Shield machine balance originating method

A shield machine and balancing technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of curtain plate breaking, starting end collapse, affecting the starting of the shield, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

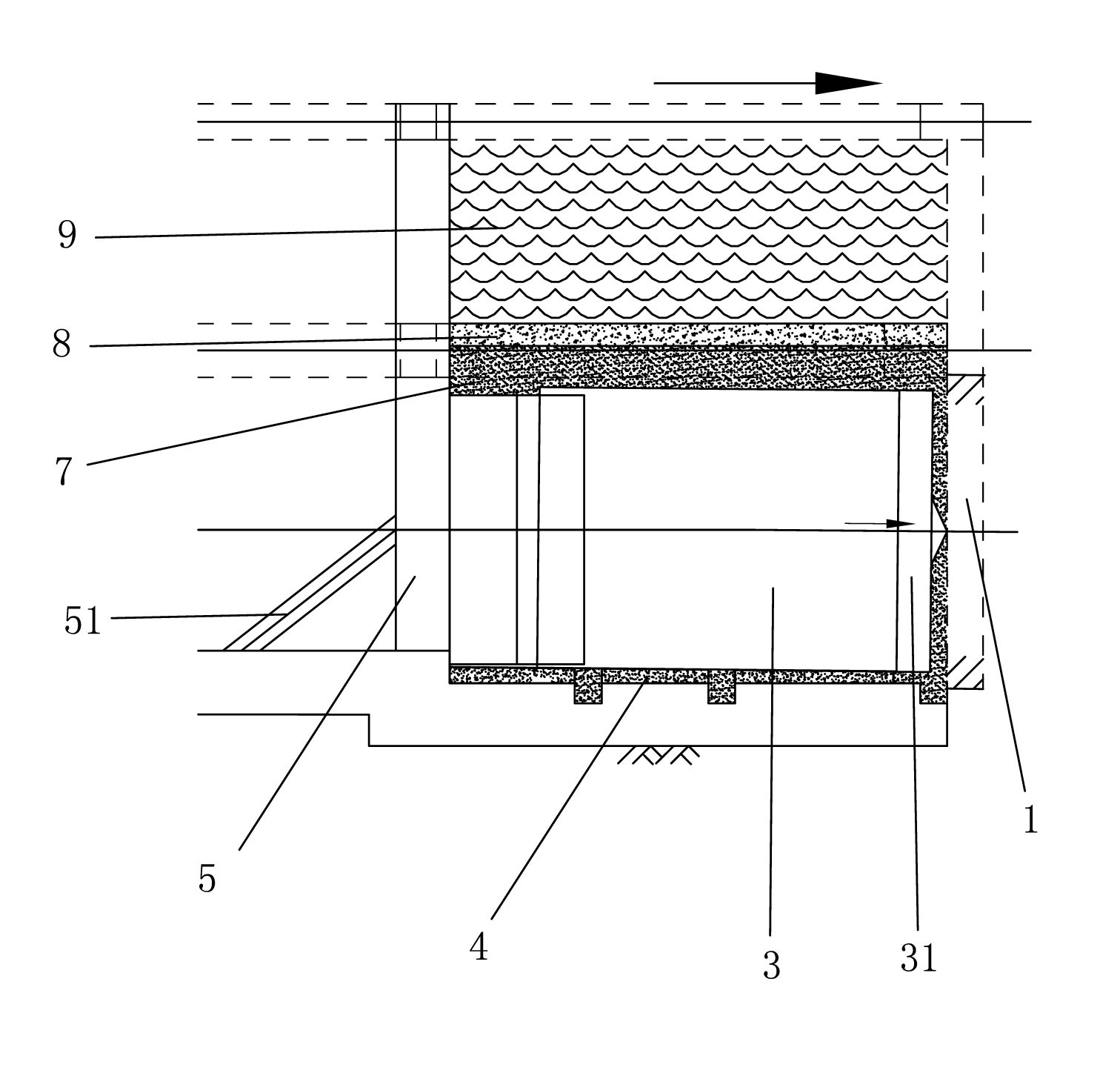

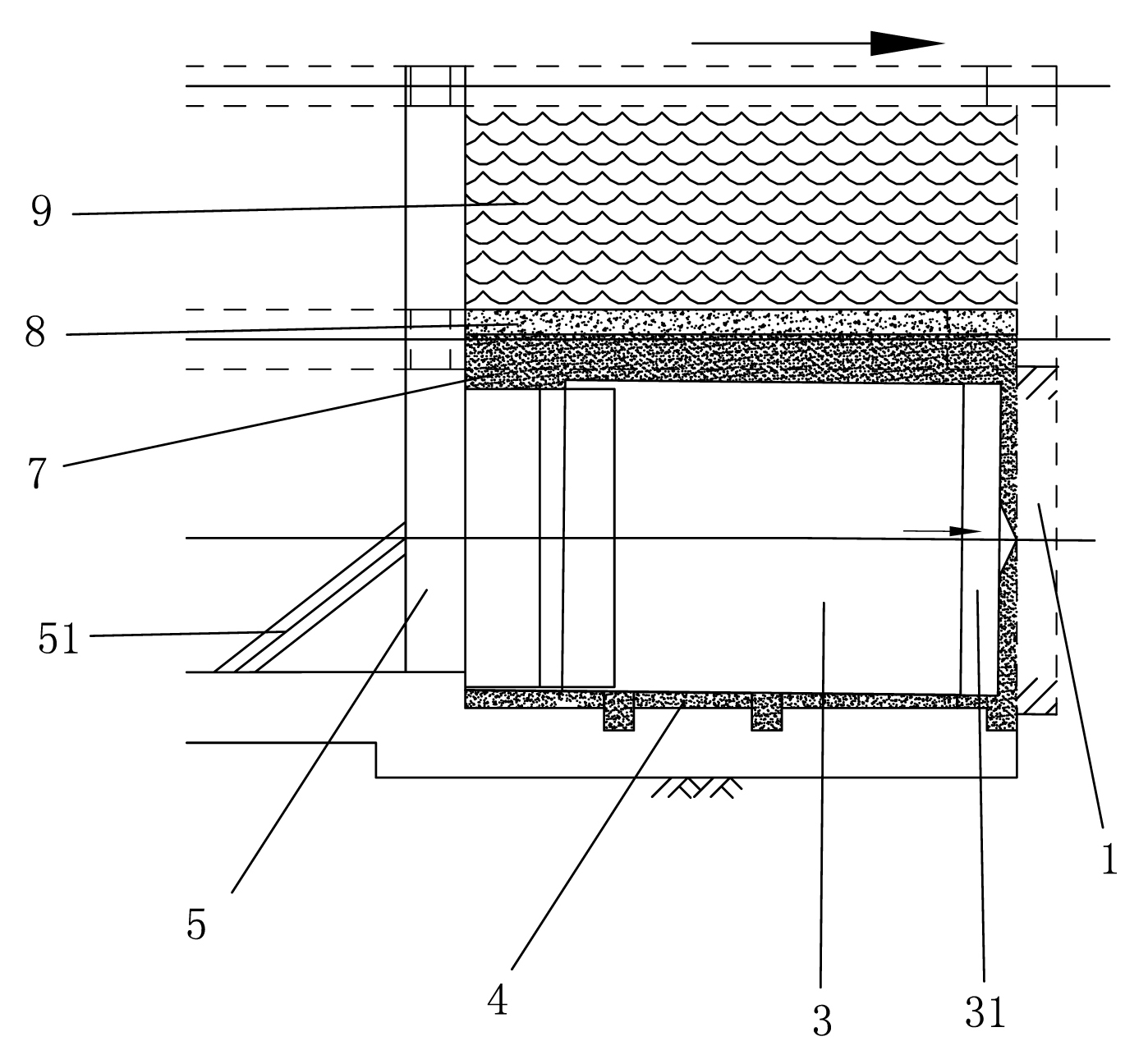

[0023] refer to figure 1 and figure 2 , a kind of shield machine balance initiation method of the present invention, comprises the following steps:

