Swinging arm mechanism controlled by using double cams

A rocker arm mechanism, double cam technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem that there is no way to change the valve lift and cycle of the engine, affect engine power, economy and emissions, complex structure, etc. problems, to achieve the effect of improving fuel economy, improving charging efficiency, and reducing exhaust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

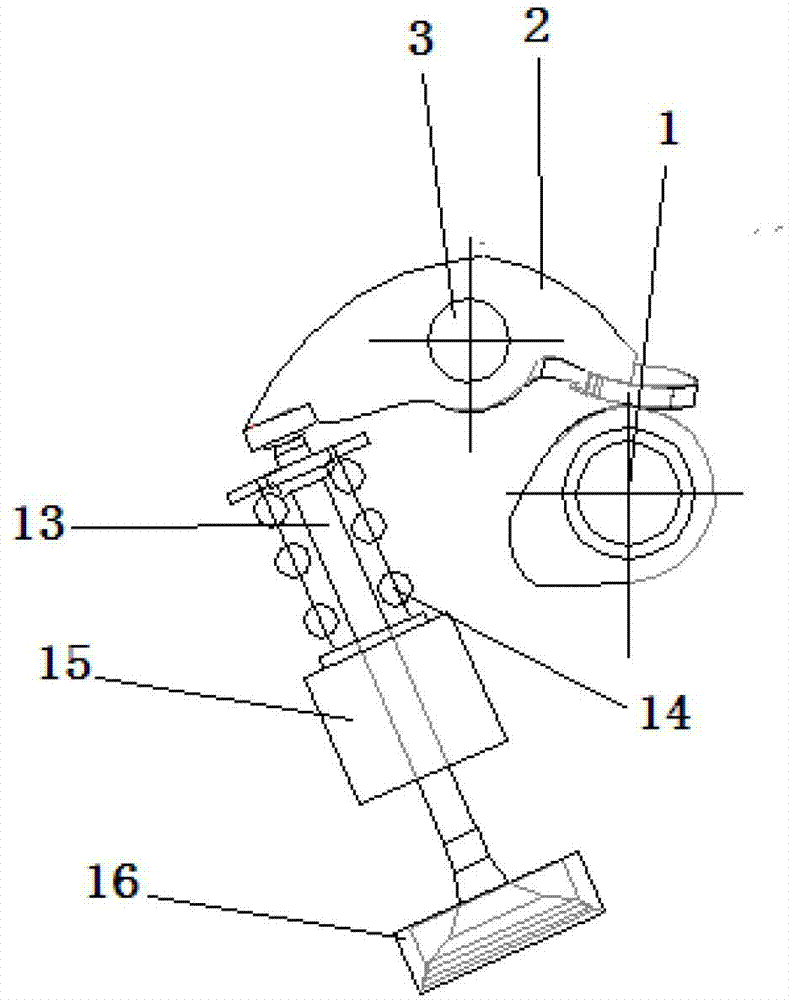

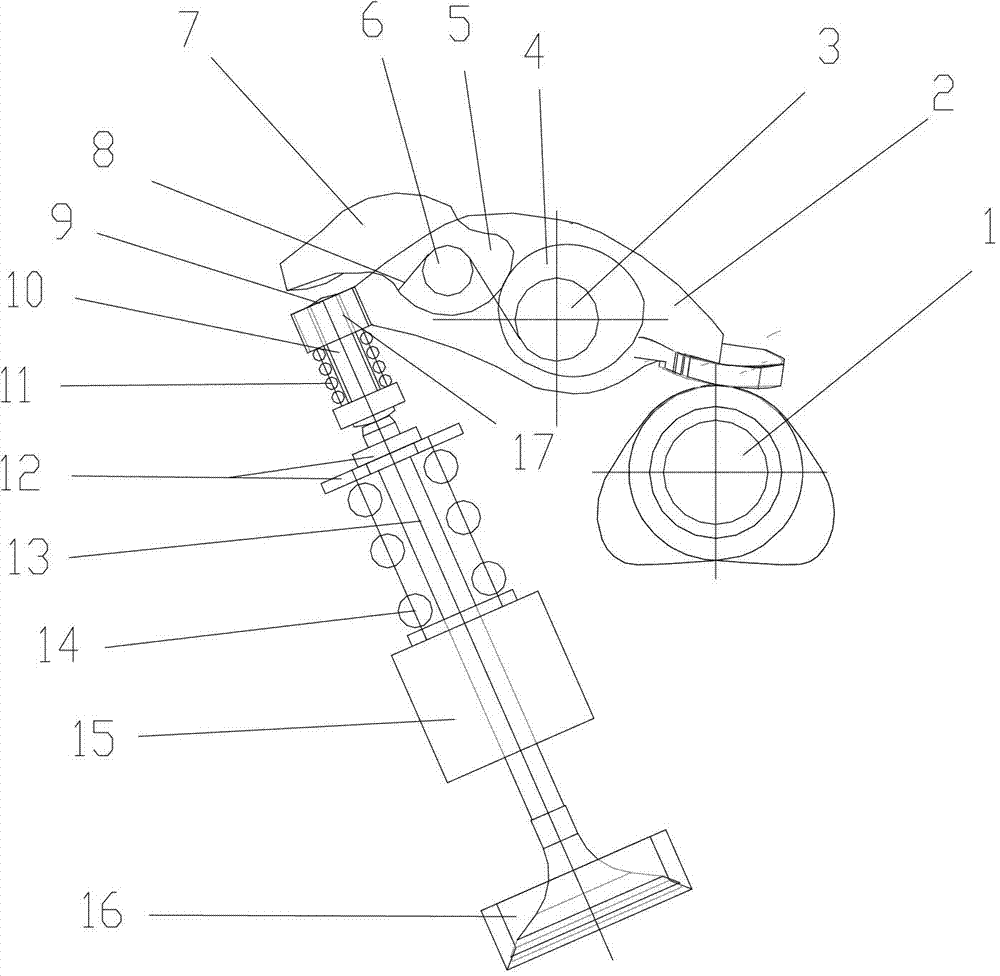

[0021] The double-cam controlled rocker mechanism of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0022] Such as figure 2 As shown, the rocker arm mechanism controlled by double cams of the present invention includes: a camshaft 1, a main rocker arm 2 rotatably connected to the main rocker arm shaft 3, one end of the main rocker arm 2 is connected to the The camshaft 1 is connected in close contact, and the main rocker arm 2 swings around the main rocker arm shaft 3 as the axis rotates with the rotation of the camshaft 1, and the other end of the main rocker arm 2 is integrally provided with a pressure ring 17, so The top of the valve stem 13 of the internal combustion engine is provided with a tappet mechanism for compressing the valve stem 13, the pressure ring 17 is slidably connected with the tappet mechanism, and the main rocker arm 2 is provided with the pressure ring 17. This end is also fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com