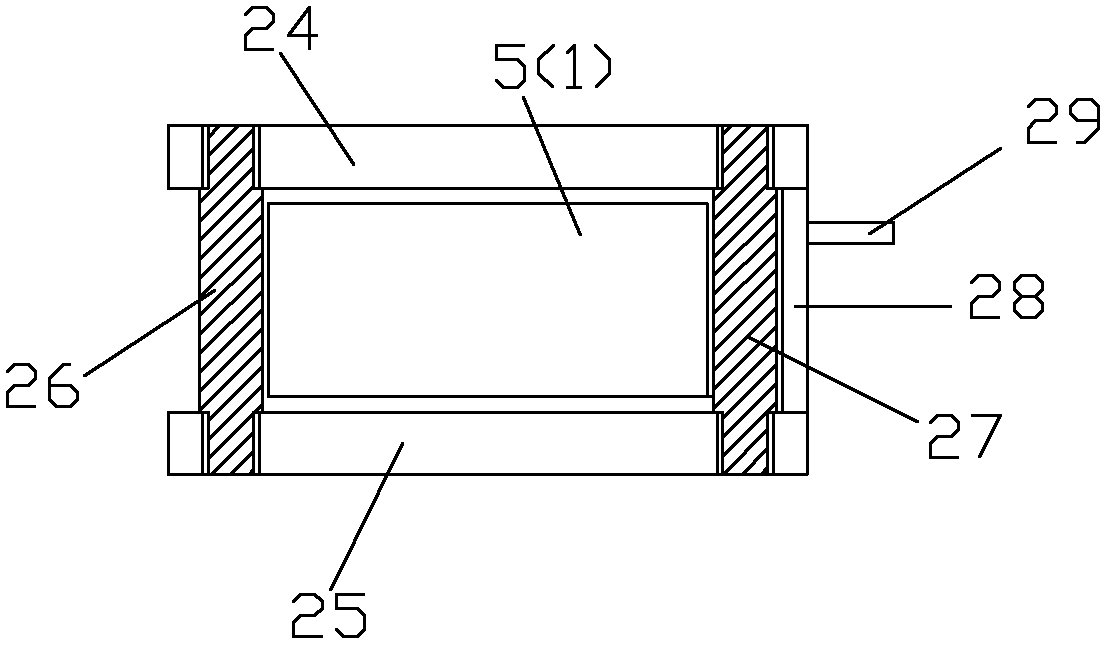

[0040] The present invention will be further described below according to accompanying drawing:

[0041] according to Figure 1 to Figure 6 It can be seen that the foundation model test device capable of bidirectional loading consists of a load-bearing frame 1, a model tank 2, a left porous permeable plate 3, a right porous permeable plate 4, a horizontal actuator reaction column 5, and a horizontal actuator Upper sliding support 6, horizontal actuator lower sliding support 7, horizontal actuator connecting rod 8, horizontal actuator diagonal rod 9, horizontal actuator 10, horizontal dowel bar 11, vertical actuator sliding Support 12, vertical actuator connecting rod 13, vertical actuator 14, vertical dowel bar 15, magnetic support 16, displacement sensor bracket 17, magnetic table base 18, displacement sensor 19, water inlet valve 20 , water supply pipe 21, constant pressure water tank 22, drain valve 23, pore water pressure gauge 31, earth pressure gauge 32, pile body strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com