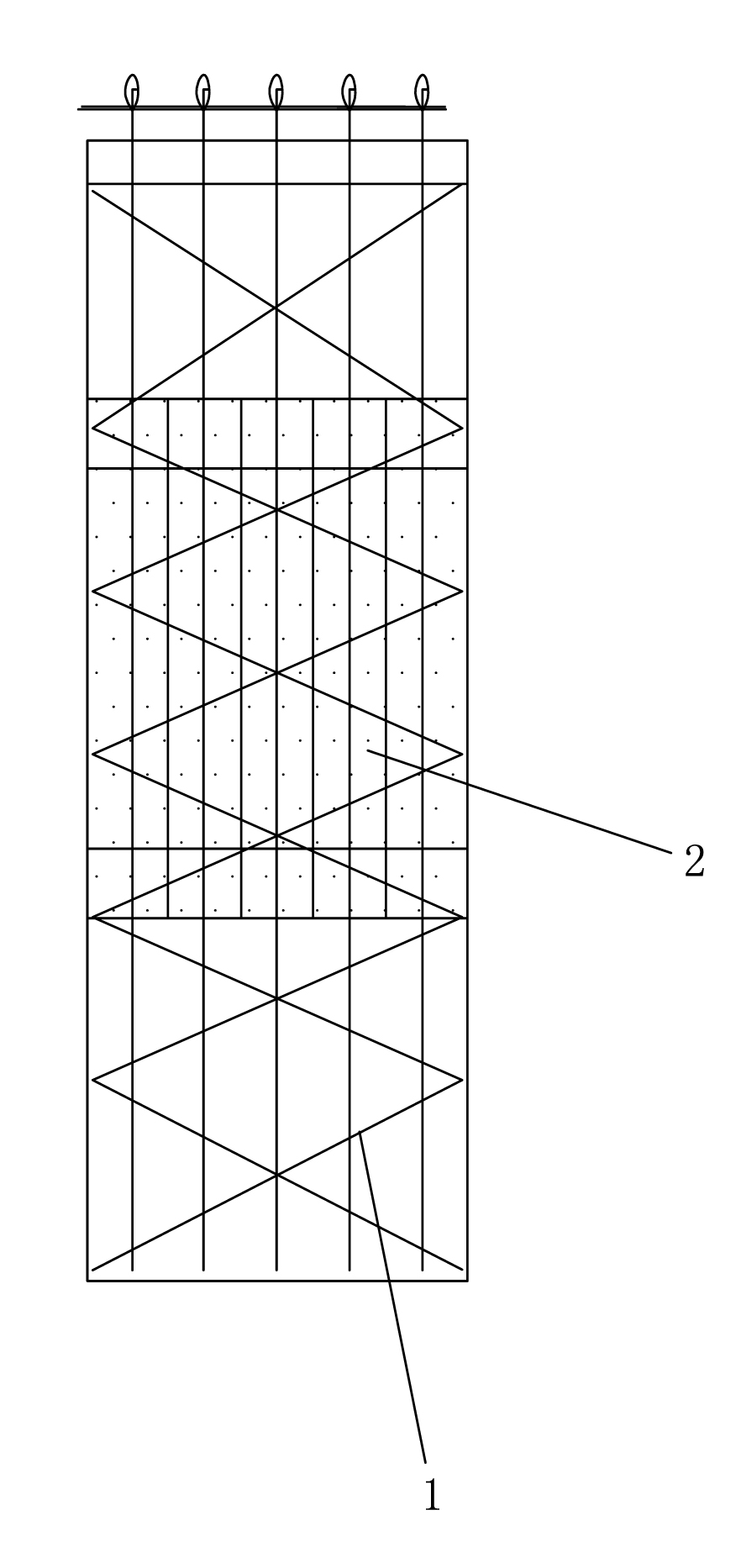

[0024] (1) Carry out the construction of the enclosure structure of the diaphragm wall 1 in the foundation pit. The diaphragm wall 1 is constructed in sections, and within the range of the tunnel centerline portal, the length of the diaphragm wall 1 is 7m, and the width of the diaphragm wall is 7m. All steel bars within the range of 7m×7m of the opening of the diaphragm wall 1 are replaced by glass fiber 2 bars, so that the shield machine 3 cutter head 31 can directly cut the opening, further improving safety.

[0025] (2) Use C30 plain concrete to pour the guide platform 4 in the starting shaft of the foundation pit. At the same time, according to the tunnel line design in the foundation pit, adjust the inclined slope of the shield starting guide platform 4, so that the slope of the top surface of the guide platform 4 is cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com