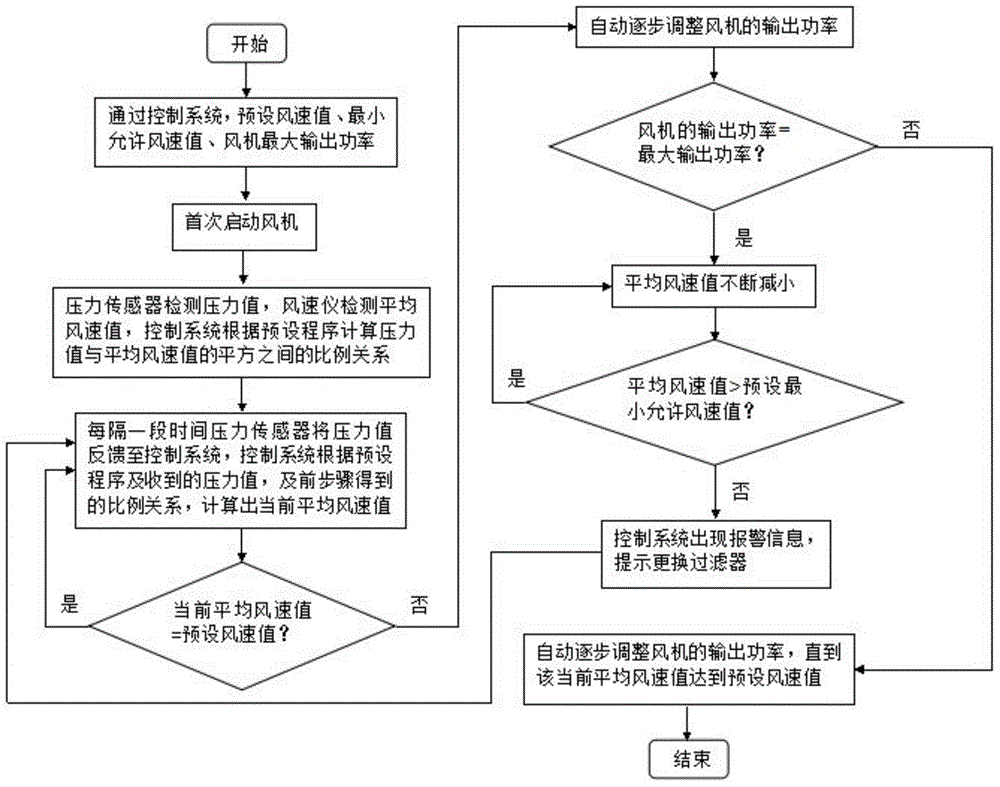

Air capacity control method of air purifying device and air purifying device

An air purification equipment and air volume control technology, which is applied in space heating and ventilation control input, heating and ventilation control system, control input related to air characteristics, etc., can solve user misleading, unscientific, and the system does not issue replacement prompts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

