Front multi-element catalyst and preparation method thereof

A catalyst and multi-component technology, applied in the field of pre-multi-component catalyst and its preparation, can solve the problems of secondary pollution, high fuel consumption, short life of three-way catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: In this embodiment, the front multi-component catalyst consists of 50% to 55% heavy calcium carbonate, 10% to 15% water glass, 5% aluminum oxide, 20% to 25% iron oxide, 0.1 %~0.15%Ce 2 o 3 and the rest of water, the shape is spherical, and the diameter is 8-10mm, wherein the iron oxide is iron oxide or ferric oxide.

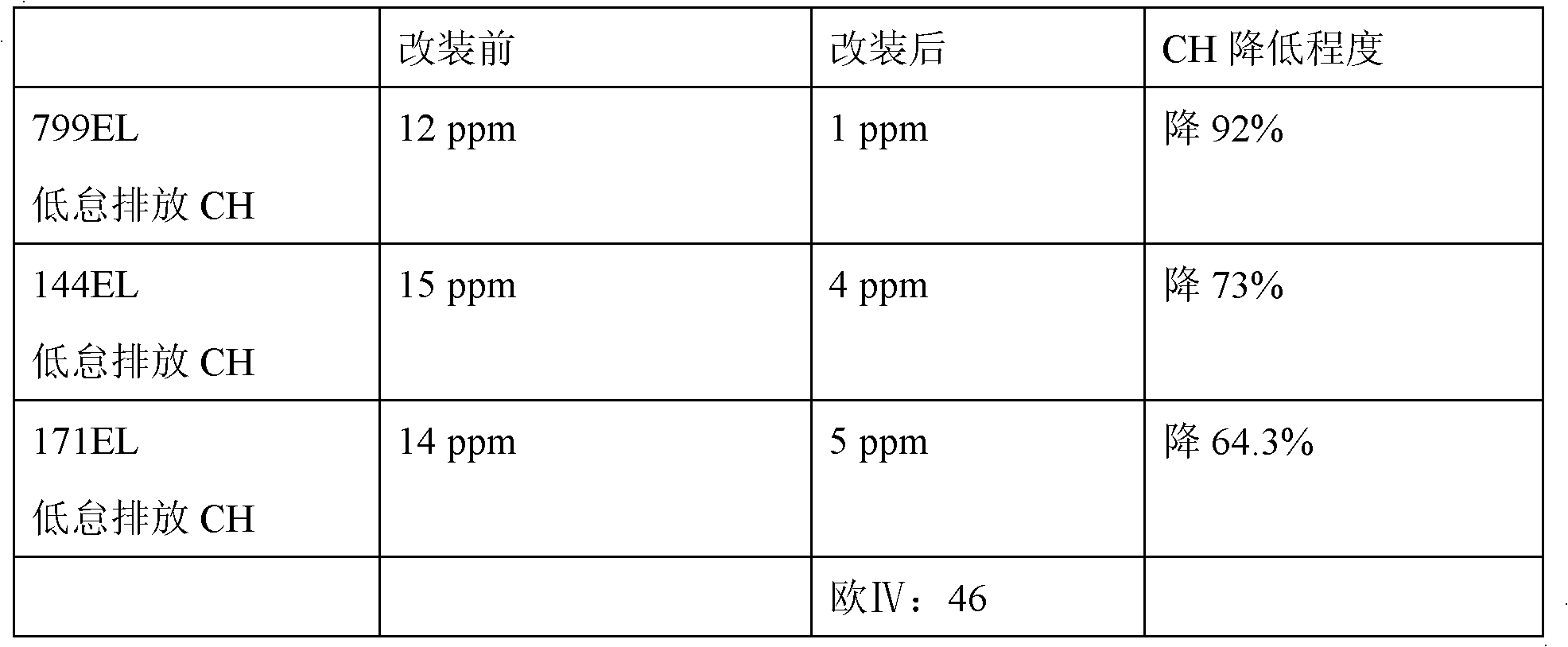

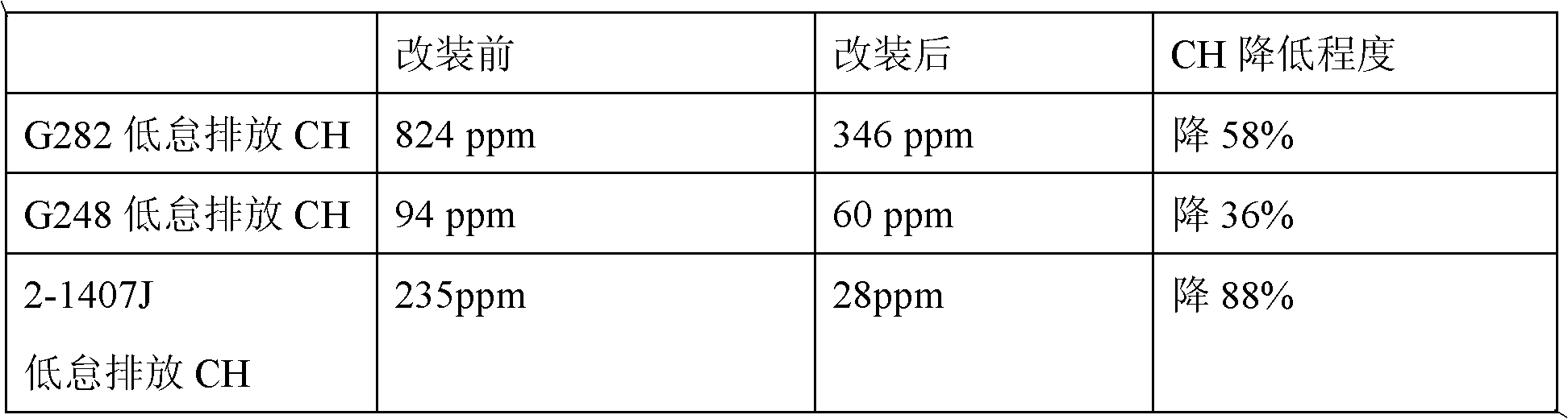

[0009] The front multi-component catalyst described in this embodiment has a rough surface and a large specific surface, and is suitable for engines fueled by gasoline, diesel or gas. The pre-multiple catalyst of this embodiment has the advantages of long life, energy saving, emission reduction, no secondary pollution, and increased power. Small cars such as cars adopt the catalyst described in this embodiment, and the emission basically achieves low emission or close to zero emission, and the LPG gas consumption drops by about 10%. The CH and CO emissions of LGP buses are also greatly reduced, and CH emissions can be reduced by...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the front multi-component catalyst consists of 52%~54% heavy calcium carbonate, 12%~14% water glass, 5% aluminum oxide, 22% ~24% Iron Oxide, 0.12%~0.14% Ce 2 o 3 and the remainder of water. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the front multi-component catalyst is composed of 53% heavy calcium carbonate, 13% water glass, 5% aluminum oxide, 23% iron oxide, 0.13% Ce 2 o 3 and 5.87% water. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com