Full-load-bearing passenger car frame weight lightening method based on high-strength steel

A high-strength steel and lightweight technology, applied to the upper structure of passenger cars, vehicle components, design optimization/simulation, etc., can solve problems such as unfavorable production applications and poor versatility, and achieve mass production, frame quality reduction, The effect of increasing the mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

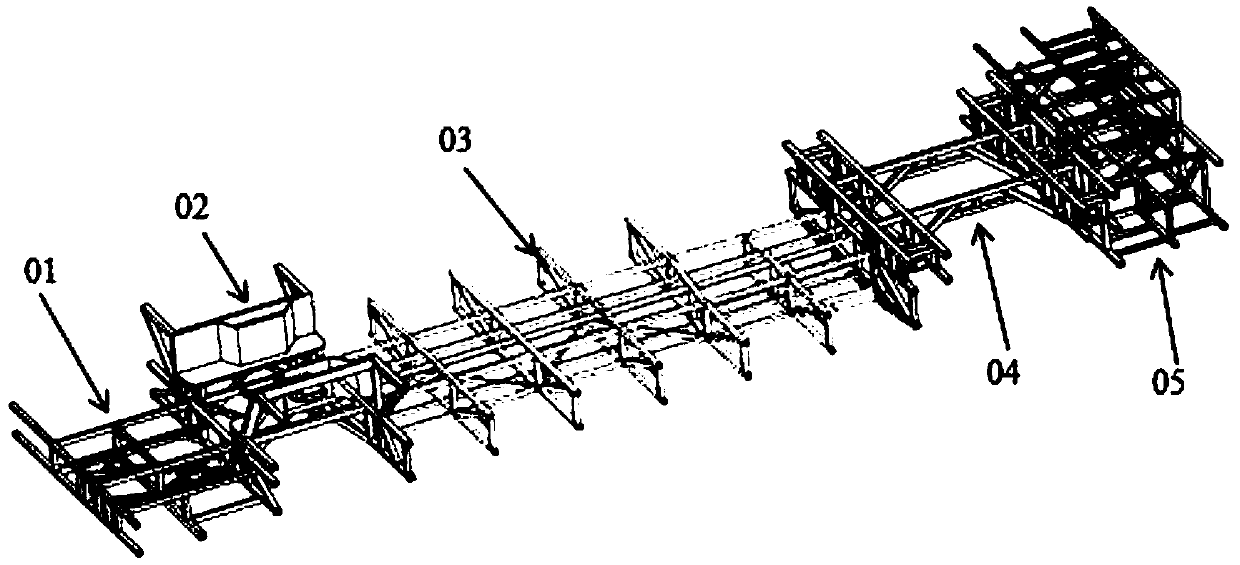

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

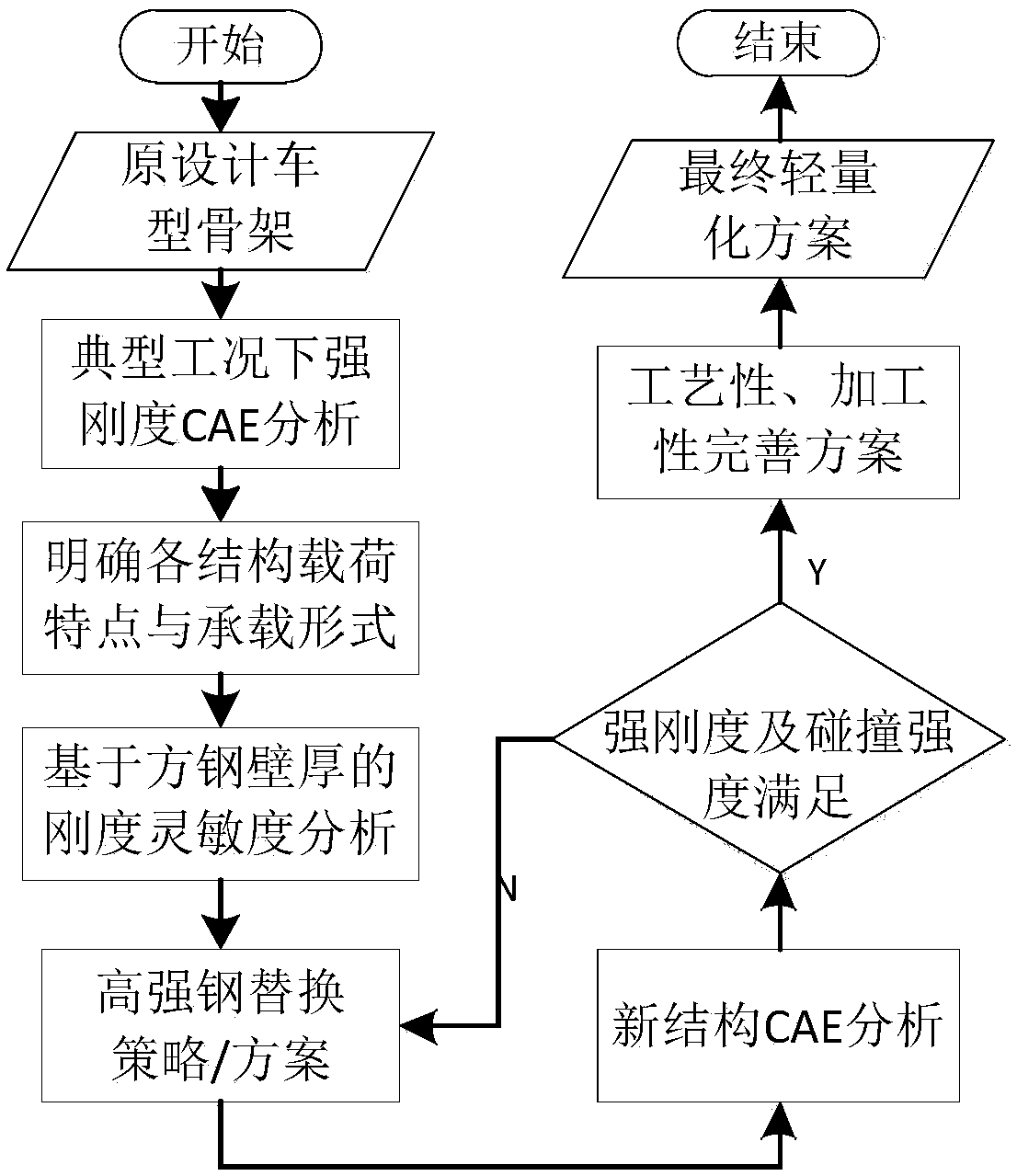

[0022] Such as figure 1 , the present invention is based on the high-strength steel full load passenger car frame lightweight method, comprising the following steps:

[0023] (1) According to the frame designed by the original ordinary steel, a finite element model is established, and the finite element analysis of the static strength and stiffness of the structure is carried out based on four typical working conditions of static bending, braking, turning and torsion.

[0024] (2) According to the static strength and stiffness analysis results of the vehicle, the force characteristics of the vehicle frame under the four working conditions of bending, braking, turning and torsion are clarified, and the equivalent stress and displacement deformation of the vehicle frame are examined.

[0025] (3) Carry out the simulation calculation of the stiffness sensitivity of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com