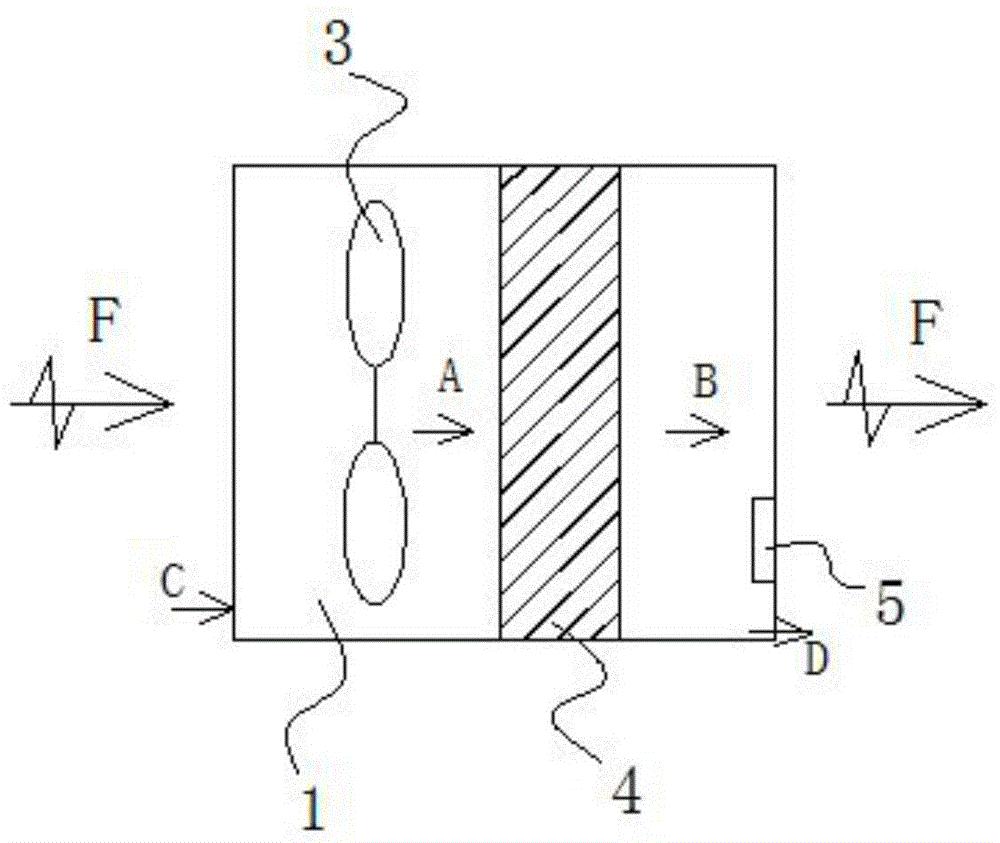

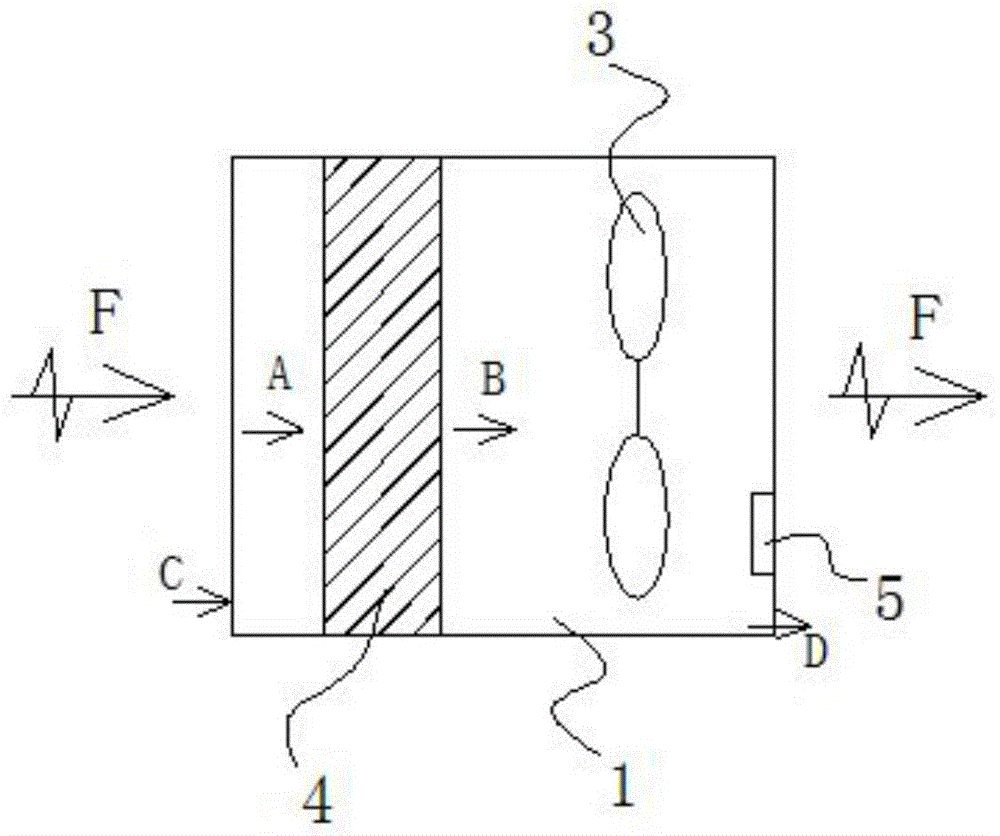

[0052] Please refer to figure 2 and image 3, Embodiment 1 of the present invention discloses an air purification device capable of air volume control, which includes a control system and a body 1, the body 1 has an air inlet C and an air outlet D, and a fan 3 and a filter are arranged inside the body 1. device 4, such as figure 2 As shown, the fan 3 is arranged on the position of the upwind direction A of the filter 4, or, as image 3 The blower 3 shown is arranged at a position in the downwind direction B of the filter 4 . A pressure sensor 5 is provided at any position in the downwind direction B of the filter 4 . The pressure sensor 5 is arranged inside the body 1 and at any position in the downwind direction B of the filter 4 . exist figure 2 and image 3 Among them, F is the ventilation direction of the air purification equipment of the present invention. Meanwhile, the control system has a preset program for analyzing and processing the pressure data of the se...

Embodiment 2

[0055] Please refer to Figure 4 , Figure 5 The main difference between the second embodiment and the first embodiment is that a ventilation duct 2 is connected to the air outlet D of the body 1, and the pressure sensor 5 is arranged inside the body 1 and is located at any position in the downwind direction B of the filter 4. position, such as Figure 4 shown; at the same time, the pressure sensor 5 can also be arranged at any position on the ventilation duct 2, such as Figure 5 shown. Other structures are the same as those in the embodiment, and will not be repeated here.

[0056] In this embodiment, the pressure sensor 5 is arranged at any position on the ventilation duct 2, as long as the pressure sensor 5 is located in the downwind direction B of the filter 4, the function of the first embodiment can be realized.

Embodiment 3

[0058] The main difference between Embodiment 3 and Embodiment 1 is that: Figure 6 As shown, a filter layer 6 is also provided at the air inlet C of the body 1, and the filter layer 6 is a dust filter. Other structures are the same as those in the embodiment, and will not be repeated here.

[0059] In this embodiment, preferably, the dust removal filter is a stainless steel dust removal filter. The air containing organic compounds passes through the stainless steel dust filter to remove dust, so that the air can be preliminarily purified before entering the body. This enables the pressure sensor 5 to better detect the pressure at its location to control the air volume output, and at the same time monitor the life of the filter element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com