Processing method of double-component elastic spandex core-spun yarn

A technology of spandex core-spun yarn and processing method, which is applied in the direction of yarn, spinning machine, textile and papermaking, etc., which can solve the problems of discomfort, large body strength, and small elasticity, and achieve strong comfort, simple operation, and overcome elasticity Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

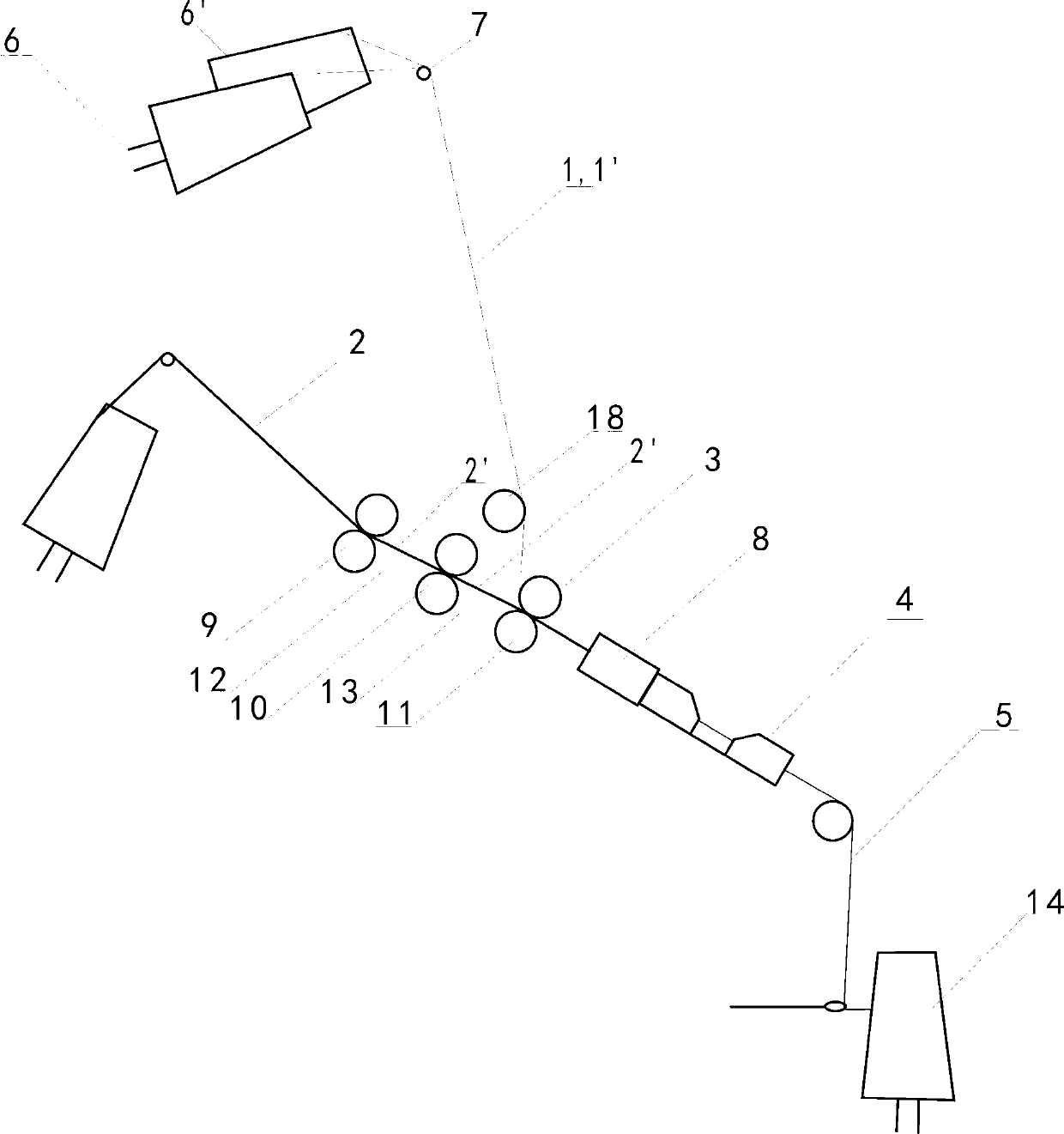

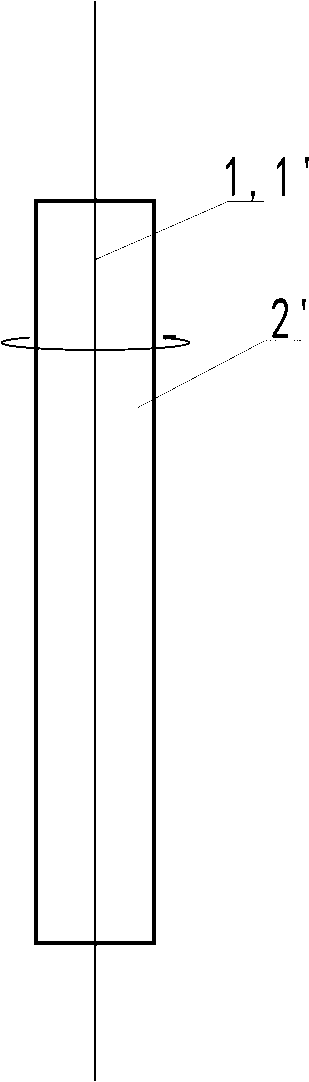

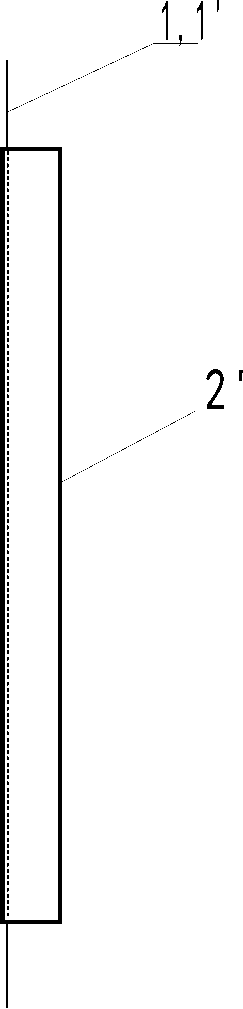

[0013] Example: the covered yarn (2) is sequentially introduced into the first group, the second group and the third group of rollers from the covered spindle through the covered yarn introducing device, and a flat strip-shaped covered yarn is formed in the preliminary stretching and rolling area (12) (2'), but because the rotational speeds of the first set of rollers (9) and the second set of rollers (10) are different, but the pressure is the same, so the flat strip-shaped outer yarn (2') is not only in the state of being rolled, but also in the state of pulling In the stretched state, its shape and tension are not stable. When the flat-shaped outer covering yarn (2') enters the rolling zone (13), the speed and pressure of the second group of rollers (10) and the third group of rollers (11) are all the same, so the shape and tension of the flat strip-shaped outer covering yarn (2') can be in a stable state in the rolling area; two kinds of elastic spandex filaments (1, 1') ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com