Coated solder material and method for producing same

A manufacturing method and solder technology, used in welding/cutting media/materials, manufacturing tools, metal material coating processes, etc., can solve problems such as uneven activation, and achieve excellent wet expansion and efficient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

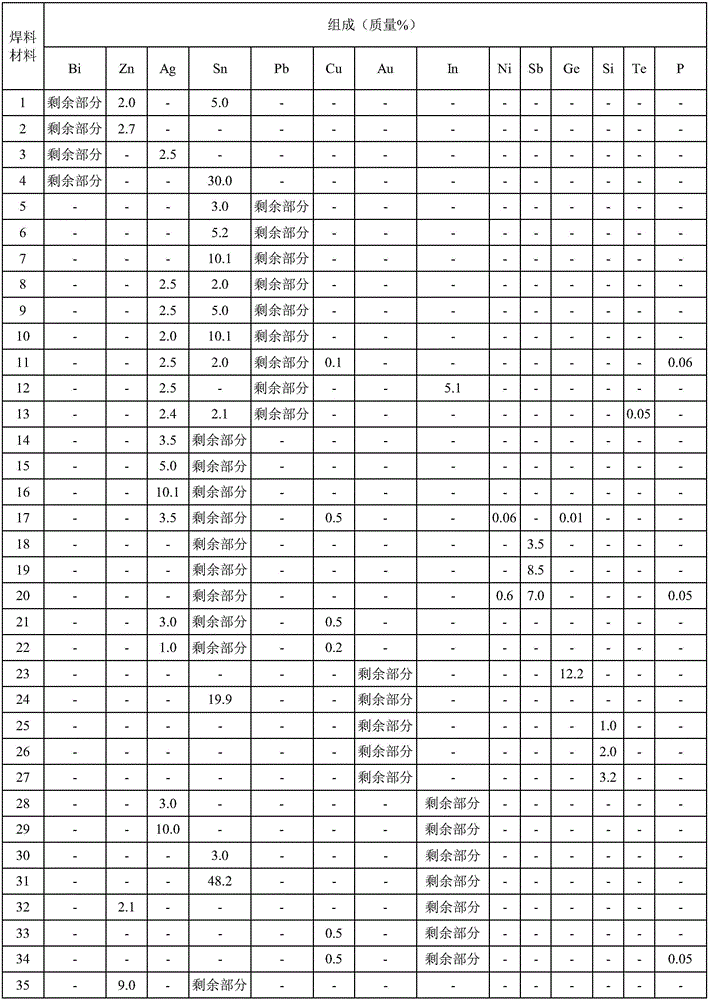

Embodiment 1~110、 comparative example 1~13

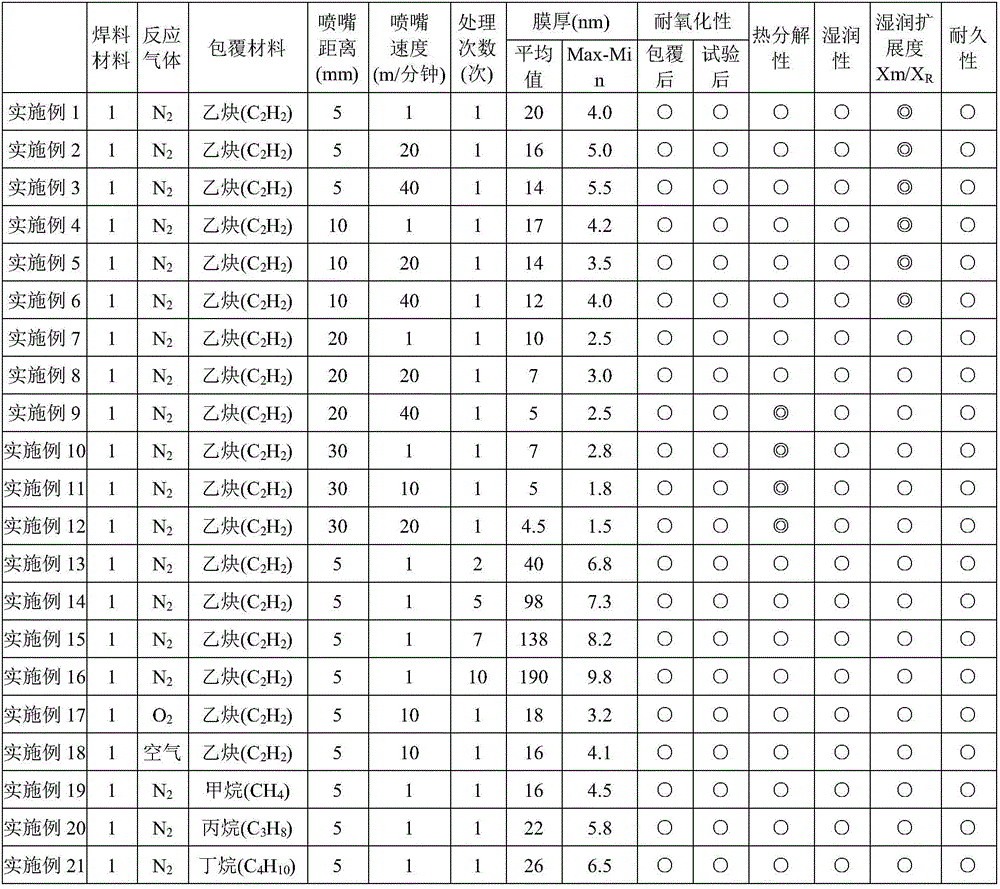

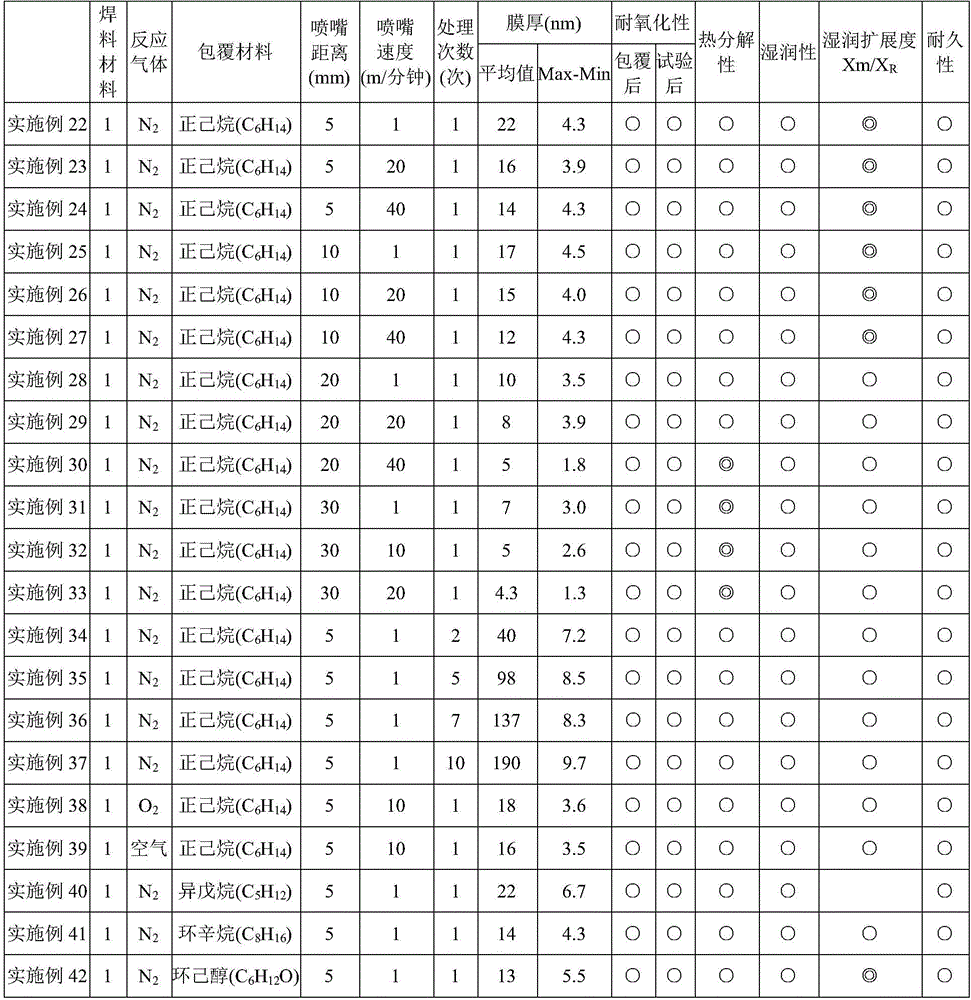

[0174] As Examples 1 to 110 and Comparative Examples 1 to 13, an atmospheric pressure plasma polymerization treatment device (plasma polymer lab system (plasma polymer lab system, plasma polymer lab system, plasma polymer lab system) PAD-1 type, Plasmatreat (Plasmatreat Co., Ltd)) samples in which coating films were formed on the surfaces of solder materials 1 to 35 under the conditions shown in Table 2. It should be noted that, in these examples and comparative examples, use N 2 As a carrier gas, the introduction amount of the coating material was adjusted to 20 g / hour, and the plasmaization conditions were set as follows.

[0175] The emission frequency of the plasma generator: 21kHz

[0176] Generator output voltage: 280V

[0177] Pressure: atmospheric pressure (1013.25hPa)

[0178] The thickness of the coating film of the obtained coating solder material and its maximum value and minimum value can be determined by adjusting the coating solder material to a state where c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com