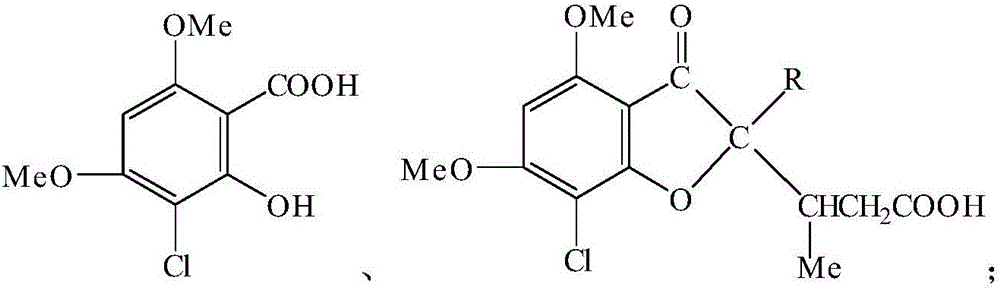

Method for removing griseofulvin in biological medicine waste residues

A technology of griseofulvin and biomedicine, which is applied in the field of removing griseofulvin from biomedical waste residues, can solve problems such as no oxidation method research reports, and achieve good environmental protection application prospects, high removal rate, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Griseofulvin content is 2360ppm. Griseofulvin waste residue 20g adds 180g water, forms the slurry that solid content is 10%; Carry out steam sterilization 20 minutes; Add oxidant potassium persulfate 20g, catalyst FeSO 4 ·7H 2 O2g, cocatalyst phosphoric acid 10g, reacted 3 hours under 90 ℃, normal pressure condition; Through separation and drying again, obtain the product 24.62g that solid content is 80%; After testing griseofulvin residue is 20ppm, and degradation rate reaches More than 99%.

Embodiment 2

[0031] Griseofulvin content is 2100ppm. Griseofulvin waste residue 200g adds 600g water, forms the slurry that solid content is 25%; Carry out steam sterilization 30 minutes; Add oxidant potassium permanganate 50g, catalyst CoCl 2 2.5g, cocatalyst oxalic acid 10g, reacted at 10°C and normal pressure for 8 hours; then separated and dried to obtain 259g of product with a solid content of 75%; the residual amount of griseofulvin was 20.7ppm after detection, and the degradation rate Reach more than 99%.

Embodiment 3

[0033] Griseofulvin content is 3000ppm. Griseofulvin waste residue 1500g adds 3500g water, forms the slurry that solid content is 30%; Carry out steam sterilization 60 minutes; Add oxidizing agent 30% hydrogen peroxide 600g in the slurry afterwards, catalyst FeCl 2 180g, co-catalyst hydrochloric acid 170g, reacted for 1 hour under the conditions of 180°C and 0.5MPa pressure; then separated and dried to obtain 1930g of a product with a solid content of 70%; the residual amount of griseofulvin was 16.9ppm after detection, and the degradation The rate reaches more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com